When Your Fridge Fails: A How-To for Commercial Refrigerator Repair

Share

Why Commercial Refrigerator Repair Can't Wait

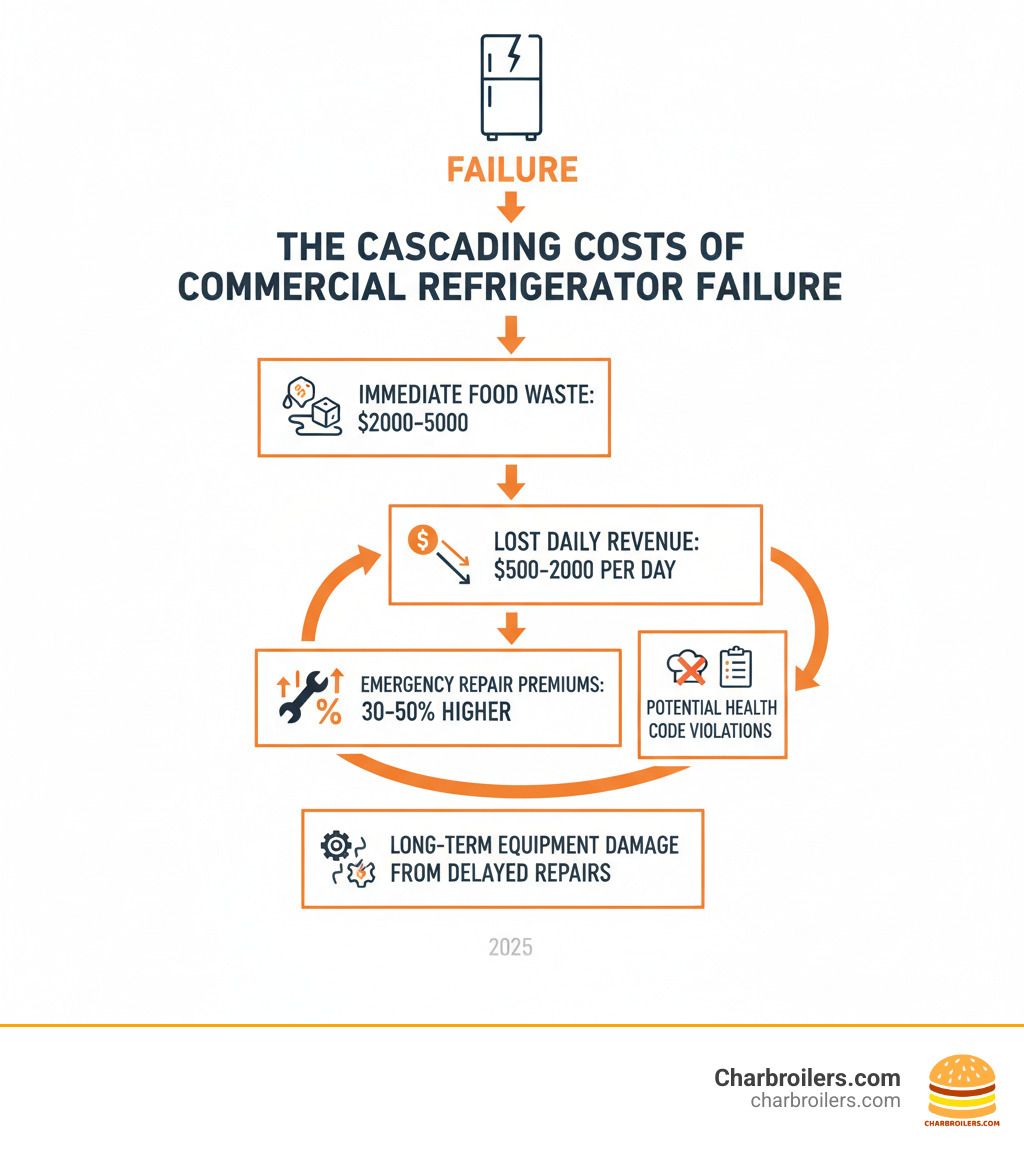

Commercial refrigerator repair is essential for addressing equipment failures that threaten your business. A broken refrigeration system requires immediate solutions to prevent inventory loss, lost revenue, and health code violations. With thousands of dollars of inventory at risk, downtime can devastate a restaurant's bottom line.

