Commercial Refrigeration: Your Essential Buying Guide

Share

Why Choosing the Right Commercial Fridge and Freezer Matters

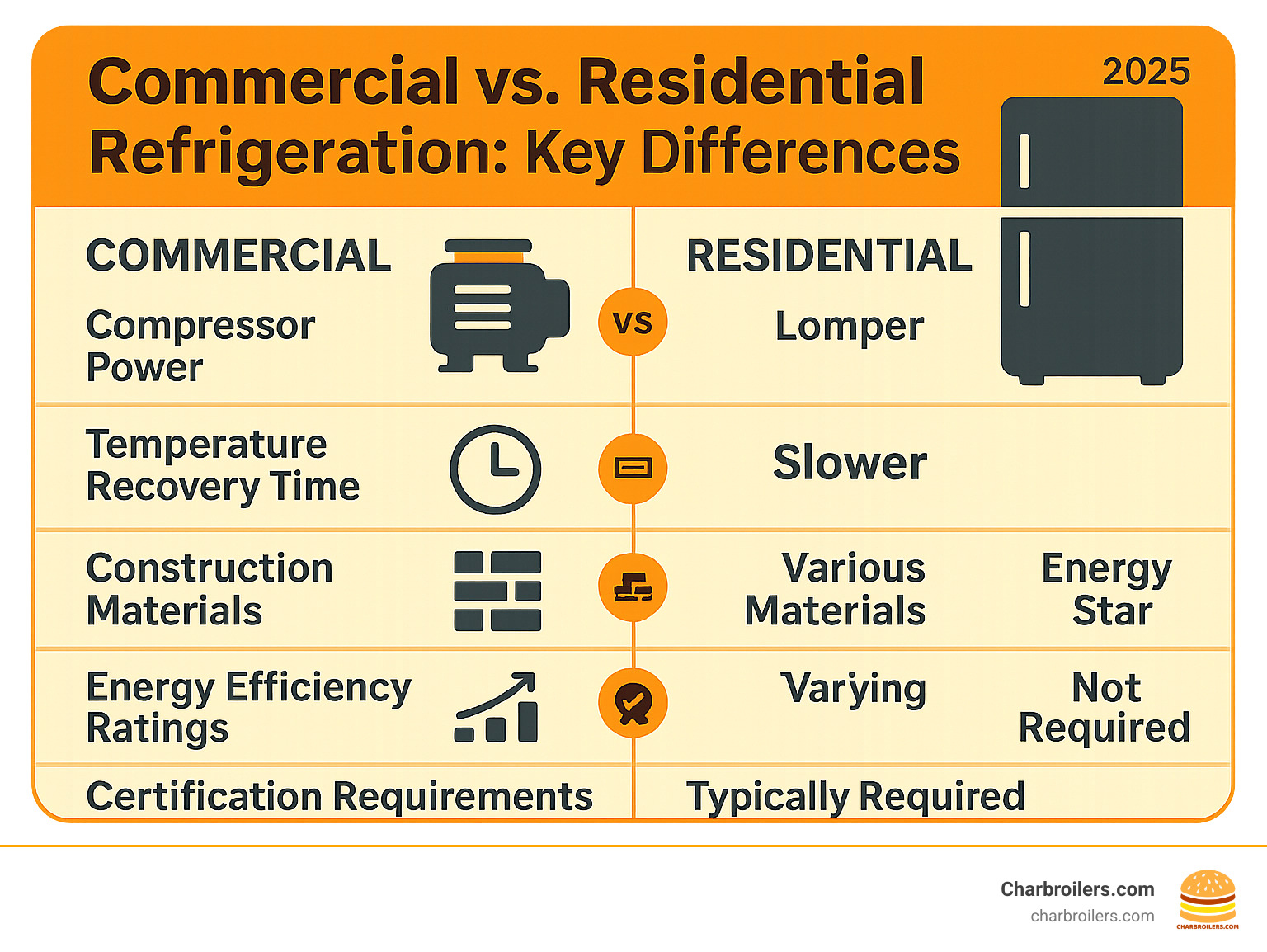

A commercial fridge and freezer is the backbone of any food service operation, ensuring ingredient freshness and helping meet strict health codes. Unlike residential units, commercial models offer superior temperature control, faster recovery times, and durable construction designed for busy kitchens.

