Top Premium Commercial Ice Makers to Keep Your Cool Factor High

Share

Why Premium Commercial Ice Makers Are Essential for Your Business Success

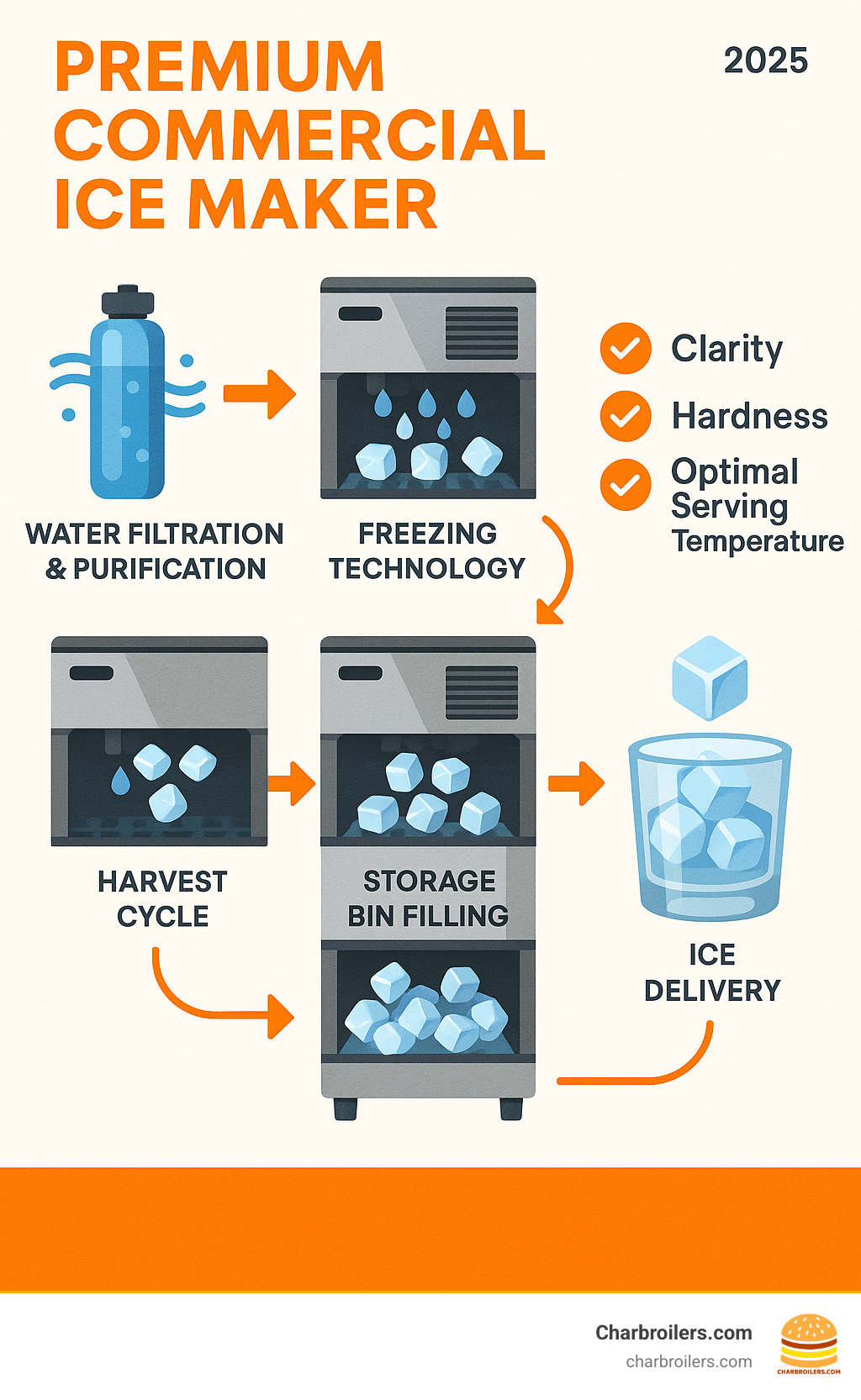

A premium commercial ice maker is the backbone of any successful foodservice operation. It delivers consistent ice, advanced sanitation, and energy efficiency to keep customers happy and operating costs down.

