Cool Choices for Commercial Ice Maker and Bin Setups

Share

Why Every Foodservice Operation Needs the Right Ice Setup

A commercial ice maker and bin system is essential equipment for restaurants, bars, hotels, and cafeterias that serve beverages or need ice for food preservation. The right setup ensures you never run out of ice during peak service while maintaining food safety standards.

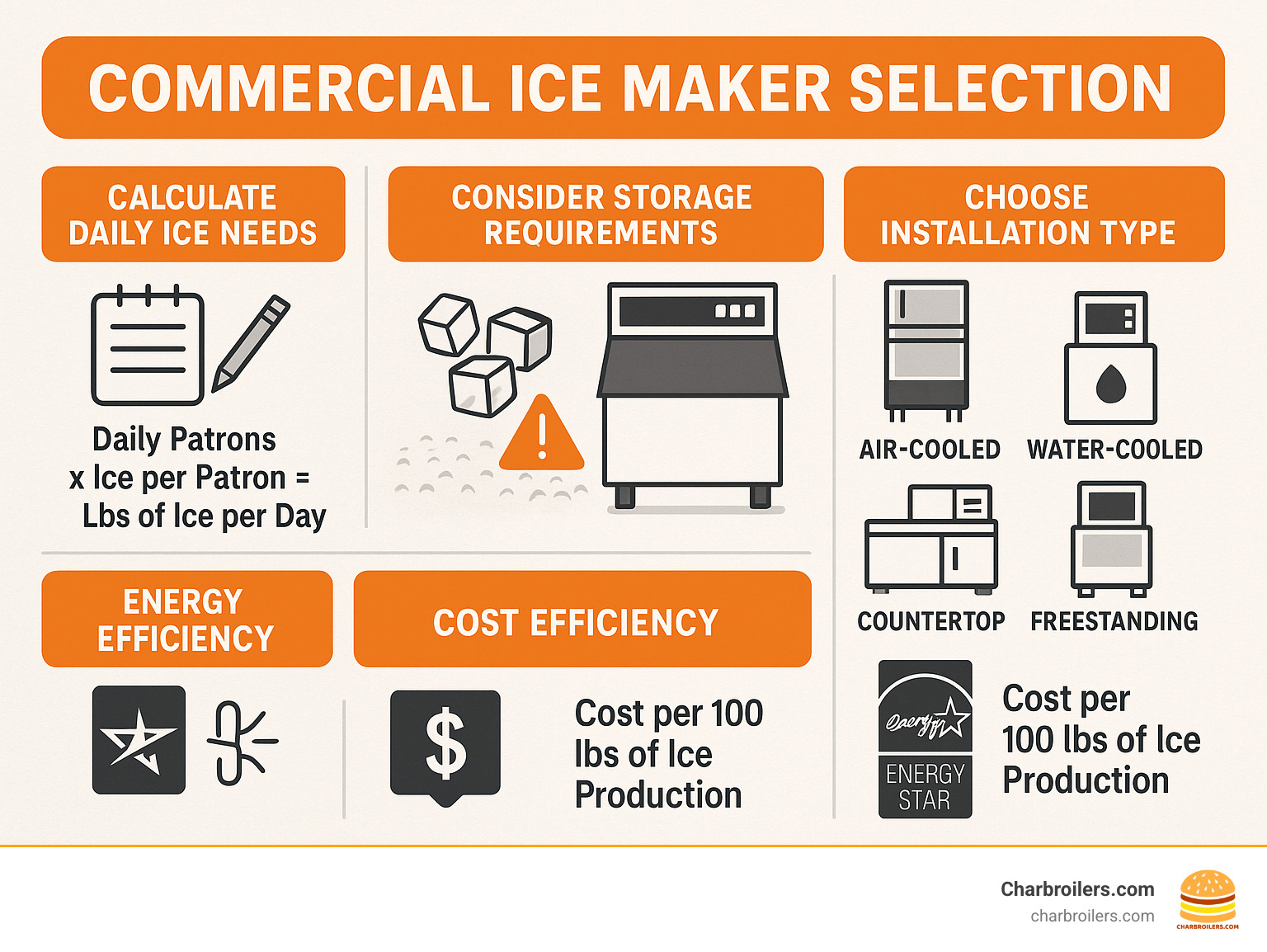

Key considerations when buying a commercial ice maker and bin:

