Kitchen Grease Trap Guide: Installation, Cleaning & Regulations

Share

Behind every great commercial kitchen, there's an unsung hero working around the clock: the kitchen grease trap. This piece of equipment is the single most important gatekeeper for your plumbing, stopping fats, oils, and grease (FOG) from creating the kind of clogs that lead to plumbing nightmares and jaw-dropping repair bills.

A properly working grease trap isn't just a "nice-to-have"—it's an absolute must for preventing hefty fines, operational shutdowns, and serious environmental damage.

The Unseen Hero of Your Commercial Kitchen

Think of your grease trap as the first line of defense for both your restaurant's pipes and the city's entire sewer system. Every single time a greasy pan gets rinsed or food scraps are washed down the drain, FOG is introduced into your wastewater. Without a trap, that greasy water flows straight into the sewer lines where it cools down and solidifies, creating enormous blockages that have been nicknamed "fatbergs."

These blockages are a disaster waiting to happen. They can cause raw sewage to back up directly into your establishment—or even your neighbors'—leading to immediate health hazards and forced closures. A kitchen grease trap prevents this with a brilliantly simple design based on basic physics.

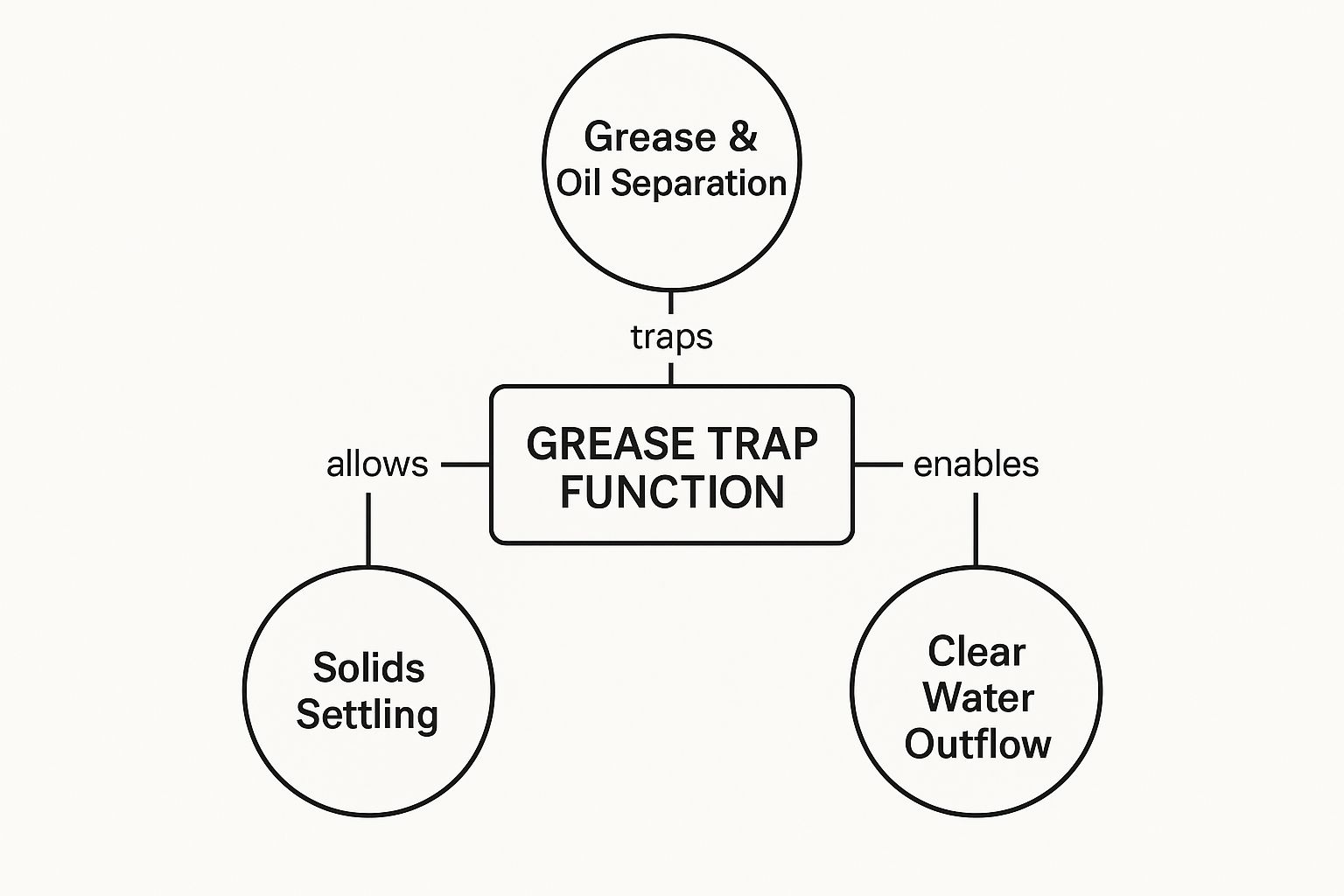

Here’s the breakdown of how it works:

- Wastewater enters the trap: All the water from your kitchen sinks and floor drains flows into the unit first.

- FOG separates and floats: Inside the trap, a system of baffles slows the water down. This gives the lighter-than-water fats, oils, and grease a chance to float to the top.

- Solids sink: At the same time, any heavier food particles sink to the bottom, forming a layer of sludge.

- Clearer water exits: The remaining water, now mostly free of grease, flows out of the trap and safely into the sewer system.

A Critical Component of Kitchen Operations

This separation process is absolutely vital. Managing FOG isn't just a good idea; in most places, it's a legal requirement designed to protect public infrastructure. As the number of restaurants and food service businesses grows, so do the environmental regulations, making these devices more essential than ever.

The global grease traps market was valued at around USD 1.20 billion and is projected to climb to USD 1.64 billion, growing at a CAGR of about 2.25%. This isn't just a random statistic; it shows a worldwide trend toward stricter FOG management.

