The Ultimate Checklist for Commercial Refrigerator Repair Services

Share

Why Commercial Refrigeration Repair Can Make or Break Your Business

Commercial refrigeration repair is critical for any food service business. Equipment failure can cost between $1,000 to $5,000 per day in lost product and revenue, not to mention the risk of health code violations and angry customers. A failed walk-in cooler is more than an inconvenience; it's a financial crisis.

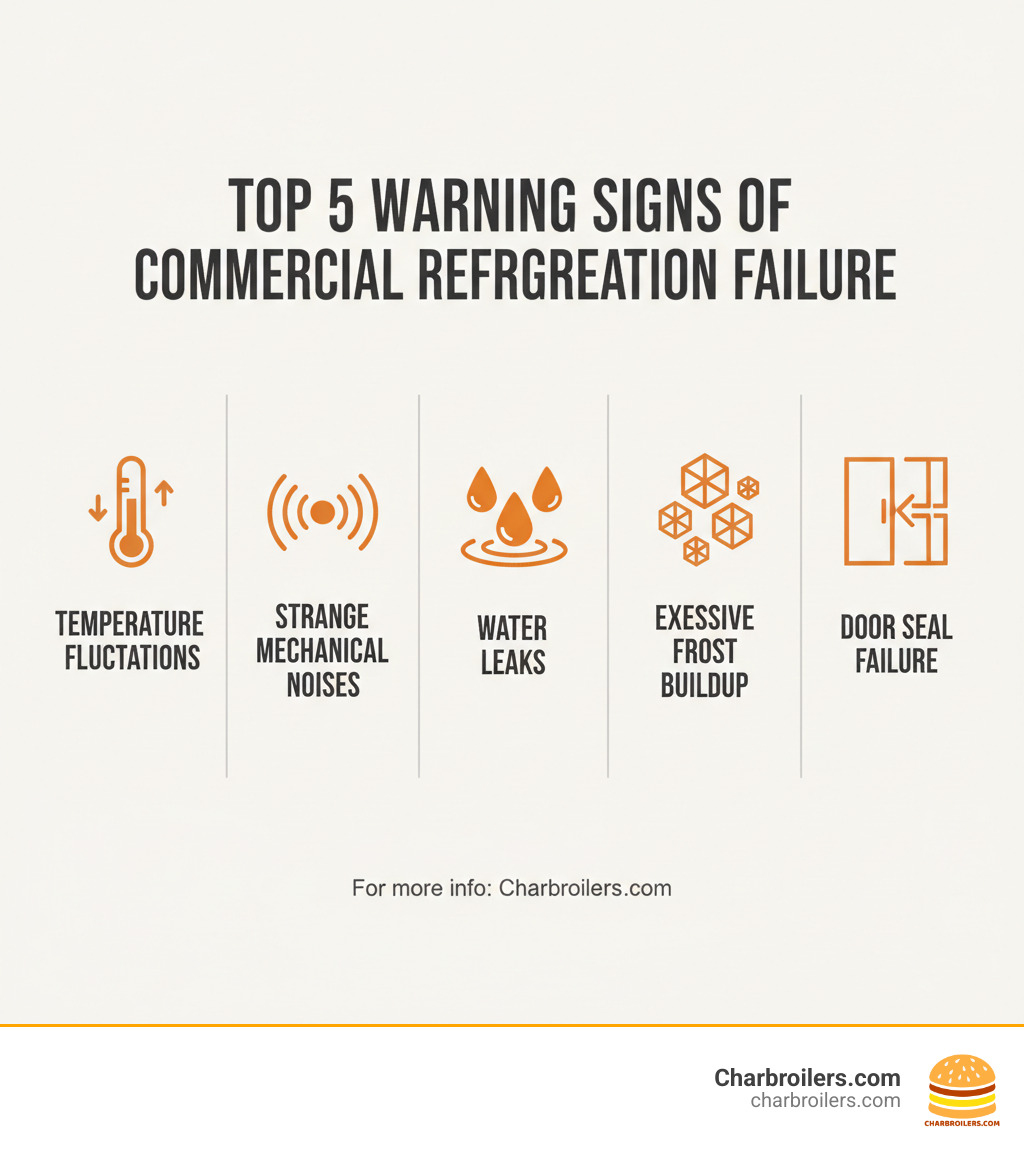

Key signs you need commercial refrigeration repair immediately:

