Coolski, Hoshizaki & More: Your Go-To Commercial Ice Cube Machine Roundup

Share

Why Your Business Needs a Commercial Ice Cube Making Machine

A commercial ice cube making machine is essential for any business that serves cold beverages or displays chilled food, including restaurants, bars, and hotels. The global market for these machines is projected to reach $4.1 billion by 2030, highlighting their importance in the food service industry.

Quick Answer: What to Know Before You Buy

- Production Capacity: Machines range from 50 lbs to over 2,000 lbs per day.

- Popular Types: Modular (high-volume), undercounter (space-saving), and countertop (small operations).

- Cooling Methods: Air-cooled (most common), water-cooled (for hot environments), or remote condenser (noise reduction).

- Price Range: $250 to $5,000+ depending on capacity and features.

- Top Brands: Hoshizaki, Manitowoc, Ice-O-Matic, Scotsman, and Coolski.

- Key Features: ENERGY STAR certification, automatic cleaning, and built-in storage bins.

Ice is a critical ingredient that impacts beverage presentation, food preservation, and customer satisfaction. Choosing the right machine—whether for crystal-clear cocktail cubes or soft nugget ice—directly affects your operational efficiency and bottom line.

I'm Sean Kearney from Charbroilers.com, and I've spent over a decade helping restaurants find the right equipment, including commercial ice cube making machines that match their specific production needs and budget. I know that the right equipment at a fair price makes all the difference in a successful operation.

The Ultimate Checklist: Choosing the Perfect Commercial Ice Maker

Choosing the right commercial ice cube making machine requires careful consideration of your business's unique needs. To find your ideal machine, focus on six key factors: daily ice volume, ice type, cooling method, available space, machine configuration, and installation requirements.

