Cooler Than Cool – The Ultimate Back Bar Cooler Buying Guide

Share

Keeping Your Drinks Perfectly Chilled: Why Back Bar Coolers Matter

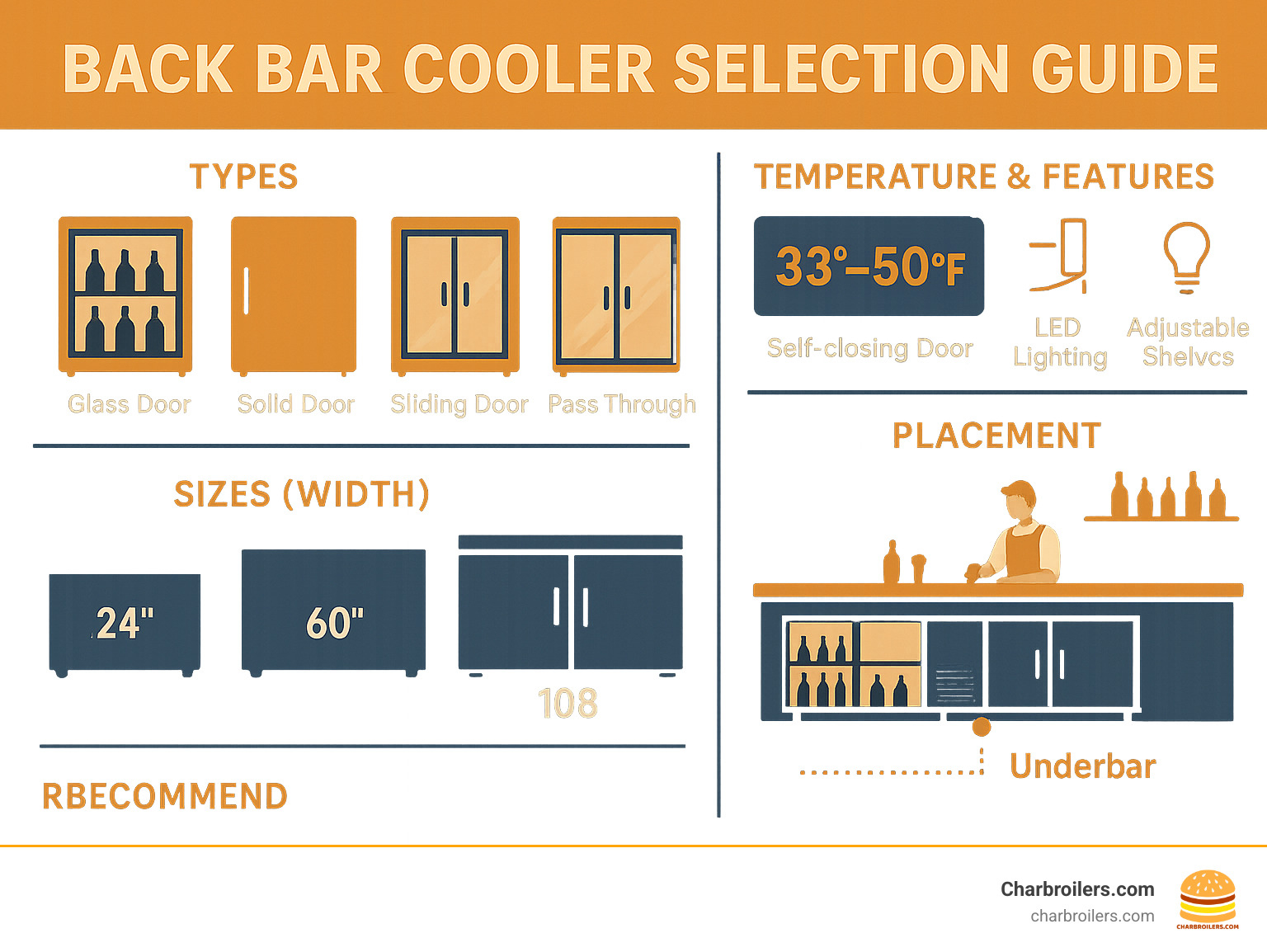

Back bar coolers are essential refrigeration units designed specifically for bars and restaurants to store and display beverages at optimal serving temperatures. If you're looking to purchase one for your establishment, here's what you need to know:

