Keep Your Cool with These Restaurant-Ready Commercial Refrigerators

Share

Keep Your Restaurant Food Fresh and Safe

If you're searching for a commercial refrigerator for restaurant use, here's what you need to know:

Quick Guide to Commercial Refrigerators for Restaurants: 1. Types: Reach-in (most common), undercounter, prep tables, merchandisers, walk-ins 2. Size Range: 2 cubic feet to 56+ cubic feet capacity 3. Temperature: Maintains 32°F to 41°F for food safety 4. Price Range: $2,000-$5,000+ depending on size and features 5. Key Features: Stainless steel construction, digital controls, self-closing doors, heavy-duty compressors

The heart of any successful restaurant kitchen is reliable refrigeration. A commercial refrigerator for restaurant use is specifically designed to handle the demands of a busy food service environment, unlike residential units that quickly fail under professional use. These workhorses maintain consistent food-safe temperatures despite frequent door openings, high ambient kitchen temperatures, and 24/7 operation demands.

When your ingredients stay properly chilled, you're not just preserving flavor—you're protecting your customers and your business reputation. Modern commercial refrigerators now offer impressive energy efficiency with eco-friendly refrigerants like R290, which has a global warming potential (GWP) as low as 3, helping both the planet and your utility bills.

I'm Sean Kearney from Charbroilers.com, with over a decade of experience helping restaurant owners select the right commercial refrigerator for restaurant kitchens that balance performance, space constraints, and budget considerations. Having equipped hundreds of foodservice operations with reliable refrigeration solutions, I understand the critical factors that separate a smart investment from an expensive headache.

Why Every Restaurant Needs Commercial-Grade Refrigeration

Walk into any busy restaurant kitchen, and you'll notice the steady hum of refrigeration working tirelessly in the background. Unlike your fridge at home, a commercial refrigerator for restaurant use faces a marathon, not a sprint. While your home refrigerator might be opened a dozen times daily, restaurant units endure hundreds of openings during a single busy shift, with warm, humid air rushing in each time.

This is exactly why commercial refrigeration isn't an optional upgrade—it's an absolute necessity. These workhorses come equipped with heavy-duty compressors built for continuous operation, rapidly bouncing back to safe temperatures after those constant door swings. The door hinges and gaskets themselves are engineering marvels, designed to withstand thousands of openings without failing when residential models would have given up long ago.

There's also the critical matter of health department compliance. The National Sanitation Foundation (NSF) sets strict standards for food service equipment, and health inspectors specifically check for this certification. Non-compliant units can lead to violations or even temporary closure—a nightmare scenario for any restaurant owner.

Food safety isn't just about passing inspections—it's about protecting your customers. The CDC reports that about 48 million Americans suffer from foodborne illnesses annually, with improper food storage temperatures being a major culprit. Commercial refrigerators help restaurants implement Hazard Analysis Critical Control Point (HACCP) protocols by maintaining those crucial consistent temperatures, often with digital logs that verify you're doing everything right.

What Makes a "commercial refrigerator for restaurant" Different?

