Cool Compliance – Your Guide to NSF ANSI Standard 7 for Refrigerators and Freezers

Share

Keeping Food Safe: The Role of NSF/ANSI 7

When you run a busy kitchen, keeping food safe is your top priority. That's why understanding nsf ansi standard 7 commercial refrigerators and freezers is so important.

Here’s a quick look at what it means:

- What it is: A widely recognized standard for commercial refrigerators and freezers.

- Its goal: To set clear rules for materials, design, build, and performance. This makes sure your equipment protects food and promotes hygiene.

- Why it matters: It stops food from getting contaminated. It also ensures your fridges and freezers hold food at the right temperatures. This keeps your customers safe and helps you meet health regulations.

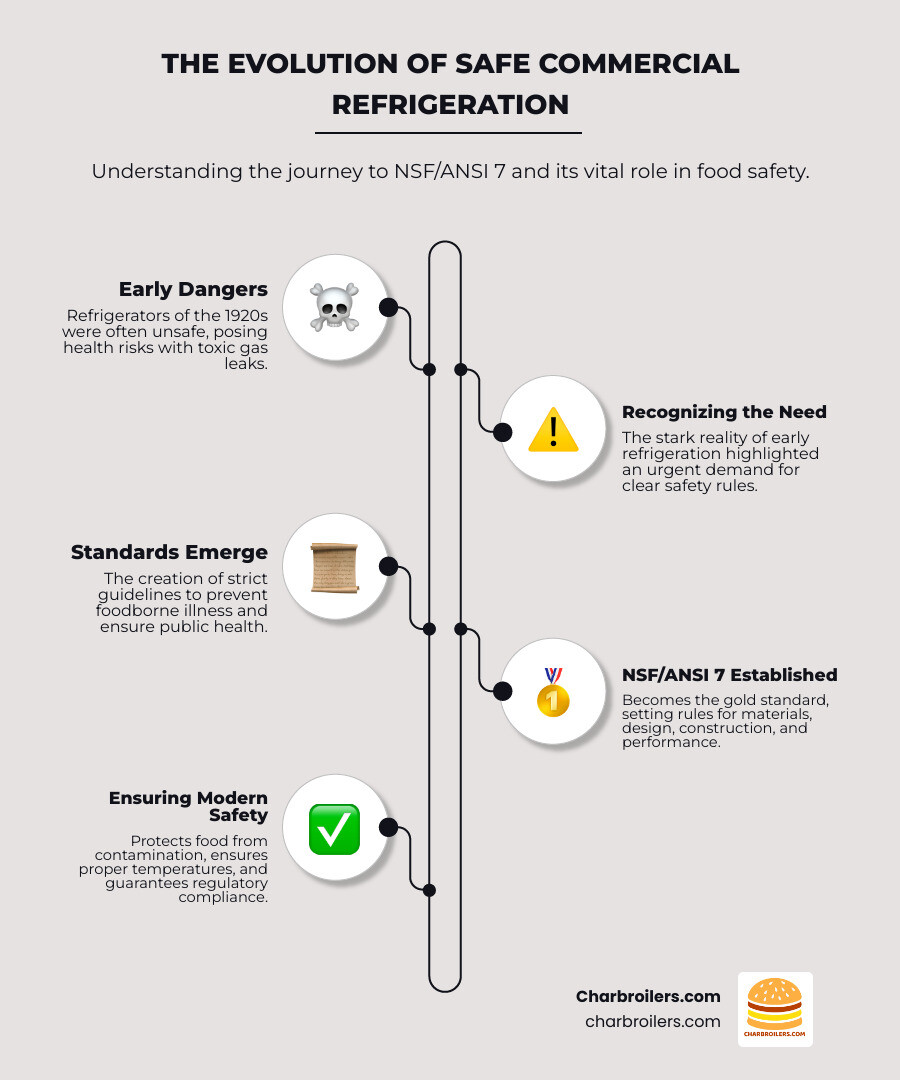

In the demanding world of commercial food service, ensuring food safety is not just a best practice—it's a critical necessity. Imagine a time when refrigeration was far from safe. The refrigerators of the 1920s, for example, could be deadly. Their motors often broke down, letting out toxic gases that harmed families. This stark reality showed the urgent need for clear safety rules.

Over time, this led to the creation of strict guidelines. Today, NSF/ANSI 7 is the gold standard for commercial refrigeration equipment. It protects public health by making sure the tools you use are safe and reliable.

