No Bin, No Problem! Commercial Ice Makers for Modular Setups

Share

Why Modular Ice Makers Are Changing Commercial Kitchens

A commercial ice maker without bin gives you the flexibility to scale your ice production and storage exactly how your business needs it. These modular units, also called ice heads or ice machines without bins, produce between 350 to over 1,500 pounds of ice per day while letting you choose your own storage solution separately.

Quick Answer for Buyers:

- Modular ice makers = ice production head only (no built-in storage)

- Production range = 350-1,500+ lbs per 24 hours

- Key benefit = customize storage capacity to match your volume needs

- Best for = high-volume restaurants, hotels, healthcare facilities

- Requires = separate storage bin or dispenser to operate

The biggest advantage? You can start with a smaller bin and upgrade your storage capacity later without replacing the entire ice maker. This modular approach also improves hygiene since you can clean the storage area separately from the ice production components.

Energy efficiency matters too. Modern modular units can use as little as 5.2 kWh per 100 pounds of ice produced, making them cost-effective for busy operations that need consistent ice supply throughout the day.

I'm Sean Kearney from Charbroilers.com, and I've spent over a decade helping restaurants find the right equipment at fair prices. Through my experience in the restaurant equipment industry, I've seen how choosing the right commercial ice maker without bin can solve space constraints while giving operators the flexibility to grow their ice storage as their business expands.

Commercial ice maker without bin glossary:

Why Choose a Modular/Binless Ice Maker?

Picture this: your restaurant is buzzing on a Friday night, and you're running low on ice. With a traditional ice maker, you're stuck with whatever storage capacity you bought two years ago. But with a commercial ice maker without bin, you could have upgraded your storage without replacing the entire unit.