Quick Action Guide for Refrigerator Failures:

- Emergency Response: Immediately call a certified refrigeration technician for 24/7 service.

- Initial Assessment: While waiting, check power connections, door seals, and temperature settings.

- Food Safety: Move perishable inventory to backup cooling within 4 hours (per USDA guidelines).

- Service Call Costs: Expect $145-$180 plus tax for an initial diagnosis in most markets.

- Warranty Protection: Look for at least a 1-year parts and labor warranty on all repair work.

Unlike home units, commercial systems run 24/7 under heavy loads, making them prone to wear. This guide covers recognizing warning signs, understanding common failures, navigating the repair process, and preventing future breakdowns through proper maintenance.

I'm Sean Kearney from Charbroilers.com. With over a decade in the restaurant equipment industry, I've seen how critical prompt *commercial refrigerator repair is. Knowing your equipment and when to act can save thousands in lost inventory and emergency repair costs.*

Know your commercial refrigerator repair terms:

Recognizing the Red Flags: Signs Your Unit Needs Attention

Ignoring the warning signs from your commercial refrigerator can turn a minor fix into a costly disaster. Be alert for these red flags, as they are your equipment's way of asking for help before you face spoiled inventory and health code violations.

Key Warning Signs

Pay attention to any changes in your unit's performance, as different symptoms point to specific problems. Catching them early can save you from major commercial refrigerator repair.

- Temperature Fluctuations: If your cooler can't hold a steady temperature or has warm spots, your food is in the danger zone. Inconsistent cooling is a clear sign of trouble.

- Unusual Noises: While commercial units are noisy, new or louder sounds require attention. Clicking often indicates a struggling compressor relay, while grinding or squealing suggests a failing fan motor. A loud hum can point to a vibrating or overworked compressor.

- Constant Cycling or Running: A motor that runs constantly without cycling off is working itself to death and wasting electricity. Conversely, a compressor that cycles on and off too frequently (short-cycling) may indicate dirty coils or low refrigerant.

- Water Leaks or Puddles: Moisture pooling inside the unit or on the floor is never normal. It usually points to a blocked drain line or a damaged component.

- Excessive Frost or Ice Buildup: Frost on evaporator coils or ice in the fresh food compartment indicates a problem with the defrost system or failing door seals.

- Damaged Door Seals: Gaps or cracks in door gaskets let cold air escape, forcing your unit to work overtime. This leads to higher energy bills and component strain.

- Food Spoiling Prematurely: If produce wilts or dairy spoils before its expiration date, your refrigerator is not maintaining a safe temperature. This is a direct hit to your bottom line and a risk to customers.

Trust your instincts. If something seems off, it probably is. For more on how different refrigeration types have unique needs, see our guide on different fridge types.

Common Culprits: What Breaks and Why

When a commercial refrigerator fails, it's usually one of several key components giving out. Understanding what breaks and why helps you identify issues and make informed decisions about commercial refrigerator repair.

Your refrigeration system relies on several parts working together: the compressor (the heart), condenser and evaporator coils (heat exchange), fans (air circulation), the thermostat (the brain), and door gaskets (the seal). When one fails, the whole system suffers. Learn more in our refrigeration equipment guide.

The Most Frequently Repaired Parts

Certain components bear the brunt of 24/7 operation and are common points of failure.

- Compressor: This is the most critical and expensive component. Failure means the unit stops cooling entirely. It can be caused by electrical issues, overheating, or age.

- Condenser Coils: When covered in dust and grease, these coils can't release heat. This forces the compressor to overwork, leading to higher energy bills and eventual breakdown.

- Evaporator Fan Motor: A failed fan motor stops circulating cold air, causing uneven temperatures and frost buildup.

- Thermostat: A malfunctioning thermostat leads to erratic temperature control, causing food to freeze or the unit to run endlessly.

- Door Gaskets: Worn, cracked, or dirty gaskets allow warm air to enter, forcing the system to run constantly and increasing energy costs.