As Sean Kearney from Charbroilers.com, my decade-plus experience in restaurant equipment has shown me the vital importance of nsf ansi standard 7 commercial refrigerators and freezers for busy kitchens. I'm passionate about helping restaurants find the right, compliant equipment for their needs.

Nsf ansi standard 7 commercial refrigerators and freezers terms to learn:

- commercial upright frost free freezer

- small commercial freezer

- frigidaire commercial frost free upright freezer

What is NSF/ANSI 7 and Why is it the Gold Standard?

When you hear us talk about nsf ansi standard 7 commercial refrigerators and freezers, we're really discussing the gold standard for keeping food safe in professional kitchens. It’s not just a fancy name; it's a super important benchmark that makes sure your refrigeration equipment is up to snuff when it comes to food protection and cleanliness. Think of it as a strict set of rules that commercial fridges and freezers must follow to be considered truly safe for handling food.

The main reason this standard exists is pretty straightforward: to protect public health. It does this by setting clear, minimum requirements for everything from the materials used in your equipment to how it's designed, built, and how well it performs. This means that every certified piece of equipment is like a trusty guardian, built specifically to stop food from getting contaminated and to keep it at just the right temperature.

The Critical Importance for Public Health and Your Business

So, why should we care so much about something like nsf ansi standard 7 commercial refrigerators and freezers? Well, ignoring it can lead to some pretty big headaches, or worse! For any commercial kitchen, this certification is absolutely vital for a few key reasons:

First and foremost, it's all about preventing foodborne illness. This standard is expertly designed to drastically reduce the chances of harmful bacteria growing and spreading. By making sure your equipment holds correct temperatures, stops cross-contamination, and is a breeze to clean, it acts as a shield, protecting your customers and, let's be honest, your business's good name.

It also gives you incredible peace of mind by ensuring food safety. When you choose equipment certified by NSF/ANSI 7, you know it's gone through rigorous testing. It’s not just about keeping food chilled; it’s about keeping it genuinely safe to eat.

Then there's the big one: regulatory compliance. The food service world has a lot of rules, and health inspectors are always on the lookout for NSF certification. It’s a clear sign that your equipment meets all those crucial public health standards. Using certified gear helps you sail through health inspections, avoiding costly fines or having to shut down operations. Nobody wants that!

This standard also plays a huge role in building customer trust. Today's diners are more clued-in about food safety than ever before. When they see you're using NSF-certified equipment, it sends a powerful message: "We care about your health, and we prove it by using top-tier, safe equipment." That trust is invaluable.

Lastly, it can give you a real competitive advantage. Beyond just ticking boxes for compliance, having NSF/ANSI 7 certified equipment shows everyone—from potential clients to your loyal customers—that you're dedicated to the highest operational standards in the industry. It sets you apart from the crowd.

Understanding the Key Players: NSF and ANSI

To truly get how important nsf ansi standard 7 commercial refrigerators and freezers is, let's meet the two powerhouse organizations behind it: NSF International and the American National Standards Institute (ANSI). They're like the dynamic duo of safety standards!

NSF International actually started way back in 1944. It began as the National Sanitation Foundation, aiming to standardize sanitation and food safety here in the U.S. Fast forward to today, and it's a global leader in public health and safety. NSF International is a "third-party" certifier. This means they're totally independent, verifying that products meet health, environmental, and safety standards through tough testing, material checks, surprise inspections, and regular re-testing. They've helped create over 75 standards for sanitary food equipment and have certified thousands of products. You can dive deeper into their work right here: NSF Food Equipment Standards.

Then there's the American National Standards Institute (ANSI), founded in 1918. ANSI is a non-profit group that coordinates voluntary business standards across the U.S. Now, here’s the cool part: ANSI doesn't write the standards themselves. Instead, they make sure organizations like NSF International follow super rigorous rules when developing standards. When you see "NSF/ANSI" together, it means NSF International developed the standard, and ANSI gave it their stamp of approval. This shows it meets ANSI’s strict requirements for being open, balanced, consensual, and fair. This partnership ensures that the standard is incredibly solid, widely accepted, and truly represents the best practices in the industry.

Together, NSF International and ANSI make sure that nsf ansi standard 7 commercial refrigerators and freezers is a trusted, globally recognized symbol of excellence for commercial food equipment. It’s their collaboration that makes it the gold standard we rely on.