Outfitting your kitchen with the right equipment is the foundation of a successful business. Just as a grease trap is non-negotiable for protecting your plumbing, having the right cooking and prep tools is essential for executing your menu. For a full rundown of everything you'll need, check out our commercial kitchen equipment checklist. This guide makes sure you've covered all your bases, from prep tables to the final cooking station, helping you build an efficient and compliant operation from the ground up.

Picking the Right Grease Trap for Your Kitchen

Choosing the right kitchen grease trap isn't a one-size-fits-all deal; it’s about matching the equipment to your kitchen’s specific workflow. Just like picking the right oven or fryer, the wrong choice can create daily headaches, while the right one just works quietly in the background. The three main players—hydromechanical, gravity, and automatic—each have a specific job to do.

Get this choice wrong, and you're looking at constant maintenance headaches, fines for non-compliance, and even messy sewage backups. The right unit, however, protects your plumbing, keeps the inspectors happy, and lets you focus on what really matters: your food and your customers.

Small-Scale Solutions: Hydromechanical Grease Traps

For smaller spots like cafes, delis, or food trucks, a hydromechanical grease trap is usually the perfect fit. These are the compact, indoor units you often see installed right under a three-compartment sink or near a specific prep area that generates grease. They work on a simple but effective principle, using a series of baffles to slow down the wastewater, giving grease and oil enough time to separate and float to the top.

Their smaller footprint makes them a go-to for kitchens where space is tight and grease output is relatively low. Think of a coffee shop that makes grilled paninis or a small bakery frying donuts. They do need more frequent cleaning—often weekly or bi-weekly—but their lower upfront cost and simple installation make them a practical pick for low-volume operations.

High-Volume Powerhouses: Gravity Interceptors

When your kitchen is pumping out a serious amount of grease, you need a much bigger solution. This is where gravity interceptors come into play. We're talking about huge underground tanks, often holding 1,000 gallons or more, buried outside the building. These are the workhorses for high-volume restaurants, hospitals, school cafeterias, and food processing plants that need to handle a massive flow of wastewater.

Because of their sheer size, they can hold a ton of fats, oils, and grease (FOG) before they need to be serviced. This means they are typically pumped out by a professional service every 60 to 90 days, not every week. While the installation is a full-blown construction project with a higher price tag, their capacity is non-negotiable for large-scale food service operations that would overwhelm a small indoor grease trap in a matter of hours.

