Keeping It Cool – Your Essential Guide to Restaurant Walk-In Fridges

Share

Why Every Restaurant Kitchen Needs a Walk-In Fridge

A restaurant walk in fridge is the backbone of any commercial kitchen - a large, room-sized refrigeration unit that keeps massive amounts of food at safe temperatures while giving staff easy access to ingredients. Here's what you need to know:

Key Facts About Restaurant Walk-In Fridges: - Temperature Range: 33°F to 40°F for coolers, -10°F to 0°F for freezers - Storage Capacity: Roughly 28 lbs of food per cubic foot of space - Food Safety: Keeps all food below 41°F to prevent bacterial growth - Shelf Life: Prepared foods stay fresh for up to 7 days when properly stored - Energy Efficiency: Modern units use 50% less energy than older models - Average Lifespan: 15 years with proper maintenance

Without a reliable walk-in, restaurants face serious problems. Food spoils faster, storage space runs out during busy periods, and health inspectors start asking tough questions. As one industry expert puts it: "The walk-in cooler is considered the heart of the kitchen - and if it does not cool food properly, the establishment faces an imminent health-hazard crisis."

Walk-ins come in different sizes and configurations. Small restaurants might need a 6x6 foot unit, while high-volume kitchens require 20x40 foot spaces or larger. The upfront cost ranges from $5,000 for basic small units to $50,000+ for large custom installations. But the investment pays off through reduced food waste, better organization, and regulatory compliance.

I'm Sean Kearney from Charbroilers.com, and I've spent over a decade helping restaurants find the right equipment at fair prices, including countless restaurant walk in fridge installations.

How a Restaurant Walk-In Fridge Works & Why Your Kitchen Needs One

Think of a restaurant walk in fridge as your home refrigerator's big brother - way bigger, much tougher, and built to handle the chaos of a busy commercial kitchen. The basic science is the same: a compressor pushes refrigerant through coils, pulling heat out of the storage area and dumping it outside.

What makes these units special is their heavy-duty construction. We're talking about thick insulation panels - usually 4 to 6 inches of high-density foam sandwiched between metal or fiberglass walls. This creates an airtight barrier that keeps temperatures steady even when your staff is rushing in and out during the dinner rush.

The compressor and evaporator work together with the compressor (often located outside) doing the heavy lifting, while the evaporator coils inside distribute cold air evenly throughout the space. This ensures every corner stays at the right temperature.

Your kitchen absolutely needs this level of refrigeration for TCS foods - that's Time/Temperature Control for Safety foods like meat, dairy, seafood, and prepared dishes. These ingredients can turn dangerous fast if they get too warm.

Standard Temperature Ranges for Coolers & Freezers

For walk-in coolers, you want to stay between 33°F and 40°F. Most operators aim for around 35°F to 38°F because it gives them a safety buffer. Here's why that matters: once food hits 41°F, bacteria start multiplying fast.

The bacterial growth curve is scary when you see the numbers. Between 41°F and 135°F (the "danger zone"), bacteria can double every 20 minutes. Leave a tray of chicken salad at 45°F for four hours, and you've got a potential health code violation.

Walk-in freezers operate between -10°F to 0°F. This hard freeze stops bacterial growth completely and prevents ice crystals that ruin food texture.

Benefits of a Restaurant Walk-In Fridge for Commercial Kitchens

Bulk storage is the obvious win. Instead of cramming ingredients into multiple reach-in units, you can store large quantities in one organized space. This means fewer deliveries, better purchasing power, and less time playing food Tetris.

Workflow efficiency is where walk-ins really shine. Picture your prep cook gathering soup ingredients - instead of opening four different units, they walk into one space and grab everything at once.

Regulatory compliance becomes much easier when you have proper cold storage. Health inspectors love seeing organized walk-ins with clear temperature logs and proper food separation.

The reduced spoilage alone can pay for your walk-in over time. When ingredients stay at optimal temperatures with good airflow, they last longer. One restaurant owner told me, "Our walk-in cut our food waste by 30% in the first year. The money we saved on spoiled ingredients basically paid for the unit."

