Breaking the Ice on Ice Vending Machines – Your Ultimate Guide

Share

Why Ice Vending Machines Are Revolutionizing Automated Retail

Ice vending machines are self-service kiosks that automatically produce, store, and dispense bagged ice to customers 24/7. These machines offer a lucrative business opportunity with high profit margins, minimal labor, and growing consumer demand for convenient, contactless service.

Key benefits of ice vending machines:

- High profitability - Production costs under $0.50 per bag, retail prices $2-$4 per bag

- Low maintenance - Automated operation with minimal weekly oversight required

- Growing market - Part of the $30.3 billion global vending machine industry

- Year-round demand - Essential commodity with consistent sales potential

- Passive income - 24/7 operation without staffing needs

- Scalable business - Can expand to multiple locations for increased revenue

The ice vending industry has grown rapidly, driven by rising traditional ice delivery costs and consumer preference for fresh, on-demand products. With over $2.5 billion in annual U.S. ice sales and production costs as low as ten to twenty cents per bag, the profit potential is substantial.

Modern machines feature advanced technology like smartphone monitoring, UV sanitization, multiple payment options, and energy-efficient compressors. They can produce from 800 to over 7,000 pounds of ice daily, with storage capacities ranging from 500 to 6,500 pounds.

As Sean Kearney from Charbroilers.com, I've spent over a decade in the commercial equipment industry. I know that quality construction, energy efficiency, and operational reliability are key to a strong ROI, whether you're buying a charbroiler or an ice vending machine.

Simple ice vending machines glossary:

