Temperature Tango: Fine-Tuning Your Commercial Fridge for Peak Performance

Share

Why Commercial Fridge Temperature Control Matters for Your Restaurant

Commercial fridge temperature control is the difference between a thriving restaurant and a health code violation. Here's what you need to know:

Quick Answer: Essential Temperature Settings

- Commercial Refrigerators: 34°F to 40°F (1°C to 4°C)

- Commercial Freezers: 0°F or below (-18°C or below)

- Perishable Foods (meat, dairy): Store closer to 34°F (1°C)

- Beverages & Non-Perishables: Store around 38°F to 40°F (3°C to 4°C)

- Monitoring Frequency: Check temperatures 2-4 times daily

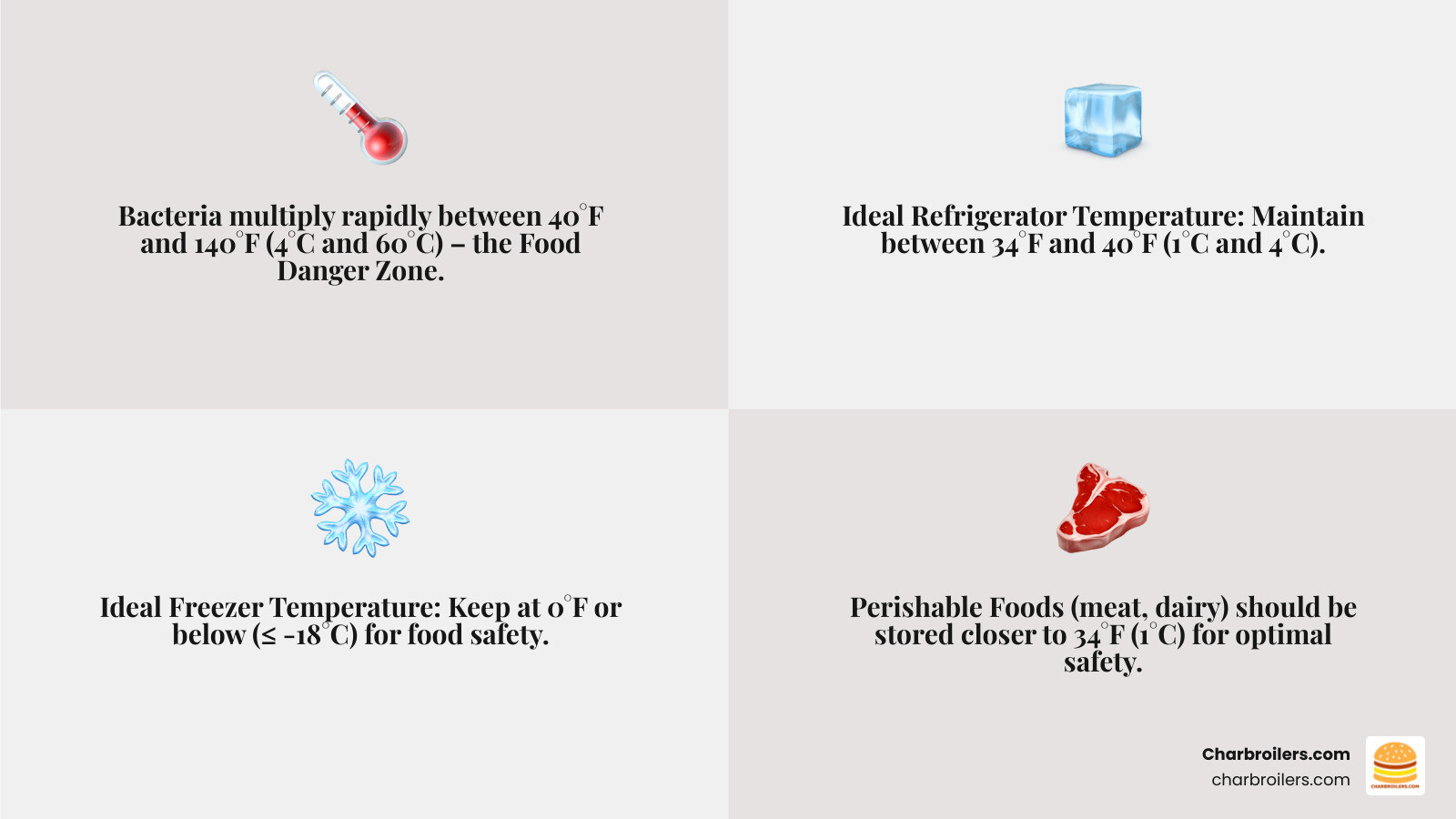

When temperature control fails, premium steaks can become lukewarm and unsafe overnight. The stakes are high: bacteria multiply rapidly between 40°F and 140°F, turning inventory into a health hazard. A single degree off target can lead to spoiled food, wasted money, failed inspections, and sick customers. Your refrigeration system isn't just storing food—it's protecting your business.

Proper temperature control also impacts profitability. Running a fridge too cold wastes energy, while running it too warm spoils inventory. Finding the right balance requires understanding and maintaining your equipment.

I'm Sean Kearney, founder of Charbroilers.com. With over a decade of experience in commercial kitchen equipment, I've seen how essential commercial fridge temperature control is for success. I'm here to help you master it.

Commercial fridge temperature control vocabulary:

Why Proper Temperature is Non-Negotiable

In a busy kitchen, commercial fridge temperature control is non-negotiable. Health departments create temperature regulations to protect customers from foodborne illness, and fridge temperatures are one of the first things they check. A single violation can lead to fines, closure, or a damaged reputation.

Bacterial growth happens faster than you think. In the 'danger zone' between 40°F and 140°F, bacteria can double every 20 minutes. Proper temperatures put the brakes on this invisible threat.

Temperature control also directly impacts your financial bottom line. A cooler running just a few degrees too warm can lead to wilted produce, soured dairy, and spoiled meat. With restaurant profit margins often as thin as 3-5%, this waste is money in the trash.

Energy consumption is another factor. Running refrigeration too cold forces the compressor to work overtime, increasing your electric bill for no added safety benefit. Maintaining the correct temperature is the most energy-efficient approach.

