Fixing Common Issues with Imperial Frost Free Commercial Freezers

Share

Why Your Imperial Frost Free Commercial Freezer Needs Expert Troubleshooting

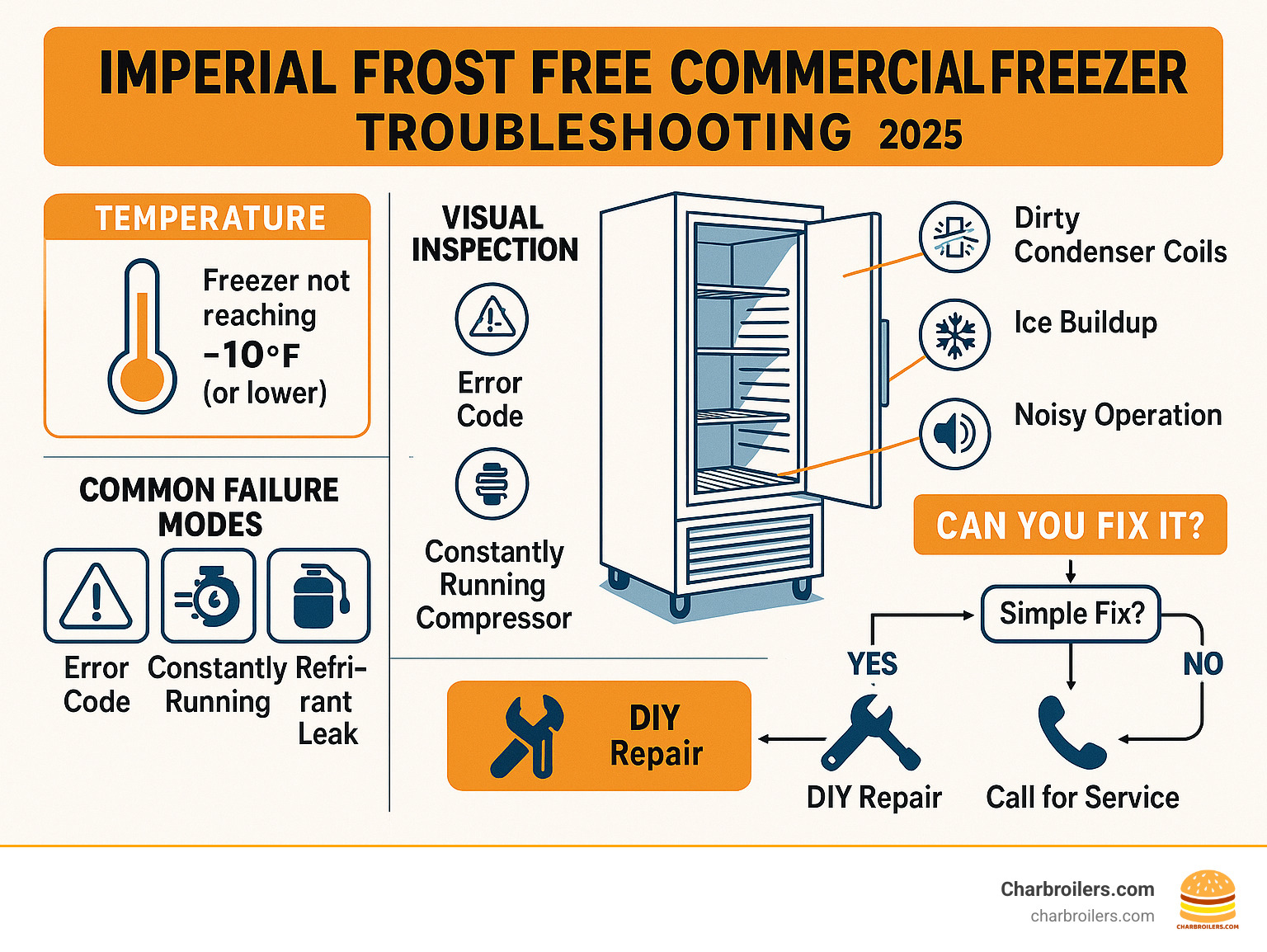

Imperial frost free commercial freezer units are workhorses in busy restaurant kitchens, but when they break down, your food safety and bottom line are at risk. Here are the most common issues and quick identification tips:

Most Common Problems:

- Temperature not reaching -10°F - Usually dirty condenser coils or failed door gaskets

- Ice buildup despite frost-free design - Blocked drain lines or faulty defrost heater

- Loud noises or vibrations - Fan blade obstructions or loose mounting hardware

- Error codes after power outages - Controller reset needed or sensor faults

- Compressor running constantly - Low refrigerant or temperature control issues

Based on real troubleshooting cases, these freezers often fail when bottom shelves won't freeze while top shelves work fine - a clear sign of refrigerant or circulation problems. One restaurant owner found their 20-year-old Imperial unit only reached 20°F instead of the required sub-zero temperatures, pointing to a refrigerant leak.