Top Premium Commercial Ice Maker Features:

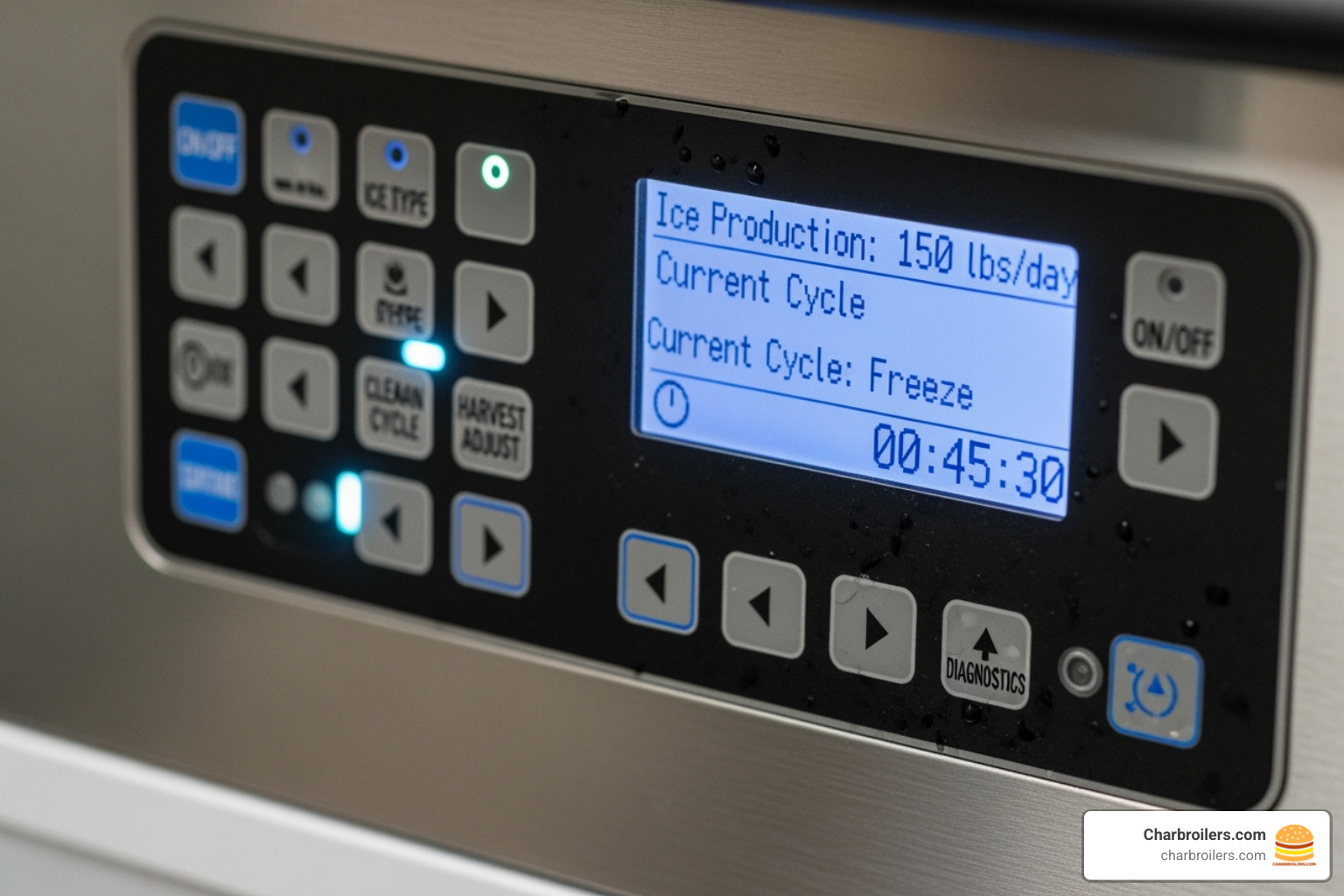

- Production Capacity: 86-1,560 lbs per 24 hours depending on model size

- Ice Types: Cube, crescent, nugget, flake, and gourmet options

- Cooling Systems: Air-cooled, water-cooled, or remote-cooled configurations

- Smart Features: Self-diagnostics, programmable production, automatic cleaning cycles

- Energy Efficiency: ENERGY STAR® certified models with up to 23% water savings

- Sanitation: Antimicrobial protection, dishwasher-safe components, growth inhibitors

The right ice maker can transform any busy restaurant, hotel, or bar. As one Miami restaurant owner noted: "The ice machine was running in no time. Ice cubes are superb. The smart features help us out big time!"