The Capacity Boost That Grows With You

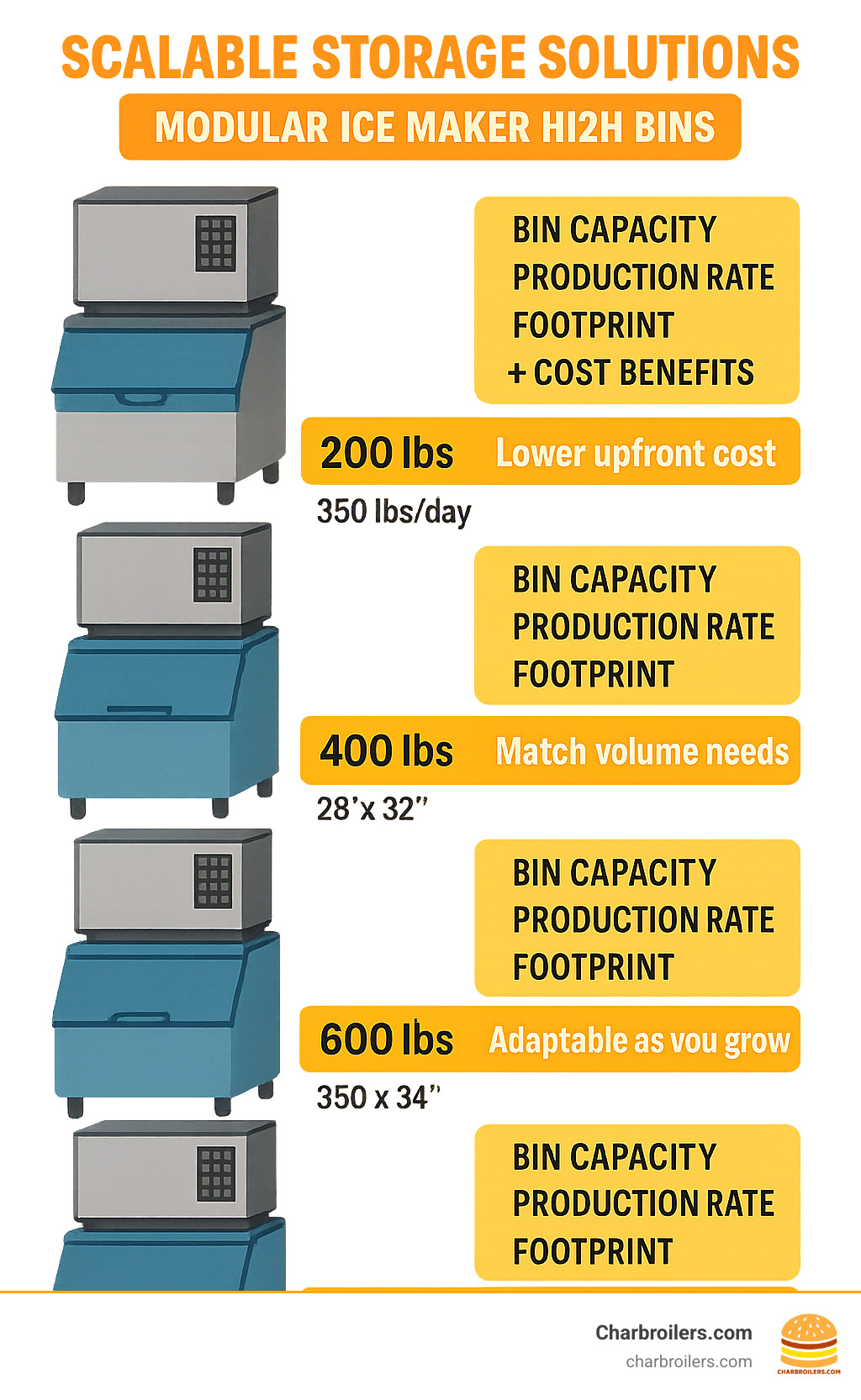

Traditional ice makers trap you in a one-size-fits-all world. A modular ice head changes that game completely. You can start with a 300-pound bin for your lunch crowd and upgrade to 600 pounds when your evening service picks up.

The beauty is in the flexibility. Your ice production stays consistent while your storage adapts to real-world demand. We've watched coffee shops double their storage capacity during summer months without touching their ice maker.

Space Savings That Actually Work

Here's where modular units get clever. They separate the noisy, heat-generating ice maker from the storage bin. This means you can tuck the ice head into a well-ventilated back area while keeping your bin right where your staff needs it most.

One bakery owner told us this setup cut her team's steps in half. The ice head sits in their prep area, but the bin stays next to their beverage station. No more running across the kitchen with buckets of ice during the morning rush.

Workflow and Hygiene Made Simple

Here's something most people don't think about until it's too late: cleaning day. With a traditional unit, sanitizing means shutting down your entire ice operation. Not ideal when you've got customers waiting.

A commercial ice maker without bin keeps producing ice while you deep-clean the storage area. Your ice maker hums along happily while you scrub every corner of that bin. This separation also makes daily cleaning faster and more thorough.

Expandability Without the Headache

Restaurant needs change faster than equipment budgets allow. Maybe you're catering more events, or perhaps you've added a smoothie bar. With modular ice makers, you can adapt without major equipment purchases.

Need more storage? Add a second bin. Slower winter months? Switch to a smaller bin and save on energy costs. The ice production stays constant while your storage flexes with your business.

Ventilation Flexibility That Saves Money

Traditional units dump all their heat in one spot, making your HVAC system work overtime. Modular ice makers let you place the heat-generating head where it won't fight your air conditioning.

This smart placement can cut your cooling costs by 15-20% in warmer climates. Your ice maker stays happy with proper ventilation, and your electric bill stays reasonable.

Sustainability and Energy Efficiency

Modern modular units pack serious efficiency into their compact design. ENERGY STAR certified models use advanced compressor technology that produces more ice while consuming less power.

The energy savings add up quickly in high-volume operations. Better efficiency means lower operating costs and a smaller environmental footprint - something your customers increasingly care about.

For detailed information about matching ice makers with the right storage solutions, check out our guide on bin setups.

Best Commercial Ice Maker Without Bin Models Reviewed

After testing dozens of modular ice makers in real commercial kitchens, I've learned that the best commercial ice maker without bin isn't just about production numbers. It's about finding the sweet spot between capacity, reliability, and features that actually matter during a busy dinner rush.

The modular ice maker market breaks down into three main production tiers. Compact units handle 300-450 pounds per day and work perfectly for coffee shops and small bars. Mid-range models produce 550-800 pounds daily, which covers most restaurants and hotels. High-volume units crank out 1000+ pounds per day for large operations that can't afford to run out of ice.

Modern modular heads come with features that would have been luxury items just five years ago. Stackable designs save precious floor space, while antimicrobial protection keeps your ice safe without constant chemical treatments. Self-diagnostic systems now alert you to maintenance needs before they become expensive problems.

The one-touch sanitize controls have been a game-changer for busy kitchens. Instead of mixing cleaning solutions and following complex procedures, you press a button and let the machine handle the sanitization cycle. This means staff actually clean the equipment instead of skipping it when things get hectic.