- Daily production capacity - ranges from 60 lbs to over 600 lbs per 24 hours

- Storage bin size - available from 66 lbs to 580 lbs capacity

- Ice type - full cube, half cube, nugget, flake, or crescent shapes

- Cooling method - air-cooled, water-cooled, or remote condenser

- Installation type - modular, undercounter, countertop, or freestanding

- Energy efficiency - look for Energy Star certification to reduce operating costs

Commercial ice makers differ significantly from residential units. They're built for continuous operation, produce much larger quantities, and include features like antimicrobial protection and automatic cleaning cycles. Most commercial units use between 4.87 and 7.9 kWh of energy per 100 lbs of ice produced.

The investment pays off quickly. Restaurant operators report that having adequate ice capacity prevents service delays during busy periods and eliminates the cost and hassle of buying bagged ice.

I'm Sean Kearney from Charbroilers.com, and with over a decade in the restaurant equipment industry, I've helped countless operators choose the right commercial ice maker and bin systems for their specific needs.

How Commercial Ice Makers Differ From Residential Units

Commercial ice makers dramatically outperform residential units in every aspect that matters for foodservice operations. When restaurant owners make the switch to a proper commercial ice maker and bin system, they're amazed at how their ice worries disappear.

Production rates tell the whole story. Home ice makers might produce 5-10 pounds daily, while commercial units start at 60 pounds and can exceed 1,900 pounds when you need serious volume. Restaurant owners go from constantly scrambling for bagged ice to having abundant supply just by sizing their equipment properly.

Compressor duty in commercial machines is built for continuous operation without breaks. These heavy-duty compressors handle the constant demand of busy kitchens, bars, and dining rooms where ice never stops flowing.

Food-code compliance isn't optional in commercial kitchens. Every commercial unit meets NSF standards and includes features like antimicrobial surfaces and easy-to-clean food zones. This protects customers and maintains your reputation.

Insulation and construction quality shows the real difference. Commercial bins keep ice frozen longer in hot kitchen environments. Stainless steel construction handles constant use and commercial-grade sanitizers that would damage residential equipment.

Key Commercial Features to Know

Modern commercial ice maker and bin systems include features that make operation easier and more hygienic:

Filtration systems remove chlorine, sediment, and contaminants that affect ice taste or damage machines. Replaceable filter cartridges are easy to swap when needed.

Antimicrobial liners use silver ion technology to fight bacteria growth inside machines and storage bins, providing 24/7 protection between cleanings.

Automatic cleaning cycles eliminate guesswork from maintenance. One-touch sanitize and descaling controls keep everything running smoothly.

Energy Star certification reduces utility bills through advanced insulation, smart compressors, and optimized harvest cycles.

Programmable diagnostics monitor performance and alert you when maintenance is needed, often before problems become expensive repairs.

Touchless dispensing reduces contamination risk and gives customers confidence in your hygiene standards.

Matching Machine Capacity & Storage Bin Size to Your Business

Choosing the right size commercial ice maker and bin system can make or break your operation. Too many restaurants struggle with empty ice bins during dinner rush, while others waste money on oversized equipment.

The key is understanding peak demand, not average needs. That busy Friday night when every table is full? That's when you need your ice system to shine. Peak demand planning means calculating for your busiest periods, not quiet Tuesday afternoons.

If you need 300 pounds of ice during your busiest 8-hour service period, your machine should produce at least 400-500 pounds per day. Ice machines work on 24-hour production cycles, and you need time to build reserves before the rush hits.

Storage buffer requirements vary by service style. A coffee shop with steady traffic needs less storage than a cocktail bar that goes from quiet to slammed in an hour. The storage bin is your insurance against running out when you need ice most.