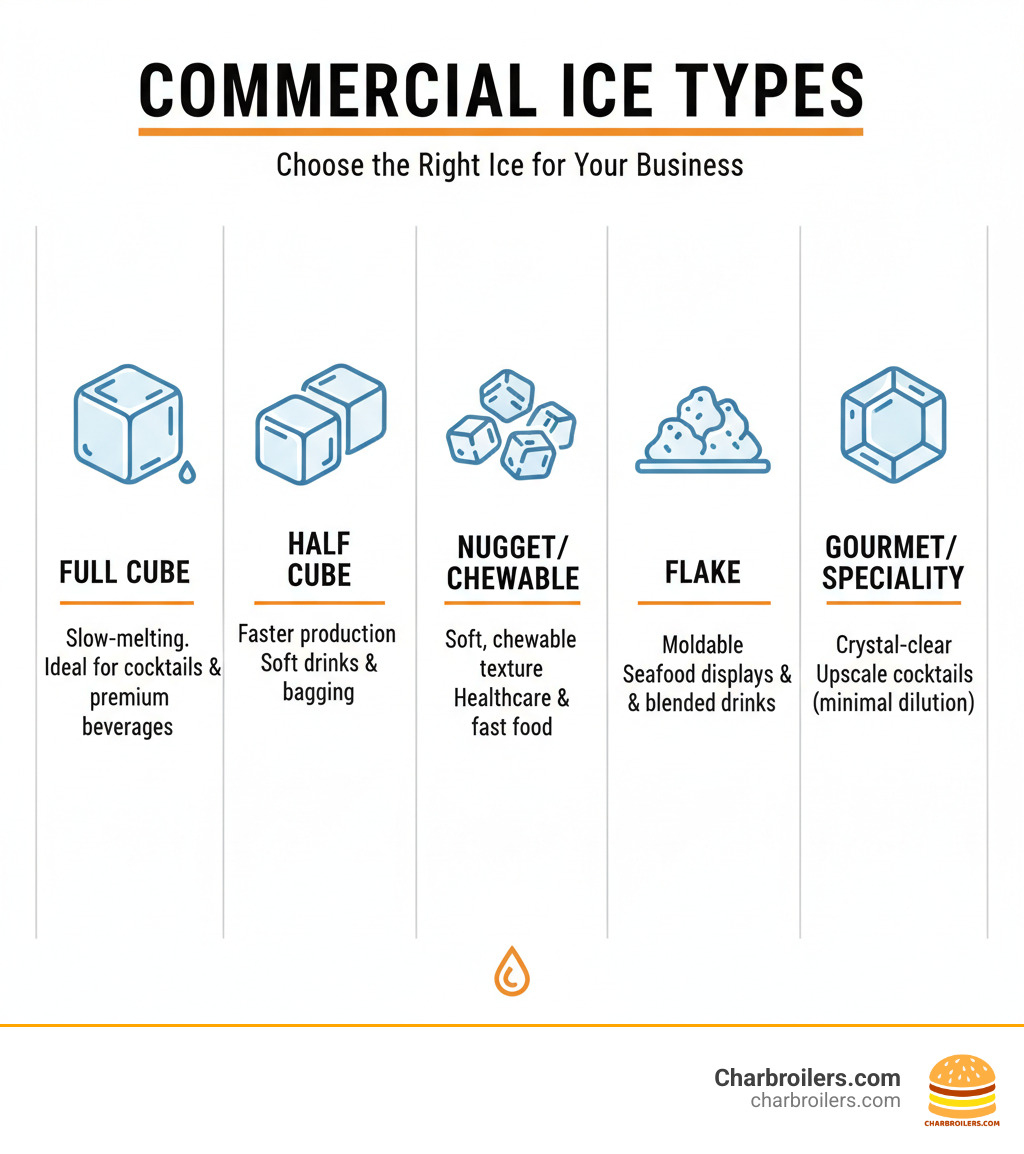

A Guide to Ice Types and Their Uses

The shape and texture of your ice can significantly impact a customer's experience. A craft cocktail bar has different needs than a healthcare facility, so your commercial ice cube making machine must produce the right type of ice for your application.

- Full cubes are large, slow-melting, and ideal for cocktails and premium beverages where minimal dilution is desired.

- Half cubes are smaller, chill drinks faster, and are a versatile choice for soda fountains and general use.

- Nugget ice is soft and chewable, making it a favorite in healthcare settings and for specialty soft drinks.

- Flake ice is soft and moldable, perfect for seafood displays, salad bars, and blended drinks.

- Gourmet ice is a premium, crystal-clear, and very slow-melting option for high-end establishments.

- Crescent cubes have a unique half-moon shape that reduces splashing in drinks and is gentle on dispensing equipment.

For a deeper dive, check out our guide: Ice, Ice Baby: Best Commercial Ice Making Equipment to Keep Your Business Cool.

| Ice Type | Shape | Melt Rate | Best For | Clarity |

|---|---|---|---|---|

| Full Cube | Large, solid, square or rectangular | Slow | Cocktails, premium beverages, general use, bagging ice | High (crystal clear) |

| Half Cube | Smaller, square or rectangular | Medium | Soft drinks, blended beverages, soda fountains, general use | High (clear) |

| Nugget/Chewable | Soft, irregular, chewable | Medium | Soft drinks, healthcare facilities, blended drinks, smoothies | Opaque (chewable texture) |

| Flake | Small, soft, irregular flakes | Fast | Food displays (seafood, salad bars), blended drinks, medical applications | Opaque |

| Gourmet/Specialty | Clear, slow-melting, often cylindrical or top-hat shaped | Very Slow | Upscale cocktails, fine dining, high-end presentations | Very High (dense, crystal clear) |

| Crescent Cube | Half-moon shape | Medium | Soft drinks, bagging, reduces splashing, gentle on dispensing equipment | High (clear, often slightly opaque) |

Sizing Up Your Needs: Production Capacity and Storage

How much ice does your business need? Commercial ice cube making machines range from 50-pound models to units producing over 2,000 pounds daily. To find the right size, calculate your peak demand, not your average. Consider your busiest hours, the number of cold drinks served, and any other uses like food displays. Since high ambient temperatures can reduce ice production, it's wise to choose a machine that can produce 10-20% more than your calculated peak need.

Storage capacity is just as important. An integrated bin might hold 12 to 80 pounds, while separate bins for modular units can store over 500 pounds. Your storage should match your production and usage patterns. If you have major rush periods, a larger bin will ensure you have enough ice harvested during slower times. For more on this, read our article on Cool Choices for Commercial Ice Maker and Bin Setups.

Cooling Systems and Configurations

Your machine's cooling system affects its placement, running cost, and noise level.

- Air-cooled machines are the most common and energy-efficient. They use ambient air to cool the condenser and require good ventilation.

- Water-cooled units use water to cool the condenser, making them ideal for hot or poorly ventilated kitchens. They use more water but don't add heat to the room.

- Remote condenser systems separate the noisy, heat-producing condenser from the ice-making head, resulting in a quieter, cooler workspace. This is a great option for open kitchens or upscale environments.

You also have three main configurations:

- Undercounter units are self-contained and fit under a standard counter, perfect for bars and cafes.

- Modular machines consist of an ice-making head on top of a separate storage bin, offering maximum flexibility and scalability for high-volume operations.