At-a-Glance Grease Trap Comparison

To make sense of these options, it helps to see them side-by-side. Each type has its place, and the best choice depends entirely on your kitchen's volume, space, and how much hands-on maintenance you're willing to do.

| Trap Type | Typical Location | Best For | Key Advantage | Key Disadvantage |

|---|---|---|---|---|

| Hydromechanical | Indoors, under-sink | Small cafes, delis, food trucks | Low initial cost & compact size | Frequent manual cleaning required |

| Gravity Interceptor | Outdoors, underground | Large restaurants, hospitals | Huge capacity, infrequent service | High installation cost & space needs |

| Automatic (AGU) | Indoors, near equipment | Busy QSRs, modern kitchens | Self-cleaning, low labor | Highest upfront cost |

This table gives you a quick snapshot, but the real decision comes down to balancing the upfront investment against the long-term operational costs and labor for your specific business.

The Modern Automated Approach

For businesses that want to cut down on manual labor and keep things running as efficiently as possible, Automatic Grease Removal Units (AGUs) are a fantastic option. These units are about the same size as hydromechanical traps but come with a crucial upgrade: a self-cleaning function. An internal skimmer periodically scrapes off the collected grease and moves it into a separate, easy-to-empty container.

By automating the removal process, AGUs dramatically reduce how often you need to do manual cleanouts and keep the unit working at peak performance all the time. This can be a total game-changer in a busy kitchen where every minute of staff time counts.

While AGUs have the highest sticker price, they can deliver a solid return on investment through lower labor costs, fewer professional pumping fees, and consistently reliable performance. They’re an excellent choice for almost any establishment, from a high-turnover quick-service restaurant to a fine dining kitchen that wants a more "set it and forget it" approach to grease management.

Understanding Grease Trap Installation and Costs

Putting in a kitchen grease trap can feel like a massive undertaking, but once you break down the process and the costs involved, it becomes a lot more straightforward. The final bill isn't just about the unit itself. It’s a mix of a few key factors that every kitchen manager needs to have on their radar.

Right off the bat, the price is heavily shaped by the trap's type, size, and what it's made of. A small, under-sink hydromechanical unit might only set you back a few hundred dollars. On the other hand, a big, in-ground gravity interceptor can easily run into the tens of thousands.

Trying to squeeze a grease trap into an existing kitchen is almost always a bigger, more expensive headache than planning for one in a new build. It can mean cutting through concrete floors and completely re-routing your plumbing lines.

Budgeting for Your Grease Trap

The material you choose for the grease trap is a huge factor in both its price and how long it will last. It’s a major consideration in the commercial grease trap market, which was valued at roughly $2.5 billion and is projected to grow at a 6% clip.

Plastic models are popular because they have a lower upfront cost and are simpler to install. However, stainless steel units, while more of an investment, are gaining ground because they're built to last and stand up to corrosion much better. You can dive deeper into the commercial grease trap market trends and data to see the full picture.

Here’s a quick look at what will make up your total installation cost:

- Unit Price: This depends on the size (gallons per minute rating), the type (hydromechanical vs. gravity), and the material (plastic, steel, or fiberglass).

- Labor and Installation: This is a big chunk of the cost. Hiring a licensed plumber is non-negotiable. You need to be sure the installation meets every single local plumbing and health code.

- Site Preparation: For those big outdoor interceptors, this means digging, maybe pouring concrete, and hooking everything up to the main sewer lines.

- Permit Fees: Your city or county will require permits for this kind of plumbing work, and that fee gets added to the total bill.

The Total Cost of Ownership

It’s a huge mistake to only focus on the initial purchase price. To get the real financial picture, you have to look at the total cost of ownership over the unit's entire life. This includes the upfront investment plus all the ongoing costs needed to keep the system running and compliant.

The real cost of a kitchen grease trap isn't just what you pay to install it; it's the sum of its purchase price, professional installation, regular cleaning services, and any potential repairs or fines over its lifetime.

