Chill Out: A Deep Dive into Commercial Ice Production Methods

Share

Why Commercial Ice Production is Essential for Your Foodservice Operation

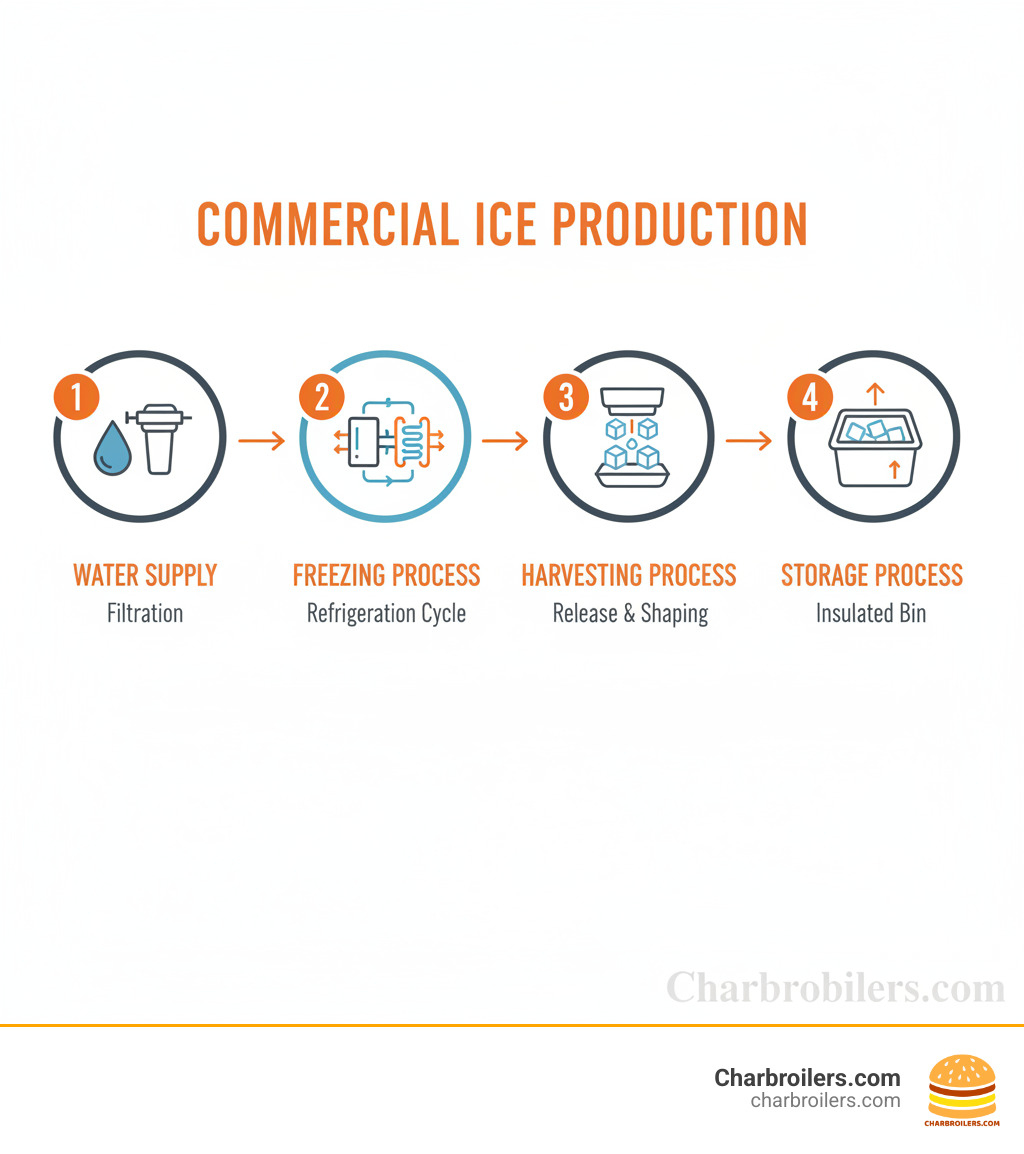

Commercial ice production is the automated process of generating large, consistent volumes of ice. It involves four key stages:

- Water Supply: Filtered water enters the machine.

