Freeze Frame – 2025's Best Industrial Ice Machines Reviewed

Share

Why Industrial Ice Machines Are Critical for Commercial Success

Finding the best industrial ice machine for your business isn't just about keeping drinks cold - it's about protecting food quality, maintaining customer satisfaction, and ensuring operational efficiency in high-demand environments.

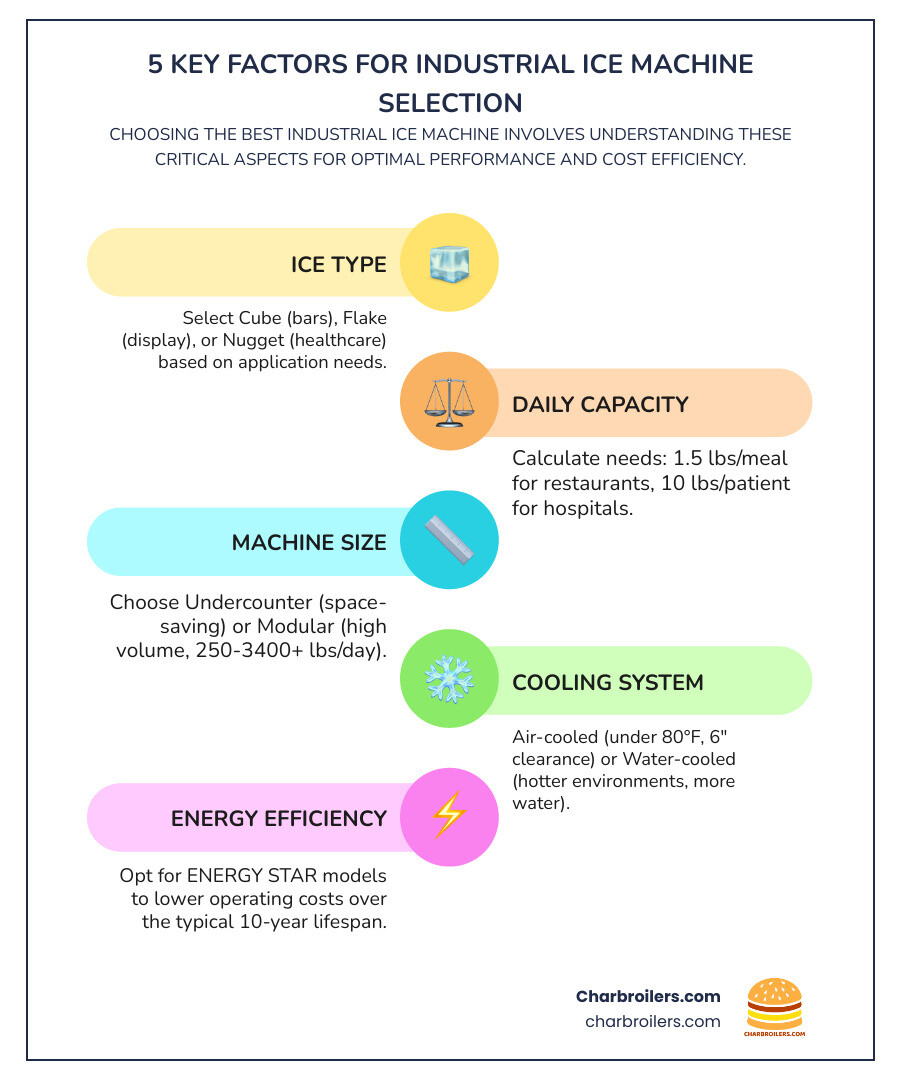

Top Industrial Ice Machine Categories:

- Cube Ice Machines: Best for restaurants and bars (slow melting, premium appearance)

- Flake Ice Machines: Ideal for seafood displays and produce cooling (maximum surface area)

- Nugget Ice Machines: Perfect for healthcare and beverage service (soft, chewable texture)

- Modular Systems: High-capacity units producing 250-3,400+ lbs per day

- Undercounter Units: Space-saving options for smaller operations (up to 350 lbs/day)

The stakes are high when choosing industrial ice equipment. Restaurants typically use 1.5 pounds of ice per meal served, while hospitals require about 10 pounds per patient daily. A restaurant serving 250 customers needs approximately 450 pounds of ice per day, but peak demand and hot weather can push requirements even higher.