For reference on industry-standard production specifications, you can check professional ice machine clearance sources for certified used options.

High-Volume Commercial Ice Maker Without Bin (1000+ lbs/day)

The Ice-O-Matic CIM1446FA Elevation Series is what happens when engineers actually listen to restaurant owners. This beast produces 1,560 pounds of full-cube ice per day under standard conditions. Even when your kitchen hits 90°F and your water temperature climbs to 70°F, it still delivers 1,210 pounds daily.

What makes this unit special is the dual-exhaust cooling system. Instead of dumping all that heat into your kitchen, it directs the hot air away from your prep areas. We tested this in our Seattle location during a brutal summer heat wave, and the difference was noticeable. The kitchen stayed cooler, and the ice maker kept producing at full capacity.

The one-touch sanitize controls eliminate the guesswork from cleaning cycles. The PURE ICE antimicrobial protection works continuously in the food zones, giving you peace of mind during health inspections. At 48.25" wide by 24.25" deep, it's substantial but not overwhelming.

This commercial ice maker without bin works best for large restaurants, hotels, and healthcare facilities that need consistent high-volume production. The stackable design means you can add storage bins above or below without redesigning your entire ice station.

Mid-Range Modular Head for Restaurants & Hotels

The 550-800 pounds per day range hits the sweet spot for most restaurants. These units give you serious production capacity without requiring a dedicated equipment room. The 22-30 inch width fits into standard prep areas where larger units simply won't work.

Cube ice melts slowly and works perfectly for beverages. Nugget ice is chewable and popular in healthcare settings and soft drink applications. Flake ice excels for seafood displays and food preservation. The beauty of modular systems is that you can choose the ice type that matches your specific needs.

Most mid-range units consume 6-8 kWh per 100 pounds of ice, making them cost-effective for daily operation. The filter-ready design extends equipment life by protecting internal components from water quality issues. This is especially important in areas with hard water or high mineral content.

The stackable configuration saves valuable floor space in cramped kitchens. You can mount storage bins directly above the ice maker head or position them separately based on your workflow needs.

Compact Commercial Ice Maker Without Bin for Small Venues

Don't underestimate these smaller units. A commercial ice maker without bin in the 300-450 pound range still outproduces most self-contained models while giving you complete storage flexibility.

The Scotsman C0322MA exemplifies this category perfectly. It produces 350 pounds per day in a 22-inch width that fits behind soda dispensing stations or in narrow prep areas. The energy consumption of just 5.2 kWh per 100 pounds makes it one of the most efficient units we've tested.

The WaterSense adaptive purge control is smarter than it sounds. Instead of flushing water on a fixed schedule, it monitors actual conditions and only purges when necessary. This saves water and reduces operating costs without compromising ice quality.

Coffee shops love these units because they can start with a small bin and upgrade storage as their iced drink sales grow. Food trucks use them to expand beyond the limited ice capacity of their onboard equipment. The AgION antimicrobial protection and AutoAlert maintenance indicators keep the ice safe and the equipment running smoothly.

The reusable air filter cleans from the outside, so maintenance doesn't require moving the entire unit. This might seem like a small detail, but it matters when you're dealing with tight installation spaces.

Buying Guide: Sizing, Ice Types & Bin Pairing

Getting the sizing right feels like a guessing game, but it doesn't have to be. I've walked hundreds of restaurant owners through this process, and there's actually a pretty reliable way to nail your ice needs without breaking the bank.

Start with your busiest day. Think about that Friday night when you're slammed, or the weekend when everyone wants iced drinks. That's when you'll find out if you bought enough ice capacity or not.

