Ice Machines That Mean Business: Hotels, Offices, and Beyond

Share

Why Your Business Needs the Right Commercial Ice Machine

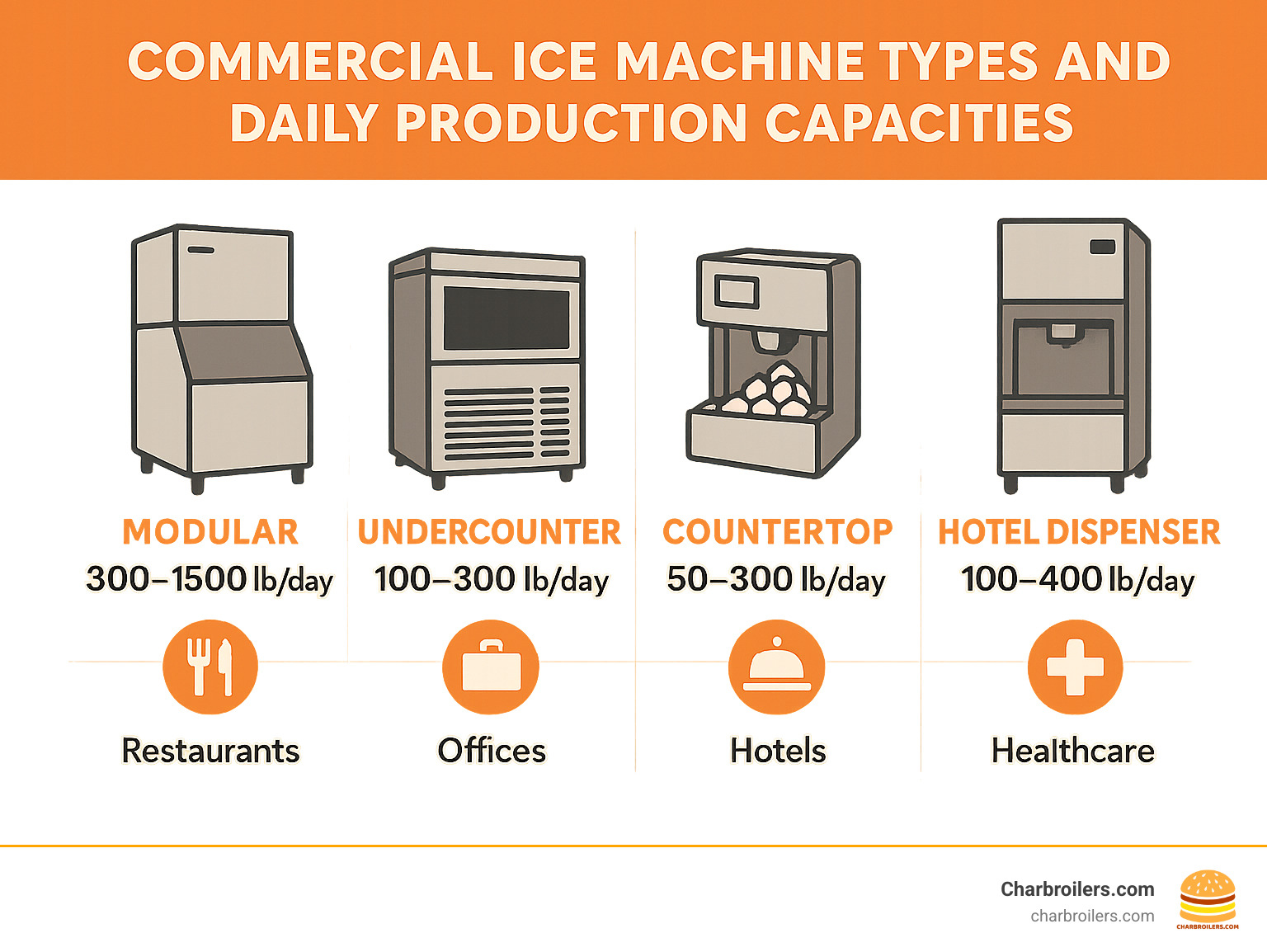

An ice machine for commercial use is essential for restaurants, hotels, offices, and healthcare facilities that need reliable, high-volume ice production. Unlike residential ice makers that produce 20-50 pounds daily, commercial units range from 100 to over 1,500 pounds per day with specialized features like antimicrobial protection and energy-efficient operation.