- Purpose: Stores beverages within easy reach of bartenders while maintaining ideal serving temperatures (33°F-50°F)

- Types: Available in glass door, solid door, sliding door, and pass-through configurations

- Sizes: Range from 24" to 108" in width to fit various bar spaces

- Cost factors: Energy efficiency, refrigerant type, door style, and size

- Key features: Self-closing doors, LED lighting, adjustable shelving, digital temperature controls

The bar industry is and demanding, with customers expecting quick service and perfectly chilled drinks. While bartenders impress guests with colorful cocktails, back bar coolers quietly run compressors night and day to keep beverages at optimum temperatures and merchandise products effectively. These unsung heroes of beverage service are vital for consistency, safety, and operational efficiency.

Glass door models are excellent for merchandising and customer engagement, creating a modern and refined look for your establishment. Solid door versions offer better insulation, energy savings, and are ideal for items not meant to be displayed. Whichever style you choose, a properly functioning back bar cooler ensures increased customer satisfaction and sales.

I'm Sean Kearney from Charbroilers.com, with over a decade of experience helping restaurant owners select the perfect back bar coolers for their unique operational needs. After years of working with establishments of all sizes, I've learned that the right refrigeration equipment can significantly impact both workflow efficiency and your bottom line.

What Are Back Bar Coolers & Why They're Non-Negotiable

Back bar coolers are specialized refrigeration units designed to fit under or behind a bar counter, typically standing 34-36 inches tall. These aren't just regular refrigerators with a fancy name – they're purpose-built workhorses that keep beverages perfectly chilled while ensuring bartenders can grab what they need without missing a beat.

Think of back bar coolers as the silent partners in your bar operation. While your bartenders are mixing drinks and chatting with customers, these units are quietly maintaining ideal temperatures for every beverage in your arsenal. They're engineered specifically for the high-demand, environment that is commercial bar service.

I've visited hundreds of bars over the years, and I can tell you that the difference between a smooth operation and a chaotic one often comes down to these essential units. They're non-negotiable because they directly impact your service quality, product integrity, and ultimately, your bottom line.

The most successful bar managers understand that back bar coolers do much more than just keep drinks cold. They maintain consistent temperatures between 33°F and 50°F (depending on the beverage), create an organized system for quick access during rushes, support food safety standards for perishable garnishes, and with glass door models, they even improve your bar's visual appeal.

As one bar owner told me recently, "When our back bar cooler went down for just one night, we not only lost product but also saw a 30% decrease in drink orders because service slowed dramatically." That's the reality – these units aren't luxury items; they're essential infrastructure.

Back Bar Coolers & Bar Workflow

Ever watched a skilled bartender during a Friday night rush? It's like watching a carefully choreographed dance. The strategic placement of back bar coolers is crucial to maintaining this rhythm.

These units are specifically designed with a height of 34-36 inches to fit perfectly under standard bar counters, creating a seamless workflow. This thoughtful design allows bartenders to maintain eye contact with customers while reaching for beverages – a small detail that makes a huge difference in service quality.

In busy establishments, every movement counts. A well-positioned back bar cooler enables bartenders to grab bottles, cans, and mixers without breaking stride. This means less time spent retrieving products, minimal interruption in customer engagement, reduced traffic behind the bar, and faster order fulfillment when it matters most.

I remember talking with a veteran bartender who put it perfectly: "Bartending is something of a performance—your equipment should enable that show, not steal it." The right back bar cooler becomes an invisible assistant, supporting your staff's rhythm rather than disrupting it.

The ROI of Proper Beverage Temperature

Let's talk money. Investing in quality back bar coolers delivers a tangible return through improved product quality and higher customer satisfaction. It's simple: beverages served at their optimal temperature not only taste better but also reflect your establishment's attention to detail.

The temperature impact goes beyond just customer perception. Beer served too warm foams excessively and tastes flat. Wine at improper temperatures loses its distinctive flavor profile. Mixers and garnishes kept above 40°F can spoil quickly, increasing waste. Consistent temperatures extend product shelf life, directly reducing inventory loss.