Finally, it affects product quality. Temperature fluctuations compromise the texture, flavor, and nutrition of your ingredients. Customers can taste the difference, even if they don't know why.

For a deeper look at regulatory requirements, check out our guide: Cool Compliance: Your Guide to NSF/ANSI Standard 7 for Refrigerators and Freezers.

The Ideal Temperature Ranges

Mastering commercial fridge temperature control means knowing the right numbers for each food type.

Commercial refrigerators should run between 34°F and 40°F (1°C to 4°C). This range slows bacterial growth without freezing fresh ingredients.

Commercial freezers must maintain 0°F or below (≤ -18°C). At these temperatures, bacterial activity virtually stops, allowing for long-term storage.

Within the refrigerator's range, store perishable foods like raw meat, poultry, and dairy at the colder end, around 34°F (1°C). Beverages and less sensitive items can be kept at 38°F to 40°F (3°C to 4°C).

Temperatures vary within a unit. Top shelves and areas near the door are warmer. Place sensitive items like proteins on lower shelves toward the back, and use warmer zones for heartier produce and beverages.

Mastering Your Commercial Fridge Temperature Control System

Every commercial refrigeration unit has a temperature control system. Understanding it helps you spot problems early.

The sensor (a probe inside the unit) measures the temperature and reports to the controller. The controller compares this reading to your desired temperature, or 'setpoint.'

If the temperature is too high, the controller signals the actuator (a relay switch) to turn on the compressor, which starts the cooling cycle. Once the setpoint is reached, the controller tells the compressor to rest.

To prevent constant cycling that wears out the compressor, systems use a 'deadband'—a small buffer zone. For example, with a 38°F setpoint and a 2°F deadband, the compressor might shut off at 37°F and restart at 39°F. This design makes commercial fridge temperature control efficient and reliable.

Digital vs. Analog: A Guide to Commercial Fridge Temperature Control

Commercial refrigeration equipment uses either digital or analog temperature controllers. Knowing the difference helps you get the most from your unit.

Digital controllers are the modern standard, showing the exact temperature on a screen. Adjustments are precise and easy, often to a tenth of a degree. Many include features like programmable defrost cycles, temperature alarms, and data logging, making them ideal for compliance and food safety. Their main downside is a higher upfront cost.