Quick Commercial Ice Machine Guide:

- Small Operations (100-300 lbs/day): Undercounter or countertop units for cafes, small bars

- Medium Volume (300-800 lbs/day): Self-contained machines for restaurants, offices

- High Volume (800+ lbs/day): Modular systems for hotels, large restaurants, hospitals

- Ice Types: Full cubes (cocktails), nugget (healthcare), flake (seafood display), crescent (general use)

- Key Features: ENERGY STAR certification, antimicrobial technology, water filtration

The commercial ice machine market offers everything from compact 15-pound countertop nugget dispensers perfect for office break rooms to massive modular systems producing over 1,500 pounds daily for busy hotel floors. Water-cooled units work best in hot kitchens, while air-cooled models suit most environments with proper ventilation.

Price ranges vary significantly - entry-level undercounter units start around $1,000, while high-capacity modular systems can exceed $6,000. ENERGY STAR certified models reduce utility costs while maintaining consistent ice quality.

I'm Sean Kearney from Charbroilers.com, and after over a decade in restaurant equipment, I've helped countless businesses find the perfect ice machine for commercial use that fits their space, budget, and volume needs. Whether you're running a busy restaurant kitchen or managing a corporate office, the right ice machine keeps operations running smoothly while controlling costs.

Commercial Ice Machine Categories & Ice Types

Choosing the right ice machine for commercial use starts with understanding your options. Each type has unique strengths that shine in different situations.

Machine Types by Configuration

Modular ice machines are the heavy lifters of the commercial world. These powerhouses separate the ice-making head from the storage bin, giving you incredible flexibility. Picture a busy restaurant kitchen during dinner rush - that's where these units truly shine, cranking out anywhere from 300 to over 1,500 pounds of ice daily.

The beauty of modular systems lies in their adaptability. Need more ice as your business grows? Simply stack a second head unit on top to double your production without taking up more floor space.

Undercounter ice machines are the space-saving champions. These self-contained units slip right under your counter and typically produce 65-260 pounds daily with built-in storage holding 12 to 80 pounds. Most models are just 15 inches wide - perfect when every square inch of your bar or kitchen counts.

Countertop ice machines bring ice production to the smallest spaces. Producing 15-100 pounds daily, these compact units excel in employee break rooms, small cafes, and healthcare facilities. Many specialize in nugget ice, which patients and elderly customers find easier and safer to chew.

Hotel ice dispensers solve the guest service puzzle with touchless operation and daily production ranging from 180-500 pounds. Available in 22-inch and 30-inch widths, these units offer ice-only models or combination ice-and-water dispensers for maximum guest convenience.

Ice vending machines represent a completely different business opportunity. These substantial units store up to 6,500 pounds of ice and can handle up to 50,000 customer visits annually, creating passive income streams.

Ice Shape Guide

The ice shape you choose can make or break your beverage program. Each type serves specific purposes, and getting this right impacts both customer satisfaction and your bottom line.

Full cube ice measuring 7/8" x 7/8" x 7/8" is the premium choice for bars and upscale restaurants. These solid cubes melt slowly, preserving drink quality and looking professional in glassware.

Half cube ice at 3/8" x 7/8" x 7/8" strikes a nice balance - it cools drinks faster than full cubes while maintaining an attractive appearance. This versatile option works well for soft drinks and general beverage service.

Crescent cube ice was designed with economics in mind. These curved cubes fit perfectly in glasses, displacing more liquid while using less ice. It's a smart choice for high-volume operations looking to control beverage costs.

Nugget ice earns its nickname "chewable ice" honestly. Soft and easy to chew, it's become essential in healthcare facilities and senior living communities where safety matters most.