- Temperature fluctuations - Food not staying at safe temperatures

- Strange noises - Grinding, clicking, or loud humming sounds

- Water leaks - Pooling around the unit or inside compartments

- Excessive frost buildup - Ice forming where it shouldn't

- Door seal problems - Gaskets not creating a tight seal

- Rising energy bills - System working harder than normal

With an estimated 70% of food spoilage attributed to refrigeration failures, the stakes are high. Fortunately, regular maintenance can reduce the likelihood of breakdowns by up to 80%, and proper repairs can extend your equipment's lifespan by up to 30%.

This guide will walk you through everything you need to know about commercial refrigeration repair—from spotting warning signs to choosing the right service and minimizing downtime.

I'm Sean Kearney from Charbroilers.com. With over a decade in the restaurant equipment industry, I've seen how refrigeration issues can devastate unprepared businesses. My experience has taught me that prevention and quick action are your best defenses against costly breakdowns.

Is Your Cooler in Crisis? Recognizing the Warning Signs

When your refrigeration system shows signs of trouble, it's crying out for help. These warning signs are urgent signals that your business could be heading toward a costly disaster. Catching these red flags early can save you thousands of dollars and prevent the loss of an entire day's worth of inventory.

Temperature fluctuations are a major red flag. When your cooler can't hold its set temperature, you risk food spoilage and health code violations. This could be due to erratic cycling or defrosting issues.

Strange noises like grinding, clicking, or unusually loud humming are alarm bells. A healthy refrigerator should have a consistent, quiet hum. These sounds often point to failing compressors or struggling fan motors.

Water leaks or pooling around your unit signal improper drainage. This could mean clogged drain lines or failing evaporator coils, forcing your system to work overtime to remove excess humidity.

Excessive frost or ice buildup chokes your system's efficiency. Thick ice on coils or walls acts like an insulator, preventing proper heat transfer and forcing your compressor to work much harder.

Door seal failure is a sneaky problem. When gaskets crack or tear, cold air escapes and warm air rushes in, driving up energy bills and compromising food safety. Your unit will run constantly to compensate.

Increased energy bills are often an early warning sign. If your utility costs are climbing, your refrigeration system may be the culprit, as struggling components consume more electricity for worse performance.

An estimated 70% of food spoilage stems from refrigeration failures. This is often preventable with attention to these warning signs. For restaurants with walk-in units, our guide Keeping It Cool: Your Essential Guide to Restaurant Walk-In Fridges offers deeper insights.

Common Types of Commercial Refrigeration Systems

Understanding your equipment helps you spot problems faster. Commercial refrigeration repair needs vary depending on the system.

- Walk-in coolers and freezers are the workhorses of the food service industry, handling massive inventory loads.

- Reach-in units are upright refrigerators and freezers that keep frequently used ingredients accessible. Door seals and temperature recovery are critical.

- Display cases must keep products cold while looking appealing, balancing refrigeration with customer visibility.

- Undercounter refrigerators maximize space in cramped kitchens, making proper ventilation crucial.

Businesses from restaurants and grocery stores to hospitals and breweries rely on these systems and cannot afford downtime. For a comprehensive look, check out our guide: Commercial Refrigeration Equipment Explained: No Sweat.

The High Cost of Neglect

Ignoring warning signs is expensive. The cascading costs of refrigeration failure can turn a manageable repair into a business-threatening crisis.

- Product loss is immediate. Spoiled meat, dairy, and produce mean lost food cost, prep labor, and potential profit.

- Lost revenue from downtime can be devastating. Data shows that emergencies can cost businesses $1,000 to $5,000 per day.

- Health code violations can result in fines, closures, and severe damage to your reputation.

- Equipment damage from neglect often creates a domino effect. A small, cheap fix can escalate into a multi-thousand-dollar compressor replacement.

Proactive maintenance and prompt commercial refrigeration repair are essential insurance policies for your operation's survival.

The Proactive Approach: Why Preventative Maintenance is Key

Instead of scrambling for an emergency repair at 2 AM, imagine your equipment humming along perfectly. That's the power of preventative maintenance—turning potential disasters into manageable check-ups.