A Deep Dive into the Requirements of NSF ANSI Standard 7 Commercial Refrigerators and Freezers

The nsf ansi standard 7 commercial refrigerators and freezers is comprehensive, covering everything from the materials used to the equipment's overall performance. It's structured to address the specific needs of different refrigeration unit types, ensuring that each piece of equipment is fit for its intended purpose in a commercial kitchen.

The standard's structure is typically organized by the type of refrigeration unit being evaluated, with specific sections dedicated to various equipment categories. This means that while there are overarching principles, the detailed requirements can vary significantly based on the equipment's design and its intended use. For instance, a display refrigerator will have different requirements than a walk-in freezer, especially concerning visibility and access.

One crucial aspect is how the standard differentiates requirements based on the type of food stored. Equipment designed for packaged products (like bottled beverages or pre-wrapped sandwiches) will have less stringent interior requirements compared to units intended for unpackaged or raw foods. Similarly, equipment handling Time/Temperature Control for Safety (TCS) foods – those requiring strict temperature control to prevent bacterial growth – will face more rigorous performance testing than units storing non-TCS foods (where temperature is for quality, not safety, like a beverage cooler).

Equipment Covered by the Standard

The scope of nsf ansi standard 7 commercial refrigerators and freezers is broad, encompassing a wide range of commercial refrigeration equipment essential for food service operations. This includes:

- Storage Refrigerators: Such as reach-in, under-counter, walk-in, and roll-in units. These are the workhorses of any kitchen, designed for bulk storage. If you're curious about walk-ins, we have an essential guide for you: Keeping It Cool Your Essential Guide To Restaurant Walk In Fridges.

- Storage Freezers: Similar to refrigerators, these include reach-in, under-counter, walk-in, and roll-in freezers, designed to maintain freezing temperatures for long-term food preservation.

- Rapid Pull-down Units: These are specialized refrigerators and freezers designed to quickly reduce the temperature of hot foods to safe cold-holding temperatures.

- Refrigerated Food Transport Cabinets: Equipment used to safely transport cold food from one location to another while maintaining temperature.

- Refrigerated Buffet Units: Units designed to hold and display cold food items on a buffet line, ensuring they remain at safe temperatures for serving.

- Refrigerated Food Preparation Units: Often seen as prep tables, these units include refrigerated compartments and work surfaces for food preparation, keeping ingredients cold.

- Display Refrigerators: Designed to showcase cold food items to customers, such as deli cases or grab-and-go units.

- Beverage Coolers: Units specifically for chilling and displaying beverages.

- Ice Cream Cabinets: Specialized freezers for storing and dispensing ice cream.

Material and Construction Requirements

One of the cornerstones of nsf ansi standard 7 commercial refrigerators and freezers is its stringent requirements for materials and construction. This isn't just about aesthetics; it's about ensuring hygiene and durability in demanding commercial environments.

- Food Zones and Non-Food Zones: The standard clearly defines "food zones" (surfaces that food directly touches) and "non-food zones." Materials in food zones must meet the highest standards of safety and sanitation.

- Smooth and Easily Cleanable Surfaces: All surfaces, especially those in food zones or splash zones, must be smooth, non-absorbent, and easily cleanable. This means no crevices where food particles or bacteria can hide. Internal angles or corners within a food zone, for example, must have a minimum continuous radius of 1/4 inch to prevent dirt accumulation and facilitate cleaning.

- Corrosion-Resistant and Non-Toxic Materials: Equipment must be constructed from materials that resist corrosion from food, cleaning compounds, sanitizers, and refrigerants. If a material is in a food zone, it must also be non-toxic and not impart any undesirable odors, tastes, or colors to food. Often, materials must comply with NSF/ANSI 51, which sets requirements for food equipment materials.

- Durable Construction: The equipment must be robust enough to withstand the rigors of a commercial kitchen, including frequent cleaning and heavy use.

- Sealed Joints and Coved Corners: Permanent joints and seams in food or splash zones must be sealed and smooth. This prevents moisture ingress and bacterial growth.

- Vermin Prevention: The design and construction must prevent the harborage of vermin (like insects or rodents) and the accumulation of dirt, debris, and moisture. This includes proper sealing of components and accessibility for maintenance.

Performance and Temperature Mandates

Beyond materials and construction, nsf ansi standard 7 commercial refrigerators and freezers sets clear performance benchmarks, particularly concerning temperature holding and recovery. Maintaining precise temperatures is paramount for food safety.