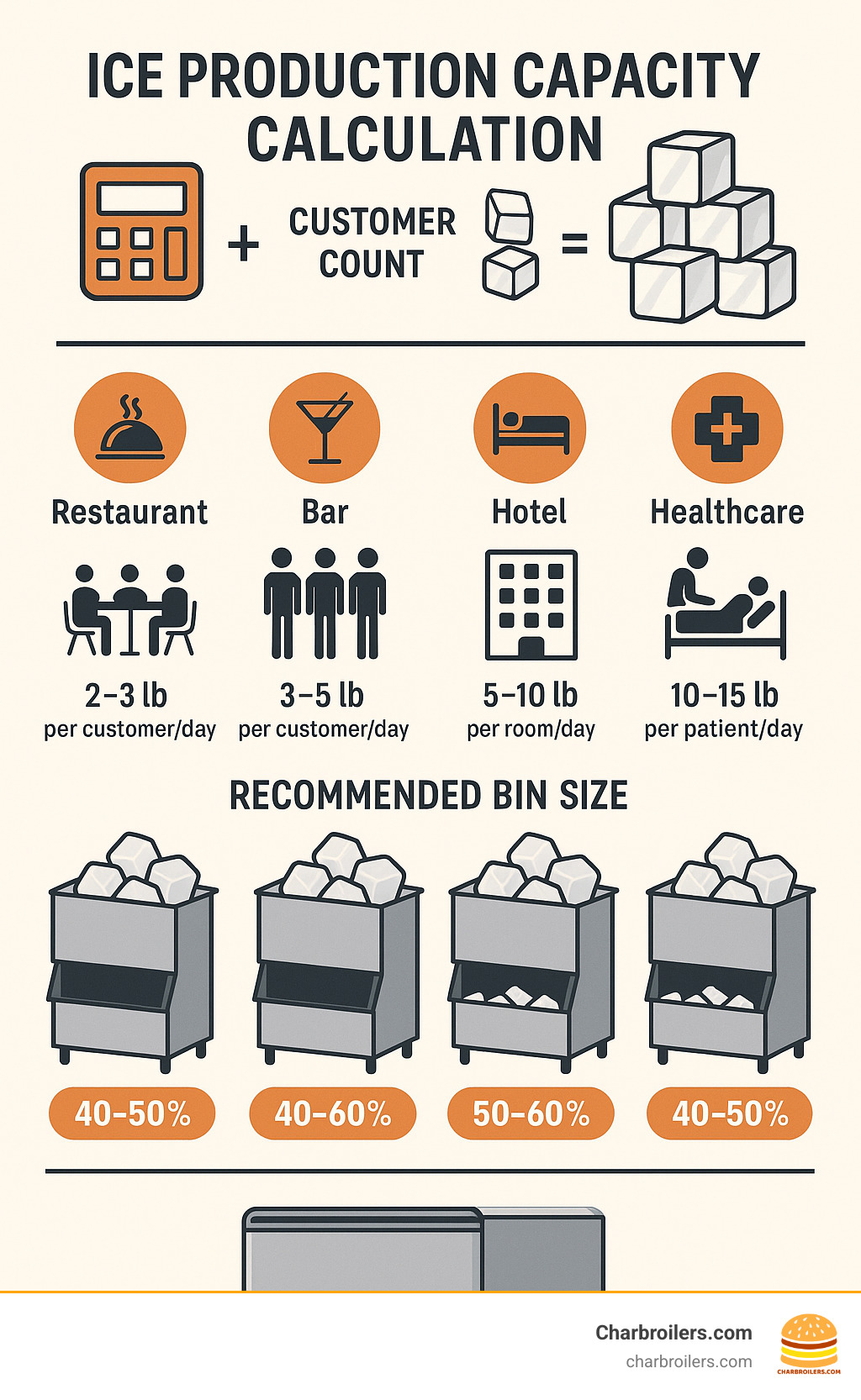

The demand calculation is simpler than you think. Restaurants typically need 2-3 pounds of ice per customer per day. Bars bump that up to 3-5 pounds because of all those cocktails and mixed drinks. Hotels are looking at 5-10 pounds per room daily, and healthcare facilities need the most at 10-15 pounds per patient.

Here's how this works in real life: Say you run a 100-seat restaurant that serves 200 customers on a busy day. That's 400-600 pounds of ice you'll need. I'd recommend a commercial ice maker without bin that produces 600-800 pounds daily to give you that safety buffer for unexpected rushes.

Ice type selection matters more than most people realize. Full cubes are your workhorses for beverages and cocktails - they melt slowly and look professional in drinks. Half cubes cool things down faster and work great for blended drinks. Nugget ice is the chewable stuff that patients love in healthcare settings, but it melts quickly. Flake ice is perfect for seafood displays and food preservation because it molds around products.

The bin size ratio is where people often mess up. Your storage bin should hold about 40-60% of your daily ice production. So if you've got a 600 lb/day ice maker, pair it with a 250-350 pound storage bin. This keeps your ice fresh while making sure you don't run out during peak times.

Water quality will make or break your investment. Hard water creates scale buildup that'll kill your ice maker. Soft water can make slushy ice that nobody wants. Installing proper filtration upfront costs way less than replacing equipment early or dealing with constant service calls.