The numbers don't lie. Regular maintenance can reduce breakdowns by up to 80% and extend your equipment's lifespan by up to 30%. Businesses also typically save 10-15% on energy costs annually. A well-maintained system runs efficiently, keeps temperatures consistent, and prevents costly surprises during the dinner rush.

Preventative maintenance catches small issues before they become big problems. A loose fan belt is a cheap fix during a routine check; if it snaps during peak hours, it could shut down your operation. For specific tips on certain units, see our guide on Fixing Common Issues with Imperial Frost-Free Commercial Freezers.

Key Components That Require Regular Attention

Each component in your refrigeration system is vital. Focusing on these key areas can save your business from costly commercial refrigeration repair emergencies.

- Condenser coils release heat but get clogged with kitchen dust and grease, forcing the compressor to overwork. Regular cleaning is essential.

- Evaporator coils absorb heat from inside the unit. If they get dirty or frosted over, the system will struggle to maintain safe temperatures.

- The compressor is the heart of the system. Its health depends on the maintenance of other components. Compressor replacement is one of the most expensive repairs.

- Door gaskets and seals prevent cold air from escaping. Even a small gap can force the system to run constantly, driving up energy costs.

- The thermostat is the brain of the operation. Regular calibration ensures accurate temperature control and prevents food spoilage.

- Drain lines channel water from defrost cycles. Clogs can cause water pooling and ice buildup.

- Fan motors circulate air. Unusual noises are often the first sign of failure.

- Refrigerant levels must be correct for optimal cooling. Certified technicians should perform regular leak checks during maintenance visits.

Keeping these components in shape is key to meeting food safety standards. For more on compliance, explore our guide: Cool Compliance: Your Guide to NSF/ANSI Standard 7 for Refrigerators and Freezers.

Latest Trends in Refrigeration Technology

The commercial refrigeration world is evolving, offering new ways to improve efficiency and reliability.

- Energy-efficient models use advanced insulation and variable-speed compressors to lower utility bills.

- Smart refrigeration systems provide real-time monitoring and remote control via smartphone, sending alerts if temperatures rise.

- Natural refrigerants like carbon dioxide and propane are replacing synthetics, offering better efficiency with less environmental impact.

- IoT monitoring and predictive maintenance use data to predict component failure, allowing for proactive repairs before a breakdown occurs.

- Modular and flexible designs allow systems to be easily expanded or reconfigured as a business grows.

Staying informed about these trends helps you make smarter equipment decisions. For more insights, check out our resources at charbroilers.com.

Your Checklist for Choosing a Commercial Refrigeration Repair Service

When your walk-in freezer quits, you need help fast. But not all commercial refrigeration repair services are created equal. The key is knowing what to look for before disaster strikes.

Choosing a repair service is like hiring a key employee. You need someone reliable, skilled, and available. The wrong choice can cost you thousands, while the right one becomes an invaluable partner in keeping your business running smoothly.

What to Expect from a Commercial Refrigeration Repair Company

A professional commercial refrigeration repair company understands that your system is the heartbeat of your operation. Key services include:

- Thorough diagnostics to inspect the entire system, not just the obvious problem.

- Part replacement expertise with access to quality parts for common failures.

- Refrigerant handling by EPA-certified technicians who can safely manage leaks and recharges.

- Emergency calls with 24/7 availability for urgent situations.

They should excel at handling common issues like compressor failure, refrigerant leak detection, and thermostat malfunction fixes.

The Value of Emergency Commercial Refrigeration Repair

When your system crashes, it's a ticking time bomb for your inventory. Emergency commercial refrigeration repair proves its worth by saving you more than the repair costs.

- 24/7 availability means help is a phone call away, day or night.

- Fast response times, typically within 2-4 hours, can be the difference between saving and losing inventory.

- Minimizing business downtime gets you back to serving customers and generating revenue quickly.

- Protecting inventory is the primary goal, often saving thousands of dollars in perishable goods.

- Peace of mind comes from knowing you have professionals ready to respond effectively.

Essential Qualities of a Top-Tier Technician

The technician who shows up at your door makes all the difference. Look for these essential qualities:

- Certified and licensed professionals with EPA certification are non-negotiable. Working with refrigerants requires specific training for safety and legal compliance, as mandated by the Environmental Protection Agency.