Quick Selection Guide:

- Reach-In Units: Standard kitchen workhorses, 1-3 doors, 23-72 cu.ft capacity

- Undercounter Models: Space-saving design for prep stations, 5-15 cu.ft capacity

- Walk-In Coolers: Bulk storage solutions, custom sizes, pallet jack accessible

- Display Refrigeration: Glass doors for merchandising, beverage coolers, deli cases

Key Decision Factors:

- Capacity: Match cubic footage to your sales volume and menu needs

- Energy Efficiency: Look for ENERGY STAR ratings and hydrocarbon refrigerants

- Certifications: Ensure NSF, ETL, or UL approval for health code compliance

- Construction: Stainless steel interior/exterior for durability and easy cleaning

The right system protects your food investment, reduces waste, and ensures smooth operation. Poor choices lead to spoiled inventory, failed health inspections, and costly repairs.

I'm Sean Kearney from Charbroilers. With over a decade in the restaurant equipment industry, I've learned that choosing the right commercial fridge and freezer is critical to your bottom line. I've helped countless operators find the perfect solutions for their kitchens.

Simple commercial fridge and freezer word guide:

- nsf ansi standard 7 commercial refrigerators and freezers

- commercial cool 3.5 chest freezer

- small commercial freezer

Why Your Business Needs Commercial-Grade Refrigeration

During a dinner rush, with staff constantly opening and closing the door, a commercial fridge and freezer shines where a residential unit would fail. Commercial-grade units are more than just large. They feature powerful compressors built for heavy use and have faster temperature recovery times. This is essential for maintaining food safety during busy hours when doors are opened frequently. Their increased storage capacity and adjustable shelving also allow for efficient organization.

For a deeper dive into how commercial refrigeration works and why it matters, check out our comprehensive guide: Commercial Refrigeration Equipment Explained: No Sweat!

The Downside of Using Residential Units

Using a residential unit to save money upfront is a false economy. It immediately voids the warranty, and its inadequate cooling power can't handle a commercial workload, leading to frequent breakdowns and spoiled food. Crucially, residential units are not built for commercial kitchens and will likely fail health inspections because they cannot maintain safe temperature standards.

Key Benefits for Food Service Operations

Investing in proper commercial refrigeration provides key benefits:

- Ingredient Freshness & Reduced Waste: Consistent temperatures keep produce crisp and proteins safe, reducing spoilage.

- Workflow Efficiency: Designs like easy-access doors and logical layouts improve kitchen speed.

- Meeting Peak Demand: Robust compressors maintain the cold chain even during the busiest hours.

- Protecting Your Investment: A quality commercial fridge and freezer safeguards thousands of dollars in inventory and provides years of reliable service.

Types of Commercial Refrigerators and Freezers

Choosing the right commercial fridge and freezer means understanding the different types available. Each unit has a specific purpose in a commercial kitchen.

| Unit Type | Capacity (Cu. Ft.) | Footprint | Best Use Case |

|---|---|---|---|

| Reach-In | 23-72 | Medium to Large | Main kitchen storage for ingredients and prepped food |

| Undercounter | 5-15 | Small | Point-of-use storage at prep stations and bars |

| Walk-In | 100+ (custom) | Very Large | Bulk ingredient storage, large volume operations |

Reach-In, Pass-Thru, and Roll-In Units

Reach-in refrigerators and freezers are the upright workhorses of most kitchens, ideal for storing daily ingredients. Pass-thru units, with doors on both front and back, improve workflow by allowing stocking from the rear and access from the front. For high-volume operations like bakeries or catering, roll-in and roll-thru units accommodate entire rolling racks, saving significant time. If you're considering a two-door setup, our guide breaks down what you need to know: Twice As Nice: Commercial 2-Door Cooler Buying Guide.