ENERGY STAR certification isn't just a nice-to-have anymore. These units use 10-15% less energy and 10-25% less water than standard models. The energy savings typically cover the higher upfront cost within 2-3 years, and that's money back in your pocket every month after that.

The key is matching your commercial ice maker without bin to your actual usage patterns, not just guessing. Most operators underestimate their peak demand and end up scrambling for ice when they need it most. Size up rather than down - you can always make less ice, but you can't make more than your machine's capacity.

Installation, Maintenance & Cost Considerations

Getting your commercial ice maker without bin up and running isn't rocket science, but the details matter. I've seen too many operators cut corners on installation only to deal with breakdowns and higher operating costs later.

Space Planning Comes First Your modular ice maker needs room to breathe. Plan for 6 inches on each side and 12 inches on top for proper airflow. The heat has to go somewhere, and cramped installations lead to overworked compressors and early failures.

Water supply requirements are straightforward but critical. You'll need a 1/2-inch supply line with water pressure between 40-80 PSI. Too low, and your ice maker struggles to fill. Too high, and you'll damage internal components.

Drainage and Electrical Essentials The drain line needs proper slope - we recommend a 3/4-inch drain with at least 1/4-inch drop per foot. Standing water in drain lines creates sanitation issues and unpleasant odors.

Most units require a dedicated 20-amp circuit, though high-volume models might need more. Check your specific model's requirements before installation day. Nothing's worse than finding you need electrical upgrades after your equipment arrives.

Maintenance That Actually Prevents Problems Here's where modular units shine compared to self-contained models. You can maintain the ice maker and storage bin separately, which means less downtime and more thorough cleaning.

Daily checks take just minutes - look at ice quality and production levels. Cloudy ice or reduced output signals problems early. Weekly bin cleaning prevents contamination and keeps your ice tasting fresh.

The big maintenance tasks happen quarterly. Deep cleaning the evaporator and condenser keeps efficiency high and prevents costly repairs. Most operators schedule this during slower periods.

Descaling frequency depends entirely on your water quality. Hard water areas need descaling every 2-3 months, while soft water locations can stretch to 6 months. Skip descaling, and you'll replace expensive components years early.

Warranty Protection and Real Costs Most manufacturers back their equipment with 3-year parts and labor warranties, plus 5-year compressor coverage. Extended warranties make sense for high-volume operations where downtime costs serious money.

Pricing breaks down predictably by capacity. Compact units producing 300-450 pounds daily run $2,500-$4,000. Mid-range 550-800 pound units cost $4,000-$7,000. High-volume 1000+ pound models range $7,000-$12,000. Don't forget storage bins add $800-$2,500 depending on capacity.

Operating costs for a typical 600-pound daily unit run $150-$250 monthly in combined electricity and water charges. ENERGY STAR certified models cut this by 15-20%, which adds up over years of operation.

Financing vs. Leasing Reality Leasing works for startups or seasonal businesses with uncertain ice needs. Buying makes more sense for established operations with predictable demand. At Charbroilers.com, our financing options extend up to 60 months, making ownership affordable without straining cash flow.

For more insights on commercial ice applications across different industries, read our guide on Ice Machines That Mean Business: Hotels, Offices, and Beyond.

Frequently Asked Questions about Modular Ice Machines

How do I match a storage bin to a commercial ice maker without bin?

The good news is that matching a storage bin to your commercial ice maker without bin is pretty straightforward once you know the basics. Think of it like buying a lid for a pot - manufacturers design these components to work together seamlessly.

Size compatibility is the easiest part. Ice maker heads come in standard widths: 22", 30", and 48". Storage bins are built to match these exact dimensions. A 30" wide ice maker sits perfectly on a 30" wide bin without any gaps or overhangs.

Capacity matching requires a bit more thought. Your bin should hold about 40-60% of your daily ice production. So if you have a 600 lb/day ice maker, you'll want a 250-350 lb storage bin. This ratio ensures you're always serving fresh ice while having enough capacity for busy periods.

Here's something many people forget: height considerations. When you stack an ice maker on top of a bin, you're looking at 75-85" total height. Make sure you have enough ceiling clearance and that your staff can still reach the ice maker for routine maintenance.

Manufacturer compatibility matters for peace of mind. While most units follow industry standards, we always recommend pairing ice makers and bins from the same manufacturer. It guarantees proper fit and keeps your warranty intact.

Does a binless modular unit improve sanitation and workflow?

This is where modular systems really shine, and it's one of the biggest reasons busy kitchens make the switch.