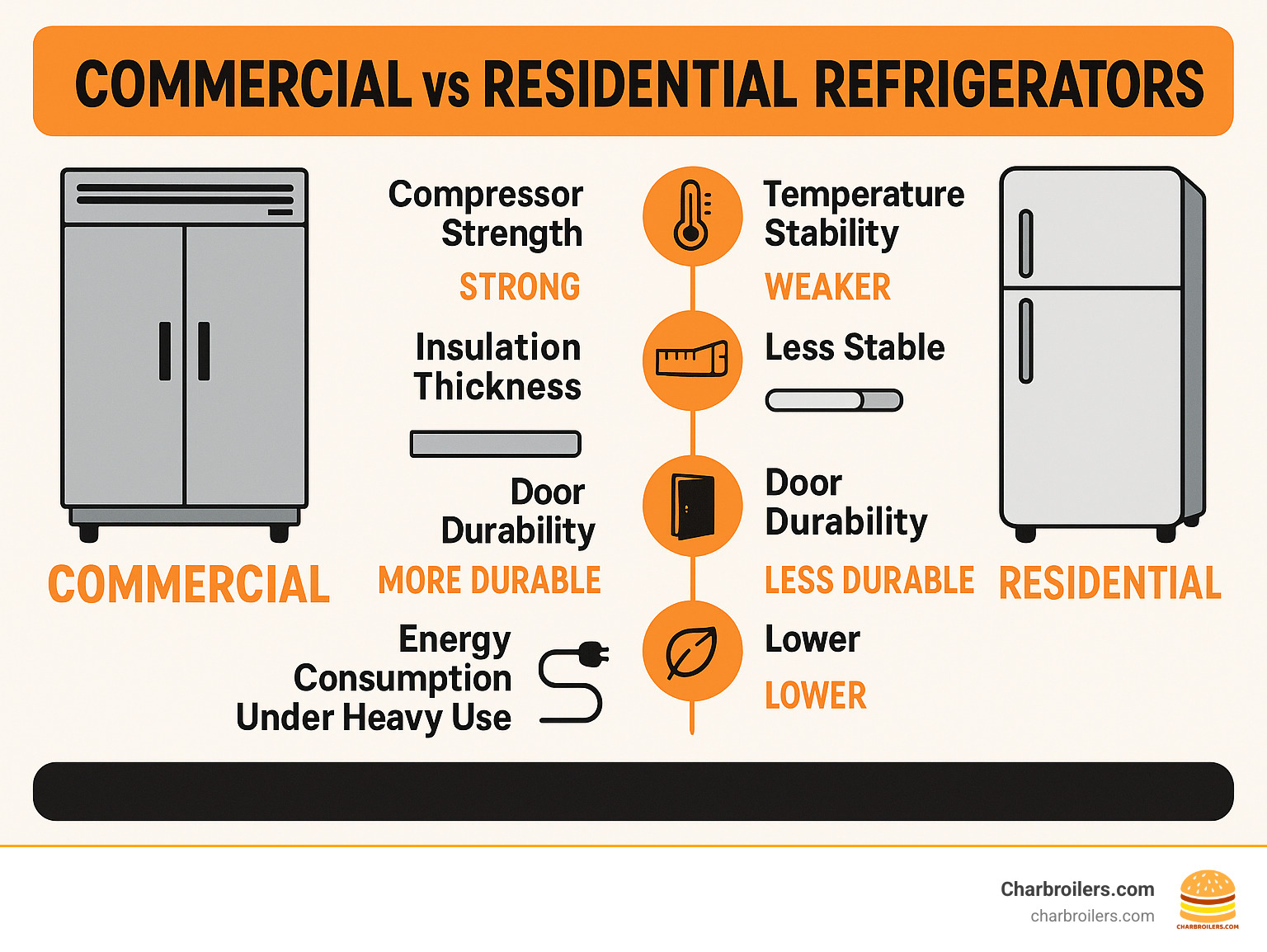

"Why can't I just use a regular refrigerator?" It's a question we hear often when helping restaurant owners in Seattle and beyond. The answer comes down to four critical differences that justify the investment:

Heavy-duty compressors form the heart of any commercial unit. While your home refrigerator's compressor might run at 30-40% duty cycle in your comfortable 70°F kitchen, commercial compressors handle 70-80% duty cycles in kitchens that can feel like saunas during peak service, often exceeding 100°F.

Thicker insulation provides the staying power commercial units need. Many commercial refrigerators feature insulation twice as thick as residential models, creating a thermal barrier that maintains stable temperatures despite those frequent door openings and hot kitchen conditions.

Stainless steel construction isn't just about looks—it's about longevity and sanitation. Quality commercial refrigerators use stainless steel inside and out because it resists corrosion from food acids, stands up to the inevitable bumps from heavy cookware, and can be thoroughly sanitized without breaking down over time.

Commercial-grade door gaskets might seem like a small detail, but they're critical. These magnetic seals withstand thousands of openings while maintaining an airtight seal. They're also designed to be removed for thorough cleaning and easy replacement, unlike many home models where changing a gasket requires major disassembly.