Machine configuration matters too. Air-cooled units need at least 6 inches of clearance and work best under 80°F ambient temperatures. Water-cooled systems perform better in hot environments but use more water. The wrong choice can mean reduced ice production exactly when you need it most.

Modern industrial ice machines range from compact 50-pound daily producers to massive 48-inch wide modular units capable of 2,500-3,400 pounds per day. Energy efficiency varies significantly - ice makers typically draw 50-160 watts with an average of 100 watts per hour. ENERGY STAR certified models can dramatically reduce operating costs over the typical 10-year commercial lifespan.

I'm Sean Kearney from Charbroilers.com, and with over a decade in restaurant equipment, I've helped countless operators find the best industrial ice machine for their specific needs and budget. My experience at Amazon and founding The Restaurant Warehouse taught me that the right ice machine choice can make or break a food service operation's efficiency and profitability.

Essential best industrial ice machine terms:

Decoding the Ice: Types of Industrial Ice and Their Applications

When we talk about finding the best industrial ice machine, one of the first things we consider is the type of ice it produces. Not all ice is created equal, and each type serves a unique purpose, impacting everything from beverage quality to food preservation and even patient comfort. Choosing the right ice type is fundamental to optimizing your operations.

Cube Ice (Full & Half): The All-Rounder

Cube ice, whether full or half-sized, is probably what most of us picture when we think of ice. It's the quintessential choice for general beverage service across restaurants, bars, and hotels.

- Full Cube Ice: These robust, slow-melting cubes are perfect for high-end cocktails and soft drinks. Their density means they dilute drinks slowly, preserving the flavor and integrity of the beverage. They also have a pleasing, premium appearance, which is why you'll often see them in fine dining establishments.

- Half Cube Ice: A versatile option, half-cube ice is smaller and more compact than full cubes, making it ideal for virtually any commercial foodservice setting. It still offers good chilling power but displaces less liquid, which can be a plus for carbonated drinks or for maximizing liquid volume in a glass. This type of ice is an excellent choice for high-volume beverage service where speed and efficiency are key.

We've explored the nuances of commercial ice equipment in more detail in our article, Ice Ice Baby: Best Commercial Ice Making Equipment To Keep Your Business Cool.

Flake Ice: The Ultimate for Display and Preservation

Flake ice is the unsung hero of the industrial ice world, especially when it comes to food preservation and display. Its unique properties make it indispensable for certain applications.

Flake ice is thin, typically around 1.5mm, and dry, allowing it to pack tightly around products without bruising or damaging them. This makes it the ideal choice for:

- Produce Displays: Think about those vibrant fruit and vegetable sections in grocery stores or farmer's markets. Flake ice cradles delicate produce, drawing out field heat and maintaining freshness and crispness.

- Seafood Counters: For fish and seafood, rapid and consistent cooling is paramount to preserving quality and preventing spoilage. Flake ice provides maximum contact with the product, ensuring even chilling. It's also gentle enough not to harm sensitive fish.

- Rapid Cooling: The thin shape and vast surface area of flake ice mean it melts quickly, transferring its cooling power efficiently. In fact, flake ice boasts more than 17,000 square feet (1,570 square meters) of surface area per ton of ice! This makes it incredibly effective for removing field heat from vegetables during harvest, or for applications like direct freezing of liquids, such as orange juice, directly on the evaporator.

- Product Protection: Because it's completely dry and free-flowing, flake ice cushions delicate items, preventing fusion in storage bins and ensuring easy distribution. It's also the most economical ice to produce, requiring only 1.3 tons of refrigeration per ton of ice from 60ºF (16º C) water. Beyond produce and seafood, it's also used in bakeries for dough mixing and in industries like poultry processing and chemical manufacturing for cooling.

Nugget & Chewable Ice: The Customer Favorite

Nugget ice, often referred to as "pebble ice" or "chewable ice," has a soft, chewable texture that makes it incredibly popular with customers and patients alike.

- Beverage Displacement: Its irregular, soft form makes it excellent for blending into smoothies, frozen margaritas, and other blended drinks, as it creates a smooth consistency. It also displaces more liquid than cube ice, giving the impression of a fuller drink.

- Healthcare Facilities: Nugget ice is particularly ideal for hospitals and healthcare settings. Its soft texture is easy for patients, especially children, to chew, making it perfect for hydration and medication consumption.