-

Temperature Holding:

- Storage Coolers: Must maintain an air temperature of 40°F (4°C) or lower.

- Storage Freezers: Must maintain an air temperature of 0°F (-18°C) or lower.

- Rapid Pull-down Units: These specialized units have a critical performance requirement: they must be capable of reducing the internal temperature of contents from 135°F (57°C) to 40°F (4°C) within 4 hours. This rapid cooling is essential for safely cooling hot foods.

-

Display Refrigerators: These units have unique requirements, especially those with automatic lockout features.

- They must restore the air temperature in their food storage compartment to 41°F (5°C) or below within 30 minutes after the door has been open for 15 minutes.

- The automatic door lock must activate if the air temperature in the food storage compartment exceeds 41°F (5°C) for more than 30 minutes (excluding the initial filling/servicing period).

- Temperature-Indicating Devices: Each refrigerated storage compartment must have at least one temperature-indicating device (like a thermometer). This device must be accurate to ±2°F (±1°C) to allow for precise monitoring of internal temperatures.

These performance standards are vital. They ensure that your equipment isn't just a cold box, but a reliable tool for preserving food quality and safety.

Staying Compliant: Recent Updates and Verifying Certification

Just like your favorite recipes get updated over time to make them even better, industry standards aren't static. They evolve to meet new challenges, accept clever new technologies, and, most importantly, keep us all safer! The nsf ansi standard 7 commercial refrigerators and freezers is a fantastic example of this continuous improvement. Staying in the know about these updates is a smart move for everyone involved, from the folks who build these machines to those of us who rely on them every day in busy kitchens.

The latest big update was to the 2023 edition, and it truly shows the commitment to always making food safety practices better. For manufacturers, it means designing and building even more compliant equipment. For us, the buyers, it helps us make super informed choices, knowing that the equipment we invest in meets the very latest safety benchmarks.

Key Changes in the Latest nsf ansi standard 7 commercial refrigerators and freezers

The 2023 edition brings some important refinements, building on significant previous updates like the one in 2016 (which became effective in late 2019). A big area of focus has been on display refrigerators, especially those clever units that feature automatic lockout features.

Here's a peek at some of the key improvements:

- If you've got a display refrigerator with an automatic lockout feature, the new standard says it must have an automatic door lock and self-closing door(s). This lock should only be disengaged by an operator or service person, adding an extra layer of security.

- They've also beefed up the temperature recovery tests. These units now need to prove they can bring their internal air temperature back down to 41°F (5°C) or below within just 30 minutes, even after the door has been held open for a full 15 minutes! This simulates those busy moments in a real-world kitchen.

- That helpful automatic lockout feature? It now has clear rules for when it activates. It should kick in if the air temperature inside the food storage compartment goes above 41°F (5°C) for more than 30 minutes (don't worry, there are exceptions for when you're first loading it up!).

- You'll also see updated labeling requirements. Equipment with these cool features will now have specific labels, like "Evaluated and tested for automatic lockout per NSF/ANSI Standard 7." This makes it super clear what you're getting.

- There were also helpful clarifications for coatings used in prefabricated walk-in and roll-in refrigerators and freezers, especially when it comes to galvanized and zinc-alloy-coated materials for floors.

These updates aren't just technical jargon; they show how the standard is always adapting to real-life kitchen needs and new technologies, all with the goal of making food safety even stronger.

How to Verify NSF Certification

So, you're excited to invest in nsf ansi standard 7 commercial refrigerators and freezers for your kitchen. That's fantastic! But how can you be absolutely sure that a product truly is certified? It's actually easier than you might think, and it's a vital step to protect your business and your customers.

First, the simplest way is to look for the NSF mark. This distinctive certification mark is like a badge of honor, typically found on a data plate or label attached right to the equipment itself. It's their seal of approval!