100-pound daily systems with 20-50 pounds storage work for coffee shops and small cafes. 300-pound systems producing 250-350 pounds daily with 150-250 pounds storage handle mid-size restaurants and bars. 600-pound systems producing 500-650 pounds daily with 300-400 pounds storage serve high-volume restaurants and catering operations.

Simple Formula for Right-Sizing

Daily ice needs = (Number of seats × Drinks per guest × Ice per drink) × Safety margin

Example: 50-seat restaurant where guests average 2.5 drinks each, you use 6 ounces of ice per drink, with a 1.5 safety margin:

50 seats × 2.5 drinks × 0.375 pounds of ice × 1.5 safety margin = 70 pounds per day

This restaurant needs at least a 100-pound daily production unit with 50+ pounds storage capacity.

Bar operations need different calculations because cocktails use more ice - often 8-12 ounces per drink. A 40-seat bar might need twice the ice of a 40-seat restaurant.

Growth planning means adding 20-30% to calculated needs if you expect expansion within two years. It's cheaper to size up initially than replace equipment later.

Cooling Methods, Installation & Operating Costs

Choosing the right cooling method for your commercial ice maker and bin system affects everything from installation costs to monthly utility bills.

Air-cooled systems are the workhorses of ice machines. They pull air across the condenser to remove heat, making them straightforward and reliable. Most restaurants choose air-cooled units because they're less expensive to install and maintain. The trade-off? They pump warm air into your kitchen, making your HVAC system work harder during summer.

Water-cooled systems use water to cool the condenser, producing no extra heat and operating quietly. The downside hits your water bill - these units can use over 100 gallons of water to make 100 pounds of ice. In areas with high water rates, this gets expensive fast.

Remote condenser systems offer a compromise. The heat-producing condenser lives outside while the ice maker stays in your kitchen. You get air cooling efficiency without kitchen heat and noise. Installation costs more upfront, but many operators find it worthwhile.

Installation requirements include dedicated electrical circuits running 208-230 volts, adequate water pressure between 10-113 psig, and proper drainage for cleaning cycles and melting ice.

Utility costs typically run 4.87 to 7.9 kilowatt-hours per 100 pounds of ice. Water usage varies dramatically - air-cooled units use 16-20 gallons per 100 pounds, while water-cooled units can use 76+ gallons. Annual maintenance costs usually run $200-500.

Choosing the Best Condenser for Your Space

Climate plays a huge role in condenser selection. Air-cooled units struggle when temperatures exceed 90°F - production drops and energy consumption soars. Water-cooled or remote systems work better in consistently hot environments.

Noise considerations matter more than expected. Air-cooled condensers sound like large refrigerators that never shut off. In open kitchens or customer areas, this becomes problematic. Remote systems move noise outside.

Local water fees can make or break water-cooled economics. When water costs exceed $8 per 1,000 gallons, air-cooled systems usually win on operating costs despite higher electricity use.

Airflow clearance is critical for air-cooled units. They need 6-12 inches on all sides for proper airflow. Inadequate clearance leads to poor performance and early compressor failure.

For more information about maintaining proper temperatures throughout your commercial kitchen, check out our guide to restaurant walk-in fridges.

Maintenance, Cleaning & Ownership Options

Proper maintenance of your commercial ice maker and bin system protects your investment and customers. After helping hundreds of restaurant owners, I've seen how maintenance makes the difference between equipment lasting 15 years versus 5 years.

Descaling frequency depends on water quality. Hard water areas might need monthly descaling, while softer water areas can stretch to quarterly. Modern units make this easier with one-touch descaling controls.

Daily sanitizing should be routine like wiping prep tables. Most health departments require weekly sanitizing minimum, but busy operations often do it daily during peak seasons. The process is straightforward and takes about 30 minutes.

Monthly maintenance includes gasket checks, drain line cleaning, and water connection inspection. A $15 gasket replacement beats health department violations.