Analog controllers are the simple dials, often numbered 1-7. They are less expensive and straightforward to use—turn one way for colder, the other for warmer. However, they lack precision and require an independent thermometer to verify the actual temperature. Adjustments are a process of trial and error, requiring you to wait 24 hours after each change.

| Feature | Digital Temperature Controllers | Analog Temperature Controllers |

|---|---|---|

| Display | LED or LCD screen showing exact temperature | Dial with numbers (e.g., 1-7) or general cold/warm indicators |

| Precision | High, often to a tenth of a degree | Lower, relies on estimation and external thermometer verification |

| Adjustments | Button-based (SET, UP/DOWN arrows), quick and precise | Dial-based, often requires small, gradual changes |

| Programmability | Often includes features like defrost cycles, alarms, historical data | Basic on/off control, no advanced features |

| Ease of Use | User-friendly for specific settings, but can be complex for advanced features | Simple and intuitive for basic adjustments |

| Cost | Generally higher upfront cost | Typically lower upfront cost |

| Monitoring | Can integrate with external monitoring systems, built-in alarms | Requires manual checks with external thermometers |

For most modern kitchens, the accuracy and features of digital controllers are worth the investment.

The Role of Modern Temperature Monitoring Systems

A door left ajar during a dinner rush can go unnoticed until it's too late. Modern temperature monitoring systems act as your kitchen's silent guardian.

These systems use wireless sensors inside your refrigeration units to track temperatures continuously. The data streams to a dashboard or mobile app, giving you real-time visibility from anywhere.

The key benefit is automated alerts. If a temperature drifts outside your set safe range, you get an instant notification via SMS, email, or app. This proactive management helps you catch small issues before they become costly disasters.

For compliance, these systems offer automatic data logging, creating a detailed audit trail for health inspectors. For any operation, but especially those with multiple units, a monitoring system can quickly pay for itself by preventing a single major food loss event. To explore options, check out resources like Monnit's commercial refrigeration solutions.

When you're ready to upgrade your equipment, our team at Charbroilers.com can help you find the right solutions.

Setting and Adjusting Your Fridge: A Step-by-Step Guide

Setting your fridge temperature correctly requires patience and the right method.

First, find your thermostat. It's usually a digital display on the front or an internal dial. If you can't find it, check your equipment manual.

Next, use an independent, calibrated thermometer for an accurate reading. Don't rely solely on the built-in display. Place the thermometer in the center of the fridge, away from vents and the door, and leave it for 24 hours to get a true baseline temperature.

To adjust, follow the golden rule of small changes. If the temperature is off, adjust the setpoint by only one or two degrees. For digital systems, use the 'SET' and arrow buttons. For analog dials, turn clockwise for colder and counter-clockwise for warmer.

Finally, and most importantly, wait another 24 hours after any adjustment. Commercial refrigeration systems need time to stabilize. Making rapid, multiple changes will only lead to frustration. Check your independent thermometer again after the waiting period and repeat the process if another small adjustment is needed.

For more guidance, our Detailed Guide to Comparing Commercial Refrigerators is packed with practical insights.

Best Practices for Commercial Fridge Temperature Control

Maintaining the correct temperature is about daily habits.

- Check temperatures regularly: Do this two to four times daily and keep a log. Automated monitoring systems can handle this for you.

- Load your fridge properly: Don't overfill it. Aim for 70-80% capacity to allow cold air to circulate. Blocked airflow creates warm spots where food can spoil.

- Ensure air circulation: Leave space between items and don't block internal vents or coils. Cold air needs clear paths to reach every corner.

- Manage door openings: Train staff to be quick and ensure doors close properly. For high-traffic walk-ins, consider strip curtains to minimize temperature swings.

Troubleshooting and Maintenance for Consistent Cooling

Even with perfect practices, temperature fluctuations can happen. Most issues are minor and fixable if caught early. Understanding common problems and performing routine maintenance is the best way to ensure reliable commercial fridge temperature control.

If you arrive to find your walk-in at 50°F instead of 38°F, don't panic. The cause is often simple, like dusty condenser coils or a worn-out door gasket. However, some situations require a professional. If you've checked the basics and the problem persists, call a qualified technician for issues like refrigerant leaks or compressor failures.