- Freezing Process: A refrigeration system cools the water to 32°F (0°C) or below.

- Harvesting Process: Ice is released from the freezing surface and shaped.

- Storage Process: Finished ice drops into an insulated storage bin.

For any restaurant, bar, or hotel, ice isn't just frozen water—it's a critical ingredient. Every drink and food display depends on a reliable supply of clean, consistent ice. Yet, many operators only think about their ice machine when it breaks down.

The global commercial ice machine market is projected to reach $2.1 billion by 2028, reflecting the simple truth that businesses need flawless ice production daily. Running out of ice during peak hours isn't just an inconvenience; it's a costly problem that can disrupt service.

This guide covers everything you need to know about commercial ice production, from how machines work to choosing the right one for your budget and space. We'll explore ice types, cooling systems, and key purchasing considerations.

I'm Sean Kearney, founder of Charbroilers.com. With over a decade of experience helping restaurants source reliable equipment, I've seen that understanding commercial ice production is essential for running a smooth, profitable operation.

Commercial ice production terms to learn:

The Core of the Chill: How Commercial Ice Machines Work

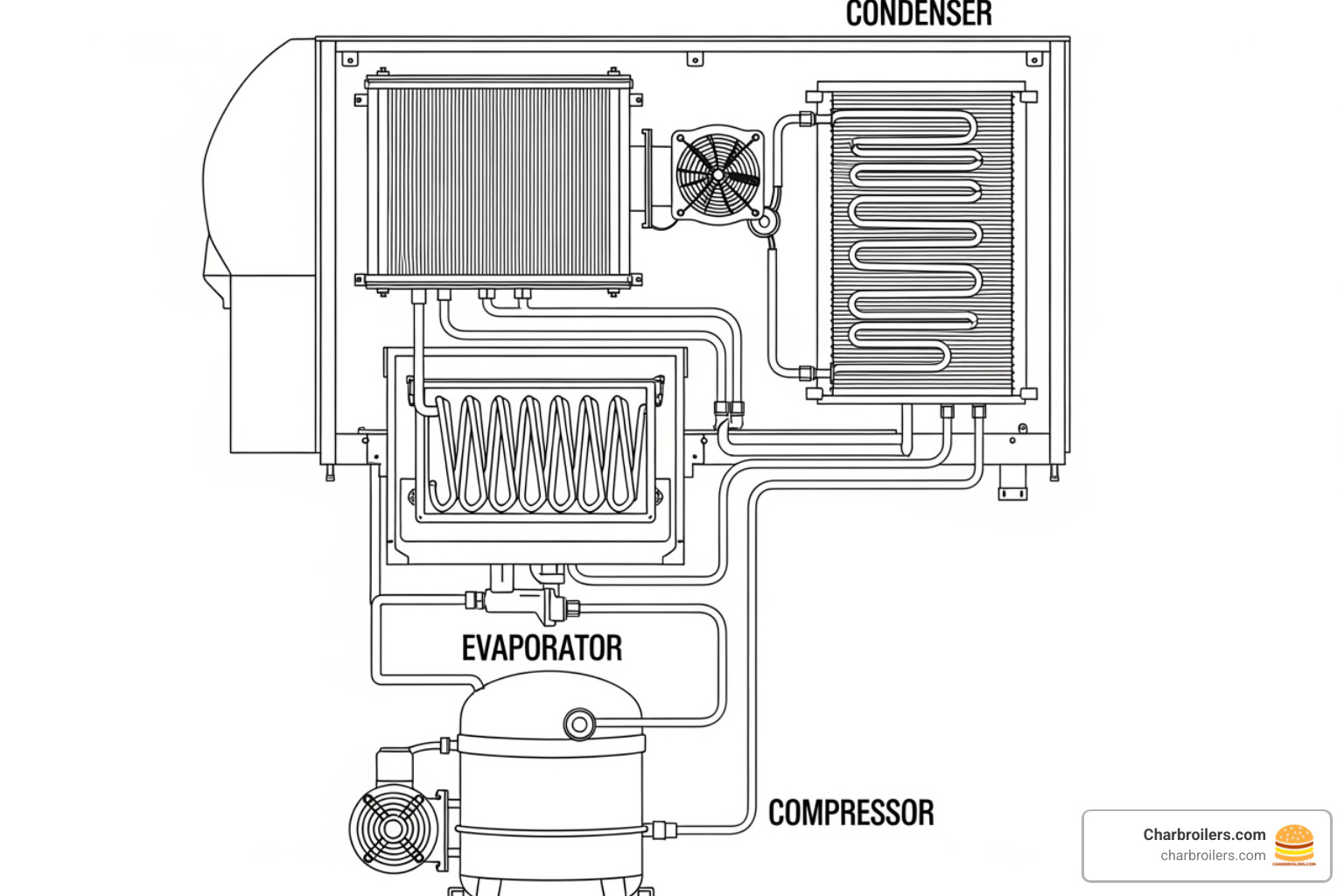

A commercial ice machine is a refrigeration powerhouse engineered to transform water into perfect ice. The core technology is the vapor compression refrigeration cycle, the same system used in your walk-in cooler. It uses a refrigerant that circulates through four key components:

- The compressor pressurizes the refrigerant gas.

- The condenser cools the gas, turning it into a liquid.

- An expansion valve drops the liquid's pressure and temperature.

- The evaporator uses the super-cold refrigerant to absorb heat from water, freezing it solid.

This continuous cycle is how commercial ice production happens. From water entering the supply line to ice tumbling into the storage bin, every step is carefully orchestrated.

The Four-Step Cycle of Commercial Ice Production

Every commercial ice machine follows a reliable four-step pattern. Understanding this process highlights the importance of proper maintenance.

Step 1: Water Supply. Water enters through a supply line, ideally passing through a filtration system. Filtering removes impurities and minerals, which results in clearer ice and prevents scale buildup that can damage the machine and shorten its lifespan.