Beyond these differences, commercial refrigerators typically feature powerful forced-air cooling systems that circulate cold air throughout the cabinet. This ensures uniform temperatures from top to bottom—essential when storing different types of ingredients that all need to stay safely chilled.

Impact on Food Safety & Regulations

The FDA Food Code isn't suggesting that foods should be stored at 41°F or below—it's mandating it. This temperature requirement forms the foundation of most state and local food safety regulations, and for good reason. The "temperature danger zone" between 41°F and 135°F is bacteria's favorite playground, where they multiply most rapidly.

A properly functioning commercial refrigerator for restaurant use becomes your first line of defense against this invisible threat. Commercial units recover quickly after door openings, maintaining safe temperatures even during the chaos of a dinner rush. Many modern models include digital displays and alarms that alert your staff when temperatures drift toward the danger zone, providing peace of mind during busy service.

Food safety regulations also require proper labeling and dating of stored foods—another area where commercial refrigerators shine. Many units now include specialized label holders or even built-in label printers to help you stay compliant. This makes it easier to implement proper First-In, First-Out (FIFO) stock rotation, reducing food waste while maintaining safety standards.

Research from the USDA Food Safety and Inspection Service confirms what experienced restaurateurs already know: consistent refrigeration at or below 40°F significantly slows bacterial growth on perishable foods. Their studies show that bacteria grow about twice as slowly at 41°F compared to 45°F—highlighting why those few degrees matter tremendously.

Scientific research on safe cold-holding further emphasizes that maintaining the cold chain impacts not just safety but quality preservation. For many perishable items, every 5°F increase above optimal storage temperature can slash shelf life by half—directly affecting your food costs and the quality of dishes you serve.

Choosing the Right Commercial Refrigerator for Restaurant Operations

Let's face it – picking the perfect commercial refrigerator for restaurant use can feel overwhelming. I've helped hundreds of restaurant owners through this process, and I always tell them the same thing: your specific operation should guide your choice, not just what looks good in a catalog.

Think of reach-in refrigerators as the trusted workhorses of most kitchens. Available in single, double, or triple-door configurations, these versatile units offer between 23 and 72 cubic feet of storage. Most of our restaurant clients end up with two-door models – they hit that sweet spot of capacity for mid-sized operations without hogging too much kitchen real estate.

When counter space is precious (and when isn't it?), undercounter refrigerators become your best friends. These compact units slide neatly beneath work surfaces, giving you 5.5 to 20 cubic feet of cold storage exactly where your staff needs it – at their stations. I've seen these transform workflow in tight kitchens.

For sandwich shops and pizza places, prep tables are absolute game-changers. They brilliantly combine refrigerated storage below with ingredient wells on top, keeping toppings cold and within arm's reach. Available in lengths from a modest 27 inches to an impressive 119 inches, there's a size for every operation.

If you want to boost your impulse sales (who doesn't?), merchandisers with glass doors let customers see those tempting desserts and cold beverages. Our restaurant clients report up to 30% higher sales of displayed items compared to keeping them behind solid doors – that's real money in your pocket.

High-volume operations might need to think bigger with walk-in coolers. While technically not refrigerator units, they're worth considering if you're storing large quantities of ingredients or prepped items.

And let's not forget the bar area! Specialized bar coolers, back bar refrigerators, and glass frosters keep those beverages perfectly chilled for happy customers. Nothing kills a cocktail program faster than warm beer or room-temperature white wine.

Most successful restaurants I work with end up using a strategic combination of these different types. The right mix creates an efficient workflow where cold storage is available exactly where it's needed.

Sizing a Commercial Refrigerator for Restaurant Footprints

Finding the right size commercial refrigerator for restaurant use goes beyond just measuring your available space (though that's important too!).

Here's a practical tip I share with new restaurant owners: calculate about 1.5 cubic feet of refrigeration space per meal served during your busiest service. So if you're cranking out 100 meals during the dinner rush, you'll need roughly 150 cubic feet of refrigeration distributed throughout your kitchen. This simple formula has saved many clients from the headache of undersized refrigeration.