Quick Safety Check: If your freezer can't freeze a bowl of water overnight on the bottom shelf, you have a serious cooling problem that needs immediate attention.

I'm Sean Kearney from Charbroilers.com, and with over a decade in restaurant equipment, I've helped countless kitchen operators keep their imperial frost free commercial freezer units running smoothly. My experience taught me that preventive maintenance beats costly emergency repairs every time.

Imperial frost free commercial freezer helpful reading:

- commercial upright frost free freezer

- frigidaire commercial frost free upright freezer

- haier commercial frost free freezer

How Imperial Frost-Free Technology Keeps Ice Away

Ever wonder how your imperial frost free commercial freezer magically prevents ice buildup? It's actually a clever dance of technology that runs quietly in the background, keeping your food frozen without the headache of manual defrosting.

The system relies on air circulation fans that constantly move cold air around every corner of the cabinet. When these fans start failing, you'll notice the telltale sign - your bottom shelves staying warmer while the top shelves work perfectly fine.

The real star is the automatic defrost heater. This component kicks in periodically to melt away any ice formation on the evaporator coil. When this heater fails, you'll wonder why your "frost-free" freezer suddenly looks like an ice cave.

All that melted ice has to go somewhere. The drain pan and tube system channels meltwater away from your food storage area to an evaporation pan. When this drain gets clogged, water backs up and freezes right where you don't want it.

The electronic controller acts as the brain, managing defrost timing, fan operation, and keeping that critical food-safe zone between -10°F and 10°F. Modern controllers are smart - they'll even lock the unit if temperatures climb too high, protecting your food investment.

The whole system works through compressor cycles that maintain consistent temperatures while the other components handle ice prevention. When any piece fails, the entire system's efficiency drops like a rock.

More info about Haier frost-free tech

Defrost Cycle Explained

The defrost cycle is where most imperial frost free commercial freezer headaches begin, so let's break down what should happen when everything's working correctly.

Your freezer has an evaporator sensor that's constantly monitoring ice buildup on the evaporator coil. When it detects trouble, it triggers the defrost cycle automatically.

The heater activation timing is typically 15-20 minutes for freezers. During this time, the compressor usually takes a break to avoid working against the heating element.

Some Imperial units use a hot-gas bypass system instead of electric heaters. This method routes hot refrigerant gas to melt the ice, which is more energy-efficient but requires precise pressure control.

As ice melts, meltwater removal becomes critical. The water flows through a drain tube to an evaporation pan, usually located underneath the unit. The drain must stay clear and properly sloped.

The thermistor feedback system signals when defrost is complete, typically when the coil reaches 32°F or higher. Most units run about 4 defrost cycles per day, though this might need adjustment based on door opening frequency and local humidity levels.

Key Components to Inspect Regularly

Regular inspection prevents most imperial frost free commercial freezer failures. Focus your attention on these critical areas that tend to cause the most trouble.

Door gaskets are your first line of defense against warm air infiltration. Check for tears, warping, or lost elasticity monthly. Here's a simple test - close a dollar bill in the door and try pulling it out. If it slides out easily, your gasket needs replacement.

The evaporator coil sits inside the freezer compartment and should stay relatively clean with minimal ice buildup. Heavy frost accumulation here is a dead giveaway that your defrost system isn't working properly.

Your condenser coil (usually on the back or bottom) dissipates heat from the refrigeration process. When dust and debris coat this coil, your compressor works harder and runs hotter, shortening its lifespan significantly.

Listen to your fan motor regularly - it should run quietly and smoothly. Unusual noises or vibrations often signal bearing problems or blade obstructions.

Test your drain line monthly by pouring warm water down the drain. Water should flow freely to the evaporation pan without backing up. This simple check prevents most water-related freezing issues.

Finally, keep an eye on your controller board for error codes or unusual display readings. Modern controllers store fault codes that help you track down problems before they become expensive repairs.