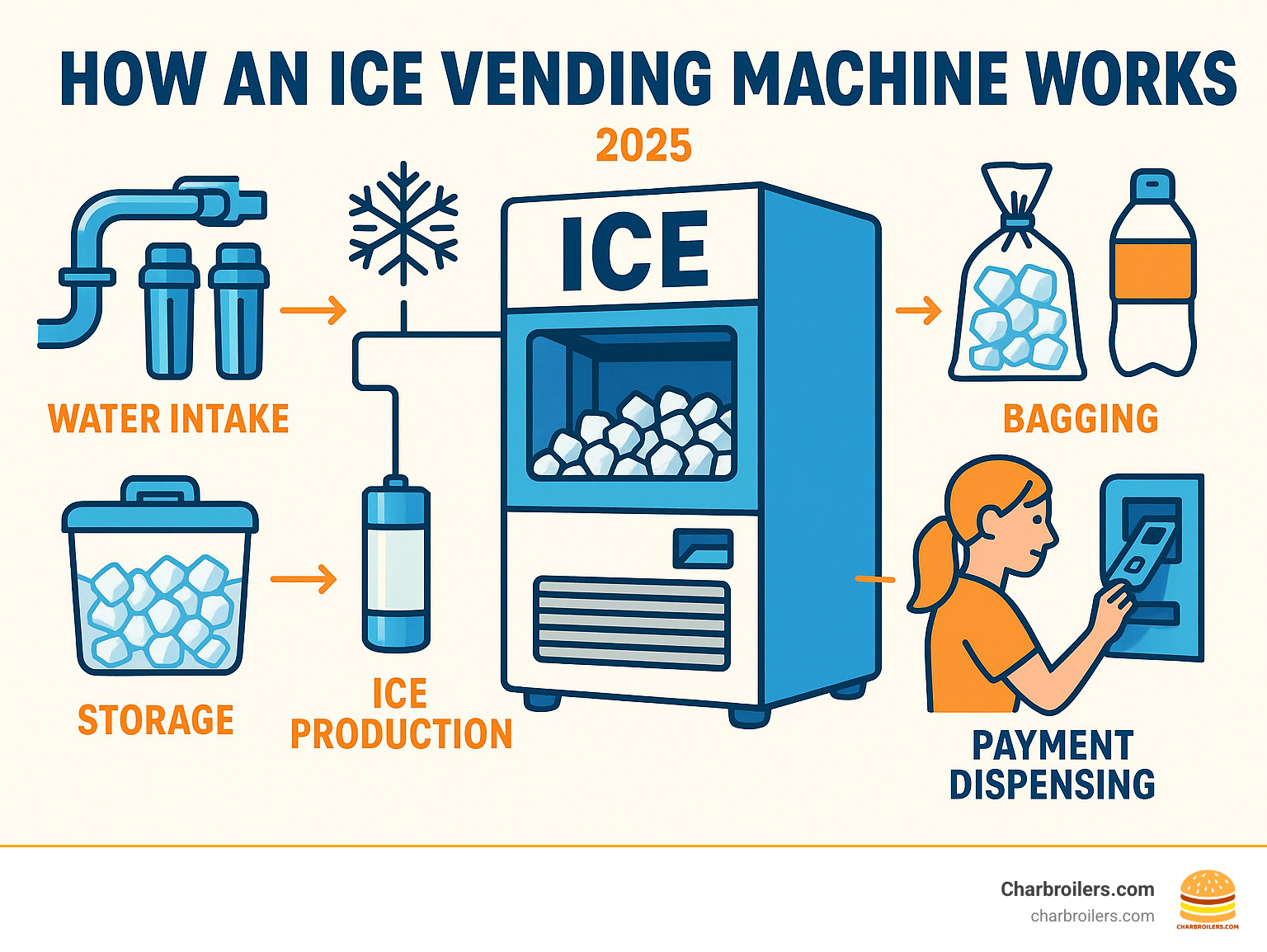

How Ice Vending Machines Work and Key Features to Look For

Ice vending machines are essentially mini ice factories and retail stores in one. They combine water purification, ice production, and smart dispensing technology.

The process begins with a multi-stage water purification system, typically using filtration, reverse osmosis (RO), and UV sterilization. This ensures the ice is clean and safe, creating a premium product that customers can trust.

Next, the purified water goes to the ice maker unit. These powerful units can produce significant quantities of ice, with some models making over 1,900 pounds daily and multi-unit systems exceeding 7,400 pounds.

The fresh ice moves into an insulated storage bin. These energy-efficient bins use thick, food-grade insulation to keep ice frozen without extra refrigeration. The machine automatically pauses production when the bin is full and resumes as levels drop, ensuring a constant supply.

When a customer pays, the dispensing mechanism quickly fills, seals, and dispenses a bag of ice.