Choosing the Right Walk-In: Size, Type & Energy Efficiency

Picking the perfect restaurant walk in fridge feels overwhelming at first - there are so many options, and getting it wrong means either cramped storage or wasted money. But once you understand the key factors, the decision becomes much clearer.

Calculating the Perfect Capacity for Your Menu

The industry uses a simple rule: 28 pounds of food per cubic foot of storage space. But that's just the starting point.

Your menu tells the real story. A pizza shop storing mostly cheese, pepperoni, and dough needs different space than a steakhouse with whole cuts of beef and fresh seafood. Start by listing every cold ingredient you use, then estimate how much you keep on hand during your busiest weeks.

Future growth matters more than most people realize. I've seen too many restaurants outgrow their walk-ins within two years. It's always cheaper to buy slightly bigger now than to replace the whole unit later.

Don't forget about service clearances - you need room to actually work inside. Plan for 40-inch aisles if you roll carts in and out, or at least 30 inches for comfortable foot traffic.

Comparing Indoor vs Outdoor Restaurant Walk-In Fridge Options

| Feature | Indoor Units | Outdoor Units |

|---|---|---|

| Space Impact | Uses valuable kitchen real estate | Frees up interior space |

| Access | Easy staff access during service | May require brief outdoor trip |

| Installation | Standard electrical/plumbing | Requires weatherproofing |

| Durability | Protected environment | Must withstand weather extremes |

| Cost | Lower upfront cost | Higher due to weatherproofing |

| Energy Efficiency | Stable ambient temperature | Variable based on weather |

Indoor units are the simpler choice. Standard installation, easy access during busy service, and protection from weather. The downside? They take up expensive kitchen real estate.

Outdoor units free up interior space but need serious weatherproofing. We're talking vinyl roofs, rain hoods, and low-ambient kits for cold climates. Quality fiberglass construction actually performs well, absorbing only 0.04 BTUs compared to metal alternatives. According to thermal conductivity research, proper insulation makes outdoor units surprisingly efficient.

New vs. Used: Pros, Cons & Financing Paths

New walk-ins give you peace of mind. Full warranty coverage (typically 1-5 years on components), the latest energy-efficient technology, and custom sizing options.

Used walk-ins can save you 40-60% on purchase price. The trade-off is limited warranty (often 30 days to 1 year) and unknown maintenance history.

Cost ranges vary widely:

- Small (6x6): $5,000-$8,000 new, $3,000-$5,000 used

- Medium (8x10): $7,000-$12,000 new, $4,500-$8,000 used

- Large (10x20): $15,000-$25,000 new, $10,000-$18,000 used

Many suppliers offer 100% financing options, making new units accessible even with tight budgets.

Energy-Saving Features to Look For

LED lighting uses 75% less energy than old-school bulbs and generates less heat inside the cooler.

ECM fan motors are game-changers. These variable-speed motors adjust based on actual cooling demand, saving 30-50% on fan energy.

High-efficiency compressors reduce energy consumption by 20-30% compared to older models.

Smart controls let you fine-tune temperatures and get alerts if something goes wrong.

Strip curtains might look simple, but these vinyl barriers significantly reduce cold air loss during extended door openings.

For more detailed insights on maximizing commercial refrigeration efficiency, check out our comprehensive guide: More info about our services.

Safe Storage, Organization & Compliance Inside Your Walk-In

Proper organization isn't just about efficiency - it's about food safety, regulatory compliance, and protecting your customers' health. The way you arrange items in your restaurant walk in fridge can mean the difference between passing and failing a health inspection.

