Top Commercial Electric Deep Fryers for Your Kitchen

Share

In a busy professional kitchen, commercial electric deep fryers are your secret weapon for consistency, efficiency, and safety. Think of them as high-performance ovens with thermostats so perfectly calibrated that every single batch of fries comes out golden brown, every single time. This level of precision solves some of the most common kitchen headaches, like inconsistent food quality and runaway energy costs, streamlining your entire operation from day one.

Why Modern Kitchens Rely on Electric Deep Fryers

The shift to commercial electric deep fryers isn't just a trend; it's a smart, strategic move for kitchens that demand superior performance and total control. Unlike their gas counterparts, which can struggle with temperature swings, electric models use heating elements submerged directly in the oil. This means direct, consistent heat, faster recovery times between batches, and perfectly cooked food that keeps your customers coming back for more.

This reliability is a huge reason the market is booming. The global commercial electric deep fryer market was valued at around USD 1.23 billion in 2022 and is on a steady growth track. This expansion is tied directly to the foodservice industry's demand for equipment that delivers absolute temperature control and serious energy efficiency.

The Core Benefits for Your Operation

For any restaurant owner or kitchen manager, the advantages of going electric hit the bottom line—hard. An electric fryer isn't just another piece of cooking equipment; it's a tool for achieving operational excellence.

Here's what you gain:

- Unmatched Consistency: Electric thermostats hold oil temperatures with incredible precision, taking all the guesswork out of frying. This is absolutely crucial for maintaining your brand standards and delighting customers.

- Enhanced Safety: With no open flames or gas lines to manage, electric fryers significantly lower the fire risk in a high-pressure kitchen environment. It’s peace of mind you can’t put a price on.

- Improved Efficiency: These units heat up faster and have quicker temperature recovery times, allowing your team to smash through high-volume orders without a single delay.

- Easier Installation: Since they don’t need gas line hookups, electric models offer much more flexibility in where you can place them, making them a perfect fit for almost any kitchen layout.

To help you make the right call for your fry station, we’ve put together a guide reviewing the top commercial deep fryers available. This resource takes a deeper dive into the models that can truly elevate your kitchen's output. For anyone looking to upgrade their entire cook line, we also offer information on our wide selection of commercial charbroilers for your restaurant, including infrared, gas, and electric char broilers.

How an Electric Fryer Actually Works

To really get why commercial electric deep fryers are so precise, it helps to pop the hood and see what’s going on inside. This isn't just a pot of hot oil on a stove; it’s a finely-tuned system where every piece has a job, all working together to pump out perfectly fried food, batch after batch. The whole operation runs on a simple but brilliant principle: direct heat transfer.

At the very heart of the machine, you’ll find the heating elements. You can think of these as the fryer's engine. These powerful electric coils are submerged right in the cooking oil, which means nearly every bit of energy they generate goes straight into heating that oil. This direct contact is exactly why electric fryers are famous for their lightning-fast heat-up times and quick temperature recovery, even when you drop in a basket of frozen fries.

It’s a far more efficient setup than gas models, which heat the outside of the fry pot and waste a ton of energy heating the air around it. An electric fryer’s efficiency translates directly to less wasted energy and lower utility bills over the long haul.

The Brains and the Brawn of Frying

The heating elements supply the raw power, but it's the thermostat that provides the smarts. This component is the fryer's brain, constantly keeping tabs on the oil's temperature. It switches the heating elements on and off as needed to hold a super-consistent temperature, often staying within just a few degrees of whatever you’ve set. This accuracy is your best defense against the two cardinal sins of frying: burnt food from oil that’s too hot, and greasy, soggy food from oil that’s too cold.

The fry pot, or tank, is the real workhorse, holding the oil and all that delicious food. But its design is a lot more clever than it looks, especially when it has a feature that can literally save you thousands of dollars a year on oil.

The secret to longer oil life and better-tasting food isn't just about temperature; it's about what happens to the crumbs. This is where a well-designed fry pot makes all the difference.

A crucial design feature in many top-tier electric fryers is the cold zone. This is an area at the very bottom of the fry pot, tucked underneath the heating elements. Since heat naturally rises, the oil down in this zone stays significantly cooler than the main cooking area above it.