According to research from a leading beverage industry association, properly chilled drinks increased repeat orders by 23% compared to establishments serving the same products at inconsistent temperatures. That's not just a quality issue – it's a significant revenue factor.

The reputation boost from consistently serving drinks at their ideal temperature creates long-term value through positive word-of-mouth, higher ratings on review platforms, increased customer loyalty, and stronger positioning in competitive markets.

As the food service industry continues to evolve, the latest research on commercial refrigeration shows that temperature control isn't just about taste – it's becoming a key differentiator for successful bars and restaurants. The right back bar cooler isn't just a purchase; it's an investment in your business's reputation and longevity.

Back Bar Coolers: Types & Must-Have Features

When you're shopping for back bar coolers, you'll find yourself facing quite a few options. Don't worry though—I'll walk you through the different types and features so you can find the perfect match for your bar or restaurant.

Think of your back bar cooler as a silent partner in your business. It needs to fit your space, keep your drinks perfectly chilled, and make your bartenders' lives easier. Let's break down your options.

You'll find glass door units that showcase your beverages while maintaining temperature—perfect when you want customers to see that impressive craft beer selection. Solid door units offer better insulation and energy efficiency, ideal for items that don't need to be displayed.

Working with a tight space? Sliding door models are your friend, preventing those awkward moments when swing-out doors block the walkway behind your bar. For high-volume spots, especially with island bars, pass-through units with doors on both sides let staff access drinks from either side—a real time-saver during rush hour.

And of course, underbar coolers are specifically designed to fit snugly under your counter at that standard 34-36 inch height, making the most of your limited bar space.

The best back bar coolers come equipped with features that make your life easier. Look for LED lighting that beautifully showcases your products without generating excess heat (and running up your electric bill). Adjustable shelving is a must—yesterday you stocked standard beer bottles, today you're featuring tall craft brews, and tomorrow who knows?

Self-closing doors are a bartender's best friend during a busy shift. No one has time to check if the cooler door closed properly when there's a line of thirsty customers! Many quality units feature doors that stay open when you need them to (above 90°) but automatically close when you're done.

Other features worth considering include digital temperature controls for precise management, lockable doors to keep your inventory secure after hours, and forced-air cooling that eliminates those annoying temperature inconsistencies that can ruin a perfectly good beer.

If you're planning to place your cooler against a wall, look for a front-breathing design that doesn't require side or rear clearance for ventilation. And don't underestimate the value of heavy-duty casters—they make cleaning and rearranging your bar setup so much easier.

Glass Door vs. Solid Door Back Bar Coolers

The great debate: glass doors or solid doors? This choice affects everything from your energy bill to your bar's aesthetic appeal.

| Feature | Glass Door Coolers | Solid Door Coolers |

|---|---|---|

| Energy Efficiency | Less efficient due to heat transfer | More efficient with better insulation |

| Merchandising | Excellent for product display | No visual merchandising capability |

| Interior Lighting | LED lighting showcases products | Lighting only visible when opened |

| Condensation | May develop condensation in humid environments | Minimal condensation issues |

| Price | Generally more expensive | Typically more economical |

| Weight | Heavier due to glass components | Lighter construction |

| Temperature Stability | More susceptible to fluctuations | Better temperature maintenance |

| Ideal Use | Customer-facing bars, retail display | Back-of-house, storage-focused areas |

Glass door back bar coolers create that modern, refined look that draws customers in. There's something enticing about seeing those bottles and cans perfectly arranged and illuminated. As one bar designer told me, "The back bar is at the center of any bar's attraction and is always in the customer's view." If you want to showcase your selection of craft beers or premium spirits, glass is the way to go.

Solid door models might not win any beauty contests, but they're the reliable workhorses of the bar world. They offer better insulation, energy savings, and temperature stability. Many bar owners opt for a smart combination—glass door units where customers can see them, and solid door models for back-of-house storage or less visible areas.

Size & Capacity Calculations

Choosing the right size back bar cooler is a bit like buying shoes for a growing teenager—you want room to grow, but not so much that they're swimming in them.

Standard widths range from 24 inches for single-door models up to 108 inches for four-door units. Most stand 34-36 inches tall to fit under bar counters, with depths typically between 24 and 30 inches.