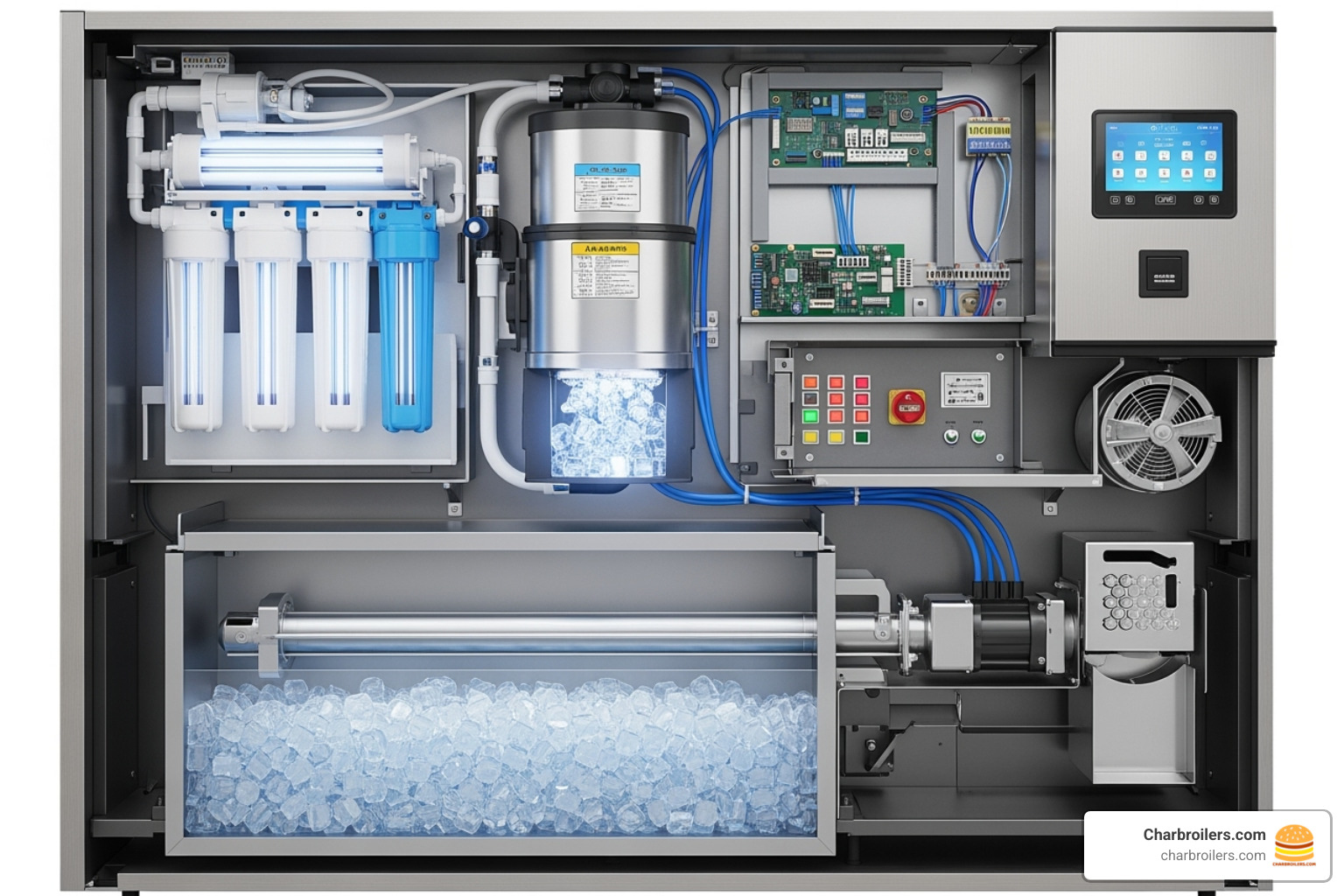

Core Components and Technology

At the heart of every ice vending machine is its ice maker unit. For modular setups, our insights on No Bin, No Problem: Commercial Ice Makers for Modular Setups can be helpful. Several key technologies work together for efficiency:

- Insulated Storage Bin: Vital for freshness and energy savings, insulated bins range from 500 pounds (IM500) to thousands of pounds in larger models.

- Payment Systems: Flexible payment systems accept cash, credit/debit cards, and mobile payments like Apple Pay and Android Pay for customer convenience.

- Remote Management Software: Systems like Icetalk™ or Everest's Basecamp allow owners to monitor sales, inventory, and machine health from any device, providing alerts for low stock.

- Energy-Efficient Compressors: Energy-efficient compressors using eco-friendly refrigerants like R290 are becoming standard, reducing environmental impact and utility costs.

- Weatherproofing Features: Outdoor machines require weatherproofing, such as corrosion-free frames, hurricane tie-downs, and cold weather packages to ensure durability.

- Durability and Construction: Durable construction, like all-steel frames with precision seams, ensures longevity and protects against moisture. Quality design focuses on precise temperature control.

- Smart Features: Advanced features include load cells for accurate inventory tracking, inset doors for better insulation, and spring-assisted hinges for a secure closure.

- Certifications: Look for ADA compliant, ETL listed, and NAMA certified machines, which indicate compliance with industry standards for accessibility, safety, and quality.

Comparing Machine Types and Sizes

Ice vending machines come in various sizes to fit different business needs. Choosing the right one is a key step.

- Compact Models: Machines like the IM500 have a smaller footprint and hold around 500 pounds of ice, perfect for locations with moderate demand or tight space. The KI810 is another owner-friendly, lower-priced option for new entrepreneurs.

- Mid-size Units: Models like the IM600XL or IM1000 balance style, production, and technology, storing 1,000 to 1,500 pounds of ice. They are a good fit for many convenience stores or hotels.

- Large-capacity Machines: For high-traffic areas, larger machines are necessary. Models like the IM1500 (1500 lbs storage, 1909 lbs/day production) or the modular IM2500 Series II are designed for huge demand. The Ice House model can store a massive 6,500 pounds of ice.

- Ice and Water Combo Units: Many modern machines offer both ice and purified water, which can double revenue streams and attract more customers by reducing single-use plastic bottle waste.

Key considerations when choosing a machine include:

- Production Capacity (lbs/day): Match this to your busiest days.