Door count matters more than you might think. While that three-door reach-in offers more capacity than a two-door model, it also demands more clearance space for the doors to swing open. In tight kitchens, sometimes two smaller units placed strategically work better than one monster unit.

Think about your kitchen's workflow zones when deciding where refrigeration goes. Your prep station needs cold storage nearby. So does your cooking line. And your plating area. Map out how food moves through your kitchen, and you'll see the natural spots where refrigeration belongs.

I always suggest buying slightly larger than your current needs if budget allows. Your menu will evolve, and your business will grow (fingers crossed!). That extra space will seem like a brilliant investment down the road. But don't go overboard – consistently underfilled units waste energy and valuable kitchen real estate.

Installation & Space Considerations

Proper installation of your commercial refrigerator for restaurant use isn't just about where it looks nice – it directly impacts performance, energy bills, and how long your unit will last.

First, respect the clearance requirements. These aren't suggestions – they're necessities. Most commercial refrigerators need at least 3 inches of breathing room on all sides and 12 inches on top. Without this space, air can't circulate properly around the condensing unit. I've seen perfectly good refrigerators fail prematurely simply because they were shoved against a wall.

Electrical requirements might not be sexy, but they're crucial. Most standard reach-ins run on 115V/60Hz power and pull between 5-15 amps, but larger units might need 208-230V service. Always, always check the manufacturer's specs and get a licensed electrician involved before installation. Dedicated circuits prevent overloads that can damage your expensive equipment.

Keep your refrigeration away from heat sources – it's just common sense, but I can't tell you how many kitchens I've walked into where the refrigerator sits right next to the fryer or in a sunbeam. For every 10°F increase in the air temperature around your unit, you could be burning up to 20% more energy. That adds up fast on your utility bills.

Flooring and leveling might seem minor, but they're anything but. Your refrigerator needs to sit level to ensure proper door sealing and drainage. Many health inspectors will specifically check this, and most health codes require easily cleanable flooring under and around refrigeration equipment.

Don't forget about condensate management. Units with automatic defrost create water that has to go somewhere. Some units have built-in evaporator pans, while others need to connect to floor drains or condensate pumps. Planning for this during your kitchen design phase saves significant headaches later.

I always recommend working with a kitchen designer or equipment specialist who can create a comprehensive plan addressing all these factors. At Charbroilers.com, we help restaurants think through these details before purchase to ensure smooth installation and optimal performance.

Must-Have Features & 2024 Trends

When I talk with restaurant owners about upgrading their refrigeration, they always ask me, "What features should I be looking for?" The refrigeration landscape in 2024 has evolved dramatically, with technology that not only keeps food safer but also saves you money in the long run.

Today's commercial refrigerator for restaurant use comes packed with smart features that would have seemed like science fiction just a decade ago. Digital temperature controls and displays have become the new standard, giving you precise control down to the degree. I love models with external displays that let your staff check temperatures without opening the door—a simple feature that actually saves significant energy over time.

Those self-closing doors might seem like a small upgrade, but they're game-changers during rush periods when staff might not fully close a door. Many newer models even include door alarms that beep when left open too long—a feature that's saved countless restaurants from food spoilage incidents.

The switch to LED lighting inside refrigeration units isn't just about being modern. These lights run cooler, last years longer than fluorescents, and provide better visibility for your team when they're searching for ingredients during the dinner rush. The energy savings are just icing on the cake.

Security matters too, especially for high-value inventory items. Door locks protect your expensive proteins and prevent unauthorized access after hours. Some of my clients have upgraded to programmable electronic locks that integrate with their security systems—perfect for multi-location operations.

One feature that chefs particularly appreciate is adjustable shelving systems that can be reconfigured as menu needs change. Look for heavy-duty options rated for at least 80 pounds per shelf, so they can handle those full hotel pans of prepped ingredients without bending.