Filter changes are like oil changes - skip them at your own risk. Depending on water quality and usage, filters need changing monthly to annually. Keep spare filters in stock.

The ownership landscape offers multiple options. Certified used equipment delivers 50-60% savings with warranty coverage. Rental programs have become attractive, especially for new businesses, with rent-try-buy options where 60% of rental payments credit toward purchase.

For insights into ice hygiene best practices, check out this scientific research on ice hygiene.

Rent, Buy, or Lease?

Purchasing outright offers lowest long-term cost but requires significant upfront capital. For established operations with steady cash flow, buying usually makes financial sense.

Rental payments are 100% tax-deductible and preserve working capital for other business needs. This is valuable for new restaurants needing to conserve cash.

Upgrade flexibility is where rental shines. As your business grows, you can easily adjust ice capacity without selling existing equipment. This flexibility is especially valuable for seasonal operations.

Service inclusion in rental agreements simplifies life considerably. Many programs include maintenance, repairs, and replacement equipment, providing predictable cost structure and eliminating surprise repair bills.

Best Commercial Ice Maker and Bin Combos of 2024

After testing dozens of systems throughout the year, I can recommend the top performers that deliver real value for restaurant operators. The best commercial ice maker and bin systems balance production capacity, energy efficiency, and long-term reliability.

Performance tiers serve different business needs. Entry-level systems producing 60-150 pounds daily work for coffee shops and small cafes, costing $1,200-2,500. Mid-range units handle 200-400 pounds daily with improved features, running $2,500-5,000. High-volume systems producing 500+ pounds daily include advanced diagnostics, priced $5,000-12,000.