Flake ice excels at food preservation and display. It molds around seafood, produce, and salad bar items, providing maximum surface contact for optimal cooling.

Bullet ice cools drinks quickly thanks to its hollow design and increased surface area. While it doesn't look as premium as cube ice, it gets the job done efficiently in high-volume beverage operations.

| Ice Shape | Best Uses | Melting Speed | Appearance |

|---|---|---|---|

| Full Cube | Cocktails, premium service | Slow | Excellent |

| Half Cube | Soft drinks, general service | Medium | Good |

| Crescent | General foodservice | Medium | Good |

| Nugget | Healthcare, break rooms | Fast | Fair |

| Flake | Food display, preservation | Very Fast | Poor |

| Bullet | High-volume beverage service | Fast | Fair |

Capacity and Space Considerations

Finding the right capacity for your ice machine for commercial use requires honest assessment of your needs. Commercial units range from compact 15-pound daily producers perfect for small offices to massive systems churning out over 1,500 pounds for large hotels and hospitals.

Space planning goes beyond just the machine itself. Modular units need separate bin space, while self-contained models require adequate clearance for ventilation and service access.

The golden rule for ice storage is maintaining a 2:1 or 3:1 storage-to-production ratio. If your machine produces 400 pounds daily, plan for 800-1,200 pounds of storage capacity. This buffer ensures you never run out during peak periods.

How to Choose an Ice Machine for Commercial Use

Choosing the perfect ice machine for commercial use can feel overwhelming with so many options available. Your ice machine needs to work harmoniously with your space, utilities, and daily operations. A bargain machine that can't handle your peak lunch rush or doesn't fit through your doorway isn't much of a bargain at all.

Calculating Your Ice Needs

Let's start with the most important question: how much ice do you actually need? This isn't just about your busiest day - it's about understanding your peak demand patterns and building in some breathing room.

Restaurant owners typically need 1.5-3 pounds of ice per customer. Bars and nightclubs can burn through 3-5 pounds per customer during peak hours. Hotels should plan for 2-5 pounds per occupied room daily. Office buildings are more predictable at about 1 pound per employee.

Here's the tricky part: your ice needs aren't spread evenly throughout the day. That restaurant serving 200 customers might see 150 of them during a 4-hour dinner rush. Your ice machine might produce steadily all day, but your storage capacity needs to handle those concentrated busy periods.

Don't forget about seasonal swings either. Summer can boost ice consumption by 20-40% in most operations. We always recommend building in a growth buffer of 20-25% to handle business expansion or those unexpectedly busy days.

Utility Requirements and Infrastructure

Your shiny new ice machine for commercial use is only as good as the infrastructure supporting it. Let's talk about the behind-the-scenes requirements that can make or break your investment.

Water quality is absolutely critical. Poor water will kill your ice machine's performance and shorten its lifespan dramatically. Hard water creates scale buildup that clogs internal components, while highly chlorinated water can damage seals and valves. Most manufacturers strongly recommend water filtration systems.

Electrical requirements vary significantly by machine size and type. Most commercial units need 208-230V power, and larger machines can draw 25+ amps. That means dedicated circuits and proper electrical planning before installation.

Every ice machine needs proper drainage for cleaning cycles and automatic defrost. Your floor drain should be within 6 feet of the unit and properly sized for the water volume.

Ventilation is where many installations go wrong. Air-cooled units need adequate clearance for airflow - typically 6 inches on the sides and 12 inches on top. In hot kitchens, consider water-cooled or remote-condensing units that move heat outside your building.

For comprehensive guidance on optimizing your commercial kitchen setup, our back-bar cooler buying guide covers similar infrastructure considerations.

Sizing Your Ice Machine for Commercial Use

Getting the size right prevents both frustrating ice shortages and wasteful energy consumption. We recommend calculating your peak hourly demand first, then ensuring your storage capacity can handle 4-6 hours of peak service without ice production.