- Countertop models are smaller, portable units suitable for low-volume needs or special events.

Our guide No Bin, No Problem: Commercial Ice Makers for Modular Setups explains how to make the most of these versatile systems.

Top Picks: A Roundup of the Best Commercial Ice Cube Making Machine Models

After years of helping restaurants and bars find their perfect match, we've learned which commercial ice cube making machine models consistently deliver on performance, reliability, and value.

At Charbroilers.com, we focus on equipment that can handle the real-world demands of food service. The best machines are built tough, produce ice consistently, and don't quit when you need them most. We work with industry-leading brands like Hoshizaki, Manitowoc, Ice-O-Matic, Scotsman, and Coolski because they've earned their reputations in commercial kitchens. The models we recommend most often feature durable stainless steel construction, energy-efficient operation, and intuitive controls. For a closer look at premium options, check out our guide to Top Premium Commercial Ice Makers to Keep Your Cool Factor High.

Best for High-Volume Kitchens: Modular Ice Machines

For a busy restaurant or hotel, running out of ice can hurt business. Modular ice machines are the solution for high-volume operations. These powerful units consist of an ice-making head that sits on a separate storage bin, allowing you to scale production and storage independently. They typically produce between 500 and 2,000+ pounds of ice daily, enough to handle multiple service areas at once. Most modular units offer a choice of full cube, half cube, or crescent ice, and their durable construction is designed for continuous operation. Our review of Freeze Frame: 2025's Best Industrial Ice Machines Reviewed covers the latest innovations in this category.

Best for Bars & Cafes: Undercounter Ice Machines

In a bar or cafe, every square foot counts. Undercounter commercial ice cube making machines solve the space puzzle by fitting neatly beneath a counter. These self-contained units combine the ice maker and storage bin into one compact package. Their front-breathing design allows for installation flush against walls or between other equipment. With a typical production capacity of 50 to 300 pounds per day, they are perfectly sized for most small to medium-sized businesses. Many models are also ADA compliant, making them accessible and convenient for staff. For more insights, see our article Stay Cool Under Pressure: Commercial Ice Makers Machines Reviewed.

Best for Self-Service & Specialty Drinks: Dispensers and Nugget Makers

Some businesses require a specialized approach to ice service.

Ice dispensers are ideal for self-service environments like hotel lobbies and office break rooms, providing hygienic, touchless access to ice. Nugget ice makers produce soft, chewable ice that is popular in healthcare facilities and for specialty drinks, as it absorbs flavors well. The growing demand for "the good ice" has made these machines a competitive advantage for many businesses. Learn more about how different businesses benefit from specialized ice machines in our guide: Ice Machines That Mean Business: Hotels, Offices, and Beyond.

Keeping It Cool: Operation, Maintenance, and Longevity

Your commercial ice cube making machine is a hardworking piece of equipment that requires regular care to ensure it runs smoothly, produces clean ice, and lasts for years. Proper operation and maintenance will save you money on repairs and extend the life of your investment.

How a Commercial Ice Cube Making Machine Works

A commercial ice cube making machine uses a refrigeration cycle to freeze water efficiently. Water enters the machine and is pumped over a super-cooled evaporator plate. As the pure water molecules freeze to the plate, mineral impurities are washed away, which is why commercial ice is often very clear. Once the ice reaches the proper thickness, the machine enters a harvest cycle, gently warming the plate to release the ice into a storage bin. This process repeats continuously to keep your bin full. For more technical details, see our deep dive: Chill Out: A Deep Dive into Commercial Ice Production Methods.

Essential Maintenance for Peak Performance

Regular maintenance is crucial for producing clean, high-quality ice and preventing costly breakdowns.

- Daily: Visually inspect the ice bin and scoop for cleanliness.

- Weekly: Wipe down the exterior and run any self-cleaning cycles.

- Every 3-6 Months: Replace the water filter. This is your first line of defense against scale buildup and contamination, ensuring your ice tastes fresh.

- Every 6 Months: Descale the machine using an approved cleaner to remove mineral buildup from internal components. This is especially important in areas with hard water.

- Bi-Annually: Schedule professional service. A trained technician can perform a thorough deep clean and inspect components to catch potential problems early.

This proactive approach keeps your commercial ice cube making machine running at peak efficiency and can significantly extend its lifespan. For more expert tips, explore our guide: Beyond the Chill: Unveiling the Best Commercial Ice Makers for Peak Performance.

To Buy or To Lease? Exploring Your Options

When acquiring a commercial ice cube making machine, you can either buy it outright or explore leasing/financing options. The right choice depends on your budget and business needs.