Perhaps the most exciting development is the rise of smart monitoring systems that connect your refrigerator to your smartphone. These IoT-enabled units send alerts if temperatures drift into danger zones, track door openings, and can even predict when maintenance will be needed before problems occur. It's like having a 24/7 kitchen manager just for your refrigeration.

And don't overlook the importance of ENERGY STAR certification. These units typically use 30-40% less energy than standard models—savings that add up to thousands of dollars over the equipment's lifetime.

Sustainability Upgrades & Eco-Friendly Refrigerants

The days of environmentally harmful refrigerants are quickly fading into history, and that's good news for both the planet and your operating costs. The star of this eco-revolution is R290 (propane) refrigerant.

With a global warming potential (GWP) of just 3—compared to the thousands measured in older refrigerants—R290 dramatically reduces your operation's environmental impact. But the benefits aren't just environmental. This natural refrigerant actually improves system efficiency, often leading to lower energy bills and better performance.

The Department of Energy didn't mess around with their 2023 efficiency standards, requiring commercial refrigeration to be approximately 40% more efficient than previous requirements. Manufacturers have responded impressively, developing better insulation, smarter compressors, and sophisticated control systems that know exactly when cooling is needed.

Yes, units with these advanced green features might cost 10-15% more upfront, but don't let that initial price tag fool you. The energy savings typically deliver complete payback within 2-3 years. Many of my clients have also taken advantage of utility company rebates for ENERGY STAR equipment, sometimes covering up to 30% of the purchase price.

Beyond refrigerants, look for refrigerators with recycled materials in their construction, smart defrost systems that only run when actually needed, and variable speed compressors that adjust to real-time cooling demands. Some advanced models even feature hot gas defrost systems that cleverly reuse heat from the refrigeration cycle.

The Department of Energy's research on energy efficiency confirms what we're seeing in real-world applications—these technologies can slash refrigeration energy consumption by up to 60% compared to older models. That's serious money back in your pocket every month.

Innovations Setting the New Standard

The refrigeration industry isn't standing still, and several breakthrough technologies are now becoming mainstream in commercial refrigerator for restaurant applications.

Variable-speed compressors represent a quantum leap over traditional single-speed models. Rather than the old on/off cycling that causes temperature fluctuations, these smart systems adjust their output based on actual cooling needs. The result? More stable food temperatures, significantly reduced energy consumption, and compressors that last years longer because they're not constantly starting and stopping.

I've seen kitchen staff fall in love with the new touchscreen user interfaces that have replaced old-school thermostats and control panels. Beyond being more intuitive to use, these interfaces often include training videos, maintenance reminders, and troubleshooting guides right on the display—perfect for training new staff.

One of my favorite innovations is adaptive defrost technology. Instead of running defrost cycles on a fixed schedule (whether needed or not), these systems use sensors to determine when frost has actually built up. This prevents unnecessary defrost cycles, saving energy and reducing those temperature spikes that can affect food quality.

For multi-location operations, cloud monitoring and predictive maintenance systems are revolutionary. These systems connect your refrigeration units to the internet, allowing for remote monitoring and proactive service. I've had clients receive alerts about potential compressor issues days before failure would have occurred, allowing them to schedule maintenance during off-hours instead of dealing with emergency repairs during Saturday night service.

Health-conscious operators appreciate the new antimicrobial surfaces and materials being incorporated into shelving, door handles, and interior surfaces. These help reduce bacterial growth and cross-contamination risks—an extra layer of protection beyond your regular cleaning protocols.

If you're interested in other cutting-edge kitchen equipment innovations, take a look at our article on commercial ice makers that highlights similar technological advancements changing the game for food service operations.

Cost, Maintenance & FAQs

Let's talk dollars and sense when it comes to your commercial refrigerator for restaurant investment. I've helped hundreds of restaurant owners steer this decision, and the sticker price is just the beginning of the story.

Think of commercial refrigeration as a three-tier market. At the entry-level ($2,000-$3,300), you'll find basic single or double-door reach-ins that get the job done with standard stainless exteriors and simple digital controls. They're like the reliable sedan of refrigeration—functional but without the bells and whistles, typically backed by 1-3 year warranties.