For restaurants, multiply your peak customers per hour by 3 pounds, then multiply by 6 hours of service. A restaurant hitting 50 customers per hour during dinner rush needs a machine producing at least 900 pounds daily (50 × 3 × 6 = 900).

Hotels should take average occupancy, multiply by 4 pounds per room, then add a 30% seasonal buffer. A 100-room hotel at 75% occupancy needs roughly 390 pounds daily (100 × 0.75 × 4 × 1.3 = 390).

Office buildings are simpler: multiply employees by 1 pound and add a 20% buffer for growth and peak days.

Your storage capacity should hold 50-100% of daily production, depending on your service pattern. Operations with concentrated rush periods need larger storage ratios to avoid running out during peak times.

Installation Tips for an Ice Machine for Commercial Use

Proper installation sets the foundation for years of reliable service. After seeing countless installations, here are the details that separate smooth operations from ongoing headaches.

Location selection matters more than most people realize. Choose a spot with stable ambient temperature (ideally 70-75°F), good ventilation, and easy access for service calls. Avoid locations near fryers, ovens, or areas with direct sunlight.

Water filtration isn't optional in most markets. Install a quality system rated for your machine's capacity and commit to replacing cartridges every 6-12 months. The cost of regular filter changes is nothing compared to premature equipment failure from poor water quality.

Floor preparation needs to handle serious weight. A 400-pound storage bin plus ice can total over 800 pounds. Make sure your floor is level and structurally sound.

Remote condensing is worth considering for hot environments or noise-sensitive areas. These systems locate the heat-producing condenser outside your building, reducing kitchen heat load and noise while improving efficiency.

Clearance requirements aren't suggestions - they're necessities. Most units need 12-18 inches on the service side and 6 inches on other sides for proper airflow and maintenance access.

Efficiency, Maintenance & Common Challenges

Keeping your ice machine for commercial use running efficiently isn't just about saving money—it's about ensuring consistent ice quality and avoiding those dreaded mid-rush breakdowns that can derail your entire operation.