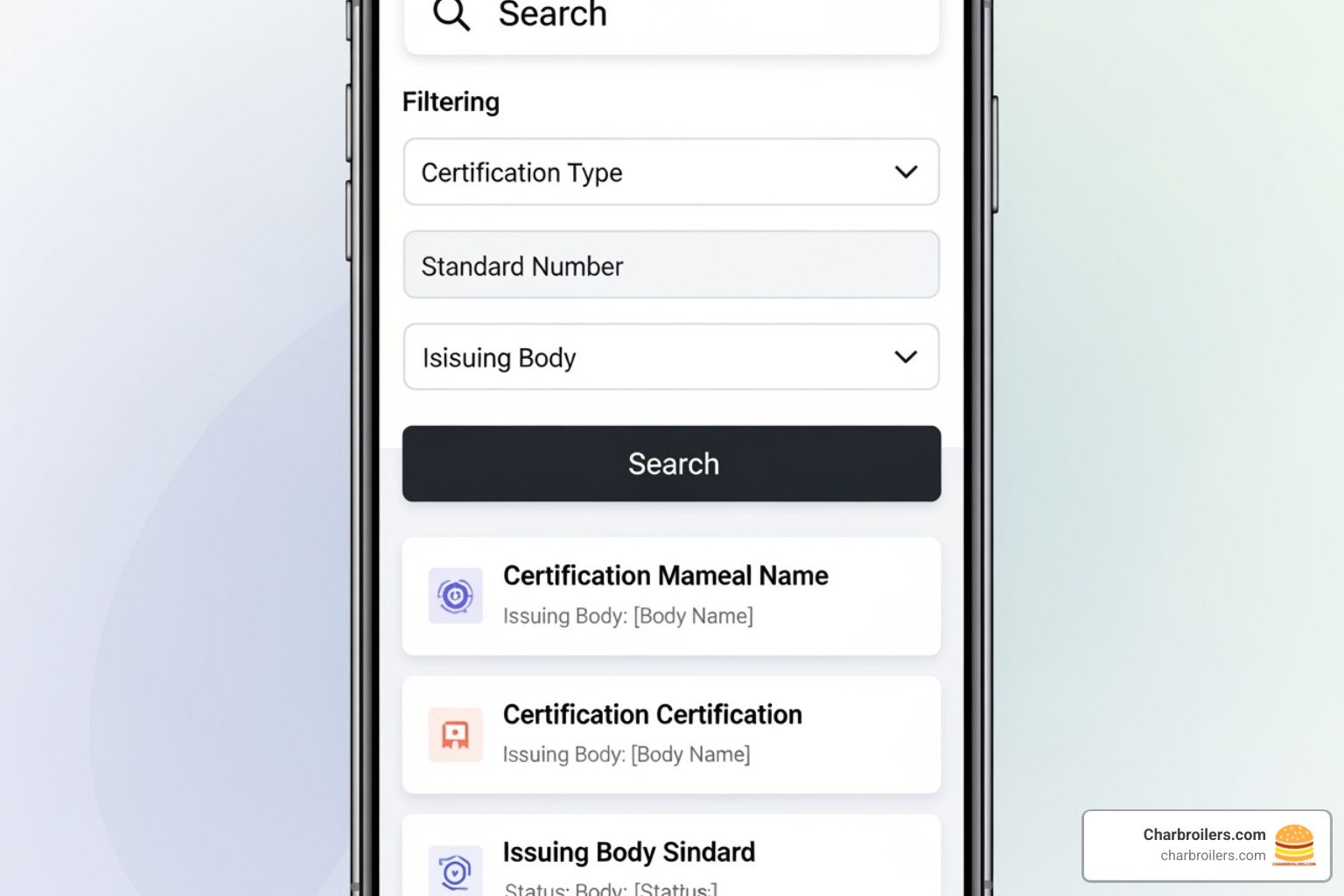

For definitive verification, though, we can go straight to the source: NSF International's official online database. This is the most reliable way to confirm a product's certification status and gain total peace of mind.

- Just pop over to the official NSF search portal: Search for NSF Certified Food Equipment.

- Once there, you can easily search by the manufacturer's name, the model number, the product type, or even by the specific standard itself (like NSF/ANSI 7). This tool is incredibly handy for making sure what you're buying is the real deal, authenticated and compliant.

By taking these straightforward steps, we ensure that the equipment we bring into our kitchens isn't just claiming to be compliant, but truly is, backed by the rigorous testing and trusted certification of NSF International. It's all about making sure your kitchen is as safe and efficient as possible!

Frequently Asked Questions about the NSF/ANSI 7 Standard

We know that diving into industry standards can sometimes feel like trying to solve a puzzle. There are lots of acronyms and specific terms! To help clear things up about nsf ansi standard 7 commercial refrigerators and freezers, we've gathered some of the questions we hear most often. Think of us as your friendly guides through food safety standards.

What is the difference between NSF/ANSI 7 and other food equipment standards like NSF/ANSI 2?