Why Components Fail

Most equipment failures are preventable and stem from a few key causes.

- Wear and Tear: Constant, 24/7 operation puts immense stress on all motors, fans, and seals.

- Poor Maintenance: Neglecting basic upkeep like cleaning coils and checking seals is the leading cause of premature failure. Clogged drain lines, dirty fans, and grimy gaskets all lead to expensive emergencies.

- Electrical Issues: Power surges or faulty wiring can instantly damage motors and control boards.

- Blocked Airflow: Stacking boxes against vents or placing the unit too close to a wall restricts air circulation, causing components to overheat and fail.

The Repair Process: A Guide to Commercial Refrigerator Repair

Knowing what to expect from a service call can reduce stress when your refrigerator fails. Here’s a walkthrough of the commercial refrigerator repair process.

Preparing for a Service Call

To speed up the repair, prepare before the technician arrives. Empty the unit to provide safe access and protect your inventory. Have the unit's make, model, and serial number ready. Also, note any symptoms you've observed (e.g., strange noises, temperature issues) and have any warranty or service records on hand.

Finding a Qualified Technician

Commercial refrigeration requires specialized knowledge. You need a technician who is certified and insured, with specific experience in commercial systems. Look for professionals with credentials for safely handling refrigerants (like EPA Section 608 certification in the US). Check online reviews and ask for recommendations from other business owners. A reputable technician will offer a warranty on their work. Our guide on local cooling experts can help.

Diagnosis and Repair vs. Replace

The technician will perform a thorough inspection, checking everything from power connections to refrigerant pressure. They will explain their findings and provide an estimate for the repair. Based on the diagnosis, you'll face the repair vs. replace decision. Consider the age of the unit (most last 10-15 years), the cost of the repair, and its service history. If a major repair is needed on an older unit, replacement might be the smarter long-term investment. Charbroilers.com offers a wide selection of new equipment.

Always ask about the warranty on parts and labor before work begins. A minimum one-year warranty is standard for reputable companies. Get the terms in writing. For more tips, see the ultimate repair service checklist.

The Importance of Prompt Repair

Delaying repairs costs money. Prompt action is critical for:

- Minimizing Downtime: Every hour of downtime is an hour of lost revenue.

- Preventing Food Loss: Perishables left above 40°F for over four hours must be discarded, leading to thousands in losses.

- Avoiding Costlier Repairs: A small leak today can become a seized compressor tomorrow. Prompt repairs are almost always cheaper.

- Health Code Compliance: A malfunctioning unit risks violations, fines, or closure. Learn more about NSF/ANSI Standard 7.

Typical Repair Costs

- Service Call Fee: Expect to pay $145-$180 plus tax for the initial diagnosis, which is often credited toward the final repair cost.

- Labor Rates: Charged hourly and vary by region.

- Parts Costs: These vary widely. A door gasket may be $50-$150, while a compressor can cost $1,500-$3,000 plus labor.

Factors like unit type, part availability, and emergency service needs will influence the final price. For major repairs, we offer flexible payment options. If considering a new unit, consult our guide to commercial refrigerator costs.

Commercial vs. Residential Repair

Commercial repair is not a job for a residential technician. The differences are significant:

- System Complexity: Commercial units are larger, more powerful, and use industrial-grade components designed for continuous, heavy use.

- Technician Qualifications: Commercial techs require specialized training and certifications to handle complex systems and commercial-grade refrigerants.

- Urgency and Impact: A commercial breakdown means immediate financial loss and business disruption, demanding a rapid and efficient response.

Prevention Is Better Than Cure: Maintenance Best Practices

Fixing a broken refrigerator is always more expensive and stressful than preventative maintenance. A regular maintenance schedule optimizes performance, reduces energy bills, and extends your equipment's lifespan, saving you from emergency commercial refrigerator repair calls.

Professional service is recommended at least twice a year, with your staff performing weekly checks. A structured program prevents breakdowns and lowers utility bills. For specific tips, see our guide to walk-in fridge maintenance.