Clear ice cubes pack tightly into glasses and displace more liquid, increasing profits while delivering a premium experience. With production capacities ranging from 86 lbs to over 1,500 lbs, choosing the right model requires understanding your specific needs.

I'm Sean Kearney from Charbroilers.com, and with over a decade of experience helping restaurants find the right equipment, I've seen how a premium commercial ice maker can boost efficiency and customer satisfaction. Let me walk you through everything you need to know to make the perfect choice.

Basic premium commercial ice maker glossary:

Decoding Your Ice Needs: Machine Types, Ice Shapes, and Cooling Systems

Selecting the ideal premium commercial ice maker starts with understanding its core components and how they fit your needs. It's about making the right kind of ice, in the right quantity, with the most efficient system for your space. Let's break down the machine types, ice shapes, and cooling methods.

Machine Types and Their Ideal Kitchens

Commercial ice makers come in several configurations to fit different spaces and production needs.

Undercounter Ice Makers: These compact units fit neatly under countertops and include a built-in storage bin. They are perfect for establishments with limited space, such as small bars, cafes, or hotel lobbies. Models like the Hoshizaki KM-81BAJ (86 lbs/day) are ideal for smaller operations or as a supplementary ice source.

Modular Ice Machines (Ice Machine Heads): The workhorses for high-volume operations, these units sit atop a separate storage bin, allowing for immense scalability. Models like the Maxx Ice MIM452 (460 lbs/day) or the Ice-O-Matic CIM1446FA (1560 lbs/day) are perfect for large restaurants, hotels, and hospitals that need a constant, high-volume ice supply. No Bin, No Problem: Commercial Ice Makers for Modular Setups

Self-Contained Units: These all-in-one solutions combine the ice maker and storage bin into a single appliance. They offer higher production than undercounter models and are great for businesses that need significant ice but prefer an integrated unit. Capacities can range from 65 lbs to over 300 lbs daily.

The Shape of Water: Choosing the Perfect Ice for Your Menu

The type of ice you serve can significantly impact customer experience and your bottom line.

Cube Ice (Full, Half, Dice): The classic choice. Hard, clear, and slow-melting, it's ideal for beverages where dilution is a concern. Smaller half-dice cubes pack tightly for quicker chilling.

Flake Ice: Composed of small, soft pieces, flake ice molds easily around products, making it perfect for food displays like seafood or salad bars.

Nugget Ice (Chewblet): Soft, porous, and chewable, this ice is a favorite for smoothies and soft drinks because it absorbs the beverage's flavor.

Gourmet Ice (Top Hat, Octagonal): This hard, clear, and slow-melting ice is visually appealing, making it a premium choice for high-end bars where presentation is key.

Crescent Ice: Hoshizaki's signature shape is hard, clear, and packs tightly in glasses to maximize liquid displacement and reduce splashing. Commercial Crushed Ice Maker

Cooling Systems Explained: Air, Water, and Remote

The cooling method is crucial for your ice maker's efficiency and operational costs.

Air-Cooled: The most common type, these units use ambient air to cool the condenser. They are energy-efficient and easy to install but require adequate ventilation to dissipate heat.

Water-Cooled: These machines use circulating water to cool the condenser, making them highly efficient in hot or poorly ventilated spaces. They are quieter but consume more water.

Remote-Cooled: The condenser is installed separately (e.g., outdoors), which significantly reduces heat and noise in the kitchen. This is a great solution for high-volume operations in hot climates, though installation is more complex.

Here's a quick comparison:

| Feature | Air-Cooled | Water-Cooled | Remote-Cooled |

|---|---|---|---|

| Initial Cost | Lowest | Medium | Highest |

| Energy Usage | Generally lower (electricity) | Higher (water), lower (electricity) | Medium (electricity), lower (indoor heat load) |

| Water Usage | Lowest | Highest | Lowest (for ice making only) |

| Noise Level | Moderate (fan noise) | Lowest | Quietest (condenser located remotely) |

| Heat Dissipation | Into ambient air (requires ventilation) | Into water (no heat added to room) | Outdoors/remote location (no heat added to room) |

| Ideal Environment | Well-ventilated, moderate temperatures | Poorly ventilated, hot environments, quiet zones | Hot environments, noise-sensitive areas, space-constrained kitchens |

Sizing for Success: Production Capacity and Storage Bins

Getting your ice maker size right is critical. Too small, and you'll run out during peak hours; too big, and you're wasting money. The key is to match your busiest day's ice usage with the right production and storage capacity.