Move up to mid-tier options ($3,300-$5,000), and you're investing in better insulation, more precise temperature control, and that valuable ENERGY STAR certification. These units often pay for themselves through efficiency, with warranties extending to 3-5 years. It's like upgrading to a nicer vehicle with better gas mileage and a longer guarantee.

The premium category ($5,000+) brings all the cutting-edge features to your kitchen—variable-speed compressors, smart monitoring systems that alert your phone when temperatures drift, and antimicrobial surfaces. These top-shelf units typically come with 7-year warranties because manufacturers know they're built to last.

Here's the good news: you don't need to drain your bank account upfront. At Charbroilers.com, we understand restaurant cash flow challenges, which is why we've created financing packages specifically for food service businesses—many with 0% interest for qualified buyers. This lets you preserve capital for those thousand other things your restaurant needs.

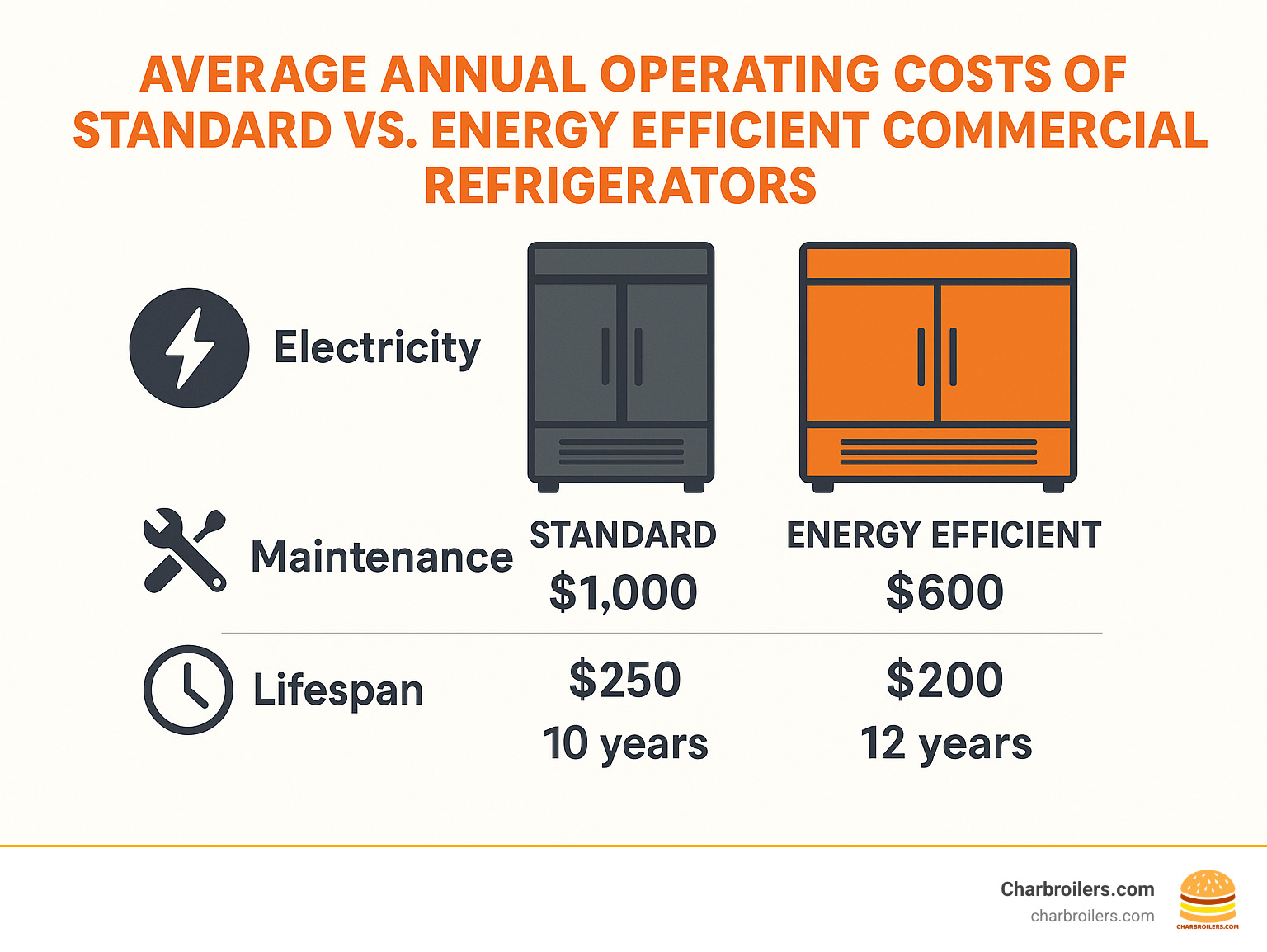

The math on quality refrigeration makes sense when you look at the big picture. Those premium units might save you $200-$500 yearly on electricity alone compared to basic models. Add in the reduced food waste (up to 30% less spoilage with consistent temperatures), and suddenly the "expensive" option becomes your smartest financial move.

Budget Breakdown & Financing Tips

When I sit down with restaurant owners to plan their refrigeration budget, we look at the full financial picture. Beyond the purchase price, remember to factor in installation costs ($200-$800 depending on complexity), annual energy expenses ($300-$1,200 based on efficiency and local rates), and routine maintenance ($200-$600 yearly).

I always recommend setting aside about 10% of your purchase price annually as a repair fund. It's like having an emergency fund for your home—you hope you won't need it, but you'll sleep better knowing it's there.

Smart financing can make premium equipment accessible even on tight budgets. Equipment leasing lets you preserve capital with manageable monthly payments over 2-5 years. Many restaurant owners don't realize they can leverage the Section 179 tax deduction to write off the full purchase price in year one rather than depreciating it slowly.