This simple bit of physics has a massive impact:

- Crumb Collection: As little bits of breading and food break off during frying, they sink. Instead of getting scorched in the hot cooking oil, they fall harmlessly into the cooler cold zone.

- Oil Preservation: Burnt particles are the enemy of clean oil; they degrade it fast, tainting the flavor and color. By trapping these particles in the cold zone, the fryer keeps the main body of oil cleaner for much, much longer.

- Cost Savings: Making your oil last longer means you replace it less often, which leads to huge savings on one of your kitchen's biggest expenses. It also means every single batch of food tastes fresh, not like the burnt leftovers from the last few orders.

Choosing the Right Features for Your Kitchen

Once you’ve nailed down the basics, picking the right commercial electric deep fryer is all about choosing features that will actually make you money. Sure, every fryer heats oil, but the advanced options are what separate a good fryer from a truly great one. These aren’t just shiny bells and whistles; they’re workhorse tools designed to boost your kitchen's bottom line through smarter workflow, rock-solid consistency, and serious cost savings.

Think of features like automatic basket lifts, built-in oil filtration, and programmable timers as your fry station's MVP support staff. They work behind the scenes to slash labor needs, cut down on oil waste, and guarantee every single order meets your high standards. When you invest in these capabilities, you’re not just buying a piece of metal—you’re upgrading your entire frying operation.

Features That Drive Profitability

When you're looking at a new fryer, try to see past the upfront price and focus on its long-term financial impact. Some features are specifically engineered to save you a ton on oil, labor, and energy, paying for themselves many times over.

- Built-in Oil Filtration Systems: This is, without a doubt, the single most impactful feature for saving money. A built-in system turns the messy, dreaded task of manual filtering into a simple, quick process. More importantly, it can extend the life of your cooking oil by 50% or more. That translates to thousands of dollars in savings on supplies each year.

- Automatic Basket Lifts: In a high-volume kitchen, consistency is king. Auto-lifts remove all the guesswork from cooking. They pull the baskets out of the hot oil at the exact moment the food is perfectly done, preventing costly overcooking and waste.

- Programmable Controls: These let you pre-set specific cook times and temperatures for everything on your menu. This feature empowers any employee, from a seasoned pro to a brand-new hire, to deliver consistently perfect results with just one button press. It’s a game-changer for reducing training time and locking in food quality.

Choosing the right feature set is like assembling a specialized team for your fry station. Each component should have a clear purpose: to make your kitchen faster, smarter, and more profitable.

Smart Design for Everyday Use

Beyond the high-tech stuff, keep an eye out for smart design elements that just make daily life in the kitchen easier and safer. These practical details can dramatically improve your workflow and protect both your staff and your equipment. For kitchens tight on space, it's crucial to know how these features work in smaller units. You can find out more in our detailed guide on the commercial countertop fryer to see how these benefits scale down.

Finally, don’t overlook the build quality. A fryer constructed from heavy-gauge stainless steel will stand up to the brutal demands of a busy kitchen far better than a flimsy, light-duty model. Look for solid, sturdy legs, cool-to-the-touch handles, and components that are easy to get to for cleaning. These little details are big clues that you’re looking at a well-built machine designed for the long haul—an investment that will keep paying you back for years.

Countertop vs Floor Fryers: Which Is Best?

Picking the right commercial electric deep fryer is one of those crucial decisions that boils down to two simple things: how much space you have and how much food you need to fry. The debate between a countertop and a floor model isn’t about which is "better"—it's about finding the perfect fit for your kitchen's reality. Get it right, and your fry station becomes a well-oiled machine. Get it wrong, and it becomes a bottleneck on a busy Friday night.

Think of a countertop fryer as the nimble specialist. It's the go-to solution for kitchens where every inch of counter space is prime real estate. We're talking food trucks, concession stands, or bars that just need to crank out some killer appetizers. They’re easier on the wallet upfront and often portable, giving you some much-needed flexibility.

On the flip side, a floor model is the undisputed heavyweight champion. These are the workhorses built for the daily grind of high-volume restaurants, fast-food joints, and massive catering gigs. With huge oil capacities and seriously powerful heating elements, floor fryers are engineered to handle the relentless demand of a dinner rush, churning out perfect batches without breaking a sweat.