- Experience with commercial systems is crucial, as they are far more complex than residential units.

- Transparent pricing with clear estimates before work begins avoids surprise charges.

- Positive reviews and reputation from other food service operators indicate reliable service.

- Insurance and bonding protect your business from liability in case of accidents.

Specialized refrigeration technicians can diagnose and repair issues up to 50% faster than general HVAC technicians due to their focused expertise.

When your critical equipment is down, choosing a certified, experienced, and specialized commercial refrigeration repair technician is essential for protecting your business.

Frequently Asked Questions about Commercial Refrigeration Repair

When your walk-in cooler acts up, stress can set in quickly. As restaurant equipment experts, we've helped countless owners steer these situations. Here are the most common questions we hear, with practical answers to help you make smart decisions.

How much does a typical commercial refrigeration repair cost?

Commercial refrigeration repair costs typically range from $150 to $1,000. The final price depends on several factors:

- Simple fixes like replacing a door gasket or clearing a drain line are on the lower end.

- Major component failures, such as a compressor or complex refrigerant leak, are on the higher end.

- Labor costs vary by location and are higher for emergency, weekend, or holiday service.

- The type and size of the equipment also affect the cost, with walk-in freezers being more expensive to repair than small undercounter units.

Always get an upfront quote before any work begins. A reputable company will provide transparent pricing.

How can I minimize downtime when my system breaks down?

Every minute of downtime costs you money. Here are smart steps to minimize the pain:

- Vet your repair service in advance. Don't wait for an emergency. Find a company with 24/7 service and fast response times, and save their contact info.

- Know your equipment. Keep a file with the make, model, and serial numbers of your units. This helps technicians diagnose problems faster.

- Keep the area accessible. Ensure a technician can get to the unit without moving boxes or other equipment.

- Invest in a preventative maintenance plan. This is the best way to catch small issues before they become expensive emergencies.

- Learn basic troubleshooting. Check if the unit is plugged in or if a circuit breaker has tripped. But when in doubt, call a professional.

When should I repair versus replace my commercial refrigerator?

This is a critical decision that impacts your bottom line. Consider these key factors:

- Age. Most commercial units last 10-15 years. If your unit is older, replacement often makes more financial sense.

- Repair frequency and cost. If you're calling for commercial refrigeration repair multiple times a year and the bills are adding up, it's time to consider replacement.

- Energy efficiency. A new Energy Star-certified unit can save hundreds of dollars annually on utility bills, helping the upgrade pay for itself over time.

- Reliability. If your current unit struggles to maintain temperature or causes you to lose product, the peace of mind from a new, reliable unit is priceless.

- Regulatory compliance. Older units may use refrigerants that are being phased out. Upgrading keeps you ahead of changing environmental regulations.

For a deeper dive into your options, check out our Detailed Guide to Comparing Commercial Refrigerators.

Conclusion

Reliable refrigeration is the backbone of any commercial kitchen. By now, you know the warning signs of failure—from temperature fluctuations and strange noises to water leaks and frost buildup. You also understand the high cost of ignoring them, with businesses losing up to $5,000 per day during downtime.

The good news is that you can take control. Preventative maintenance is your best defense, reducing breakdowns by up to 80% and extending equipment life. When you do need commercial refrigeration repair, you know to choose an EPA-certified technician with commercial experience, transparent pricing, and 24/7 availability.

The repair-versus-replace decision is clearer now, too. By weighing your unit's age, repair frequency, and the energy savings of a new model, you can make a smart financial choice. Sometimes, investing in reliability is the best move.

Your refrigeration system is a hero, but it doesn't have to work alone. When it's time to upgrade other essential equipment, Charbroilers.com offers a comprehensive selection of commercial kitchen equipment built for busy food service operations. From charbroilers and deep fryers to griddles, we know that reliable equipment is the foundation of your success.

Whether you're facing a refrigeration emergency or planning for the future, knowledge is power. The more you understand your equipment, the better you can protect your investment. For more insights on optimizing your kitchen, check out our guide: Your Guide to Commercial Charbroilers for Your Restaurant.

Stay cool, stay prepared, and keep serving.