Diagnosing Common Problems With Your imperial frost free commercial freezer

When your imperial frost free commercial freezer starts acting up, the key is knowing what to look for. The most obvious warning signs are temperature creeping above 10°F, ice patches appearing on walls, and continuous alarm beeping.

But some problems are sneakier. A compressor that runs constantly without actually cooling anything is burning through electricity while your food slowly thaws. Service codes flashing on the display might seem like gibberish, but they're actually your freezer's way of telling you exactly what's wrong.

For proper diagnosis, you'll need a digital thermometer for accurate readings, a flashlight to peer into dark corners, and some basic patience. The Walk-In Freezers Installation Manual has detailed specs if you want to get technical about it.

Why Is My imperial frost free commercial freezer Not Reaching Temperature?

Temperature problems are the common cold of commercial freezers - they're everywhere, but usually fixable once you know what you're dealing with. Your imperial frost free commercial freezer should maintain that crucial sub-zero zone, and when it doesn't, food safety goes out the window.

Thermostat drift happens as units age. The controller might think it's keeping things at -10°F while your independent thermometer reads 15°F.

Blocked air vents are probably the easiest fix you'll ever make. When you pack your freezer like a game of Tetris, air can't circulate properly. Leave at least 3 inches around all vents, and resist the urge to line shelves with foil.

The condenser coil gets dirty faster than you'd think in a busy kitchen. Dust and grease buildup make it work harder. A monthly cleaning with a brush or compressed air keeps it happy.

Low refrigerant is the expensive problem nobody wants to hear about. You'll notice partial frosting on the evaporator coil - usually just the top section gets cold while the bottom stays warm. This one needs a professional with the right tools and certification.

Sometimes the problem is embarrassingly simple. A door left slightly ajar can sabotage your entire cooling system. Check the door alignment and gasket condition, because even a tiny gap lets warm air sneak in.

Ice Buildup Even Though It's Frost-Free

Nothing's more frustrating than ice buildup in a freezer that's supposed to be frost-free. When your imperial frost free commercial freezer develops ice despite its fancy technology, a few culprits are usually to blame.

A failed defrost heater is often the main villain. This component is supposed to melt ice automatically, but when it breaks, ice accumulates like snow on a mountain. You can test it with a multimeter, but this usually means calling in the pros.

Clogged drain lines are messier but easier to fix. Pour some warm water down the drain opening and see if it flows freely. If it backs up, grab a flexible brush and clear the blockage. Just remember to sanitize everything afterward.

Door gasket tears let humid kitchen air sneak inside, where it promptly freezes into annoying ice patches. That dollar bill test I mentioned earlier? If you can pull it out easily when the door's closed, your gasket is toast.

High humidity during busy periods can overwhelm even the best defrost system. If your kitchen gets steamy during dinner rush, that moisture often ends up as ice in your freezer.

Loud or Unusual Noises

Commercial freezers should hum quietly in the background, not sound like they're auditioning for a death metal band. When your imperial frost free commercial freezer starts making noise, it's usually trying to tell you something specific.

Fan blade obstructions create that annoying scraping or clicking sound. Ice buildup or random debris makes the fan hit surrounding parts. Clear the obstruction and check for bent blades while you're at it.

Loose mounting screws turn your freezer into a vibration machine. Over time, all that constant running loosens fan motor mounts and panel fasteners. A quick tightening session with a screwdriver often solves the problem.

A failing compressor sounds like trouble because it is trouble. When internal components wear out, you'll hear knocking, rattling, or unusually loud humming. This typically means a $1,000 repair bill and a call to a professional.

Don't forget about vibration pads under your unit. If they're missing or worn out, every little vibration gets transmitted through the floor and walls.

Error Codes & Alarms After Power Loss

Power outages are like kryptonite for modern commercial freezers. When the lights come back on, your imperial frost free commercial freezer might throw an electronic tantrum with flashing codes and beeping alarms.

Controller resets are usually the first step. Many units need a manual reset after power comes back - it's like rebooting your computer after a crash. The typical procedure involves unplugging for 10 minutes, then starting fresh.

Voltage surges during power restoration can fry sensitive electronics. Check for blown fuses or tripped breakers before panicking. Sometimes it's just a protective device doing its job.

NTC sensor faults often show up after electrical problems. These temperature sensors are delicate and don't handle power fluctuations well. When they fail, your freezer loses its ability to "feel" the temperature properly.

Some controllers use backup batteries to remember settings during outages. When that battery dies, your freezer might revert to factory defaults, which probably aren't right for your specific needs.