- Versatile Applications: Beyond healthcare, nugget ice is a hit in cafes, convenience stores, and quick-service restaurants where customers appreciate its unique mouthfeel.

To learn more about this popular ice type, check out our guide on Commercial Crushed Ice Maker.

Sizing It Up: How to Choose the Right Ice Machine Capacity

Getting the capacity right is where many business owners stumble when selecting the best industrial ice machine. It's tempting to just guess based on what feels right, but trust me - I've seen too many restaurants scrambling for ice during their dinner rush because they underestimated their needs. On the flip side, oversizing wastes money and energy.

The key is understanding that ice production isn't just about your average day. You need to plan for your busiest periods, hottest weather, and even future growth. A machine that works perfectly in January might leave you high and dry during a July heat wave when everyone wants extra ice in their drinks.

Calculating Your Daily Ice Needs

Here's where the math gets interesting. Every business type has different ice consumption patterns, and understanding yours is crucial for finding the best industrial ice machine.

Restaurants typically burn through about 1.5 pounds of ice per meal served. So if you're serving 250 customers on a busy Saturday, you're looking at roughly 375 pounds of ice. But here's the catch - that's just the baseline. Add in ice for staff drinks, kitchen prep, and those extra refills on hot days, and you could easily hit 450 pounds or more.

Cocktail bars and lounges are the heavy hitters of ice consumption. These establishments need around 3 pounds of ice per seat because mixed drinks, shaken cocktails, and wine service all demand fresh ice. A 100-seat cocktail bar might need 300 pounds daily, but during peak hours, that demand gets concentrated into just a few hours.

Healthcare facilities have unique requirements, averaging 10 pounds of ice per patient daily. This covers everything from patient hydration to therapeutic applications and food service. A 50-bed facility would need about 500 pounds of ice daily, but hospitals can't afford to run short - patient care depends on reliable ice availability.

Hotels present their own challenges. Guest ice machines typically require 5 pounds per room, while hotel catering and restaurants add another 1 pound per person served. A 100-room hotel with an active restaurant could easily need 800+ pounds of ice daily.

| Business Type | Ice Usage Estimate | Example (250 units) |

|---|---|---|

| Restaurant (per meal) | 1.5 lb. | 375 lb. |

| Cocktail Bar (per seat) | 3 lb. | 750 lb. |

| Hospital (per patient) | 10 lb. | 2,500 lb. |

| Hotel (per room) | 5 lb. | 1,250 lb. |

| Cafeteria (per person) | 1 lb. | 250 lb. |

Smart operators often install multiple smaller machines rather than one massive unit. This strategy puts ice closer to where it's needed, reduces labor costs, and provides backup if one machine needs service. For more insights on commercial ice equipment placement, check out More info about commercial equipment.

Understanding Production Ratings vs. Real-World Output

Here's where manufacturers' claims meet reality - and sometimes they don't shake hands nicely. That "24-hour yield" rating on the spec sheet? It's based on perfect laboratory conditions that rarely exist in real commercial kitchens.

Ambient temperature is the biggest factor affecting actual ice production. Air-cooled machines - which represent most commercial installations - start struggling when ambient temperatures climb above 80°F. Install one in a hot kitchen or stuffy storage room, and you might get 20-30% less ice than rated. That's why proper ventilation with at least 6 inches of clearance around air intakes is absolutely critical.

Water temperature also plays a major role. Cold incoming water means your machine works less to freeze it. Hot water from a poorly insulated supply line forces the machine to work harder, reducing output and increasing energy costs. Most ratings assume 70°F water temperature - if yours runs hotter, expect lower production.

Water quality can make or break your ice production over time. Hard water with high mineral content creates scale buildup on evaporator plates, reducing heat transfer efficiency. Poor filtration allows bacteria and slime to grow, further impacting performance. A good water filter system isn't optional - it's essential for maintaining rated capacity throughout the machine's life.

The reality is that most commercial installations see actual production rates of 70-85% of the manufacturer's rating due to these environmental factors. Plan accordingly, and you'll never be caught short when the dinner rush hits or the temperature soars.