To figure out what size you need, start by counting the maximum number of bottles, cans, and kegs you'll store during your busiest periods. Consider your product mix too—wine bottles need more height, while cans and mixers can be packed more densely.

One piece of advice I always give: add 15-20% to your current needs. Your business will grow (fingers crossed!), and seasonal fluctuations can leave you scrambling for space if you cut it too close.

A seasoned bar consultant once told me, "It's better to have a slightly larger unit with room to grow than to quickly outgrow your refrigeration and face costly replacements." Wise words.

For a quick reference, a typical 24-inch single-door back bar cooler holds roughly 100-150 12oz bottles or cans, while a 72-inch three-door unit might accommodate 400-600 containers depending on their size and your shelf setup.

Refrigerants, Temperature Ranges & Sustainability

The refrigerant in your back bar cooler matters more than you might think—both for performance and for our planet.

Modern units typically use one of two refrigerant types. R290 hydrocarbon refrigerant is the rising star—it's natural, non-toxic, and delivers up to 40% energy savings compared to traditional options. It has zero ozone depletion potential and minimal global warming impact. Then there's R134A refrigerant, a hydrofluorocarbon that's being phased out in many regions due to its higher environmental impact.

The industry is quickly shifting toward hydrocarbon refrigerants like R290, not just because they're better for the environment, but also because they're more energy-efficient. As regulations around HFCs get stricter, choosing a unit with natural refrigerants is a smart long-term investment.

Your back bar cooler should maintain temperatures between 33°F and 50°F, with the flexibility to adjust based on what you're storing. Beer tastes best at 36-38°F, white wine prefers 45-50°F, and red wine (if you're keeping it chilled) likes 55-65°F. Mixers and garnishes need to stay below 40°F for food safety.

Some fancier models offer dual-temperature zones—different sections of the same unit can maintain separate temperature settings. If you serve diverse beverage types, this feature is worth considering.

Beyond the refrigerant itself, look for sustainability features that will be kind to both the planet and your utility bills. Energy Star certification means the unit meets EPA energy-performance standards. Self-cleaning condensers maintain efficiency over time, while LED lighting with motion sensors reduces energy use when no one's around. Heavy-duty insulation and digital thermostats help maintain precise temperatures without wasting energy.

These eco-friendly features do more than just reduce your carbon footprint—they can save you hundreds of dollars annually compared to older or less efficient models. That's a win-win in my book.

Buying Checklist & Mistakes to Avoid

Shopping for a back bar cooler can feel overwhelming with so many options out there. Trust me, I've seen bar owners make costly mistakes that could have been easily avoided with a little preparation. Let's walk through what you need to know before you pull out your credit card.

Before you start browsing, grab a tape measure and note your available space. I can't tell you how many times I've heard, "I wish someone had told me to measure twice before ordering!" You'll need to know the width, depth, and height available in your bar area, plus enough clearance for doors to open properly. If space is tight, sliding doors might be your best friend.

Think about your inventory needs too. How many bottles and cans do you need to store during your busiest nights? Add about 20% to that number to accommodate future growth. There's nothing worse than outgrowing your cooler six months after purchase!

When examining technical specs, pay attention to the refrigerant type (R290 hydrocarbon is the eco-friendly choice), voltage requirements, and temperature range capabilities. Self-defrosting models will save you maintenance headaches down the road.

Don't forget to consider the practical details that will impact your daily operations. Glass doors showcase your premium products but solid doors offer better insulation. Stainless steel finishes look sleek but might show fingerprints more than black vinyl. LED lighting not only looks great but saves energy too.

On the financial side, look beyond just the sticker price. A quality warranty (ideally 1-year parts/labor and 5-year compressor), energy efficiency ratings, and available financing options can make a big difference in your total cost of ownership. At Charbroilers.com, we understand that restaurant equipment is an investment, which is why we offer financing options custom to food service businesses.

Common Pitfalls When Purchasing Back Bar Coolers

I've seen even experienced bar managers make these mistakes, so let's make sure you don't fall into the same traps.

Undersizing is probably the most expensive mistake in the long run. That cooler that seems "just right" today will feel impossibly cramped during holiday rushes or when your business grows. Always size for your busiest periods plus some breathing room.