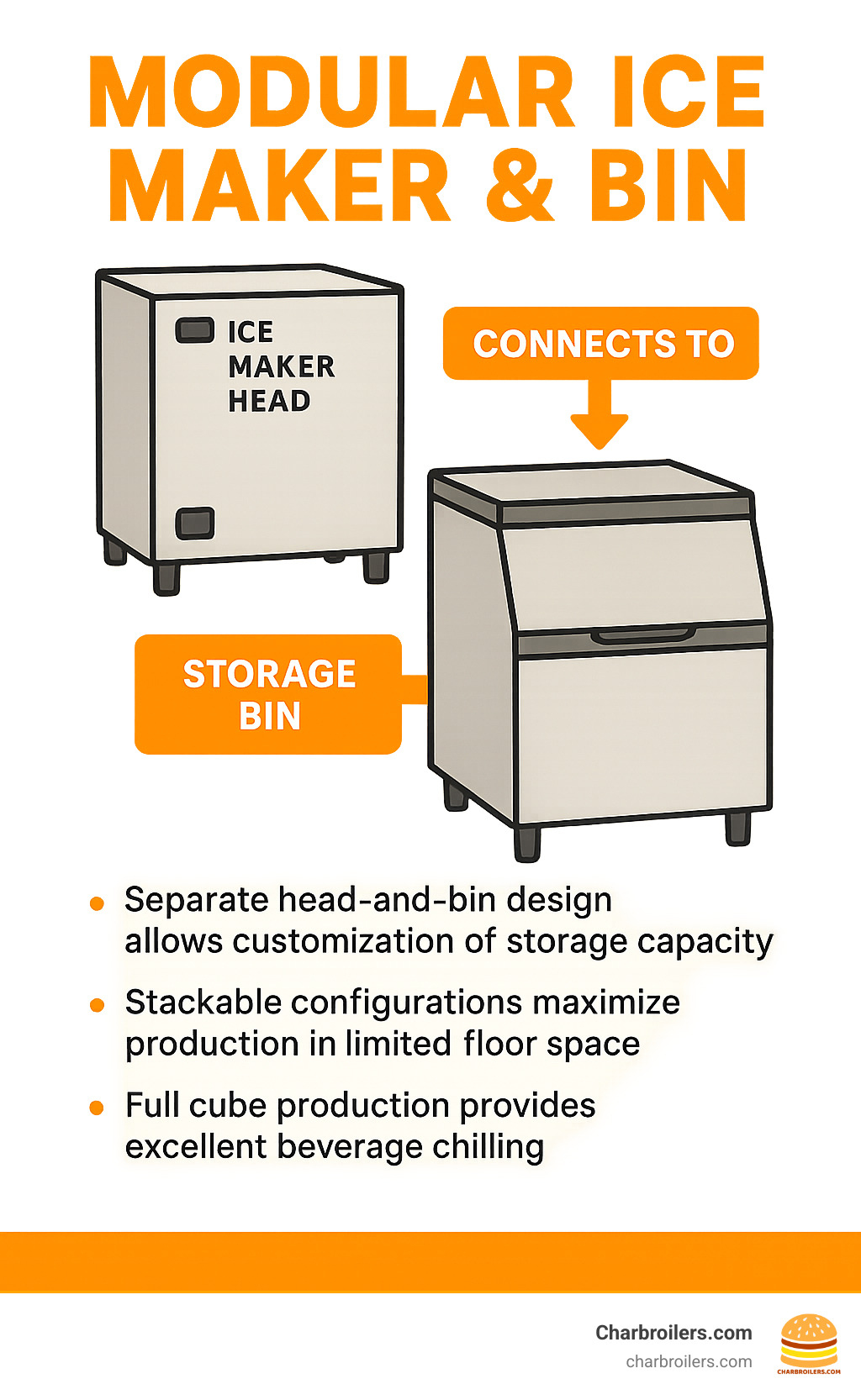

Footprint planning often determines which style works best. Tight kitchens benefit from undercounter units that preserve floor space, while operations with room can use modular systems offering more storage flexibility.

Self-contained versus modular designs depends on specific needs. Self-contained units are simpler for smaller operations, but modular systems let you customize storage capacity as your business grows.

Ice shape selection impacts functionality and customer experience. Full cubes melt slowly and look premium in cocktails. Half cubes offer good versatility. Nugget ice is popular in healthcare and quick-service for its chewable texture. Flake ice works for food display, and crescent cubes pack efficiently while allowing good liquid flow.

Undercounter Commercial Ice Maker and Bin Essentials

Undercounter units solve space challenges for bar and café operators. These space-saving designs fit under standard counters while delivering impressive production capacity.

Built-in storage typically holds 20-50 pounds of ice, perfect for steady-use operations. Coffee shops and small bars with consistent traffic rarely need massive storage - they need reliable production matching demand.

Front-breathing technology makes these units versatile for installation. Unlike units needing side or rear ventilation, front-breathing models can be built into cabinetry without losing efficiency.

ADA compliance features ensure accessibility. Controls are positioned at accessible heights, and dispensing areas accommodate various user needs - important for hotels and healthcare facilities.

Top undercounter units produce 60-125 pounds daily while maintaining Energy Star certification. Look for removable storage bins for easier cleaning and front-accessible controls for simpler maintenance.

High-Volume Modular Commercial Ice Maker and Bin Combos

Modular systems provide flexibility that busy restaurants need as they grow. The separate head-and-bin design lets you match ice production to actual needs while customizing storage capacity.

Stackable configurations work for operations needing massive capacity in limited floor space. Dual units provide backup production and different ice types. If one unit needs service, the other maintains operations.

Full cube production dominates high-volume applications because cubes melt slowly and maintain drink quality longer. Crystal-clear appearance meets presentation standards for upscale restaurants and craft cocktail bars.

Remote condenser compatibility becomes essential at high production volumes. A 600-pound daily unit generates significant heat that can overwhelm kitchen HVAC systems.

The best modular systems produce 400-650 pounds daily with storage bins holding 300-580 pounds. Top units include programmable harvest cycles, one-touch cleaning controls, and diagnostic systems.

Countertop & Dispenser-Style Commercial Ice Maker and Bin Picks

Countertop dispensers excel in healthcare facilities, office break rooms, and quick-service operations where convenience and hygiene are priorities. Nugget ice production drives most installations because customers love the soft, chewable texture.