Step 2: Freezing Process. Filtered water flows over a chilled evaporator plate. As ultra-cold refrigerant circulates through coils within the plate, it pulls heat from the water, gradually freezing it. The evaporator's design is what determines the final shape of the ice.

Step 3: Harvesting Process. Once the ice is thick enough, the machine initiates a harvest cycle. Most systems use a hot gas bypass, which briefly warms the evaporator to loosen the ice, allowing it to fall by gravity. Other machines may use mechanical scrapers or augers.

Step 4: Ice Storage. The harvested ice drops into an insulated storage bin. These bins are designed to minimize melting and include bin overflow protection sensors that stop ice production when the bin is full, saving energy and preventing messes.

Modular vs. Self-Contained Ice Machines

Commercial ice machines come in two main configurations: modular and self-contained. Your choice depends on your space and volume needs.

Modular ice machines are the high-capacity workhorses of commercial ice production. These "ice machine heads" focus solely on making ice and are designed to sit on a separate storage bin or dispenser. This flexibility allows you to mix and match components to meet high demand, with production often ranging from 300 to over 1,300 pounds of ice per day. You can scale production by getting a larger bin or even stacking multiple heads. Plus, if one component fails, you only need to replace the head or the bin, not the entire system. For more on this, see our guide on Cool Choices for Commercial Ice Maker and Bin Setups.

Self-contained ice machines are all-in-one units that combine the ice maker and storage bin into a single, compact package. Ideal for tight spaces, they often fit under counters in bars, cafes, or office break rooms. While convenient and easy to install, they produce and store less ice than modular systems. They are perfect for moderate needs or as a supplemental machine.

The right choice comes down to your daily ice requirements and available space. High-volume operations should lean toward modular systems, while businesses with limited space and moderate needs will find self-contained units a better fit. If you're considering a modular setup, we've got you covered: No Bin No Problem: Commercial Ice Makers for Modular Setups.