Preventing Cross-Contamination in a Restaurant Walk-In Fridge

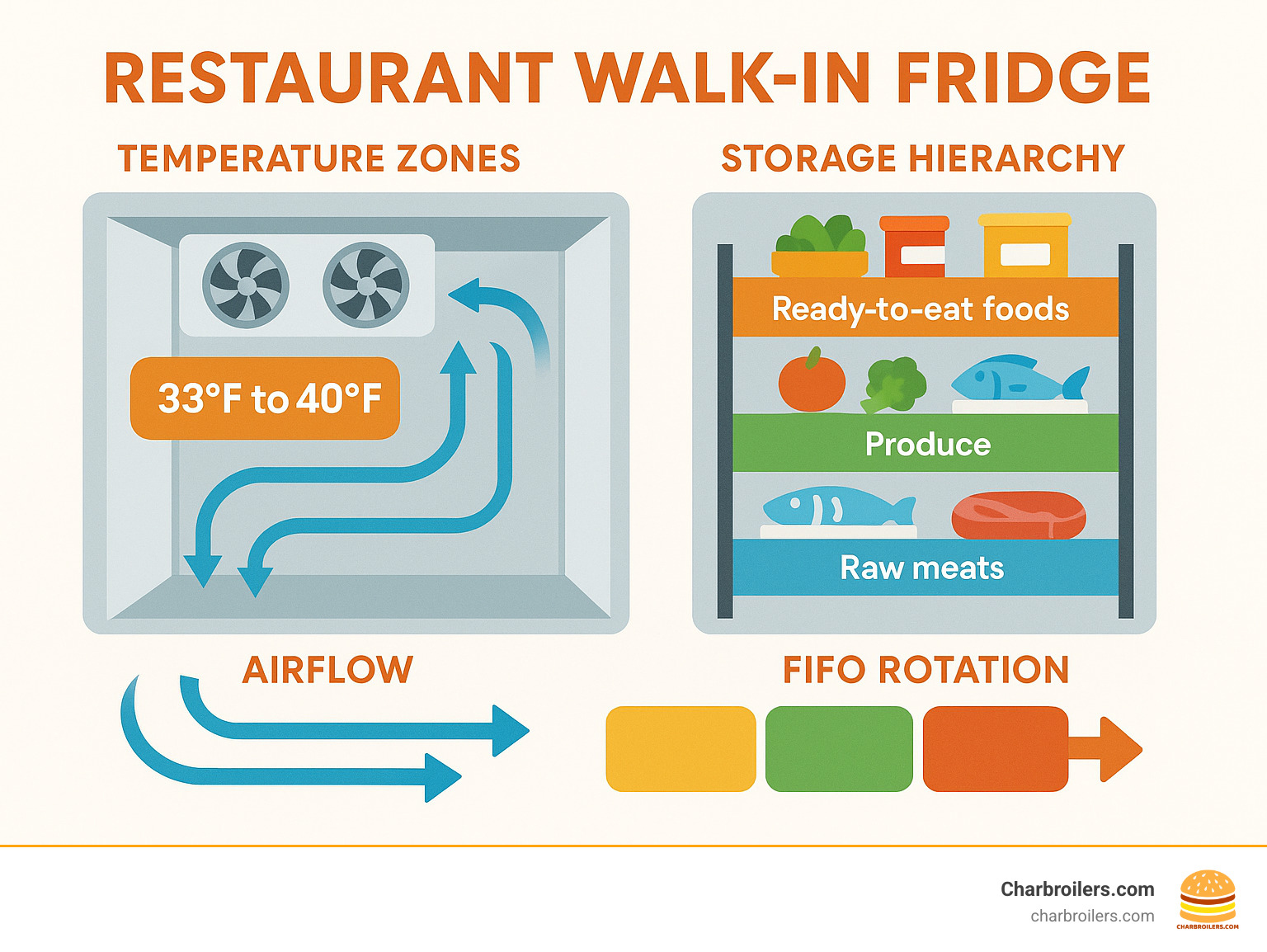

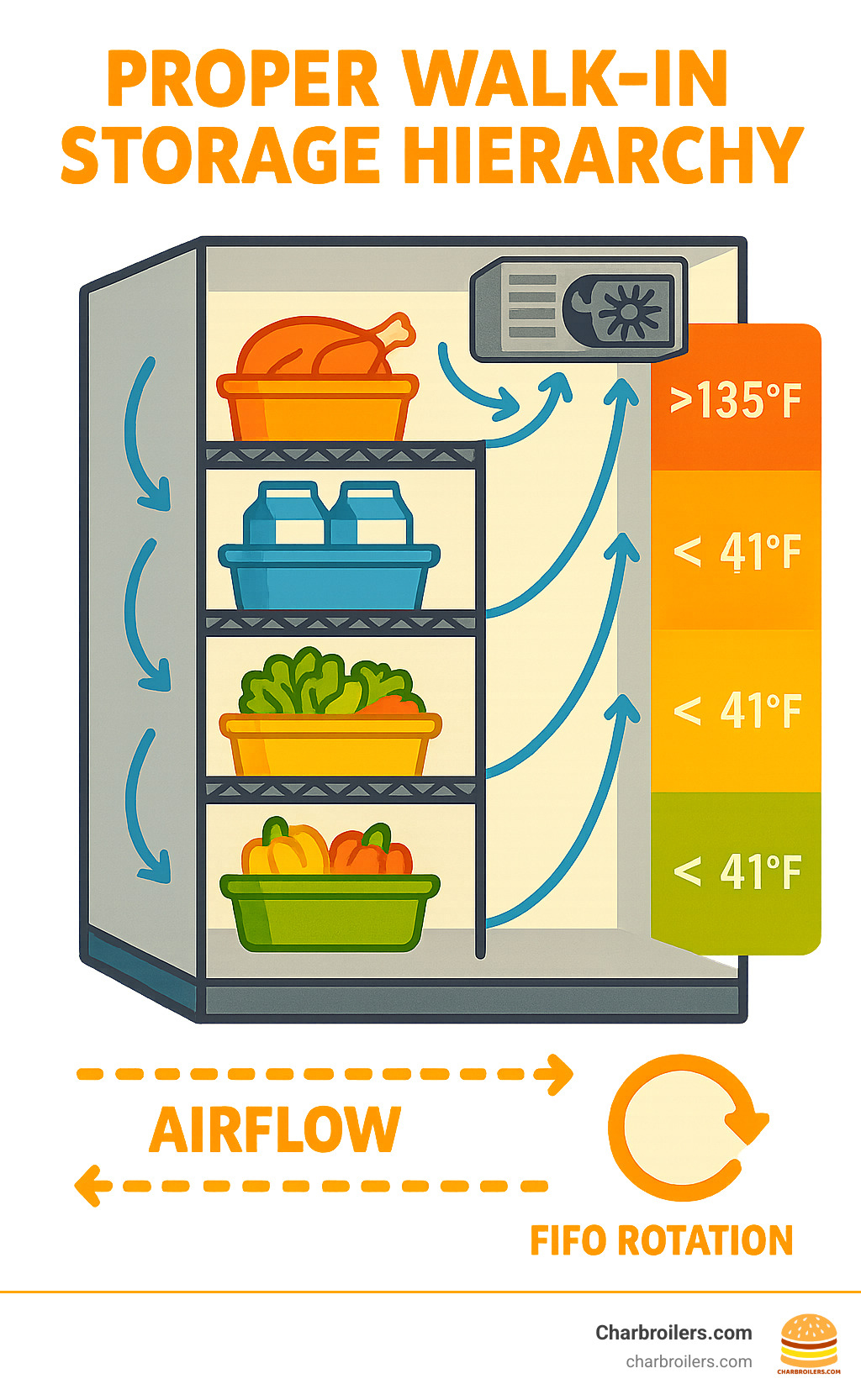

Cross-contamination happens when harmful bacteria from raw foods transfer to ready-to-eat items. The solution is a strict storage hierarchy:

Bottom Shelf: Raw poultry (highest cooking temperature required) Second Shelf: Raw beef and pork Third Shelf: Raw seafood Top Shelves: Ready-to-eat foods, produce, and cooked items

This ensures that if any drips occur, they land on foods that will be cooked to higher temperatures. Use separate, color-coded bins for each protein type. Never store anything directly on the floor.

Temperature Monitoring & Record-Keeping

Temperature monitoring requires both ambient air readings and internal food temperatures:

Ambient Monitoring: Check the air temperature inside your walk-in at least twice daily. Digital systems with remote alerts eliminate guesswork and provide automatic logging.