Many bar owners completely ignore airflow requirements, placing units flush against walls when they need ventilation space. Unless you've specifically purchased a front-breathing model, your back bar cooler needs room to breathe—typically 3-5 inches of clearance. Ignoring this leads to overheating and premature failure.

Don't forget about door clearance in tight spaces. Nothing's more frustrating than installing your new cooler only to find the door swing blocks a crucial walkway. Measure your aisle space and consider door configuration carefully.

I've seen too many buyers choose based on price alone, only to regret it when they're paying higher energy bills or calling for repairs every few months. Quality insulation and compressors cost more upfront but save money over time.

If you're running a public establishment, neglecting ADA compliance can lead to legal headaches. Make sure your cooler selection meets accessibility standards if required for your business.

Some back bar coolers sound like small jet engines, which might not matter in a sports bar but could ruin the ambiance of an upscale cocktail lounge. Ask about noise levels before purchasing if ambient sound is important in your venue.

Lastly, don't overlook drainage requirements. Some units need floor drains while others use evaporator pans. Make sure your location can accommodate whichever system your chosen model uses.

Installation & Workflow Best Practices

Smart placement of your back bar cooler can dramatically improve your bartenders' efficiency and your customers' experience. Here are my top five placement tips after years in the industry:

Position for workflow optimization by placing units within easy reach of bartending stations. Every step saved during a busy shift adds up to faster service and more sales.

For island bars, consider pass-through options that allow stocking from one side and service from the other. This keeps restocking activities from interrupting customer service.

Always plan for future expansion by leaving space for additional units if possible. Your successful bar will likely need more refrigeration as business grows.

Ensure proper leveling using the adjustable feet on your unit. This isn't just about aesthetics—level installation ensures proper door operation and drainage.

Maintain clearance for cleaning behind and under your unit. The ability to thoroughly clean around your equipment extends its life and helps maintain food safety standards.

I've had interesting debates with bar designers about whether multiple smaller units or one large cooler is better. Multiple units provide backup if one fails and can reduce temperature fluctuation since doors are opened less frequently on each. However, a single properly sized unit is often more space and cost-efficient. The right choice really depends on your specific operational needs and how risk-averse you are.

The perfect back bar cooler is the one that fits your space, meets your capacity needs, and supports your bartenders' workflow—all while keeping your beverages at the ideal serving temperature. Take your time with this decision, and your future self will thank you!

Maintenance, Energy Efficiency & Long-Term Cost of Ownership

Treating your back bar cooler right isn't just about keeping it running—it's about protecting your investment and your bottom line. I've seen too many bar owners learn this lesson the hard way after neglecting simple maintenance that could have saved them thousands.

Think of your back bar cooler as an employee that works 24/7 without breaks. Like any hardworking team member, it needs regular care to perform at its best. Those condenser coils? They're like the lungs of your system. When they get clogged with dust and debris (which happens surprisingly fast in busy bar environments), your cooler has to work harder to breathe. I recommend cleaning these coils at least quarterly—monthly if your bar is particularly busy or dusty. This simple 15-minute task can prevent your compressor from overworking, which is the quickest way to shorten your equipment's lifespan.

Door gaskets are another critical maintenance point that's easy to overlook. These rubber seals are constantly flexing and compressing, and over time, they develop tiny cracks or start to harden. A compromised gasket is like leaving your refrigerator door slightly open all day—it forces your system to run constantly while never quite reaching the right temperature. Run your hand along the gaskets monthly, feeling for any tears or stiffness, and replace them at the first sign of wear.

Temperature accuracy matters more than you might think. Many bar owners trust the digital display without verification, but sensors can drift over time. A simple refrigerator thermometer placed inside can tell you if there's a discrepancy. When your cooler runs just 5 degrees colder than necessary, you're essentially throwing money away with every electric bill.

Cleaning & Sanitizing Routine

"The cleaner the cooler, the longer it lasts," as one veteran bar manager told me, and truer words were never spoken. A clean back bar cooler not only looks better to customers who can see inside but also operates more efficiently and prevents flavor transfer between products.

For daily maintenance, quick wipe-downs of exterior surfaces and handles are essential, especially in high-volume operations. These high-touch areas can harbor bacteria that transfer to garnishes and potentially affect drink quality. Make it part of your closing routine—it takes just minutes.