For help knowing when to call a pro, see our The Ultimate Checklist for Commercial Refrigerator Repair Services.

Common Causes of Temperature Problems

When your fridge's temperature is off, check for these common culprits.

- Dirty condenser coils: These coils release heat. When coated in dust and grease, they can't work efficiently, causing the compressor to overwork and temperatures to rise.

- Faulty door seals: Cracked or worn gaskets let warm air leak in and cold air escape, forcing the unit to run constantly.

- Blocked vents: If internal vents are blocked by food containers, air can't circulate, creating hot and cold spots within the unit.

- High ambient temperature: Placing a fridge next to a heat source like a charbroiler or in a poorly ventilated area forces it to struggle to maintain its temperature.

- Malfunctioning thermostats: A faulty sensor can provide incorrect temperature readings, causing the system to either under-cool or over-cool.

- Refrigerant leaks: Though less common, a leak will cause a gradual loss of cooling power. This requires professional repair.

Your Essential Maintenance Checklist

Prevention is always better than repair. A consistent maintenance routine is key.

- Clean condenser coils monthly: This is the most important task. Turn off the unit and use a stiff brush or vacuum to remove all dust and debris.

- Inspect and clean door gaskets weekly: Wipe them down with soapy water. If you can easily slide a dollar bill through the closed door, the gasket needs replacing.

- Check and clear drain lines weekly: Clogged drains can cause water to pool inside the unit or leak onto the floor. Flush them with hot water.

- Calibrate your thermometers regularly: Verify accuracy every few months with an ice bath (32°F/0°C). An inaccurate thermometer is useless.

- Schedule professional servicing annually: A technician can perform deeper diagnostics, check refrigerant levels, and spot worn components before they fail, extending the life of your equipment.

Frequently Asked Questions about Commercial Fridge Temperatures

Here are answers to the most common questions about commercial fridge temperature control.

What temperature should a commercial refrigerator be?

The ideal range is 34°F to 40°F (1°C to 4°C). This slows bacterial growth while keeping food fresh.

Within this range, store high-risk perishables like raw meat, poultry, and dairy closer to 34°F (1°C) for maximum safety. Beverages and less sensitive items are fine at the warmer end, around 38°F to 40°F (3°C to 4°C).

On a dial from 1 to 7, which setting is the coldest?

On most analog dials, the highest number is the coldest setting. So, 7 is colder than 1.

When setting it, start in the middle (e.g., 4), place an independent thermometer inside, and wait 24 hours to check the actual temperature. Then, make small adjustments as needed, allowing the unit to stabilize after each change.

Why is my commercial fridge freezing everything?

If your fridge is freezing food, several issues could be the cause.

- Thermostat set too low: This is the most common reason. Check that the dial or digital setting hasn't been accidentally turned to its coldest position.

- Faulty thermostat or sensor: The system might think the fridge is warmer than it is, causing the compressor to run continuously and over-cool the interior.

- Blocked air vents: If cold air can't circulate, it can become concentrated in certain areas, creating frozen zones.

- Overloading: Putting too many warm items in at once can cause the system to overcompensate and freeze some contents.

If you've checked these basics and the problem persists, it's time to call a refrigeration technician to diagnose potential sensor or mechanical failures.

Conclusion

The main takeaway is this: commercial fridge temperature control is the invisible guardian of your business, protecting customers, ingredients, and your reputation.

We've covered the ideal temperature ranges, how thermostats work, and the benefits of modern monitoring. We've also provided a roadmap for setting your equipment and the maintenance habits that prevent costly disasters.

Commercial fridge temperature control demands vigilance, but it doesn't have to be overwhelming. Simple, consistent habits—like daily temperature checks and monthly coil cleaning—lead to less food waste, lower energy bills, and longer equipment life.

Your refrigeration system works 24/7. Investing in quality equipment and maintaining it properly is an investment in your food safety program and profitability.

At Charbroilers.com, we want to be your partner in success, helping you choose and use your equipment effectively. Whether you're buying your first reach-in or upgrading a walk-in cooler, we're here to help you make informed decisions.

Ready to optimize your kitchen? Explore our comprehensive guide to commercial kitchen equipment and see how the right tools can lift your operation.