Step-By-Step Fixes & Preventive Maintenance

Taking care of your imperial frost free commercial freezer doesn't have to be complicated. Think of it like maintaining a car - regular attention prevents expensive breakdowns and keeps everything running smoothly.

Your freezer works hard every day, so it deserves some TLC. Most maintenance tasks are straightforward and take just a few minutes.

Daily door inspections are your first line of defense. Make it part of your opening routine - check that the door closes completely and the gaskets seal properly. A door that doesn't seal tight is literally bleeding cold air and driving up energy costs.

Weekly coil dusting keeps your compressor happy. Those condenser coils collect dust faster than you'd expect, especially in busy kitchens. A quick brush-off or blast of compressed air works wonders.

Monthly drain flushing prevents nasty surprises. Pour warm water down that little drain opening to keep it clear. Trust me, you don't want to find a clogged drain during dinner rush.

Annual refrigerant checks by a professional catch problems before they become disasters. It's like getting a physical for your freezer - worth every penny.

The defrost cycle test is something many people forget about. Your freezer should automatically defrost several times a day. If ice keeps building up despite the frost-free design, something's not working right.

| Quick Fix | DIY or Call Tech? |

|---|---|

| Door won't close properly | DIY - Check gaskets and hinges |

| Ice buildup on walls | DIY - Check drain line first |

| Not reaching temperature | Call Tech - Likely refrigerant issue |

| Loud grinding noises | Call Tech - Compressor problem |

| Error codes after power loss | DIY - Try reset procedure first |

More info about Commercial Upright Frost Free Freezers

Resetting an imperial frost free commercial freezer After a Power Outage

Power outages happen, and your imperial frost free commercial freezer might need a little coaxing to get back to normal. Don't panic - most units just need a proper restart sequence.

Start by unplugging the unit completely and waiting 10 minutes. This allows the electrical system to reset and refrigerant pressures to balance out. I know ten minutes feels like forever when you're worried about food safety, but it's crucial.

Next, check your breaker box to make sure nothing tripped during the outage. Test the outlet with a multimeter to verify you're getting proper 115V supply. Sometimes the problem isn't the freezer at all - it's the electrical supply.

When you plug it back in, resist the urge to open the door right away. Let the unit start up naturally. The compressor might take several minutes to kick in, and that's perfectly normal.

Monitor the temperature for 4 hours after restart. Your freezer should reach -10°F within this timeframe. If it's still struggling after four hours, you probably have a bigger problem that needs professional attention.

Test the alarm system once everything's running normally. Make sure the door alarm works by leaving the door open briefly.

DIY Drain-Line Unclogging

A clogged drain in your imperial frost free commercial freezer is like a stopped-up sink - annoying but usually fixable with a little patience. Most drain clogs happen gradually, so you might not notice until water starts backing up.

Safety first - always unplug the unit before working on the drain. Remove any shelving that blocks access to the drain opening, usually located at the bottom rear of the freezer compartment. Have plenty of towels ready because this can get messy.

Start with warm water - not hot, which could damage plastic components. Pour it slowly down the drain opening and watch if it flows freely. If it backs up immediately, you've got a clog.

Use a flexible brush or pipe cleaner to gently work through the blockage. Don't force it - drain lines are delicate. Work the brush back and forth, then flush with more warm water.

Sanitize the drain once it's flowing properly. Mix one tablespoon of bleach per gallon of water, pour it down the drain, and let it sit for five minutes. This kills any bacteria or mold that might be growing in the drain line.

Finish with a clean water flush to remove any sanitizer residue. Replace any panels, reinstall the shelving, and plug the unit back in. Check that everything's working normally during the next defrost cycle.

When to Call a Professional

Some imperial frost free commercial freezer problems are beyond DIY fixes, and that's okay. Knowing when to call for help saves time, money, and prevents making problems worse.

Refrigerant leaks require EPA-certified technicians - it's the law. If you see partial frosting on the evaporator coil or the compressor runs but doesn't cool, you likely have a refrigerant issue. Don't attempt this yourself.

Compressor problems are serious business. Short-cycling, failure to start, or internal mechanical noises usually mean compressor trouble. Replacement costs around $1,000, but it's often more economical than buying a new unit.

Control board failures need specialized diagnostic equipment and programming. If your freezer operates erratically, shows display errors, or shuts down completely without obvious cause, the electronic controller might be failing.

Repeated sensor errors affect food safety. Temperature sensors and their wiring can fail, causing inaccurate readings and improper defrost timing.

