Beyond Freezers: Exploring Double Door Upright Commercial Chillers

Share

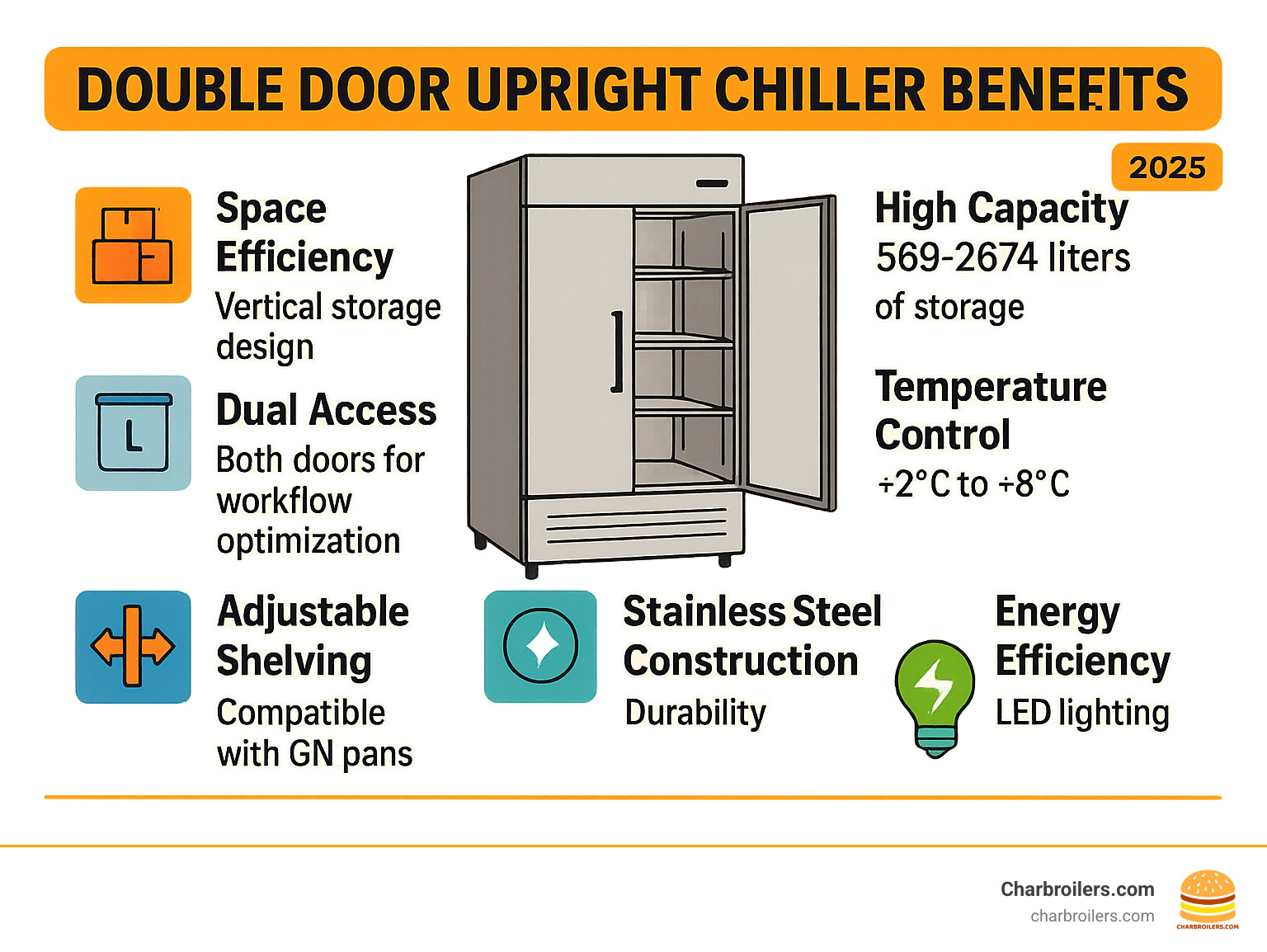

Why Double Door Upright Chillers Are Essential for Commercial Kitchens

A double door upright chiller is a vertical commercial refrigeration unit with two doors that provides high-capacity cold storage while maximizing floor space efficiency in busy kitchens. These units typically operate between +2°C to +8°C and offer superior organization through adjustable shelving systems.