Thinking long-term like this is crucial for smart budgeting. For example, that cheaper plastic trap might need to be replaced much sooner than a rugged steel one. The frequent pumping needed for a small, undersized trap also adds up over time.

It's just like the equipment that produces all that grease in the first place—your fryers need their own budget for oil and maintenance. If you're weighing those costs, our guide to choosing commercial electric deep fryers can help you understand all the related expenses. Ultimately, investing in the right size and type of grease trap from day one is the best way to avoid much bigger costs—from emergency plumbing disasters to hefty fines from the health inspector—down the road.

Getting a Handle on Grease Trap Cleaning and Maintenance

A grease trap is only as good as its cleaning schedule. If you ignore it, you’re basically asking for a messy, expensive breakdown—it’s like owning a high-performance car and never bothering to change the oil. The secret to avoiding trouble is setting up a simple, consistent cleaning routine before problems even have a chance to start.

It all begins with your kitchen crew. The single most effective thing you can do is train your staff to scrape every last bit of food off plates, pots, and pans into the trash before they hit the sink. The less gunk that goes down the drain, the less work your trap has to do, which means more time between professional pump-outs. This one habit is the foundation of smart grease management.

Finding Your Maintenance Rhythm

A rock-solid maintenance plan is a mix of three things: daily checks, in-house cleaning, and professional servicing. Each one has a specific job to do in keeping your system running smoothly and keeping the health inspector happy.

Daily and Weekly Checks

Think of your kitchen staff as your first line of defense. Get them in the habit of spotting the early warning signs that something’s not right.

- Slow Drains: Is the three-compartment sink suddenly taking forever to drain? That's usually the very first clue your grease trap is getting full.

- Foul Odors: If a nasty, sour smell is wafting up from the drains, it’s a dead giveaway that old grease is decomposing in the trap. It’s long overdue for a cleaning.

- Gurgling Sounds: Hearing strange gurgles from your pipes? That’s the sound of wastewater struggling to push its way through a partially clogged line.

In-House Cleaning vs. Professional Pumping

If you have a smaller, under-sink hydromechanical unit, your trained staff can probably handle regular cleanouts. This usually means manually scooping out the solid layer of grease at the top and the food solids that have settled at the bottom. But this has to be done right, and the waste needs to be disposed of according to local rules—which never means dumping it in the trash.

For the big, in-ground grease interceptors, professional pumping isn’t just a good idea—it’s a must. These pros show up with powerful vacuum trucks that suck the trap completely clean of all fats, oils, grease, and sludge. It's a level of clean you just can't get by hand.

The choice between DIY and professional service really comes down to your trap's size and what your local health department says. Most regulations require professional servicing every 30 to 90 days to keep you in compliance. It's absolutely critical to keep a detailed maintenance log of every cleaning, whether you do it yourself or hire it out. That log is your proof for the health inspector.

The global grease trap market, currently valued at $2.5 billion, is projected to hit $3.5 billion as wastewater regulations get tighter. This trend just goes to show how much the commercial food industry is focusing on professional maintenance and responsible grease management. You can get more details on this growing market by checking out a detailed report on grease trappers.

Keeping detailed logs and staying on top of your cleaning schedule isn't just about dodging fines. It's about protecting your equipment and saving your business from the chaos of an emergency shutdown.

Navigating FOG Regulations and Staying Compliant

Ignoring the rules for Fats, Oils, and Grease—or FOG, as it’s known in the industry—is one of the fastest ways to get hit with crippling fines or even a forced shutdown. These regulations aren't just bureaucratic busywork. They’re what stand between a functioning public sewer system and a catastrophic "fatberg" that can cause millions in damages and create a genuine public health crisis.

When an inspector walks through your door, they aren't just there to admire your clean floors. They're on a mission, working from a specific checklist to make sure your kitchen grease trap is doing its job and that you’re doing your part to keep the city's pipes clear. Knowing what they're looking for is the key to operating without constantly looking over your shoulder.

What Inspectors Are Looking For

When that health or wastewater official arrives, they're typically focused on three main things. Nail these, and you'll pass with flying colors. Miss the mark, and you could be facing some serious penalties.