Touch-free operation has become standard. Sensor-activated dispensing reduces contamination risk while appealing to health-conscious customers, especially important in healthcare settings.

Patient care applications showcase nugget ice benefits. Hospitals choose these units because soft texture works for patients with swallowing difficulties or dental sensitivities.

Top countertop units produce 15-35 pounds daily with 5-15 pounds built-in storage. The best models feature antimicrobial surfaces, easy-access cleaning points, and quiet operation.

For more insights on commercial ice equipment applications, check out our comprehensive guide to ice machines for business.

Frequently Asked Questions about Commercial Ice Maker and Bin Systems

How often should a commercial machine be cleaned?

The cleaning schedule for your commercial ice maker and bin depends on usage and local health codes.

Daily: Wipe exterior, clean ice scoop and holder, visual check of storage bin. Takes five minutes but prevents most contamination issues.

Weekly sanitizing: Most health departments require this. Run approved sanitizing solution through the entire system. Takes about 30 minutes but protects customers and keeps inspectors happy.

Monthly deep cleaning: Includes descaling for hard water areas, cleaning condenser coils, and checking gaskets for wear. Catches small problems before they become expensive repairs.

Quarterly professional service: Trained technicians completely disassemble key components, replace filters, and spot issues you might miss. Prevents costly breakdowns during busy periods.

The secret is consistency over intensity. Regular light cleaning prevents nasty buildup requiring expensive deep cleaning or equipment replacement.

What size ice maker and bin do I need for 100 seats?

For most 100-seat operations, we recommend systems producing 300-400 pounds daily with 200-300 pounds storage capacity. This assumes typical guests order 2.5 drinks with 6 ounces of ice each, plus safety margin for busy nights.

Restaurant type matters hugely. Sports bars need much more ice than fine dining establishments. Cocktail lounges can easily need 500-600 pounds daily because mixed drinks use more ice than soft drinks or beer.

We typically suggest modular systems for 100-seat operations - 350-400 pound daily production units paired with 250-300 pound storage bins. This provides flexibility and room to grow without massive upfront costs.

Is air-cooled or water-cooled more cost-effective long term?

Air-cooled systems win in most scenarios, especially in moderate climates with reasonable water costs. They're simpler to maintain, don't require water treatment systems, and have lower ongoing operating costs.

Water-cooled systems make sense in specific situations - very hot kitchens, poorly ventilated spaces, or areas where water is cheap and electricity expensive. They maintain consistent performance regardless of ambient temperature.

Local utility rates are the biggest factor. If water and sewer costs are low but electricity expensive, water-cooled might win. If water costs more than $8 per 1,000 gallons, air-cooled usually comes out ahead.

For most restaurants, air-cooled systems offer better long-term economics and simpler operation.

Conclusion

Choosing the right commercial ice maker and bin system is about understanding your unique operation and investing in reliability, efficiency, and peace of mind.

The biggest mistake operators make is sizing for average days instead of busiest periods. Always plan for peak demand, then add a buffer for growth.

Your installation environment matters more than most realize. Take time to evaluate your space, climate, and ventilation before making cooling decisions to avoid sky-high utility bills or inadequate performance.

Maintenance isn't optional - it's the difference between equipment serving you reliably for 10+ years versus constant breakdowns. Establish cleaning schedules from day one.

Think total cost of ownership rather than just sticker price. More expensive units with better energy efficiency and reliability often cost less over their lifetime than cheaper units requiring frequent repairs.

Hygiene features aren't just nice-to-haves - they're essential for protecting customers and your reputation. Antimicrobial surfaces, easy-clean designs, and proper filtration are investments in food safety.

At Charbroilers.com, we've built our reputation helping operators make smart equipment decisions that serve their businesses well for years. Whether choosing a commercial ice maker and bin system or planning your entire kitchen layout, we understand that every piece of equipment needs to work together seamlessly.

For more insights on building an efficient commercial kitchen, check out our comprehensive guide to commercial charbroilers to see how we approach equipment selection across all categories.