Buying the machine means you own it. This can be a smart long-term investment for established businesses with available capital. However, it requires a significant upfront cost, and you are responsible for all maintenance and repair expenses.

Leasing or financing offers an alternative with a predictable monthly payment instead of a large initial investment. This can be a game-changer for new or growing businesses looking to preserve capital. Many programs bundle maintenance and repairs into the monthly fee, offering peace of mind and predictable budgeting. Consider your cash flow and comfort level with equipment maintenance when deciding which path is best for your operation. You can learn more about the benefits in our article: Renting Commercial Ice Machines Made Easy and Breezy.

The Cool ROI: Costs, Benefits, and Efficiency

Understanding the return on investment for a commercial ice cube making machine is key to making a smart purchase. While there's an upfront cost, the long-term benefits to your operations, customer satisfaction, and bottom line are substantial.

The price for a reliable machine typically ranges from $1,500 to $5,000, with high-capacity modular systems costing more. This investment pays for itself through operational efficiency and increased sales of high-margin items like beverages. A dedicated machine provides a consistent supply of high-quality ice, eliminating last-minute purchases of bagged ice and ensuring every drink meets your standards. Furthermore, commercial machines are designed for food safety, with stainless steel construction and automatic cleaning cycles that prevent contamination and give you peace of mind. For a detailed cost breakdown, check out our guide: Your Essential Ingredient: A Cube Ice Machine Price Guide.