Energy Efficiency and ENERGY STAR Certification

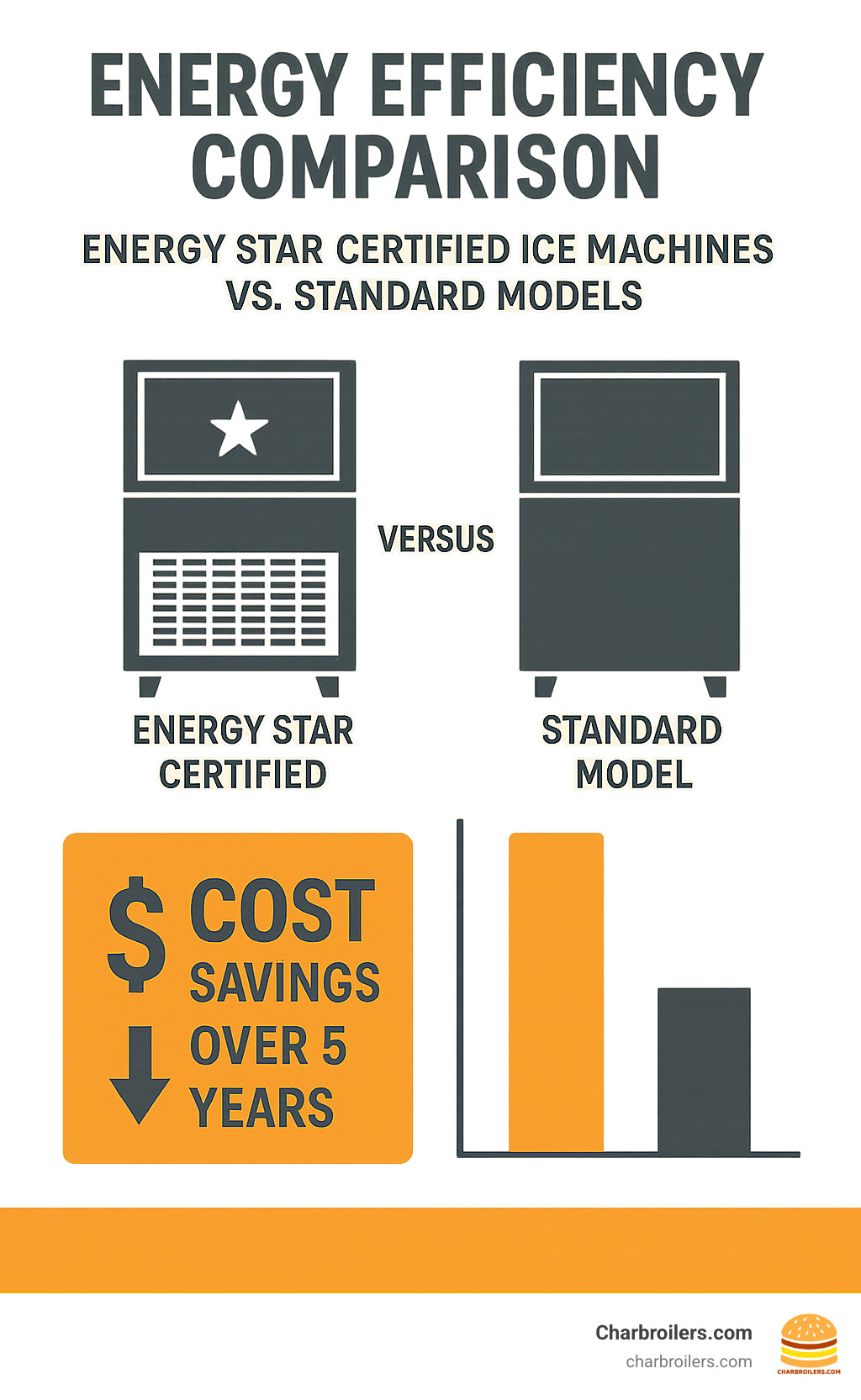

Modern commercial ice machines are significantly more efficient than units from even a decade ago. ENERGY STAR certified models can slash your utility bills by 10-15% on electricity and 10-20% on water usage compared to standard units.

Here's what those numbers mean for your bottom line: cube ice machines typically consume 4-7 kWh per 100 pounds of ice produced, while nugget ice machines use 7-10 kWh per 100 pounds due to their more complex manufacturing process.

Water usage varies dramatically between cooling methods. Air-cooled units use 15-25 gallons per 100 pounds of ice, while water-cooled systems use 15 gallons of potable water plus 200+ gallons of condenser water. In areas with expensive water rates or drought restrictions, air-cooled units usually win the cost battle despite potentially higher electrical consumption.

Maintenance Requirements and Antimicrobial Technology

The FDA considers ice a food product, which means your ice machine for commercial use needs the same attention to cleanliness as your food prep areas. Regular maintenance isn't optional—it's a food safety requirement.

Clean your ice machine every 3-6 months, or more frequently if you're running high-volume operations. Your machine will tell you when it needs attention: smaller ice cubes, cloudy or off-tasting ice, unusual odors, or slower production all signal it's cleaning time.

The cleaning process is straightforward but crucial. Turn off power and water, empty all ice, clean with approved ice machine cleaner (typically mixed 3:1 with water), rinse thoroughly, sanitize, and air dry completely before restarting. Always discard the first batch of ice after cleaning.

Modern antimicrobial technology has revolutionized ice machine hygiene. Many manufacturers now integrate silver-ion technology directly into ice-contact surfaces, continuously fighting bacteria and mold growth. This innovation extends cleaning intervals and dramatically improves ice quality, especially in high-humidity environments.

Common Challenges and Troubleshooting

After years of helping restaurants troubleshoot ice machine problems, I've noticed the same issues crop up repeatedly. Most are preventable with proper maintenance.

Scale buildup from hard water is the silent killer of ice machines. Those white, chalky deposits reduce efficiency and eventually destroy expensive components. Water filtration systems prevent this issue, while regular descaling removes existing buildup before it causes damage.