Key Benefits of Double Door Upright Chillers:

- Space Efficiency: Vertical design saves valuable floor space compared to chest freezers

- High Capacity: 569-2674 liters of storage depending on model size

- Easy Access: Both doors can be opened independently for quick ingredient retrieval

- Temperature Range: Maintains +2°C to +8°C for optimal food safety

- Organization: Multiple adjustable shelves accommodate GN pans and various container sizes

- Energy Efficiency: Modern units feature LED lighting and eco-friendly refrigerants

- Durability: Grade 304 stainless steel construction resists corrosion and ensures hygiene

The commercial refrigeration market is projected to reach $55.8 billion by 2030, with upright refrigerators holding the largest market share due to their space-saving design and accessibility. Restaurant owners consistently choose double door models for their ability to store large quantities of perishables while maintaining organized workflow during peak service hours.

I'm Sean Kearney from Charbroilers.com, and with over a decade in the restaurant equipment industry, I've helped countless kitchens optimize their operations with the right double door upright chiller solutions. My experience in the e-commerce and restaurant supply sectors has shown me exactly what food service operations need to succeed.

Double door upright chiller terms to know:

- nsf ansi standard 7 commercial refrigerators and freezers

- commercial upright frost free freezer

- commercial cool 3.5 chest freezer

Why Your Commercial Kitchen Needs This Essential Appliance

Every successful commercial kitchen runs on two things: efficiency and food safety. A double door upright chiller delivers both in spades. This isn't just another piece of equipment taking up space in your kitchen – it's the reliable workhorse that keeps your operation running smoothly, even during the busiest dinner rush.

When you're juggling orders, managing staff, and keeping customers happy, the last thing you need is equipment that slows you down. That's where these chillers shine. They're built specifically for the demanding world of commercial food service, where downtime isn't an option and every square foot of space matters.

Maximize Storage and Organization

Picture this: instead of a bulky chest freezer eating up your precious floor space, you have a sleek double door upright chiller that reaches toward the ceiling. It's like having a vertical pantry that actually makes sense for a busy kitchen.

The numbers speak for themselves. These units pack serious storage power, with capacities ranging from 569 liters all the way up to 2,674 liters for the larger models. That's enough space to store everything from fresh produce to prepped ingredients for your entire menu.

But capacity is only half the story. The real magic happens inside, where adjustable shelving lets you customize the layout to fit your needs perfectly. Those PVC-coated shelves can handle whatever you throw at them, and they're designed to work seamlessly with Gastronorm (GN) pans. No more playing Tetris with mismatched containers – everything has its place.

This kind of organization isn't just neat and tidy (though your health inspector will definitely appreciate it). It's about reducing clutter and creating a system where your staff can find what they need instantly. When your prep cook can grab ingredients without hunting through three different storage areas, that's time saved and stress reduced.

Improve Kitchen Workflow and Food Safety

Here's where the double door design really proves its worth. During peak hours, when your kitchen is firing on all cylinders, two staff members can access different sections of the chiller at the same time. No more waiting in line to grab ingredients – everyone can work efficiently without getting in each other's way.

Many models come with self-closing doors, which might seem like a small detail until you realize how often someone forgets to close a door during a busy shift. These doors snap shut automatically, keeping your food at the perfect temperature even when things get hectic.

Speaking of temperature, digital temperature displays take the guesswork out of food safety. You can see at a glance that your chiller is maintaining that crucial +2°C to +8°C range that keeps your ingredients fresh and safe. This consistent cooling isn't just about following regulations – it's about protecting your reputation and your bottom line.

The design details matter too. Rounded internal corners make cleaning easier, while specialized door gaskets help prevent cross-contamination. When your chiller actively supports your food safety efforts, you can focus on what you do best: creating great food.

For a deeper dive into how commercial refrigeration can streamline your operations, check out our guide on Commercial Refrigeration Equipment Explained: No Sweat!.

Key Features of a Double Door Upright Chiller

When you're investing in a double door upright chiller, you're not just buying a box that keeps things cold. You're choosing a piece of equipment that needs to work flawlessly through busy lunch rushes, late-night prep sessions, and everything in between. Let me walk you through the features that separate the workhorses from the headaches.

Construction, Materials, and Hygiene Standards

The foundation of any reliable double door upright chiller starts with what it's made from. Grade 304 stainless steel is the gold standard here, and for good reason. This isn't just about looking professional (though it certainly does). This grade of steel laughs in the face of daily kitchen chaos – spills, splashes, cleaning chemicals, and constant use won't faze it.

Durability and corrosion resistance matter when you're dealing with moisture, temperature changes, and the inevitable bumps and scrapes of kitchen life. But here's where the smart design details really shine: look for rounded internal corners instead of sharp 90-degree angles. Those curves aren't just prettier – they prevent food particles from hiding in crevices where bacteria love to party.