Sanitation gets so much easier with separate components. You can deep-clean your storage bin without shutting down ice production. This is huge for healthcare facilities and high-volume restaurants that can't afford to stop making ice during cleaning cycles.

Think about it: with a self-contained unit, cleaning means no ice production until you're done. With a commercial ice maker without bin, your ice maker keeps running while you sanitize the storage area. You can even have a backup bin ready to swap in during cleaning.

Workflow improvements are immediate and noticeable. You can position the storage bin exactly where your staff need ice most - right next to the beverage station, for example - while placing the ice maker head in the best spot for ventilation and maintenance access.

One of our customers cut their staff's walking time by 40% just by repositioning their ice storage closer to the service area. The ice maker itself went to a back prep area with better ventilation.

Temperature control is another hidden benefit. Separating the heat-generating ice maker from the storage area keeps your ice colder longer. The ice maker can live in a well-ventilated mechanical area while the bin stays in your service zone.

Cleaning scheduling becomes flexible. You can clean the bin during slow periods while the ice maker continues producing for the next rush. This kind of flexibility is impossible with all-in-one units.

What common mistakes should I avoid when installing?

After helping hundreds of restaurants with ice maker installations, I've seen the same mistakes over and over. The good news is they're all preventable.

Inadequate ventilation kills more ice machines than anything else. Don't install air-cooled units in enclosed spaces without proper airflow. Hot air recirculation will destroy your compressor faster than you'd believe. If you can't feel cool air coming out of the condenser area, you have a problem.

Wrong water quality is an expensive mistake. Installing a commercial ice maker without bin without proper water filtration is like buying a sports car and putting cheap gas in it. Scale buildup from hard water can destroy an ice maker in just six months. Always test your water quality first and install the right filtration system.

Undersized electrical causes headaches down the road. Many units require dedicated 20-amp circuits. Using undersized wiring causes voltage drops that damage compressors. Always follow the electrical specifications exactly - no shortcuts.

Poor drainage seems minor until you have a flood. Inadequate drain slope causes water backup and potential flooding. Make sure you have proper drainage with the right pipe sizing and slope. Water needs somewhere to go, and it won't wait for you to fix it.

Ignoring clearances is tempting when space is tight, but don't do it. Cramming an ice maker into a tight space restricts airflow and makes maintenance impossible. Follow manufacturer clearance requirements religiously - they're not suggestions.

Mixing manufacturers can work, but it's risky. While it's possible to mix ice maker heads and bins from different manufacturers, you might void warranties and run into compatibility issues. When in doubt, stick with matched systems from the same manufacturer.

Conclusion

Choosing a commercial ice maker without bin is like investing in a flexible foundation for your growing business. These modular systems adapt to your needs instead of forcing you to adapt to them - and that's exactly what smart food service operators need in today's competitive market.

Think about it this way: your ice needs today might be completely different from what you'll need next year. Maybe you're adding a catering service, expanding your dining room, or planning a second location. With a modular ice system, you're prepared for growth without the headache of replacing expensive equipment.

The bottom line benefits are clear. You'll save money on energy costs with ENERGY STAR certified units. You'll improve your kitchen's sanitation by cleaning storage areas separately from ice production. And you'll give your staff the workflow they need by placing ice storage exactly where it makes sense.

Your next steps are straightforward: Start by calculating your daily ice needs - remember that 2-5 pounds per customer rule we discussed. Choose your ice type based on how you'll actually use it. Size your storage bin for 40-60% of your daily production to keep ice fresh. And don't skip the basics like proper ventilation and water filtration.

We've seen too many operators try to save money upfront only to spend more later on repairs and replacements. A quality commercial ice maker without bin, properly installed and maintained, will serve your business reliably for years.

At Charbroilers.com, we know that every food service operation has its own unique challenges. That's why we take the time to understand your specific needs before recommending equipment. Our financing options make it easier to get the right system now instead of settling for something that barely meets your current needs.

The restaurant equipment industry moves fast, but ice is one thing that never goes out of style. Your customers expect it, your staff needs it, and your business depends on it. A modular ice system gives you the reliability and flexibility to focus on what you do best - serving great food and drinks.

Ready to explore your options? We're here to help you find the perfect ice solution that grows with your business. Our team understands the real-world demands of commercial kitchens, and we'll make sure you get equipment that works as hard as you do.

For operators considering commercial-grade ice equipment in non-traditional settings, our guide on Bring the Chill Home: Top Commercial Ice Makers for Residential Use offers valuable insights into adapting commercial ice technology for home use.