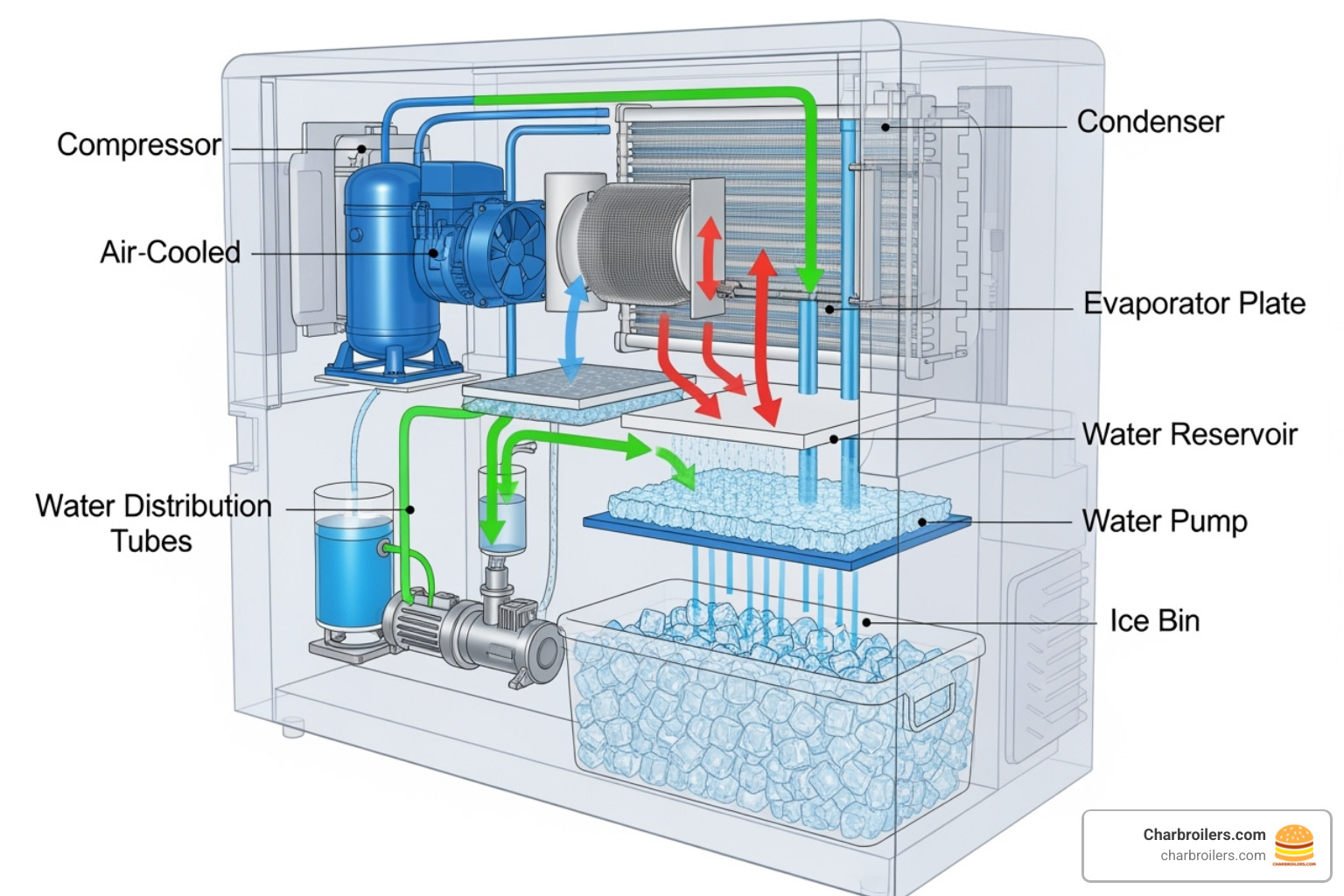

The Anatomy of the Best Industrial Ice Machine

When you're searching for the best industrial ice machine, understanding what's happening under the hood makes all the difference. These aren't just big boxes that magically produce ice – they're sophisticated pieces of engineering designed to work reliably in the toughest commercial environments.

Think of an industrial ice machine like the heart of your operation. Just as you wouldn't choose a heart without understanding how it works, you shouldn't pick an ice machine without knowing its key components and how they'll perform in your specific situation.

Cooling Systems: Air-Cooled vs. Water-Cooled vs. Remote

The cooling system is where the magic happens – and where many operators make costly mistakes. Your choice here will impact everything from your utility bills to how much ice you actually get on those sweltering summer days.