Calculating Your Daily Ice Production Needs

Ice consumption varies widely by business type. Here are some general guidelines to estimate your daily needs:

- Restaurants: 1.5 to 2 lbs of ice per seat.

- Bars: 3 lbs of ice per seat.

- Hotels: 5 lbs of ice per room, plus extra for amenities.

- Healthcare: 7-10 lbs per bed.

For smaller operations, a machine producing 80-100 lbs daily might be perfect. Mid-range businesses often need 300-500 lbs daily from models like the Maxx Ice MIM452 or Manitowoc IDT0500A. High-volume venues require serious power from machines like the Hoshizaki KM-1100MAJ (1,087 lbs) or the Ice-O-Matic CIM1446FA (1,560 lbs). These production numbers decrease in hotter conditions.

Ice Machines That Mean Business: Hotels, Offices, and Beyond

The Perfect Pair: Matching Your Ice Maker with the Right Bin

Your ice maker head and storage bin must work together. The bin stores what the maker produces, ensuring you have a steady supply.

Storage capacity should be at least 1.5 to 2 times your peak consumption. This buffer prevents you from running out of ice during your busiest hours. For example, if your dinner rush uses 200 lbs of ice, you'll want a bin that holds at least 300-400 lbs.

Undercounter and self-contained units have appropriately sized built-in storage. For modular units, you'll select a separate bin, like the Maxx Ice MIB580 which offers a substantial 580 lbs capacity. When choosing, don't forget practical considerations—your staff needs easy access for scooping, and the bin must be easy to clean.

Cool Choices for Commercial Ice Maker and Bin Setups

The Anatomy of a Premium Commercial Ice Maker: Advanced Features

The difference between a basic ice machine and a premium commercial ice maker lies in the advanced features that boost performance, simplify maintenance, and ensure ice quality. These innovations are game-changers for any busy kitchen.

Smart Technology for Best Performance

Today's ice makers are smarter, which makes your life easier. Programmable production saves energy by matching output to your busiest hours. Self-diagnostic technology provides preventative maintenance feedback to catch problems before they become disasters. Hoshizaki's EverCheck™ alert system, for instance, notifies you when the machine needs attention.

User-friendly interfaces like Manitowoc's easyTouch display simplify operation with multiple language options and automatic reminders. One-touch controls for sanitizing and descaling, found on models like the Ice-O-Matic CIM1446FA, turn complex maintenance into a simple button press.

Ice Ice Baby: Best Commercial Ice Making Equipment to Keep Your Business Cool

Innovations in Sanitation and Maintenance

Keeping ice clean is crucial for protecting your customers and your reputation. Premium ice makers make this task much easier. Automatic cleaning cycles tackle mineral buildup and bacteria without manual intervention. Antimicrobial protection, such as Ice-O-Matic's PURE ICE® or Manitowoc's Alpha-San, actively fights contamination in the food zone.

When it's time for a deep clean, removable and dishwasher-safe components make the job painless. For the highest sanitation standards, some brands offer advanced systems like Manitowoc's optional LuminIce® II Growth Inhibitor, which actively eliminates microorganisms.

The Mark of a Truly Premium Commercial Ice Maker: Energy and Water Efficiency

With rising utility costs, efficiency is a business necessity. The best premium commercial ice maker models deliver top performance while keeping bills in check.

ENERGY STAR® certification is your guarantee of efficiency. Hoshizaki, a multi-year ENERGY STAR® Partner of the Year, uses a proprietary CycleSaver™ design to optimize each ice-making cycle, saving energy and extending the machine's lifespan.

Water conservation features deliver real savings. Some Manitowoc models achieve a 23% reduction in condenser water usage and boast nearly 100% ice-to-water ratios, meaning virtually no water is wasted. Modern machines also use greener refrigerants like R410A and R290, which have a lower environmental impact. Choosing an efficient model means lower operating costs and a smaller carbon footprint.

Installation, Upkeep, and Top-Tier Brands

Getting the most from your premium commercial ice maker requires proper installation and consistent maintenance. Starting with a top-tier brand ensures you have a reliable foundation for years to come.