Your weekly deep-clean should be more thorough. Always start by unplugging the unit—this is both safer and prevents the compressor from cycling while you're cleaning. Transfer your inventory to another cooled area (or work quickly if that's not possible). Remove shelving and wash with a mild, odorless detergent—this is critical because strong fragrances can actually transfer to beverages, particularly beers.

When cleaning interior surfaces, avoid harsh chemicals like bleach or ammonia. They might seem like they clean better, but they can damage interior finishes and leave behind odors that affect product quality. Instead, use food-safe, non-abrasive cleaners that align with ServSafe guidelines, especially important if you're storing garnishes or mixers in your cooler.

Pay special attention to those door gaskets we mentioned earlier—use a soft brush to clean out debris from the creases. A clean gasket seals better, saving energy and extending gasket life. And don't forget those handles! They're among the most frequently touched surfaces in your bar and deserve extra sanitizing attention.

Energy-Savings & Sustainability Hacks

Smart bar owners know that energy efficiency isn't just good for the planet—it's good for profits. With back bar coolers running 24/7, even small efficiency improvements can add up to significant savings over time.

One of my favorite low-cost hacks is using night curtains on glass-door units during closed hours. These thermal barriers significantly reduce cold air loss while still allowing you to showcase your products during business hours. For bars open 8-12 hours daily, this simple addition can reduce energy consumption by up to 15%.

Motion-activated LED lighting is another brilliant upgrade. Standard cooler lights stay on constantly when doors are closed, but with motion sensors, they only illuminate when someone approaches—perfect for late-night operations or slow periods. The LEDs themselves use up to 90% less energy than old fluorescent lighting while generating less heat inside the cooler (less heat means less cooling needed).

Temperature logging might sound technical, but modern digital systems make it simple. These tools alert you to fluctuations before they become problems, preventing both energy waste and product loss. Some systems even connect to smartphone apps, giving you peace of mind when you're away from your establishment.

Don't overlook utility rebates when upgrading your equipment. Many energy companies offer substantial incentives for switching to energy-efficient commercial refrigeration. I've seen bar owners recover up to 30% of their purchase price through these programs. Check with your local utility provider—the savings might surprise you.

For older units still in good mechanical condition, consider a hydrocarbon refrigerant retrofit. Switching from older refrigerants to natural options like R290 can improve efficiency while significantly reducing environmental impact. This upgrade typically pays for itself within 1-2 years through energy savings alone.

Strategic placement is perhaps the simplest energy hack—just position your back bar cooler away from heat sources like cooking equipment, dishwashers, or direct sunlight. Every degree of ambient temperature increase around your cooler forces the compressor to work harder, directly increasing your electric bill.

By implementing these practical strategies, you can reduce your refrigeration energy consumption by 15-30% while extending equipment life and improving performance. That's not just good stewardship—it's smart business that improves your bottom line at Charbroilers.com, we've seen these simple changes make significant differences for our customers' operational costs year after year.

Frequently Asked Questions about Back Bar Coolers

How do I choose the right size cooler for my beverage list?

Choosing the perfect back bar cooler size is a bit like finding the right shoes – too small and you'll be uncomfortable, too large and you're wasting resources. Start with a simple inventory count of everything you need to keep cold during your busiest periods.

Most bar owners find that allowing about 1.5-2 cubic feet of interior space per case of bottled beer works well as a starting point. If you run a small neighborhood bar with a focused selection, a 24" single-door unit might be perfect. For medium-sized operations with a decent variety of offerings, look toward 48-60" two-door models. Larger establishments with extensive beverage programs will likely need 72-90" three-door units to keep everything properly chilled.

I always recommend adding about 15-20% extra capacity to whatever you calculate you need today. Why? Because your business will grow (fingers crossed!), seasonal rushes happen, and there's nothing more frustrating than playing refrigeration Tetris during a busy service. Trust me, I've seen too many bar owners regret skimping on cooler size within their first year of operation.

What temperature should my back bar cooler run at?

Temperature settings for your back bar cooler aren't one-size-fits-all – different beverages have their sweet spots for optimal flavor and freshness.