Undercounter and Worktop Models

Undercounter refrigerators and freezers provide compact, point-of-use storage that fits neatly under counters, perfect for prep stations and bars. Worktop models add a durable prep surface on top of the refrigerated base, maximizing efficiency in a small footprint. They are ideal for sandwich or salad stations. For more space-saving ideas, check out our guide: Space Savers: Best Under Cabinet Freezers for Small Kitchens.

Walk-In Coolers and Freezers

Walk-in coolers and freezers are essential for large-scale operations that require bulk storage. These custom-configurable insulated rooms allow you to buy in bulk, manage large inventories, and handle seasonal demand. They are often more energy-efficient than multiple smaller units for the same volume. For everything you need to know, dive into our guide: Keeping It Cool: Your Essential Guide to Restaurant Walk-In Fridges.

Specialty and Display Refrigeration

Specialty refrigeration meets specific operational and merchandising needs:

- Merchandisers and Glass Door Coolers: Showcase products like drinks and desserts to encourage impulse buys.

- Bar Coolers: Designed to store bottles and cans efficiently behind the bar.

- Prep Tables: Combine refrigerated compartments with a workspace for making pizzas or sandwiches.

- Deli and Bakery Cases: Display products while maintaining safe temperatures.

- Chef Bases: Low-profile refrigerated drawers that sit under cooking equipment for easy access to ingredients.

- Ice Machines: Crucial for beverages and food presentation.

Each type plays a vital role in an efficient and profitable food service operation. If you're setting up a bar area, our buying guide has you covered: Cooler Than Cool: The Ultimate Back Bar Cooler Buying Guide.

Key Factors When Choosing Your Commercial Fridge and Freezer

When choosing a commercial fridge and freezer, look beyond the price tag. Consider your kitchen layout, business volume, menu requirements, and long-term operating costs to find the right fit.

Capacity and Sizing

Calculate the cubic feet (cu. ft.) you need based on your inventory, delivery frequency, and peak service volume. An efficient interior layout with adjustable shelving is as important as total space. Always measure your available physical space, including clearance for door swing and ventilation, and ensure your capacity can handle your sales volume with a small buffer.

Energy Efficiency and Operating Costs

An energy-efficient unit saves money over its lifetime. Look for the ENERGY STAR rating and models using eco-friendly hydrocarbon refrigerants (like R290). Quality insulation and the compressor's location (top-mount vs. bottom-mount) also impact energy use. A bottom-mount compressor pulls in cooler air but may collect more debris, while a top-mount is easier to service in hot kitchens.

Temperature Control and Performance

Precise temperature control is non-negotiable for food safety. Prioritize units with digital thermostats for accuracy. Key performance indicators include temperature consistency and fast recovery time after the door is opened. Also, consider the defrost cycle: automatic systems are convenient, while manual defrost units are simpler and often less expensive upfront. For troubleshooting common temperature issues, our guide covers frequent problems and solutions: Fixing Common Issues with Imperial Frost Free Commercial Freezers.

Understanding Construction, Durability, and Compliance

A commercial fridge and freezer must be durable enough for a busy kitchen. Quality construction and proper certifications are essential for keeping your operation running smoothly and legally.

Material and Construction of a commercial fridge and freezer

Look for a stainless steel exterior and interior, which is durable, corrosion-resistant, and easy to clean. Aluminum is a less-durable alternative sometimes used in budget models. Choose between solid doors for better insulation in storage areas or glass doors for merchandising. Ensure door seals (gaskets) are high-quality to maintain an airtight seal and prevent energy loss. Heavy-duty casters are also valuable for easy cleaning and repositioning.

The Importance of Certifications for a commercial fridge and freezer

Certifications are your proof of compliance and safety. A health inspector will look for these marks:

- NSF (National Sanitation Foundation): Ensures the unit is made with food-safe materials and is easy to clean. NSF/ANSI Standard 7 is specific to commercial refrigeration.