DIY Maintenance Checklist

Incorporate these simple tasks into your weekly routine to prevent common problems:

- Clean Condenser Coils: Monthly, use a brush or vacuum to clean the coils. Dirty coils are a primary cause of compressor failure.

- Inspect Door Seals: Check weekly for cracks or stiffness. Clean them with mild soap and water. Use the dollar bill test: if you can pull a bill out of a closed door easily, the seal needs replacing.

- Verify Temperature: Use an independent thermometer to ensure your fridge is below 40°F (4°C) and your freezer is at 0°F (-18°C).

- Clear Drain Lines: Check and flush drain lines monthly to prevent water leaks and ice buildup.

- Ensure Proper Ventilation: Keep at least three inches of clearance around the unit and never block vents.

When to Schedule Professional Maintenance

Schedule professional inspections twice a year for tasks that require specialized tools and expertise:

- Refrigerant Level Checks: Only licensed technicians can safely check for leaks and handle refrigerants.

- Electrical Component Testing: Professionals can identify failing motors, relays, and capacitors before they break down completely.

- Comprehensive System Diagnostics: A technician will perform a deep clean of hard-to-reach coils, test the defrost system, and ensure all components are working together efficiently.

Frequently Asked Questions about Commercial Refrigeration

Here are straight answers to the most common questions we receive about commercial refrigerator repair.

What are the risks of not repairing a malfunctioning commercial refrigerator promptly?

Delaying repairs is a gamble with your business. The risks are significant and include:

- Financial Loss: Thousands of dollars in spoiled inventory and lost revenue.

- Food Safety Risks: Temperature fluctuations can lead to bacterial growth and foodborne illness, damaging your reputation.

- Complete Equipment Failure: A minor issue, like a failing fan, can cascade into a major one, like a seized compressor, turning a small repair into a full replacement.

- Higher Energy Bills: A struggling unit consumes far more electricity.

- Health Code Violations: Failing to maintain safe temperatures can lead to fines or even closure.

What qualifications should a commercial refrigerator repair technician have?

Don't hire a residential appliance technician for a commercial job. Look for a professional with:

- Certification and Insurance: This protects you and ensures they have proven knowledge.

- Commercial Systems Experience: You need someone who specializes in the complex, heavy-duty equipment used in food service.

- Refrigerant Handling Certification: In the US, this is typically an EPA Section 608 certification, which is required to handle refrigerants legally and safely.

- Good Reputation and Warranties: Check reviews and ensure they offer at least a one-year warranty on parts and labor. Our guide to finding local cooling experts can help.

How do door seals affect performance and energy efficiency?

Damaged door gaskets are a top cause of refrigeration problems. When seals fail, they allow warm air to leak in, forcing the system into a constant battle to stay cool. This leads to:

- Increased Energy Consumption: Your compressor runs overtime, driving up your electricity bill.

- Component Strain: The extra workload shortens the lifespan of your compressor and other critical parts.

- Temperature Instability: Inconsistent temperatures lead to faster food spoilage.

- Frost Buildup: Moisture from incoming air freezes on the evaporator coils, blocking airflow and reducing efficiency.

Regularly cleaning your seals and using the dollar bill test (if you can pull a bill from a closed door, the seal is weak) is one of the most effective and low-cost maintenance tasks you can perform.

Conclusion

Your commercial refrigerator is the heart of your kitchen. As we've covered, ignoring warning signs like strange noises or temperature swings can lead to spoiled inventory, lost revenue, and costly emergency repairs. The key takeaway is that prompt commercial refrigerator repair is not an expense—it's an investment in your business's continuity.

Prevention is your best strategy. A consistent maintenance routine, combining daily staff checks with semi-annual professional inspections, is the most effective way to ensure reliability and efficiency. By cleaning coils, checking seals, and ensuring proper ventilation, you can prevent most common failures.

When a major repair is needed or your unit reaches the end of its life, replacement may be the most cost-effective solution. Charbroilers.com offers a wide range of new commercial kitchen equipment, including refrigeration units, to meet the demands of any food service operation. We also provide financing options to help you invest in the equipment your business needs to thrive. Explore our guides, like this one on commercial kitchen equipment, to find the right solutions for your kitchen.