For immediate guidance on complex issues, consider using Expert troubleshooting chat services. Sometimes a quick consultation can save you from an expensive service call.

Frequently Asked Questions About imperial frost free commercial freezers

Running a busy restaurant kitchen means you'll have questions about your imperial frost free commercial freezer. Here are the answers to the most common concerns we hear from operators every day.

How often should the automatic defrost run?

Your imperial frost free commercial freezer comes factory-set to run 4 defrost cycles per day, with each cycle lasting about 15-20 minutes. Think of it like a scheduled cleaning - it happens automatically whether you're busy or not.

But here's the thing: your kitchen isn't a laboratory. Real-world conditions mean you might need to adjust this timing. High-humidity kitchens (think pizza places with lots of steam) often need more frequent defrost cycles, while drier environments can sometimes get away with fewer cycles.

Door opening frequency makes a huge difference too. If your staff is constantly in and out of the freezer during rush periods, you're letting in warm, moist air that creates more frost buildup. The same goes for loading hot food - always let items cool to room temperature first.

Ambient temperature around the freezer matters as well. Units tucked next to your fryer or grill work harder than those in cooler spots. If you notice ice building up despite the frost-free design, it might be time to increase the defrost frequency.

What temperature range is ideal for frozen food safety?

The FDA doesn't mess around with frozen food safety - they require 0°F or below for all frozen products. But your imperial frost free commercial freezer typically maintains -10°F to 10°F for good reason.

This range gives you a safety buffer for those inevitable moments when someone leaves the door open a bit too long or when you're loading in new inventory. It also ensures better food quality - items stay fresher longer and maintain their texture and flavor.

Health inspectors love consistent temperature logs, so make sure you're checking and recording temperatures daily. Many modern units have built-in data logging that makes this easier, but a simple thermometer check works just fine.

Bacterial growth stops completely at these temperatures, but food quality can still suffer if temperatures fluctuate too much. Consistency is key for both safety and your bottom line.

Can I store non-food items like gel packs or dry ice inside?

This question comes up a lot, especially when operators want to maximize their freezer space. Gel packs are generally fine - they're basically frozen water and won't hurt anything. Just make sure they don't block air vents or crowd your temperature sensors.

Dry ice is a different story entirely. While it won't damage your imperial frost free commercial freezer, it can create some serious safety issues. Dry ice sublimates (turns directly into gas) and can displace oxygen in enclosed spaces - not something you want in a busy kitchen.

The gas can also interfere with your temperature control systems and create pressure buildup that affects how well your unit works. If you absolutely must use dry ice for emergency situations (like during power outages), use about 7-8 pounds per 24-hour period and ensure your kitchen has proper ventilation.

For regular operations, stick to food items and approved gel packs. Your imperial frost free commercial freezer works best when it's doing what it was designed for - keeping your food safely frozen and your kitchen running smoothly.

Conclusion

Your imperial frost free commercial freezer is more than just a box that keeps things cold—it's the guardian of your food investment and your restaurant's reputation. When you follow the troubleshooting steps and maintenance practices we've covered, you're not just fixing problems; you're preventing the kind of disasters that can shut down your kitchen during dinner rush.

Most freezer breakdowns happen at the worst possible times. But with daily visual inspections and monthly condenser cleaning, you can catch problems before they become emergencies. Think of it as insurance that actually pays you back through lower energy bills and extended equipment life.

Temperature issues demand immediate attention—there's no "we'll deal with it tomorrow" when food safety is on the line. A well-maintained imperial frost free commercial freezer keeps your food at the perfect temperature while using less energy to do it.

Professional service might seem like an expense, but it's actually an investment in uptime. When your equipment fails during Saturday night service, you're not just losing the cost of spoiled food—you're losing customers, revenue, and peace of mind.

Proper loading practices and door management might seem like small details, but they're the difference between a freezer that lasts five years and one that serves you faithfully for fifteen. Your equipment works hard for you; treating it right means it'll keep working when you need it most.

At Charbroilers.com, we know how crucial every piece of your kitchen equipment is to your success. While we focus on helping you find the perfect charbroiler, deep fryer, or griddle, we understand that your entire kitchen needs to work as a team. A broken freezer can shut down your operation just as surely as a failed grill.

For more insights on keeping your commercial refrigeration running smoothly, check out our guide on keeping restaurant fridges cool. When all your equipment works together reliably, you can focus on what matters most—serving great food to happy customers.

Stay ahead of problems with your imperial frost free commercial freezer, and it'll reward you with years of dependable service and lower operating costs.