Best Practices for Installation and Longevity

Proper installation is the foundation for reliable ice production.

Location is key. Air-cooled units need ample ventilation to prevent overheating, though some models like the Hoshizaki KM-81BAJ feature front-in, front-out airflow for tighter spaces. Ensure you have a dedicated potable water line and proper drainage. Leveling the machine is also critical for even ice formation.

Perhaps the most important step is installing a water filtration system. This is not optional. Quality filtration prevents mineral buildup that can destroy internal components, keeps ice clear and tasteless, and dramatically reduces service calls. Ice-O-Matic is so confident in its filters that it offers an extended 7-year evaporator warranty when you use their system.

Bring the Chill Home: Top Commercial Ice Makers for Residential Use

A Guide to Cleaning and Sanitation for Pure Ice

Regular cleaning is non-negotiable for food safety. Modern premium commercial ice maker models simplify this process.

- Daily: Wipe down the exterior and clean the ice scoop.

- Monthly: Use the machine's self-cleaning function. This cycle should include descaling with a manufacturer-approved solution to remove mineral buildup, followed by sanitizing to eliminate bacteria or mold.

- Every 6 Months: Replace the water filter cartridge. Stick to this schedule to prevent major repairs.

Always discard the first batch of ice after any cleaning or maintenance to ensure purity.

Reputable Brands in the Premium Ice Maker Space

When investing in a premium commercial ice maker, the brand matters. Three manufacturers consistently lead in innovation, reliability, and support.

- Hoshizaki: Known for its innovative crescent cube, CycleSaver™ efficiency technology, and EverCheck™ alert system. Their long-standing ENERGY STAR® partnership proves their commitment to efficiency.

- Manitowoc: Excels in user experience with the Indigo NXT™ Series, featuring easyTouch displays and intelligent diagnostics that help operators save money.

- Ice-O-Matic: Takes hygiene seriously with PURE ICE® antimicrobial protection and dishwasher-safe components. Their extended warranty programs reward proper maintenance.

When evaluating any brand, look for build quality, comprehensive warranties, parts availability, and technological innovation. Top brands offer multi-year warranties on parts and labor, protecting your investment.

Frequently Asked Questions about Premium Commercial Ice Makers

Here are answers to some of the most common questions about choosing and maintaining a premium commercial ice maker.

How often should a commercial ice machine be professionally serviced?

Annual professional service is the standard. While your staff can handle daily cleaning, a qualified technician will perform a deep clean of critical components like condenser coils and spot potential issues before they become costly breakdowns. For high-volume operations or kitchens in harsh environments (e.g., high heat or dust), bi-annual servicing is a wise investment. Professional maintenance is often required to keep your warranty valid.

What is the most significant factor affecting an ice machine's daily production?

Temperature. The ambient air temperature around the machine and the temperature of the incoming water are the two biggest factors. Ice machines are rated under ideal lab conditions (e.g., 70°F air, 50°F water). A machine in a hot kitchen with warm water will work harder and produce significantly less ice than its advertised capacity. This is why proper ventilation for air-cooled units is absolutely critical for optimal performance.

Can I use a water filter from a different brand on my ice machine?

It's highly recommended to stick with manufacturer-approved filters. While other filters might physically fit, they can have different flow rates or filtration capabilities that negatively affect ice quality and machine performance. More importantly, using a non-approved filter can void your warranty. The small potential savings on a generic filter are not worth the risk to your machine's performance, ice quality, or warranty coverage.

Conclusion

Choosing the right premium commercial ice maker is a smart investment in your business's efficiency and your customers' satisfaction. From understanding machine types, ice shapes, and cooling systems to selecting the correct size for your needs, the details matter.

We've seen how advanced features like smart diagnostics and automatic cleaning cycles from top brands like Hoshizaki, Manitowoc, and Ice-O-Matic can streamline operations, reduce costs, and ensure you're always serving pure, high-quality ice. Proper installation and a consistent maintenance schedule will keep your machine running reliably for years.

At Charbroilers.com, we know that outfitting your kitchen means finding equipment that works as hard as you do. We're here to help you select the ideal premium commercial ice maker that keeps your beverages perfectly chilled and your operation running like clockwork.

Explore our complete guide to commercial charbroilers for your restaurant