- Storage Capacity (lbs): A larger bin prevents running out during peak times.

- Footprint: Ensure the machine fits your available space.

- Scalability: Consider if the machine can be expanded later.

- Ice Type: Most machines make cube ice, but consider customer preferences.

For more insights on optimizing your setup, check out our guide on Cool Choices for Commercial Ice Maker and Bin Setups.

The Business of Ice Vending Machines

Ice vending machines offer an exciting business opportunity with a high return on investment, standing out against traditional vending due to higher profit margins and lower product costs.

Profit margins are remarkably high because the primary costs are just water and electricity. With production costs under $0.50 per bag and retail prices of $2-$4, the profitability is clear. For example, producing 2,500 pounds of ice costs less than $100 in utilities but can generate significant revenue.

This is a solid business model built on constant consumer demand. The global vending machine market is projected to reach $30.3 billion by 2024, according to research from Grand View Research, with ice vending being its fastest-growing segment.

Ice vending offers a turnkey business model with no staff, minimal maintenance, and 24/7 profit potential. It's ideal for entrepreneurs or those seeking passive income. A single machine can become a 'cash cow,' with some operators reporting over $4,000 in revenue in a single weekend.

Initial Investment for ice vending machines

Starting an ice vending machine venture requires an initial investment, typically ranging from $31,200 to $92,400. This covers the machine, site preparation, installation, and other startup costs.

Here's a general breakdown of potential startup costs:

| Category | Small Setup (Compact/Used) | Medium Setup (Mid-size/New) | Large Setup (High-Capacity/New) |

|---|---|---|---|

| Machine Cost | $15,000 - $30,000 | $30,000 - $60,000 | $60,000 - $100,000+ |

| Site Prep & Installation | $5,000 - $10,000 | $8,000 - $15,000 | $10,000 - $20,000+ |

| Permits & Licenses | $500 - $2,000 | $500 - $2,000 | $500 - $2,000 |

| Initial Inventory (Bags, etc.) | $200 - $500 | $300 - $800 | $500 - $1,000 |

| Working Capital | $500 - $2,000 | $1,000 - $3,000 | $2,000 - $5,000 |

| Total Estimated Investment | $21,200 - $44,500 | $39,800 - $80,800 | $72,500 - $128,000+ |

Note: These figures are estimates. Your actual costs might vary depending on your specific location, the machine model you choose, and any unique site requirements.

You can choose between new or used machines; new models offer the latest tech and warranties, while used ones are cheaper. Key costs beyond the machine include site preparation (water, electricity, drain), installation, and permits (business, food service, sales tax). Initial inventory mainly consists of bags, costing around 18 cents each.

Several financing options are available, including equipment leasing, business credit lines, or peer-to-peer lending. It's also worth looking into SBA loans for small businesses.

Revenue Streams and Profitability

The business model for ice vending machines is straightforward, focusing on direct-to-consumer sales of an essential product.

Primary revenue comes from bagged ice sales, with options for different sizes. Many machines also offer bulk ice dispensing and filtered water sales, creating additional income streams.

The return on investment (ROI) is typically fast, with a break-even point of 12-18 months and a full return within 2-3 years. After breaking even, annual ROI can reach 35-65%. With a lifespan of 10-15 years, the long-term earning potential is substantial, with some operators earning $25,000 annually per machine.

Profitability is seasonal, with a 40-50% sales spike in summer and a 20-30% dip in winter. Holiday periods can see a 60-80% surge. This is manageable since unsold ice simply melts and is remade, eliminating spoilage.

Key profitability factors include a high-traffic location, a competitive pricing strategy, operational efficiency, and regular maintenance. Local marketing can also boost awareness and sales. Many successful operators reinvest 60-70% of profits into new machines to build a multi-location business. For an exit strategy, machines often sell for 2-3 times their annual profit, providing a solid return.

Location, Operation, and Maintenance

Choosing the right spot for your ice vending machine is critical for success, just as it is for any food service business.

The golden rule is to go where people need ice. Prime locations include gas stations, convenience stores, hotels, and resorts. Recreational areas like campgrounds, state parks, marinas, and boat launches are also excellent choices. Other high-traffic spots are shopping centers, liquor stores, industrial parks, and college campuses. Don't overlook RV parks, apartment complexes, and hospitals, which serve populations with limited access to bulk ice.