Not All Ice is Created Equal: Types of Commercial Ice

The type of ice you use can significantly impact customer experience, food presentation, and operational efficiency. Different shapes melt at different rates, affect beverage dilution, and are suited for specific tasks. Choosing the right ice is as important as a chef choosing the right knife.

The right ice can lift a drink, preserve food more effectively, or create a smoother texture in blended beverages. Let's explore the most common types of commercial ice production and their ideal uses.

Cube, Nugget, and Flake Ice

These three types are the foundation of most foodservice operations.

Cube ice is the classic choice for beverages. Full-dice cubes are large, solid, and melt slowly, making them perfect for keeping drinks cold without quick dilution. Half-dice cubes are smaller, allowing more ice per glass, which is ideal for high-volume service. Crescent ice, with its unique curved shape, packs tightly, prevents splashing, and is known for being clear and slow-melting.

Nugget ice, also known as "Sonic ice," is a customer favorite. Made by compressing flaked ice into small, chewable nuggets, it's soft, porous, and absorbs the flavor of the drink. It's perfect for soft drinks, blended beverages, and is also used in healthcare settings. For more on this popular type, see our guide on the Commercial Crushed Ice Maker.

Flake ice is soft and snow-like, molding perfectly around items. It's the top choice for seafood displays and salad bars because it provides uniform chilling without bruising delicate products. It's also excellent for creating smooth blended drinks and for use in therapeutic ice packs.

Specialty and Block Ice Production

Beyond the basics, commercial ice production also includes options for upscale and industrial needs.

Gourmet ice is about presentation. Crystal-clear spheres, large cubes (1x1 or 2x2), and other unique shapes are designed to melt very slowly, preserving the integrity of premium spirits in high-end cocktails.

Commercial ice block machines produce large, solid blocks of ice for heavy-duty, long-term cooling. These are essential in various industries:

- Fisheries & Food Transport: Preserving perishable goods like seafood, produce, and dairy during shipping.

- Construction: Controlling the curing temperature of concrete in hot climates.

- Medical & Pharmaceutical: Maintaining the cold chain for vaccines and biological samples.

These industrial-scale machines operate on the same principles as smaller units but produce from 1 to over 100 tons of ice daily. For more on these heavy-duty options, check out A Buyer's Guide – IceTech – Ice Block Machine and our review of 2025's Best Industrial Ice Machines Reviewed.

Making the Right Choice: Selecting Your Commercial Ice Machine

Choosing the right commercial ice machine is a strategic decision that impacts your efficiency and bottom line. Before buying, conduct a business needs analysis: calculate your daily ice requirements (including peak demand) and identify the primary uses for your ice—be it for drinks, food displays, or blending.

Key Factors for Your Commercial Ice Production Needs

When selecting an ice machine, focus on these critical factors:

- Production Capacity (lbs/day): This is the most important factor. Capacity is measured in pounds per 24 hours. Calculate your average daily need and add a 15-20% buffer to handle busy periods. It's always better to have slightly more capacity than not enough.

- Ice Type Selection: As discussed, the ice type should match your menu and operational needs. Choose a machine that produces the right shape—cube, nugget, flake, or specialty—for your business.

- Machine Dimensions and Space: Measure your available space carefully. Do you need a compact undercounter model or have room for a larger modular unit? Remember to leave adequate clearance for ventilation and maintenance. Our Cube Ice Machine Price Guide can help you weigh costs against these physical constraints.

Cooling Systems: Air, Water, and Remote

The machine's cooling system affects its efficiency, cost, and where it can be installed. There are three main types: air-cooled, water-cooled, and remote-cooled.

| Cooling System | Initial Cost | Operating Cost | Efficiency (General) | Ideal Environment | Pros | Cons - | | Air-Cooled | Lower | Higher | Less efficient | Well-ventilated areas with ambient temps below 80°F | Lower initial cost, easier to install, no extra water usage. | Generates heat and noise, less efficient in hot kitchens, requires regular condenser cleaning. - | | Water-Cooled | Higher | Lower | More efficient | Hot kitchens (>80°F), areas with poor ventilation | More energy-efficient, doesn't add heat to the kitchen, quieter operation. | Higher initial cost, requires a constant water supply (increasing utility bills), may be subject to water use regulations. - | | Remote-Cooled | Highest | Varies | Very efficient | Businesses wanting to reduce kitchen heat and noise | Most energy-efficient, significantly reduces heat and noise in the kitchen, ideal for tight spaces. | Highest initial cost, complex installation requiring a professional, condenser unit must be placed outdoors or in a separate, well-ventilated room. - |