Don't overlook energy efficiency rebates from utility companies—I've helped restaurant clients recover 15-30% of their purchase price through these programs. And timing matters! Look for manufacturer promotions in the fourth quarter when companies are eager to hit annual sales targets.

At Charbroilers.com, we take pride in helping Seattle restaurants steer these options without the pressure tactics. We'd rather help you find the right solution that works for your specific kitchen and budget than push the most expensive unit on the floor.

Routine Care to Maximize Lifespan

The difference between a refrigerator that lasts 15 years and one that dies after 3 often comes down to one thing: TLC. A little preventative care goes a long way.

Daily loving is simple but crucial. Wipe those door gaskets with mild soapy water (they're magnets for grime that compromises seals), check temperatures twice daily (morning and evening), and clean spills immediately (acidic foods can actually corrode stainless steel over time).

Weekly attention involves sanitizing interior surfaces with food-safe cleaner, inspecting gaskets for signs of wear, and checking drain lines for any clogs that could lead to water pooling.

The monthly maintenance that makes the biggest difference is cleaning those condenser coils. Think of them as your refrigerator's lungs—when they're clogged with dust, the whole system struggles to breathe. A simple coil brush and vacuum can add years to your unit's life. While you're at it, check fan blades for dust buildup and tighten any loose screws.

Quarterly care steps things up with evaporator coil cleaning, refrigerant level checks, and lubricating moving parts like door hinges. This is also the perfect time to verify your temperature calibration with an accurate thermometer.

For cleaning, keep it simple—warm water and mild detergent work beautifully for most surfaces. Skip those tempting abrasive pads that can scratch stainless steel. For sanitizing, the tried-and-true solution of 1 tablespoon bleach per gallon of water works perfectly when properly rinsed.

While your staff can handle most maintenance, I strongly recommend scheduling a professional service visit annually. A trained technician can spot subtle issues before they become expensive emergencies, especially for technical tasks like refrigerant checks.

Frequently Asked Questions about Commercial Refrigerators for Restaurants

How often should I clean my commercial refrigerator?