That's a fantastic question, and one that often causes a little head-scratching! Think of it like this: different standards have different specialties, much like different tools in a toolbox.

NSF/ANSI 7: Commercial Refrigerators and Freezers is the specialist when it comes to keeping things cold and safe. This standard focuses entirely on refrigeration equipment. It lays out the strict rules for the materials, design, how it's built, and how well commercial refrigerators and freezers perform. It's all about making sure your chillers and freezers protect food and promote good hygiene.

Then there's NSF/ANSI 2: Food Equipment. This is more of a generalist standard. It covers a much wider range of food handling and processing equipment. This includes things like your bakery units, cafeteria setups, kitchen work tables, counters, hoods, shelves, and even sinks. It sets the basic rules for how these items should be designed and constructed to be safe and sanitary.

Now, sometimes these standards work together! For instance, a refrigerator (which falls under NSF/ANSI 7) might also need to use materials that meet NSF/ANSI 51: Food Equipment Materials. This specific standard ensures that any material that touches food is safe, non-toxic, and won't mess with the food's taste or quality. So, while NSF/ANSI 7 focuses on the whole refrigerator, other standards like NSF/ANSI 51 make sure the individual parts are up to snuff. It's a team effort for food safety!

Does NSF/ANSI 7 certification cover the installation of the equipment?

Nope, that's a common misconception! The nsf ansi standard 7 commercial refrigerators and freezers is all about the equipment itself. It makes sure that the refrigerator or freezer is designed, built, and performs safely and hygienically when it leaves the factory.

However, the standard doesn't tell you how to install it in your kitchen. That part is usually handled by other important rules. Things like local building codes, your health department's regulations, and the specific instructions from the equipment manufacturer dictate how your new fridge or freezer should be installed. They'll cover things like proper ventilation, electrical connections, and placement to keep your kitchen safe and running smoothly. So, while the equipment arrives certified, proper installation is still key!

Are there different requirements within nsf ansi standard 7 commercial refrigerators and freezers for units holding packaged vs. open food?

Yes, absolutely! The nsf ansi standard 7 commercial refrigerators and freezers is quite smart about adapting its rules based on how risky the food storage is. It’s all about putting the strictest measures where they're needed most.

For units holding only packaged food, like bottled drinks, canned goods, or individually wrapped sandwiches, the internal requirements are a bit more relaxed. Since the food isn't directly exposed to the equipment's surfaces, there's less risk of direct contamination. The main goal here is to make sure the unit keeps the right temperature and is generally clean.

However, for units that will store or display open food – think fresh deli meats, produce, or prepared salads – the requirements become much, much stricter. Every single surface that could touch food, or where even a tiny crumb could hide, must be super easy to clean. They also must be made of materials that are completely food-safe, non-toxic, and won't corrode. This strictness is vital to prevent any direct contamination of the food itself. It’s a practical approach to keeping everyone safe!

Conclusion: A Foundation for a Safer Kitchen

Wow, we've covered a lot of ground today! From the curious and sometimes dangerous history of early refrigeration to the rigorous demands of modern food safety, it's clear that the journey to a safer kitchen has been a long one. And at the heart of that safety, especially when it comes to keeping your ingredients perfectly chilled, lies the nsf ansi standard 7 commercial refrigerators and freezers.

This isn't just another standard; it's a critical cornerstone for any successful commercial kitchen. It's the blueprint that ensures your refrigeration equipment is built to last, easy to clean, and most importantly, capable of keeping your food safe from harmful bacteria. Choosing nsf ansi standard 7 commercial refrigerators and freezers isn't just about ticking a box for a health inspector; it's a real investment in your business's reputation, your customers' well-being, and your own peace of mind.

At Charbroilers.com, we understand that every piece of equipment in your kitchen plays a vital role in its overall success and safety. While our passion might be helping you find the perfect charbroilers, deep fryers, and griddles for your delicious creations, we're equally committed to providing you with the knowledge and resources you need to run a top-notch operation. That includes helping you steer important industry standards like NSF/ANSI 7, ensuring you're always making informed decisions for your business.

Because when you're confident in your equipment, you're free to focus on what you do best: crafting amazing food and creating memorable experiences. For more insights into keeping your kitchen running smoothly and safely, be sure to check out our guide on Commercial Refrigeration Equipment Explained No Sweat. After all, cool compliance truly leads to a safer, more successful kitchen!