Evaluating Your Kitchen’s Demands

To make the right call, you need to be brutally honest about your output. Are you frying a few baskets of onion rings an hour, or are you pushing out hundreds of pounds of fries and chicken wings every single day? Your answer will point you straight to the right piece of equipment.

- Low to Moderate Volume: If fried foods are a supporting character on your menu, not the star of the show, a countertop model is almost certainly your best bet. It gets the job done without demanding the space or electrical muscle of a bigger unit.

- High Volume: For any spot where fried food is a menu cornerstone, a floor fryer is non-negotiable. Its sheer capacity and quick recovery time are absolutely essential for keeping up with orders and making sure the 100th basket of fries is just as good as the first.

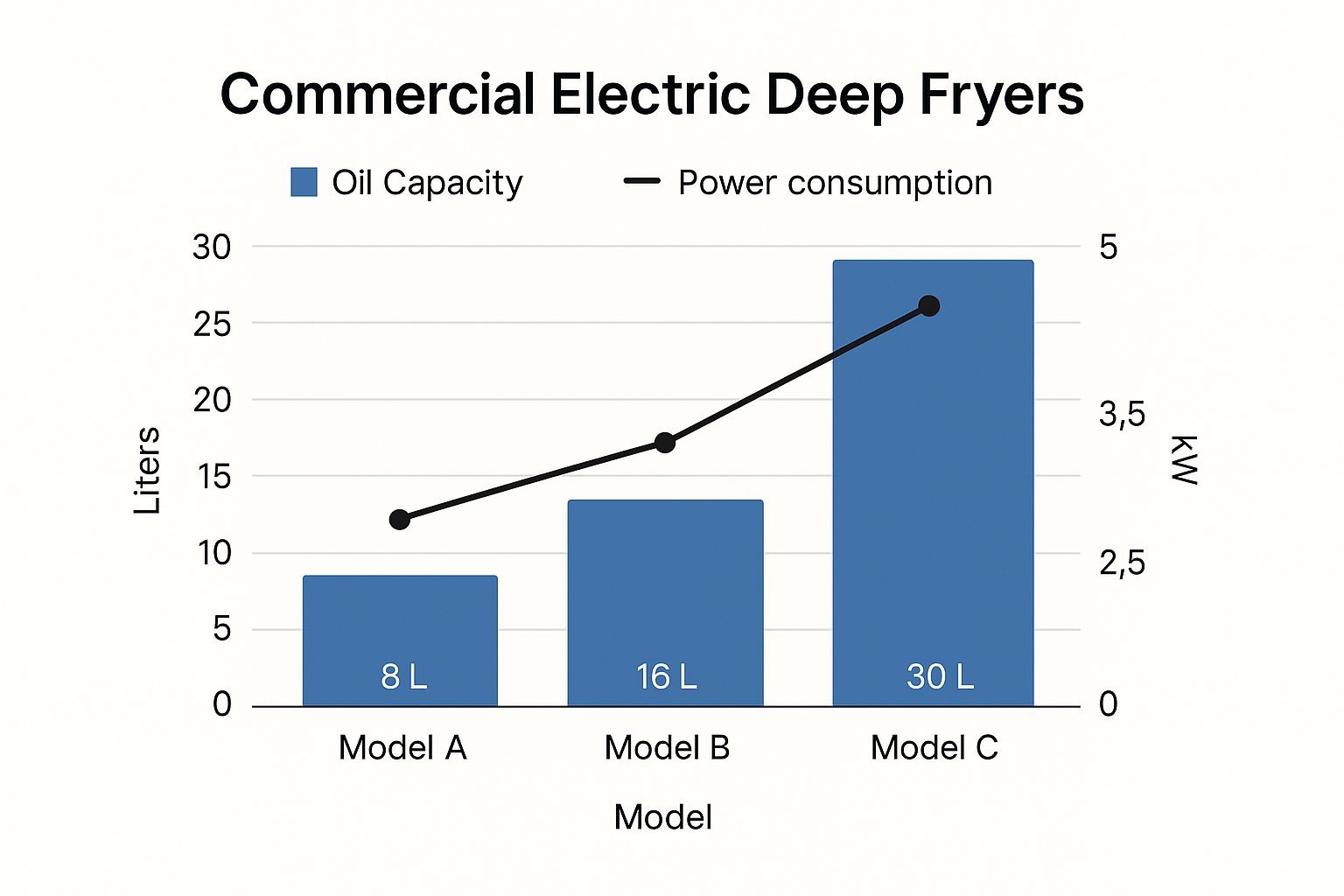

This chart really puts the relationship between a fryer's size and its power needs into perspective.