- ETL (Intertek) & UL (Underwriters Laboratories): Certify that the unit meets electrical and fire safety standards.

These certifications are often required by local health departments and give you peace of mind that your commercial fridge and freezer is safe and reliable.

For a deep dive into what NSF/ANSI Standard 7 means for your operation, check out our guide: Cool Compliance: Your Guide to NSF/ANSI Standard 7 for Refrigerators and Freezers.

Essential Maintenance and Cleaning for Longevity

Your commercial fridge and freezer runs 24/7, making regular maintenance essential for longevity and preventing costly downtime. A simple care routine can prevent most common issues, protecting your inventory and revenue.

Routine Cleaning Tasks

A consistent cleaning schedule is key to performance:

- Clean Condenser Coils: Every 90 days (or monthly in greasy environments), clean coils to prevent the compressor from overworking.

- Wipe Gaskets Daily: Clean door seals to ensure they create a tight seal, saving energy.

- Clear Drain Lines: Regularly flush drain lines to prevent water blockages and leaks.

- Sanitize Interior Surfaces: Daily sanitation prevents odors and bacterial growth.

- Inspect Door Seals: Check for cracks or tears that could let cold air escape.

Troubleshooting Common Issues

Know how to spot and address common problems:

- Unit Not Cooling: Check the power plug, circuit breaker, and ensure coils are clean and doors are sealed. If these don't work, you may have a thermostat or compressor issue requiring a professional.

- Ice Buildup: This often indicates a problem with the defrost system or a bad door seal. Do not chip ice away manually.

- Strange Noises: Rattling or grinding can signal a loose component or a failing fan motor. Address these early.

- Water Leakage: Usually caused by a blocked drain line or a problem with the condensate pan.

- Power Issues: Ensure the unit is plugged into a dedicated circuit. Never use an extension cord.

For complex issues like refrigerant leaks or compressor failure, always call a certified technician. For more detailed troubleshooting guidance, our comprehensive guide covers the most common issues: Common Problems with Commercial Refrigerators.

Frequently Asked Questions about Commercial Refrigeration

Here are answers to the most common questions we receive about commercial refrigeration.

What is the ideal temperature for a commercial refrigerator and freezer?

For food safety and quality, maintain these temperatures:

- Commercial Refrigerator: 35°F to 40°F (1.6°C to 4.4°C). This range slows bacterial growth without freezing fresh ingredients.

- Commercial Freezer: 0°F (-18°C) or below. This keeps food solidly frozen for long-term preservation.

Always verify these ranges against your local health code requirements, as they can vary.

How often should I clean the condenser coils on my unit?

The general rule is to clean condenser coils every 90 days. However, in kitchens with high grease or dust levels, you may need to clean them monthly. If you see visible buildup, it's time to clean them. A clean coil runs more efficiently and extends the life of your compressor. Always check the manufacturer's specific recommendations.

Can I use an extension cord with a commercial refrigerator?

No. Never use an extension cord with a commercial fridge and freezer. They are not rated for the high power draw and create a significant fire hazard. Using one can also cause performance issues, damage the compressor, and will void your warranty. Always plug your unit into a dedicated circuit installed by a qualified electrician.

Conclusion

Choosing the right commercial fridge and freezer is a foundational investment for your food service business. As we've covered, the key is to balance capacity, energy efficiency, and proper certifications with your specific operational needs.

Durable construction and a commitment to routine maintenance will ensure your unit provides reliable service for years, preventing costly downtime and spoiled inventory. A smart choice protects your investment and keeps your kitchen running smoothly.

At Charbroilers.com, we understand that quality equipment is the key to success. That's why we offer financing options to help you get the hard-working commercial fridge and freezer your business deserves. Your refrigeration choice today shapes your success tomorrow. Make it count. For additional insights on making the best choice for your specific needs, explore our comprehensive resource: Detailed Guide to Comparing Commercial Refrigerators.