Food Temperature: Use calibrated probe thermometers to verify that food internal temperatures stay at 41°F or below.

Record Keeping: Document all temperature readings with date, time, and staff initials. Electronic monitoring systems send alerts when temperatures exceed safe ranges.

Organization Hacks That Boost Airflow & Efficiency

Proper organization improves both food safety and energy efficiency:

Airflow Principles: Cold air needs to circulate freely around all stored items. Leave space between products and walls.

FIFO Rotation: First In, First Out rotation prevents waste and ensures freshness. Label everything with dates and use older items first.

Strategic Placement: Keep frequently accessed items near the door to minimize cold air loss. Store items that need the coldest temperatures in the back where temperatures are most stable.

The 7-day rule is critical: prepared TCS foods must be discarded after seven days, regardless of appearance or smell. This isn't negotiable - it's a health code requirement.

For detailed food safety protocols, this resource provides excellent guidance: Restaurant Walk In Cooler Food Safety Guide.

Cleaning, Maintenance & Troubleshooting Common Walk-In Issues

Your restaurant walk in fridge is like that reliable friend who's always there for you - until the day it isn't. With proper care, these workhorses can serve your kitchen faithfully for 15+ years. Skip the maintenance, though, and you might find yourself dealing with spoiled food and expensive repairs.

Daily & Weekly Cleaning Checklist

Your daily routine should take just 5-10 minutes but makes all the difference in performance and lifespan.

Start each shift by wiping up any spills immediately. Spilled liquids create slip hazards and make your compressor work harder. A quick sweep removes debris that could clog drain lines, and checking that doors close properly prevents energy waste.

Turn off the lights when you're not inside. Those bulbs generate heat, forcing your cooling system to work overtime.

Your weekly deep clean takes 30-45 minutes but prevents bigger problems. Remove everything from the shelves and clean from top to bottom. Use warm, soapy water followed by food-safe sanitizer.

Pay special attention to door gaskets during weekly cleaning. Food residue and grime can prevent them from sealing properly.

Preventive Maintenance Tasks That Extend Lifespan

Monthly maintenance protects your investment. The evaporator and condenser coils are your system's lungs - when they're clogged with dust and debris, your walk-in can't breathe properly. A simple brush and shop vacuum cleaning keeps air flowing freely.

Listen to your equipment. Fan motors that suddenly sound different are telling you something. Catching these issues early prevents breakdowns during busy service.

Annual professional service typically costs $200-$400, but it's money well spent. A qualified technician can spot problems you might miss and perform tasks requiring specialized tools.

Quick Fixes for the Top 3 Restaurant Walk-In Fridge Problems

When your unit runs too warm, start simple: toggle the breakers off for 30 seconds, then flip them back on. Check that doors are closing completely and seals are intact. Make sure stored items aren't blocking air vents.

Frost buildup on the evaporator is common. Most modern units have a manual defrost cycle accessible through the digital thermostat. Run this cycle and check that the drain line isn't clogged.

Water leaks usually trace back to drain line problems. Locate the drain line near the evaporator and use a wet vacuum to clear any clogs.

For more detailed troubleshooting guidance: Walk-in Cooler Temperature Guide | Unity Cooling Systems Inc.

Costs, Financing & Real-World Owner Insights

Understanding the true cost of a restaurant walk in fridge goes way beyond that initial price tag. The operators who plan for total ownership costs make much smarter decisions.

Budgeting for Purchase, Installation & Lifetime Operation

A basic 6x6 unit runs $5,000-$8,000, while a standard 8x10 unit costs $7,000-$12,000. Large 10x20 units hit $15,000-$25,000, and custom installations can reach $30,000-$50,000 or more.

Installation adds another $1,800-$4,800 to your budget. Electrical work alone runs $500-$2,000. Add concrete pad preparation at $300-$800, refrigeration line installation at $800-$1,500, plus permits and inspections for $200-$500.

The ongoing costs tell the real story. Energy consumption hits $800-$2,400 annually, while preventive maintenance costs $200-$400 per year. Budget another $300-$600 yearly for repairs and parts.