Removable door gaskets are another feature that shows thoughtful engineering. When those rubber seals eventually wear out or need deep cleaning, you can pop them off instead of struggling with a toothbrush in tight spaces. These design choices help you meet strict hygiene standards without breaking your back during cleaning time. For the full scoop on what makes commercial refrigeration equipment compliant, check out our guide on Cool Compliance: Your Guide to NSF/ANSI Standard 7 for Refrigerators and Freezers.

Cooling Systems and Temperature Precision

The cooling system is where the magic happens in your double door upright chiller. You'll typically encounter two main types: fan-assisted cooling and static cooling. Fan-assisted systems (sometimes called forced-air or dynamic cooling) are the workhorses of busy kitchens. They circulate cold air throughout the cabinet, ensuring every corner stays consistently cold even when you're opening doors frequently during service.

Static cooling systems are quieter and gentler, making them perfect for delicate items that don't like air movement. The choice depends on what you're storing and how often you access it.

Digital temperature controls have become standard, and thank goodness for that. No more guessing games with analog dials. These precise systems let you set and monitor temperatures within that critical +2°C to +8°C range (+35°F to +46°F) that keeps your ingredients safe and fresh. The clear displays mean anyone on your team can quickly check if everything's running properly.

Automatic defrost cycles work behind the scenes to prevent ice buildup on evaporator coils. This isn't just about convenience – ice buildup makes your chiller work harder and use more energy. These systems handle the defrosting automatically, so you don't have to shut down operations or manually scrape ice.

Energy Efficiency and Long-Term Costs

Here's where smart buying pays off in the long run. An energy-efficient double door upright chiller might cost more upfront, but it'll save you money month after month on utility bills. With energy costs constantly climbing, efficiency isn't just nice to have – it's essential for your bottom line.

High-efficiency compressors are the heart of modern energy savings. These advanced units work smarter, not harder, to maintain your set temperatures while consuming less power. Thick polyurethane insulation (often 60mm or more) acts like a high-quality winter coat for your chiller, keeping cold air in and warm air out with minimal effort from the cooling system.

Eco-friendly refrigerants like R290 aren't just better for the environment – they often perform more efficiently than older refrigerants. This means lower operating costs and compliance with evolving environmental regulations. LED lighting inside your chiller provides better visibility while using a fraction of the energy of traditional bulbs. Plus, LEDs produce less heat, so your cooling system doesn't have to work as hard to compensate.

Look for features like self-closing doors and ENERGY STAR ratings when available. These details might seem small, but they add up to significant savings over the years. You'll likely have this chiller for a decade or more, so those monthly energy savings really accumulate.

The key is thinking beyond the sticker price to the total cost of ownership. A more efficient unit often pays for the difference through lower operating costs, making it a smart investment for your kitchen's future.

Practical Considerations: Installation, Capacity, and Maintenance

Getting the right double door upright chiller is only half the battle. The real success comes from proper planning – understanding exactly what size you need, where it'll live in your kitchen, and how to keep it running like a champ for years to come. Think of this as your roadmap to making your chiller investment truly pay off.

Sizing Up Your Needs: Capacity and Shelving in a double door upright chiller

Here's where many restaurant owners get tripped up – they either go too small and regret it during busy periods, or they oversize and waste money on capacity they'll never use. Calculating required capacity for your double door upright chiller starts with understanding your actual storage patterns, not just your wishful thinking.

Take a hard look at your menu, daily volume, and delivery schedules. Are you storing mostly bulk ingredients that arrive twice weekly, or do you prep everything daily and need space for GN pans? A small café might thrive with a 569-liter unit, while a busy restaurant could easily fill a 2,000+ liter model.

The beauty of these units lies in their adjustable PVC-coated shelves. These aren't flimsy wire racks – they're robust shelves designed to handle serious shelf load capacity, often supporting 35-40kg per shelf when properly distributed. Most models accommodate standard 1/1 GN containers, with larger units fitting two per shelf level. Some can even handle 600x400mm baking trays if that's more your style.

Don't forget to consider internal versus external dimensions when planning. A unit might measure 1200mm wide externally, but the internal usable width will be less due to insulation and construction. Many manufacturers offer additional shelf sets if your needs evolve, which is handy as your business grows. For a deeper dive into comparing different refrigeration options, check out our Detailed Guide to Comparing Commercial Refrigerators.

Installation and Placement Requirements

You've found your perfect double door upright chiller – now let's make sure it actually fits and works properly in your space. This isn't just about shoving it into any available corner and hoping for the best.

Measuring your kitchen space accurately is non-negotiable. Grab a tape measure and check not just the footprint, but also the height clearance. These units are tall – often around 1960mm (about 6.5 feet) – so make sure you're not bumping into any overhead shelving or ventilation.