- Proper Sizing and Installation: The first thing they'll check is if your grease trap is even the right size for your kitchen's output. An undersized unit is an instant red flag because it can't possibly keep up with your daily load.

- Mandated Cleaning Frequency: Are you actually cleaning the trap often enough? Most municipalities follow the "25% Rule," and an inspector can tell just by looking if your unit is overflowing or neglected.

- Detailed Record-Keeping: This is often the make-or-break item. Can you show them your maintenance logs right away? Your logbook needs to be your proof, detailing every cleaning date, who did the service, and how much grease they hauled away.

From an inspector's perspective, if you don't have the records, the maintenance never happened. It’s as simple as that.

The High Cost of Non-Compliance

The fallout from ignoring FOG regulations can be severe and can escalate in a hurry. A restaurant might get a small fine for a first offense, but repeat violations can quickly spiral into fines costing thousands of dollars. In the worst-case scenarios, they can force you to buy new equipment or even suspend your business license until you fix the problem.

A well-documented compliance strategy is your best defense. Think of it less as avoiding trouble and more as building a partnership with your local water authority. It’s about keeping your kitchen running smoothly and being a good steward of your community’s infrastructure.

Making sure your kitchen grease trap is compliant is deeply tied to your kitchen’s entire workflow. The right equipment placement and flow can make FOG management much easier. To get the full picture, check out our expert advice on commercial kitchen layout and design to build efficiency in from day one.

Common Questions About Kitchen Grease Traps

Even after you get the hang of your kitchen's grease trap, some practical questions always seem to pop up during the daily grind. Getting straight answers to these common head-scratchers is key to managing your FOG system with confidence and avoiding any nasty surprises. Let's tackle some of the most frequent questions we hear from kitchen managers on the front lines.

How Often Should My Kitchen Grease Trap Be Cleaned?

The real answer depends on your trap's size, how busy your kitchen is, and—most importantly—what your local health department says. But a fantastic rule of thumb used throughout the industry is the "25% Rule."

The rule is simple: once the gunk floating on top (FOG) and the solids settled on the bottom take up 25% of your trap's total space, it's time for a professional clean-out. For most restaurants, following this guideline means scheduling a service every one to three months. Always double-check the required schedule with your local wastewater or health authority, as their rules are the law.

Does Pouring Hot Water Down the Drain Help with Grease?

Absolutely not. This is one of the most common—and damaging—myths in the kitchen. It might look like a quick fix, but pouring hot water down a greasy drain just makes the problem worse.

Sure, the hot water melts the grease for a moment, but it doesn't make it vanish. Instead, it just shoves the liquid grease further down the line. As soon as it cools off, it turns solid again, creating a much tougher, deeper clog in your plumbing. The only real solution is to scrape plates clean and let your grease trap do its job.

What Are the Warning Signs of a Full Grease Trap?

Your kitchen will give you some pretty clear hints when your grease trap is full and crying for help. Catching these signs early can save you from a disgusting, expensive, and business-halting sewage backup.

If you ignore the warning signs, you're not just risking a clog; you're risking a shutdown. A sewage backup is a critical health code violation that can force your business to close until it's resolved, leading to lost revenue and a damaged reputation.

Keep an eye (and a nose) out for these red flags:

- Foul Odors: This is usually the first sign. If you notice a persistent, sour, or rotten-egg smell coming from your floor or sink drains, your trap is likely the culprit.

- Slow Draining: Are your sinks taking forever to drain? That's a classic symptom of a full trap that’s choking off the water flow.

- Gurgling Pipes: Hearing strange gurgling sounds from the drains long after you've turned the water off often means wastewater is fighting its way through a blockage.

If you spot any of these problems, it’s time to get a professional cleaning on the schedule, pronto.

While a clean grease trap keeps your back-of-house compliant, the right cooking equipment brings your menu to life. At Charbroilers.com, we offer a wide selection of commercial charbroilers for your restaurant to deliver those signature flavors your customers crave. You can choose from advanced infrared charbroilers that provide intense, even heat with fewer flare-ups, reliable gas models known for their precise control, or efficient electric char broilers perfect for kitchens with ventilation or utility constraints. Explore our full range at https://charbroilers.com.