Walk-in repairs average $1,000.42 per service call - nearly double the cost of smaller refrigeration repairs. This makes annual maintenance contracts look smart.

Many suppliers offer 100% financing with terms from 24-84 months. The monthly payment often equals what you'll save through reduced food waste and lower energy costs.

Stories From the Line: What Operators Love (and Hate)

Sarah from Portland told me: "The bulk storage capacity completely changed our ordering. We buy direct from suppliers now, saving about 15% on food costs."

Mike, who runs a busy pizza place, shared: "Our staff loves having room to actually move around inside. No more playing Tetris with ingredients during prep."

But it's not all sunshine. Lisa from Chicago warned: "The compressor noise took some getting used to, especially with an indoor unit."

Energy costs surprise many operators. "Electricity costs were higher than expected the first year until we got used to keeping doors closed," admitted Carlos from Miami.

The biggest regret? Buying too small. "We should have bought slightly larger - we're already running out of space after just 18 months," said Jennifer from Denver.

The smart operators invest in electronic monitoring systems from day one. As Tom from Seattle put it: "The peace of mind is worth every penny. I get alerts on my phone if temperatures spike."

For more insights on commercial refrigeration equipment: More info about our commercial refrigeration guides.

Frequently Asked Questions About Restaurant Walk-In Fridges

What size restaurant walk in fridge do I need?

The 28 pounds per cubic foot rule gives you a starting point, but your actual needs depend on how you run your kitchen.

Small cafes and quick-service spots typically do well with 6x6 to 6x8 foot units. Medium-sized restaurants usually need 8x8 to 8x10 foot walk-ins. Large operations require 10x12 feet and bigger.

Start by analyzing your peak inventory levels - not your average day, but your busiest periods when you're fully stocked. Factor in your delivery schedule too. Plan for 20-30% growth to avoid outgrowing your unit in two years.

How often should a restaurant walk in fridge be cleaned?

Every single day, tackle the basics: wipe up spills immediately, sweep out debris, and check that doors are closing properly. This takes maybe five minutes.

Weekly deep cleaning is non-negotiable. Remove everything from shelves, scrub them down with warm soapy water, then sanitize. Most restaurants do this during slow periods.

Monthly maintenance keeps your system running efficiently. Clean evaporator coils, check door gaskets, and make sure drain lines aren't clogged.

Annual professional service catches problems before they become disasters.

What certifications must a restaurant walk in fridge meet?

NSF Standard #7 covers food safety compliance for commercial refrigeration. Health inspectors look for this marking first.

UL Listed equipment has passed rigorous fire and electrical safety testing to meet building codes.

EISA compliance means your unit meets federal energy efficiency standards - R-29 insulation for coolers and R-32 for freezers.

Local health codes vary significantly by location. Check with your local health department before making any purchase.

Conclusion

Your restaurant walk in fridge isn't just another piece of equipment - it's the heart of your kitchen's food safety system and the foundation of your operational efficiency.

Food safety must come first. Keep those temperatures between 33-40°F religiously, follow the storage hierarchy with raw proteins on bottom shelves, and never compromise on the 7-day rule for prepared foods.

Smart buying decisions pay dividends for years. Size your unit for future growth, not just today's needs. Those energy-efficient features like LED lighting and ECM motors might cost more upfront, but they'll save you money every month.

Maintenance is your best friend. Daily cleaning takes five minutes but prevents major problems. The average walk-in repair costs over $1,000 - that's five years of preventive maintenance in one emergency call.

Organization creates efficiency. FIFO rotation, color-coded storage systems, and proper shelving turn your walk-in from a cold storage room into a well-oiled machine.

Technology makes everything easier. Electronic temperature monitoring systems eliminate guesswork and provide the documentation health inspectors want to see.

At Charbroilers.com, we know that every piece of your kitchen equipment needs to work together seamlessly. Your restaurant walk in fridge supports the same high standards we bring to all our commercial kitchen solutions.

Ready to explore more ways to optimize your commercial kitchen? Check out our complete equipment guides: More info about our commercial refrigeration guides.