Ensuring adequate ventilation is absolutely critical, and it's where I see too many operators cut corners. Your chiller needs to breathe! Most manufacturers specify at least 2-3 inches of clearance on the sides and back, and 10-12 inches at the top. This isn't a suggestion – it's essential for proper airflow to the condenser. Skimp on this clearance, and you'll watch your energy bills climb while your chiller struggles to maintain temperature.

Leveling the unit is straightforward thanks to either robust castors with brakes (great for mobility during cleaning) or adjustable feet. Don't skip this step – an unlevel unit can cause door seal problems and uneven cooling.

Check your electrical requirements before delivery day. Most units need specific voltage and phase connections (commonly 230V/50Hz/1 phase), and you don't want any surprises when the installer arrives. Finally, be mindful of ambient temperature limits. These chillers are designed to work optimally in room temperatures up to 25°C (77°F) with relative humidity not exceeding 60%. Placing your unit next to the pizza oven or grill is asking for trouble – it'll work overtime and cost you money.

Routine Maintenance for your double door upright chiller

Here's the truth about commercial kitchen equipment: it's only as reliable as the care you give it. Your double door upright chiller can run smoothly for years with proper maintenance, or it can become an expensive headache if you neglect it.

Cleaning condenser coils tops the maintenance priority list. These coils are like the radiator in your car – when they're clogged with dust, grease, and kitchen debris, your chiller works much harder to stay cool. Plan on cleaning them monthly in busy kitchens, quarterly in lighter-use environments. A stiff brush and shop vacuum make quick work of this task, and it's the single most important thing you can do to prevent breakdowns.

Wiping down gaskets might seem basic, but those door seals are your first line of defense against warm air infiltration. Clean them weekly with warm, soapy water, and keep an eye out for tears or hardening. Removable door gaskets make this job much easier and allow for thorough cleaning that prevents bacterial buildup.

Checking temperature accuracy should be part of your routine food safety protocols anyway. Use an independent thermometer to verify that your digital display matches reality. If there's a discrepancy, address it immediately – your food safety depends on accurate temperatures.

When troubleshooting common issues like ice buildup or cooling problems, start with the basics. Check if doors are sealing properly, verify that condenser coils are clean, and make sure the unit isn't being overloaded or the doors left open too long. For more detailed troubleshooting guidance, our article on Fixing Common Issues with Imperial Frost-Free Commercial Freezers offers insights that often apply to chillers as well.

Most manufacturers require professional servicing every three months by a qualified refrigeration technician. This isn't just warranty fine print – it's smart business. A qualified tech can spot potential problems before they become expensive repairs, and regular maintenance keeps your energy costs in check. Trust me, the cost of preventive maintenance is nothing compared to replacing a compressor or losing a weekend's worth of inventory to a breakdown.

Frequently Asked Questions about Double Door Upright Chillers

Over the years, we've helped countless restaurant owners choose the perfect double door upright chiller for their operations. These are the questions that come up most often, and honestly, they're exactly the ones you should be asking.

What is the ideal temperature for a commercial chiller?

Here's the golden rule: keep your double door upright chiller between +2°C and +8°C (35°F and 46°F). This sweet spot keeps your food safely out of the danger zone where bacteria love to party and multiply.

Think about what you're storing – fresh produce, dairy products, prepped salads, and those beautiful sauces you spent hours perfecting. Each needs that consistent cool environment to maintain quality and safety. Going below +2°C risks freezing delicate items like lettuce, while anything above +8°C starts pushing into risky territory.

Always check your local food safety regulations too. What works in one region might have different requirements elsewhere, and the last thing you want is a surprise visit from the health inspector finding issues with your storage temperatures.

How do glass doors compare to solid doors on a chiller?

This choice really comes down to where your double door upright chiller lives in your operation and what you need it to do.

Glass doors are fantastic when you need to see what's inside without opening up. Picture this: it's the dinner rush, and your line cook needs to grab ingredients quickly. With glass doors, they can spot exactly what they need in seconds. These doors shine in open kitchens, display areas, or anywhere visibility matters. The downside? They're not quite as energy efficient as solid doors, and you might deal with some condensation in humid kitchens.

Solid doors are the workhorses of the back-of-house world. They offer better insulation, which translates to lower energy bills and more consistent temperatures. If your chiller is tucked away in storage areas where display doesn't matter, solid doors are usually the smarter choice. They're also typically more durable and better at handling the constant opening and closing of busy kitchen life.

Some clever manufacturers even offer combination units – one glass door and one solid door – giving you the best of both worlds.

How much clearance does a double door upright chiller need for ventilation?