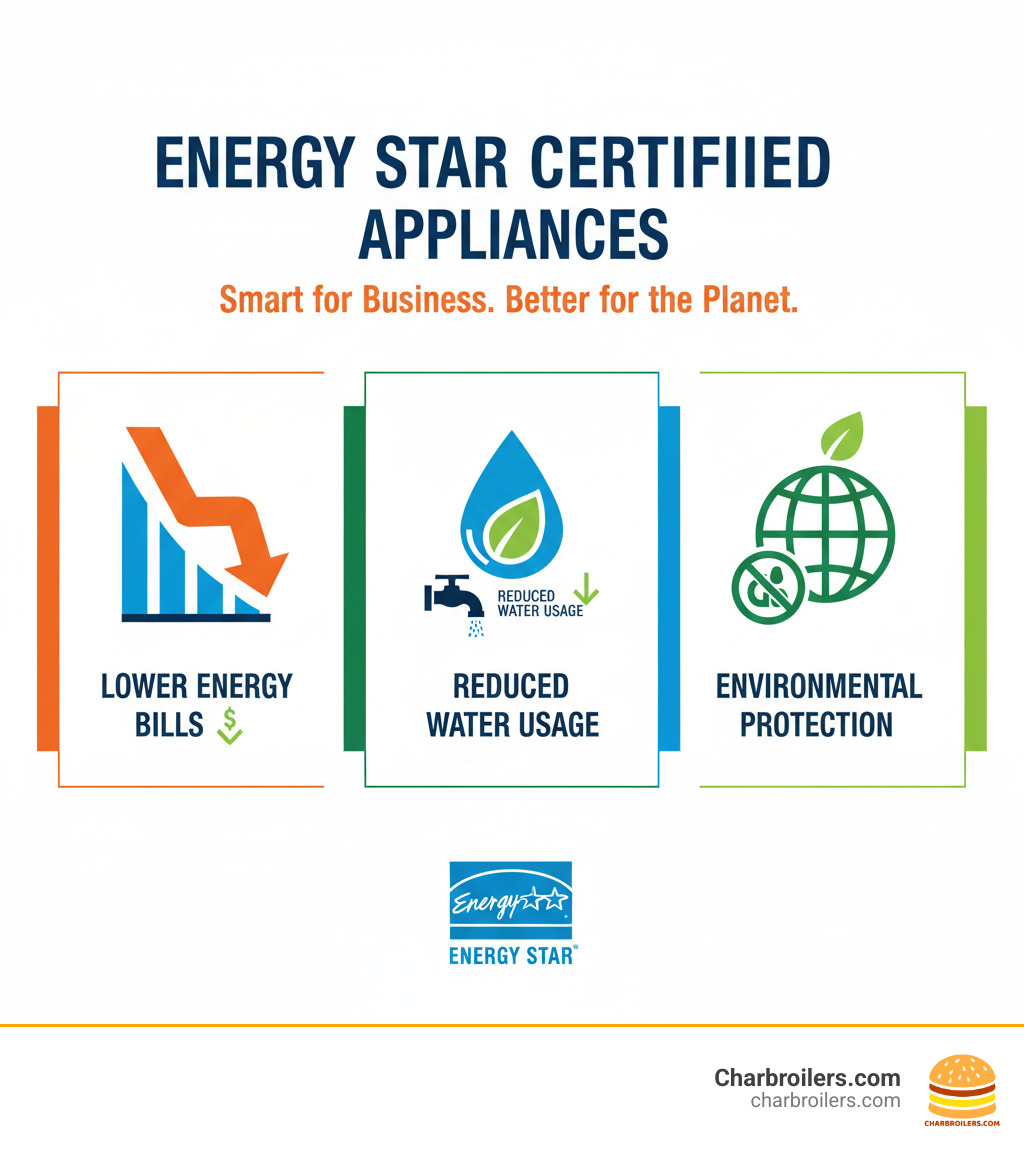

The Advantages of ENERGY STAR ae Certified Ice Makers

To maximize your ROI, choose an energy-efficient model.

ENERGY STAR ae certified ice makers are designed to meet strict EPA guidelines, meaning they use significantly less electricity and water than standard models. Some sustainable designs can reduce water consumption by up to 30%. These savings on utility bills add up over the machine's lifespan. Additionally, many utility companies offer rebates for purchasing ENERGY STAR ae equipment, which can help offset the initial cost. Choosing a certified machine also reduces your environmental footprinta valuable marketing point for today's eco-conscious customers. To learn more about the program, see ENERGY STAR.

Why a Quality Commercial Ice Cube Making Machine is a Smart Investment

A quality commercial ice cube making machine is an investment in your business's reputation. The right ice lifts every beverage, showing an attention to detail that customers appreciate. Reliable ice production prevents watered-down drinks and ensures you never have to turn away customers during peak hours. Ice is a low-cost ingredient that enables high-margin drink sales, making a dependable supply essential for profitability. A good machine provides convenience and peace of mind, freeing you to focus on running your business.

Frequently Asked Questions about Commercial Ice Makers

Here are answers to some of the most common questions we receive about commercial ice cube making machines.

How often should I clean my commercial ice machine?

Regular cleaning is essential for hygiene and performance.

- Daily: Visually check the bin and scoop.

- Weekly: Wipe the exterior and run any self-cleaning cycles.

- Quarterly: Follow the manufacturer's instructions for descaling and sanitizing the water system, especially if you notice cloudy ice or scale buildup.

- Bi-Annually: Schedule professional cleaning and maintenance to ensure compliance with health codes and keep the machine in top condition. Also, remember to replace your water filter every 3-6 months for clean, fresh-tasting ice.

What's the difference between a commercial and residential ice maker?

A commercial ice cube making machine is built for a much higher level of performance and durability.

- Production Capacity: Commercial units produce hundreds or thousands of pounds of ice daily, compared to 30-50 lbs for residential models.

- Durability: They are made with robust components like stainless steel to withstand continuous use in demanding kitchen environments.

- Ice Quality & Variety: Commercial machines produce clearer, harder ice and offer a range of shapes (full cube, nugget, etc.) to suit specific business needs.

- Certifications: They are NSF certified, meeting public health and safety standards required for food service operations.

For information on using commercial-grade machines at home, see our guide: Bring the Chill Home: Top Commercial Ice Makers for Residential Use.

Can I install a commercial ice maker myself?

We strongly recommend professional installation for a commercial ice cube making machine. Proper installation is complex and involves:

- Plumbing: Correctly connecting water supply and drainage lines to prevent leaks.

- Electrical: Ensuring the machine is connected to a dedicated circuit that meets code.

- Ventilation: Providing adequate clearance for air-cooled models to prevent overheating.

- Warranty: Many manufacturers require professional installation to validate the warranty.

A professional ensures your machine is level, safe, and operating at peak performance from day one, protecting your investment.

Conclusion

Choosing the right commercial ice cube making machine is a critical decision for your business's success. From understanding ice types and calculating production needs to selecting the right configuration and maintaining your equipment, every step matters. A reliable machine ensures you can consistently deliver high-quality beverages, improve operational efficiency, and boost your bottom line.

At Charbroilers.com, we understand that the right equipment is an essential ingredient for customer satisfaction and profitability. We're here to guide you toward an ice machine that fits your production needs, budget, and business goals. An investment in a quality ice maker pays dividends in efficiency, customer loyalty, and peace of mind.

Ready to explore all the equipment that can take your kitchen to the next level? Explore our complete guide to commercial kitchen equipment for your restaurant and find how the right tools can transform your food service operation.