Inadequate ice production during busy periods usually stems from environmental factors. High ambient temperatures, dirty condenser coils, or restricted water flow can cut production by 20-30%. Ensure proper ventilation around your unit and clean condenser coils monthly.

Ice quality problems like cloudy, soft, or bad-tasting ice typically indicate contamination or water quality issues. Check your water filters first—they're often the culprit and the easiest fix.

Frequent cycling where the machine starts and stops repeatedly usually points to airflow restrictions or dirty coils. This problem often requires professional diagnosis, as refrigerant issues can also cause similar symptoms.

Water leaks might seem minor, but they can cause major damage if ignored. Check water line connections, drain lines, and internal seals regularly.

For comprehensive guidance on maintaining efficient commercial kitchen operations, explore our resources on Latest research on sustainable equipment.

Warranty and Service Considerations

Most commercial ice machines include 3-5 year parts warranties with 1-3 years labor coverage. Compressor warranties often extend to 5-7 years, while some manufacturers offer extended evaporator warranties up to 7 years when you enroll in their water filtration programs.

Many manufacturers require annual professional service to maintain warranty validity, especially for larger commercial units. Professional technicians catch problems before they become expensive failures and ensure your unit operates at peak efficiency.

Regular professional maintenance pays for itself through extended equipment life, maintained warranty coverage, and fewer emergency service calls during your busiest periods.

Our Top Picks: Hotels, Offices & Beyond

After helping hundreds of businesses find their perfect ice machine for commercial use, I've learned that different industries have very specific needs. A hotel guest expects quiet, reliable ice access at 2 AM, while a busy bar needs crystal-clear cubes that won't dilute premium cocktails.

Hotel Applications

Hotels face unique challenges with ice machines - they need reliable 24/7 operation without disturbing guests, plus the capacity to handle everything from individual guest needs to large banquet events.

For hotel floor applications, touchless dispensers producing 300-500 pounds daily are your best bet. These units minimize contamination risk while giving guests convenient access any time of day or night. The models with both ice and water dispensing capability are worth the extra investment.

The biggest lesson I've learned about hotel ice machines? Noise levels matter more than you think. A machine that sounds fine in a busy kitchen can drive guests crazy when it's cycling at 3 AM. Look for units specifically designed for guest areas with sound dampening features.

Large hotel kitchens and banquet operations need modular systems producing 800-1,500+ pounds daily. Multiple smaller units often work better than one massive machine. If your single large unit goes down during a wedding reception, you're in trouble. Two smaller units give you backup capacity when one needs maintenance.

Office and Corporate Break Rooms

Office ice needs are surprisingly straightforward, but the key is quiet operation and minimal maintenance. Nobody wants to be the facilities manager dealing with ice machine complaints every week.

For small offices with 20-50 employees, countertop nugget ice dispensers are perfect. These compact units produce 15-33 pounds daily and fit right on your break room counter. The nugget ice is actually preferred by most office workers - it's easier to chew and doesn't make that jarring crunching sound during quiet office hours.

Larger corporate facilities with 100+ employees need undercounter or small modular units producing 200-400 pounds daily. Look for units with built-in water dispensing - it's one less appliance to maintain and employees appreciate having both cold water and ice in one spot.

The secret to office ice machine success is antimicrobial protection and easy cleaning access. Office break rooms don't always get the deep cleaning attention that restaurant equipment receives, so choose units that can handle a bit of neglect without becoming health hazards.

Healthcare and Senior Living

Healthcare facilities have some of the most specific requirements I've encountered. Patient safety comes first, which means nugget ice is strongly preferred because it's safer for patients with swallowing difficulties and much easier for elderly residents to chew.

Patient floor applications work best with wall-mounted or countertop dispensers featuring robust antimicrobial protection. These units typically need to produce 50-150 pounds daily depending on floor capacity. The touchless operation is essential.

Larger healthcare facilities need modular systems with serious antimicrobial technology for cafeteria and kitchen operations. These environments require easy cleaning access for food safety compliance, and the units need to handle the constant demand from staff, visitors, and meal service.