Most quality back bar units offer flexible temperature ranges between 33°F and 50°F, which lets you dial in the perfect chill. For your beer selection, aim for 36-38°F (with mass-market lagers tasting better on the colder side and craft ales showing more flavor complexity when slightly warmer). White wines are happiest around 45-50°F, while any mixers, juices, or garnishes should stay below 40°F to meet food safety standards.

If you're serious about wine service and need to refrigerate reds, you'll want to look at specialized dual-zone units that can maintain a separate section at 55-65°F. Those digital temperature controls aren't just for show – they allow you to fine-tune settings to match your specific inventory.

Here's a pro tip I've learned from years in the business: don't just trust the display reading. Place an independent thermometer in the center of your unit and check it regularly. The actual interior temperature sometimes differs from what the display shows, especially in older units.

How often should I clean coils and door gaskets?

Think of cleaning your back bar cooler's condenser coils and door gaskets as giving your car regular oil changes – skip it at your peril!

For condenser coils, mark your calendar for cleaning every three months at minimum. If your bar is in a dusty location or you're running at high volume, you might need to bump that up to monthly. When those coils get clogged with dust and debris, your compressor works overtime, driving up energy costs by as much as 30% and potentially cutting years off your equipment's life.

The cleaning process isn't complicated: power down the unit, locate the condenser (usually at the bottom or back), gently remove debris with a coil brush and vacuum, and use a commercial coil cleaner for any stubborn buildup. Twenty minutes of maintenance can save you thousands in repairs and replacement costs.

Door gaskets need even more attention – inspect them monthly and wipe them down weekly with mild soap and warm water. Use a soft brush to get into all those creases and folds, and make sure they're thoroughly dry before closing the doors. Think of gaskets as the weatherstripping on your house – when they fail, all your cold air escapes and warm air sneaks in.

Most gaskets need replacement every 1-2 years, depending on use. Watch for cracks, tears, hardening, or doors that don't seal properly when closed. A regular maintenance schedule for these components isn't just about preventing breakdowns – it can extend your equipment's life by 2-3 years and trim your energy bills by 10-15%. That's money back in your pocket for very little effort!

Conclusion

Choosing the perfect back bar cooler isn't just about buying another piece of equipment—it's about making a strategic investment that will serve your business day in and day out for years to come. After exploring all the options and considerations, you're now equipped to make a choice that will keep your beverages perfectly chilled and your customers delighted.

As you finalize your decision, keep these essential points in mind:

Measure your space carefully and select a size that accommodates both your current inventory and future growth. Nothing's more frustrating than outgrowing your cooler within a year of purchase! The configuration matters too—whether you need the merchandising appeal of glass doors or the superior efficiency of solid doors depends entirely on your unique bar setup and service style.

Energy efficiency isn't just good for the planet—it's great for your wallet too. Look for modern features like LED lighting, self-closing doors, and natural refrigerants that will significantly reduce your monthly utility bills. These seemingly small details add up to substantial savings over the equipment's lifetime.

Maintenance isn't optional—it's essential. Implementing a regular cleaning schedule for your back bar cooler will extend its operational life and prevent costly emergency repairs. Those few minutes spent cleaning coils and checking gaskets translate directly into years of additional service from your equipment.

When comparing options, look beyond the sticker price. The true cost includes energy consumption, maintenance requirements, and expected lifespan. That bargain-priced cooler might end up being the most expensive option when you calculate its total cost of ownership over 5-10 years.

Here at Charbroilers.com, we understand that every bar has its own personality and operational needs. Our team is passionate about helping you find equipment that fits your specific requirements—not just pushing whatever happens to be in stock. We offer flexible financing options designed specifically for food service businesses, making it easier to invest in quality equipment that will serve you reliably through countless busy nights.

By avoiding the common pitfalls we've discussed and following installation best practices, you'll maximize your return on investment while ensuring every drink you serve is at its perfect temperature. In an industry where the details make all the difference, few things impact customer satisfaction more directly than that first sip of a perfectly chilled beverage.

For more insights about equipping your commercial kitchen and bar, visit our blog at Charbroilers.com, where we regularly share practical advice and industry trends to help your business thrive. Because when your business succeeds, we succeed too.