The Future of Freeze: Trends in Commercial Ice Production

The commercial ice machine market is growing, projected to reach $2.1 billion by 2028. This growth is fueled by the expanding foodservice industry and a focus on efficiency and sustainability. While North America and Europe have been the largest markets, the Asia-Pacific region is now growing fastest.

Technological advancements are shaping the future of commercial ice production:

- IoT Integration: New machines offer remote monitoring via smartphone or computer to track performance and predict maintenance, reducing downtime.

- Energy-Efficient Compressors: Modern compressors can cut operational costs by up to 30%, saving money and reducing environmental impact.

- Antimicrobial Treatments: Built-in antimicrobial surfaces inhibit the growth of bacteria and mold, leading to safer, cleaner ice.

- Sustainable Refrigerants: The industry is shifting to eco-friendly refrigerants like R290 to comply with global standards and reduce environmental harm.

- Compact & Multi-functional Designs: To save space, manufacturers are creating smaller modular units and all-in-one machines that combine ice making and dispensing.

- Solar Power Compatibility: Some new models are compatible with solar power, allowing for off-grid or mobile ice production.

These trends point to a future of smarter, more efficient, and sustainable commercial ice production. For a look at how ice machines fit various business models, check out our insights in Ice Machines That Mean Business: Hotels, Offices, and Beyond.

Frequently Asked Questions about Commercial Ice Machines

We get a lot of questions about commercial ice machines, which are a vital investment for any foodservice operation. Here are answers to the most common ones.

How much ice does my business need?

Getting your ice capacity right is crucial. Over- or under-sizing your machine can be costly. Use these guidelines to estimate your daily needs:

- Restaurants: Plan for 2 pounds of ice per customer seat. A 100-seat restaurant needs about 200 lbs daily.

- Hotels: A good estimate is 5-10 pounds of ice per room.

- Fisheries: Use a 1:1 ice-to-fish ratio by weight. One ton of fish requires one ton of ice.

- Bars & Healthcare: Bars often need more ice per customer than restaurants due to high beverage volume. Healthcare facilities have unique needs, often favoring nugget ice.

Important: Always add a 15-20% buffer to your calculation to handle peak demand, heat waves, or special events. Running out of ice directly impacts revenue and customer satisfaction.

What maintenance is required for a commercial ice machine?

Regular maintenance is essential for performance and longevity. Neglecting it leads to breakdowns and unsanitary ice.

- Regular Cleaning: Daily, clean and properly store the ice scoop. Weekly, wipe down the machine's exterior. Monthly, clean the interior of the storage bin.

- Water Filter Replacement: Change filters every 3-6 months, depending on water quality. This prevents mineral buildup and ensures better-tasting ice.

- Condenser Cleaning: Air-cooled condensers need their coils cleaned monthly or quarterly to remove dust and grease. Water-cooled units require periodic descaling.

- Professional Servicing: Schedule professional service twice a year. A technician can perform deep cleaning, check refrigerant levels, and catch potential problems before they become emergencies.

What is the average lifespan of a commercial ice machine?

A well-maintained commercial ice machine should last 8 to 15 years. Several factors influence its longevity:

- Build Quality: Reputable brands using high-quality materials like stainless steel typically last longer.

- Maintenance: A consistent cleaning and servicing schedule is the single most important factor in extending your machine's life.

- Water Quality: Hard water causes scale buildup that wears down components. Proper filtration is crucial for protection.

- Usage & Environment: A machine running at maximum capacity 24/7 or operating in a hot, greasy kitchen will experience more wear and tear.

Investing in a quality machine and committing to its maintenance ensures you'll get reliable commercial ice production for years to come.