Air-cooled ice machines are the workhorses of the industry, and for good reason. They're straightforward to install and don't guzzle water like their water-cooled cousins. But here's the catch – they're picky about their environment. If your kitchen regularly hits above 80°F, or if you can't provide at least 6 inches of clearance around the air intake and discharge, your machine will struggle like a marathon runner in a sauna.

I've seen too many operators install air-cooled units in hot storage rooms or cramped corners, then wonder why their ice production drops just when they need it most. These machines also pump heat into your space, which might mean your HVAC system works overtime during peak hours.

Water-cooled ice machines are the steady performers in challenging environments. They use a continuous flow of water to cool the condenser, making them ideal when ambient temperatures consistently exceed 80°F or when space is tight. They're also quieter – a blessing if your ice machine sits near dining areas. The trade-off? Your water bill will definitely notice. In areas where water is expensive or restricted, this can add up quickly.

Remote condenser systems are the premium solution for extreme conditions. Picture this: your ice-making head stays cool and quiet indoors while the heat-generating condenser lives outside on your roof or in a well-ventilated area. It's like having your cake and eating it too – superior performance without the indoor heat and noise. Yes, installation is more complex and expensive, but the long-term benefits often justify the investment.

We explore these cooling options in much more detail in our guide: Choosing the Best Ice Machine for Your Business in 2025.

Machine Configuration: Finding the best industrial ice machine for your space

Space is always at a premium in commercial kitchens, so choosing the right configuration can make or break your workflow efficiency.

Modular units are the heavyweights of ice production – and my personal favorites for high-volume operations. These systems separate the ice-making head from the storage bin, giving you incredible flexibility. Want more storage? Pair a smaller head with a larger bin. Need maximum production? Go with a large head and appropriately sized bin.

You'll find modular units in 22-inch, 30-inch, and 48-inch widths. The smaller units typically produce 250-500 pounds daily, while those impressive 48-inch wide monsters can churn out 2,500 to 3,400 pounds per day. That's enough ice to keep a busy hospital or large hotel running smoothly.

Undercounter ice machines are perfect for operations where space is tight but ice needs are moderate. These self-contained units slip neatly under counters and typically max out around 350 pounds per day. They're ideal for smaller bars, cafes, or as supplemental units in larger operations.

Ice dispensers offer the convenience of self-service, making them popular in hotels and healthcare facilities. They produce, store, and dispense ice all in one unit, with outputs ranging from 120 to 618 pounds daily. Some combination units even add water dispensing, perfect for break rooms and patient areas.

For detailed setup guidance, check out our comprehensive article: Cool Choices For Commercial Ice Maker And Bin Setups.

Key Features for the best industrial ice machine

Beyond the basics, certain features separate good ice machines from great ones – and great ones from the best industrial ice machine for your specific needs.

Energy efficiency should be at the top of your priority list. With machines drawing anywhere from 50 to 160 watts (averaging around 100 watts per hour), an ENERGY STAR rated unit can save substantial money over its typical 10-year commercial lifespan. Those savings add up faster than you might think. For readers unfamiliar with the program, see ENERGY STAR for a concise overview of its efficiency standards.

Maintenance and cleaning features directly impact both your bottom line and food safety. Look for machines with self-cleaning cycles – they're worth their weight in gold when you're dealing with busy schedules and tight labor. Removable parts and accessible components make routine maintenance less of a headache for your staff.

Water quality and filtration cannot be overlooked. Poor water quality is like kryptonite for ice machines, causing mineral buildup that reduces efficiency and shortens lifespan. A robust water filtration system isn't optional – it's essential insurance for your investment. Many modern machines include helpful alerts for filter changes and cleaning cycles.

Durability and construction quality matter more than you might initially think. A commercial ice maker should reliably serve your operation for about 10 years with proper maintenance – significantly longer than the 4-5 year lifespan of home units. Look for stainless steel components and solid construction that can handle the demands of commercial use.

If you're considering modular setups without built-in storage, our guide No Bin, No Problem: Commercial Ice Makers For Modular Setups provides valuable insights for your decision-making process.

Frequently Asked Questions about Industrial Ice Machines

When you're shopping for the best industrial ice machine, it's natural to have questions about maintenance, longevity, and installation. After helping hundreds of businesses find the perfect ice solution, I've noticed the same concerns come up again and again. Let me share what I've learned from real-world experience.

How often does an industrial ice machine need to be cleaned?

Here's the truth: every six months is the bare minimum for a thorough cleaning, but your actual needs depend on your specific situation.