Don't make the mistake of cramming your double door upright chiller into the tightest possible space. These units need room to breathe, literally.

Most manufacturers want you to leave 2-3 inches on the sides and back, and a generous 10-12 inches at the top. This isn't just a suggestion – it's critical for proper airflow to the condenser. Without adequate ventilation, your chiller becomes like a marathon runner trying to compete while holding their breath.

I've seen too many kitchens where owners tried to save space by pushing units against walls or under low shelving. The result? Higher energy bills, inconsistent temperatures, and equipment that dies young. Always check your specific model's manual, as requirements can vary slightly, but never skimp on ventilation space.

Keep your chiller away from heat sources like ovens and grills too. Your poor chiller is already working hard to stay cool – don't make its job harder by parking it next to a 500°F grill.

How do brands and price points vary for double door upright chillers, and what factors justify higher costs?

The double door upright chiller market is like shopping for a car – you've got economy models and luxury options, with plenty in between. Prices typically start around CAD $3,299 for basic units and climb significantly for premium models.

Higher prices usually mean better materials – think full Grade 304 stainless steel construction versus mixed materials. Advanced cooling technology like high-performance compressors and sophisticated digital controls also bump up costs, but they deliver better temperature consistency and reliability.

Energy efficiency is a big price factor too. Units with better insulation, eco-friendly refrigerants like R290, and efficient compressors cost more upfront but save money on electricity bills for years. Specialized features like lockable doors, heavy-duty castors, and antibacterial components add value but also add cost.

Brand reputation matters in commercial kitchens. Established manufacturers with proven track records charge premium prices, but they also offer the reliability that keeps your operation running smoothly during the dinner rush.

The smart approach? Consider your total cost of ownership, not just the sticker price. A higher-quality chiller that runs efficiently for 10+ years often costs less than a cheap unit that breaks down frequently and guzzles electricity.

What are the warranty and after-sales support options typically offered with double door upright chillers?

Warranty coverage for double door upright chillers varies more than you might expect, so it's worth asking detailed questions before you buy.

Standard parts warranties are common – usually one year covering replacement parts if they fail due to manufacturing defects. Parts and labor warranties are better because they cover both the parts and the technician's time to install them. This can save you hundreds of dollars on service calls.

Extended warranty options are often available for additional cost, which might make sense for high-volume operations where downtime is expensive.

Watch out for warranty exclusions though. Most don't cover glass breakage, light bulbs, cosmetic damage, or problems caused by poor maintenance. Some manufacturers require quarterly maintenance by qualified technicians to keep warranties valid – skip this, and you might void your coverage entirely.

After-sales support quality varies dramatically between suppliers. The best offer technical support hotlines, guaranteed parts availability, and networks of authorized service technicians. When your chiller acts up at 2 AM before a big catering event, having reliable support can be a business-saver.

Before purchasing, ask specifically what's covered, what maintenance is required to maintain warranty coverage, and how quickly you can get parts and service. These details might seem boring now, but they become incredibly important when you need them most.

Conclusion

Investing in the right double door upright chiller is truly a game-changer for your commercial kitchen. It's not just another appliance purchase – it's a strategic decision that can transform how your kitchen operates day in and day out. When you carefully consider the construction quality, cooling technology, capacity needs, and energy efficiency features we've discussed, you're setting yourself up with a reliable workhorse that will serve your business faithfully for years to come.

The numbers don't lie – the commercial refrigeration market is experiencing significant growth, and energy efficiency has become a key driving force behind purchasing decisions. This trend means your choice of chiller isn't just about today's needs; it's about future-proofing your operation and protecting your bottom line through lower energy costs and improved operational efficiency.

At Charbroilers.com, we've seen how the right refrigeration solution can make or break a kitchen's workflow. We understand that every food service operation has unique challenges, whether you're running a busy restaurant, a catering business, or a institutional kitchen. That's why we offer an extensive range of refrigeration solutions – from compact upright chillers perfect for smaller operations to large-capacity double door upright chillers designed for high-volume establishments.

Our commitment goes beyond just selling equipment. We want to equip your kitchen with tools that genuinely help you succeed. When your ingredients stay fresh longer, your staff can work more efficiently, and your energy bills stay manageable, that's when you know you've made the right investment. Your double door upright chiller becomes more than just cold storage – it becomes the foundation of a well-organized, food-safe operation.

Ready to explore your options? Check out our comprehensive selection and dive into our helpful guides like Keep Your Cool: Restaurant-Ready Commercial Refrigerators to find which refrigeration solution will work best for your specific needs. Your kitchen – and your bottom line – will thank you for making this smart investment.