Think of cleaning in layers: daily wipe-downs of high-touch surfaces and gaskets, weekly interior cleaning with sanitizer, monthly condenser coil cleaning, and quarterly deep cleaning of evaporator coils. This graduated approach keeps food safe while extending equipment life. Those door gaskets need special attention—daily cleaning prevents mold growth that can compromise your temperature seal.

What warranties are typical for commercial refrigerators?

Standard coverage runs 1-3 years for parts and labor, with compressors often getting extended coverage (3-5 years). The industry is trending toward better protection, especially with eco-friendly R290 refrigerant models, where manufacturers are so confident in reliability that many offer up to 7-year warranties. Always read the fine print about what voids coverage—improper installation is often the culprit.

Are energy-efficient units worth the upfront cost?

In almost every scenario, yes. While ENERGY STAR units typically cost 10-15% more initially, they consume 30-40% less energy. With refrigeration running 24/7/365, that efficiency translates to $200-$500 yearly savings. Most restaurants see complete payback within 2-3 years, after which those savings go straight to your bottom line. The environmental benefits are a welcome bonus.

Can I use a residential refrigerator in my commercial kitchen?

I hear this question often, and the answer is a firm no. Health departments require NSF-certified equipment, and residential units simply aren't built for commercial demands. A home fridge might handle 30 door openings daily in 70°F ambient temperatures, but your kitchen staff might open doors 300+ times in a 90°F kitchen environment. Beyond potential health code violations, residential units in commercial settings typically void their warranties immediately.

How do I know what size refrigerator my restaurant needs?

A good rule of thumb is 1.5 cubic feet of refrigeration space per meal served during your busiest service. But consider your prep schedule too—if you're prepping just once daily, you'll need less storage than if you're doing big prep sessions twice weekly. We can help you calculate your specific needs based on your menu and service style.

What's the difference between top-mounted and bottom-mounted condensing units?

It's about more than just appearance. Top-mounted units discharge heat upward and away from the cabinet, making them ideal for dusty environments like bakeries where floor dust can quickly clog coils. Bottom-mounted units offer easier maintenance access and benefit from cooler air at floor level (typically 15°F cooler than ceiling height), improving efficiency in hot kitchens. Your specific environment should guide this choice.

How long should a commercial refrigerator last?

With proper maintenance, quality commercial refrigeration should serve your kitchen faithfully for 10-15 years. Premium models often exceed this, with some high-end units still performing beautifully after two decades. The key is consistent maintenance and prompt attention to small issues before they become major problems.

Conclusion

Choosing the right commercial refrigerator for restaurant use isn't just about keeping food cold—it's about investing in the backbone of your kitchen operations. The refrigerator you select today will impact your food safety, energy bills, and operational efficiency for years to come.

Modern commercial refrigeration has evolved dramatically, offering features that were unimaginable just a decade ago. From energy-efficient models that can cut your utility costs by 30-40% to smart refrigerators that send alerts to your phone when temperatures drift, today's options can truly transform how your kitchen functions.

When making your decision, think beyond the price tag. Consider what that refrigerator will cost (or save) you over its entire lifespan. A quality unit with proper maintenance becomes a trusted kitchen partner for 10-15 years, silently protecting your ingredients, your customers' health, and your reputation day after day.

The right refrigeration solution reduces food waste through consistent temperatures, cuts emergency repair costs with reliable performance, and even helps the environment with eco-friendly refrigerants. These benefits compound year after year, making a quality refrigerator one of the smartest investments in your business.

At Charbroilers.com, we understand the challenges Seattle restaurants face when selecting equipment. We've helped hundreds of food service operations find refrigeration solutions that perfectly balance their space constraints, menu needs, and budget realities. Our team is ready to guide you through the options and ensure you get exactly what your operation needs—no more, no less.

For more information about equipping your commercial kitchen with other essential equipment, be sure to check out our comprehensive guide to commercial charbroilers for your restaurant.

In the world of restaurants, your refrigeration is only as reliable as its performance during your busiest service. Invest in equipment that stands up to the challenge, and you'll create the foundation for years of successful food service that keeps customers coming back and your business thriving.