Water quality makes a huge difference. If you're dealing with hard water full of minerals, you might find yourself cleaning every three to four months to prevent that stubborn scale buildup. I've seen machines in areas with terrible water quality that needed attention monthly - it's not fun for anyone involved.

High-volume operations face their own challenges. When you're cranking out hundreds of pounds of ice daily, bacteria and slime have more opportunities to develop. The good news is that many modern machines come with self-cleaning cycles that help with daily maintenance. Just remember - these automated cycles are helpful, but they don't replace the deep cleaning that only human hands (or professional service) can provide.

Think of it this way: ice is food, and you wouldn't serve food from a dirty kitchen. Regular cleaning isn't just about keeping your machine running efficiently - it's about protecting your customers' health and maintaining the quality they expect.

What is the average lifespan of an industrial ice machine?

A well-maintained commercial ice machine should give you about 10 years of reliable service. That's actually pretty impressive when you consider that home units typically tap out around four to five years.

The secret to hitting that 10-year mark? Regular maintenance and quality water filtration. I can't stress this enough - a good water filter system is like insurance for your ice machine. It protects those expensive internal components from the minerals and sediment that love to cause problems.

Operating conditions matter too. Machines stuck in sweltering hot rooms or cramped spaces with poor ventilation work harder and wear out faster. It's like asking someone to run a marathon in a sauna - they might finish, but it's going to take a toll.

Quality matters when you're making this investment. A well-built machine from a reputable manufacturer will outlast a bargain unit every time. Think of it like buying a reliable work truck versus the cheapest option on the lot.

Can I install an industrial ice machine myself?

I get it - installation costs can sting, and it's tempting to tackle it yourself. But honestly? Professional installation is worth every penny, and here's why.

Plumbing gets complicated fast. These machines need dedicated cold water lines with shutoff valves and proper drainage. Get the drainage wrong, and you could be looking at water damage that costs way more than professional installation. Local codes are picky about drain types and placement for good reason.

The electrical requirements aren't simple either. Most industrial units need dedicated circuits, and improper connections can be dangerous or damage your expensive new machine. I've seen too many warranty claims denied because someone tried to save a few bucks on installation.

Your warranty depends on it. Most manufacturers require professional installation to keep your warranty valid. Skip this step, and you're on your own if something goes wrong in year two.

Professional installers also know the tricks that make your machine perform better from day one. They'll make sure everything is level, properly connected, and calibrated. It's like the difference between a mechanic tuning your car versus trying to do it yourself with a YouTube video.

Trust me - the peace of mind and optimal performance you get from professional installation make it a smart investment in your best industrial ice machine purchase.

Conclusion: Making the Smartest Investment for Your Business

Selecting the best industrial ice machine isn't just another equipment purchase—it's a strategic investment that touches every aspect of your operation. From keeping cocktails crystal clear to preserving seafood displays at peak freshness, the right ice machine becomes an invisible yet essential partner in your business success.

Throughout this guide, we've explored how matching ice type to your specific application can make all the difference. Cube ice transforms ordinary beverages into premium experiences, while flake ice's incredible 17,000 square feet of surface area per ton makes it irreplaceable for food preservation. Nugget ice keeps healthcare patients hydrated and happy, proving that sometimes the softest solution is the strongest one.

Calculating your capacity needs accurately protects you from both costly over-investment and the nightmare of running out of ice during your busiest rush. A restaurant serving 250 customers needs about 450 pounds daily, but environmental factors like ambient temperature above 80°F can dramatically impact your actual output.

The technical decisions matter too. Air-cooled systems need their 6-inch breathing room, while water-cooled units excel in hot environments despite higher utility costs. Remote condensers solve the toughest installation challenges, though they require more upfront investment.

Configuration choices shape your daily workflow. Modular units in 22", 30", or 48" widths handle high-volume demands, while undercounter machines maximize tight spaces without sacrificing quality. Energy efficiency through ENERGY STAR ratings, robust water filtration systems, and self-cleaning cycles all contribute to your machine's 10-year commercial lifespan.

At Charbroilers.com, we've seen how the right equipment choices transform food service operations. Just as we help you find the perfect charbroiler or griddle, choosing your best industrial ice machine deserves the same careful consideration of your unique needs, space constraints, and growth plans.

Ready to explore other essential kitchen equipment? Check out our Guide to commercial charbroilers for your restaurant.