Before committing, research demographics with U.S. Census data and analyze local competition using tools like Google Maps. Aim for a location with over 1,000 daily visitors and few nearby competitors. You can then approach the property owner about leasing a small plot of land.

Operational Best Practices for ice vending machines

Following key operational practices ensures your ice vending machine business runs smoothly.

Modern machines feature remote monitoring (e.g., Icetalk™, Basecamp), allowing you to track sales, inventory, and machine health from a smartphone. This eliminates the need for daily site visits. Daily operations consist mainly of digital check-ins to monitor status, alerts, and sales trends.

If your machine accepts cash, establish a secure, regular cash collection schedule. While the business is automated, providing a customer service number on the machine builds trust.

Local SEO is also crucial. Optimize your Google My Business profile so your machine appears in "ice near me" searches. Positive customer reviews will boost your online visibility and drive traffic. For businesses considering ice solutions for their own operations, our guide on Ice Machines That Mean Business: Hotels, Offices, and Beyond offers valuable insights.

Maintenance and Upkeep

Ice vending machines are low-maintenance, but consistent upkeep is essential for optimal performance.

The most critical task is water filter replacement every six months. This is not optional; it ensures great taste and prevents mineral buildup. Some machines also need salt refills for their water softener every few weeks.

Thanks to self-cleaning features, manual cleaning of the ice maker and bin is only needed every few months. The ice maker unit itself needs periodic professional check-ups to run efficiently. Expect to pay for regular health department testing (around $50 per test) to ensure your ice meets safety standards.

Learning basic troubleshooting for simple issues can save time and money, and modern diagnostic tools simplify this process. With proper care, these machines are built to last 10-15 years.

If you're exploring different equipment options, see if renting is a better fit with our guide on Renting Commercial Ice Machines Made Easy and Breezy.

Frequently Asked Questions about Ice Vending

Starting a new business raises many questions. Here are answers to the most common ones about ice vending machines.

How much does it cost to start an ice vending machine business?

The initial investment typically ranges from $30,000 to over $90,000, depending on factors like new vs. used equipment and site requirements. A used machine setup might cost around $45,000, while a new, high-capacity model can exceed $100,000. This total cost includes the machine, site preparation, installation, permits, and initial supplies. Financing options are widely available to help manage this upfront investment.

What kind of maintenance is required for an ice machine?

Maintenance is minimal but crucial. Key tasks include remote weekly checks, periodic cleaning of the ice maker and bin, and replacing water filters every six months to ensure ice quality and prevent damage. Some models require salt refills for water softeners. Remote monitoring systems alert you to potential issues, simplifying upkeep. Regular health department tests (around $50 each) are also required to meet safety standards.

Are ice vending machines a profitable business?

Yes, the business can be highly profitable. With production costs under $0.50 per bag and retail prices of $2-$4, the profit margins are excellent. Operators often break even within 12-18 months and achieve a full ROI in 2-3 years, with subsequent annual returns of 35-65%. Success hinges on a prime location, reliable equipment, and consistent operation. A well-placed machine can generate significant passive income 24/7.

Conclusion

Ice vending machines are more than just automated kiosks; they are a significant business opportunity, blending a reliable product with modern convenience. The economics are compelling: production costs under $0.50 per bag against retail prices of $2-$4 create impressive profit margins. Combined with minimal labor and 24/7 operation, the potential is clear.

This industry values the same principles as quality commercial kitchen equipment: robust construction, energy efficiency, and smart technology. Features like remote monitoring are practical tools that ensure smooth operation. The business model is also highly scalable. You can start with one machine and expand to multiple locations, building an enterprise with less stress than a traditional food service business.

While location and maintenance are key, the business model is refreshingly simple. As automated retail booms, ice vending is a top-growing segment, and the consistent demand for ice provides a stable foundation for a business.

At Charbroilers.com, we believe quality equipment is the foundation of success. This principle applies whether you're buying a charbroiler or an ice vending machine. Choose reliable equipment to set yourself up for long-term profitability.

If you're ready to explore other commercial equipment opportunities for your business, explore our comprehensive guides to commercial equipment for your business. The key is always quality, smart planning, and a commitment to serving your customers well.