Bar and Restaurant Service

This is where ice quality really shows. Cocktail service demands premium full-cube ice that melts slowly and looks professional in the glass. Nothing ruins a $15 cocktail experience like cloudy, fast-melting ice that waters down the drink before the customer takes their second sip.

High-volume bars need modular systems producing 800-1,200 pounds daily with large storage bins to handle peak service periods. Friday and Saturday nights can consume incredible amounts of ice, and running out during the dinner rush is a disaster.

Small bars and cafes can usually get by with undercounter units producing 100-300 pounds daily. The key is choosing units that produce the ice shape matching your primary beverage service.

Self-service beverage stations in restaurants need dispensers that minimize contamination while providing easy customer access. Look for units with protective shields and easy cleaning access.

Specialized Applications

Some operations have unique ice needs that standard restaurant equipment doesn't address well. Seafood markets, salad bars, and catering operations need flake ice machines that produce soft, moldable ice perfect for food display and preservation.

Ice vending machines represent a completely different business model - they're passive income generators for high-traffic locations. These units can store 2,400-6,500 pounds and serve thousands of customers annually with minimal maintenance.

For those interested in bringing commercial-grade ice production home, check out our guide on Bring the Chill Home: Top Commercial Ice Makers for Residential Use.

Small Footprint Solutions

Space-constrained operations face tough choices, but there are creative solutions. 15-inch wide undercounter units fit in surprisingly tight spaces, while countertop models don't require any floor space at all. Wall-mounted dispensers work great for patient rooms or small offices where floor space is premium.

Some operations need high production in minimal space. Stacking modular units or using high-efficiency models can double production capacity without increasing footprint significantly.

The key is matching equipment to your specific constraints without sacrificing capacity. Don't let space limitations force you into inadequate ice production - running out during peak periods costs more than finding creative installation solutions.

Conclusion

Finding the perfect ice machine for commercial use doesn't have to feel overwhelming. After helping countless restaurants, hotels, and offices over the years, I've seen how the right ice machine transforms daily operations - and how the wrong one creates endless headaches.

The sweet spot comes from matching your actual needs rather than guessing. That busy restaurant serving 200 customers needs different ice than a corporate break room with 50 employees. A cocktail bar requires those perfect full cubes that won't dilute premium drinks, while a healthcare facility needs soft nugget ice that's safe for patients.

Start with your peak demand periods and add that 20-25% growth buffer. It's better to have slightly more capacity than to run out of ice during your busiest Friday night rush.

Energy efficiency pays for itself over time. Those ENERGY STAR certified models cost a bit more upfront, but they'll save hundreds annually in utility costs. When you're running equipment 24/7, those savings add up quickly.

Don't forget the installation fundamentals - proper water filtration, adequate drainage, and good ventilation. I've seen too many great machines fail because someone skipped the water filter or crammed the unit into a space without proper airflow.

Regular maintenance keeps everything running smoothly. Clean your machine every 3-6 months, replace water filters on schedule, and don't ignore unusual noises or ice quality changes. A little preventive care beats expensive emergency repairs every time.

Whether you need a compact countertop unit for your office or a massive modular system for your hotel, the key is finding equipment that fits your specific situation. Consider your space constraints, utility requirements, and long-term growth plans.

At Charbroilers.com, we've built our reputation on understanding the real-world challenges of commercial kitchen operations. Our flexible financing options make it easier to get the equipment you need without straining your cash flow - because we know every dollar matters in the food service business.

We're here to help you steer the options and find an ice machine for commercial use that keeps your operation running smoothly for years to come. Whether you're opening your first restaurant or expanding an existing operation, the right equipment makes all the difference.

Ready to upgrade your ice production? Contact us today to discuss your specific requirements and explore our financing options. We'll help you find the perfect solution that fits your needs, space, and budget.

For more guidance on building the perfect commercial kitchen setup, check out our comprehensive More info about guide to commercial charbroilers to see how the right equipment combination can transform your entire food service operation.