As you can see, when the oil capacity (the bars) jumps from Model A to Model C, the power required (the line) has to climb steeply to keep up. More oil means you need more power to heat it fast and keep it hot.

Countertop vs Floor Model Commercial Electric Deep Fryers

Let's put these two fryer types head-to-head. This table breaks down the key differences to help you decide between a compact countertop fryer and a high-capacity floor model.

| Feature | Countertop Fryer | Floor Fryer |

|---|---|---|

| Best For | Food trucks, bars, small cafes, low-volume kitchens | High-volume restaurants, QSRs, large catering operations |

| Footprint | Small and compact, frees up floor space | Large, requires dedicated floor space and ventilation |

| Capacity | Typically 10 to 30 lbs of oil | Often 40 to 100+ lbs of oil |

| Power Needs | Usually plugs into standard or slightly higher outlets | Requires professional installation and high-voltage wiring |

| Upfront Cost | Lower initial investment | Higher initial investment |

A floor model might look like the obvious choice because of its power, but for a smaller operation, it could be an expensive, oversized headache. It’s all about finding the right tool for the job.

The right fryer isn't always the biggest or most powerful one; it's the one that integrates seamlessly into your kitchen's workflow and budget, maximizing efficiency without creating new problems.

Ultimately, this choice shapes what your kitchen is capable of. A countertop fryer gives smaller ventures agility and affordability. A floor fryer provides the raw power and capacity you need to dominate a high-volume market.

Operating Your Fryer for Maximum Profit and Safety

Getting your new commercial electric deep fryer unboxed and installed is just the beginning. The real magic—and profit—happens when you master its daily use. A well-run fryer is a cash cow for any kitchen, but it demands respect. That means being smart about how you manage your oil and deadly serious about safety.

Let's talk about your fryer's biggest expense: the cooking oil. Getting this right doesn't just make your food taste better; it directly pads your bottom line. A few simple habits can dramatically extend the life of your oil, saving you a small fortune over the long haul.

Mastering Oil Management and Temperature Control

The number one rule for protecting your oil? Nailing the temperature. Most foods fry to golden perfection somewhere between 350°F and 375°F. If you let the oil get hotter than that, it starts to break down fast, creating nasty off-flavors and dramatically shortening its usable life. Keeping it in that sweet spot is everything.

Filtering your oil every single day is just as important. At the end of a shift, running the oil through a filter gets rid of all the tiny food particles and sediment. If left behind, those bits just burn and turn your beautiful, clean oil into a sludgy mess. If your fryer has a built-in filtration system, this is a quick and painless process.

Protecting your cooking oil is one of the highest-impact, lowest-cost ways to boost profitability. Clean, well-maintained oil produces better-tasting food and drastically reduces replacement costs.

If you're looking to make this process even easier, exploring our lineup of commercial electric deep fryers can show you models where advanced filtration and precision temperature controls are already built right in. It’s an investment that pays for itself in oil and labor savings.

Essential Safety Protocols for Your Fry Station

A kitchen in the middle of a dinner rush is no place to be casual about safety, especially around vats of hot oil. Putting clear, non-negotiable rules in place protects your people, your equipment, and your entire business from accidents that are completely preventable.

Your team's safety playbook should absolutely include these practices:

- Prevent Splatters: Never, ever drop wet or icy food into hot oil. Water and hot oil create a violent, explosive reaction that can cause serious burns. Always pat food dry before it goes into the basket.

- Handle with Care: Staff needs to be trained to treat hot oil with extreme caution. That means using the right personal protective equipment (PPE), like heat-resistant gloves and aprons, especially when filtering or changing the oil.

- Cleanliness is Safety: A daily wipe-down is a must. Grease buildup is a massive fire hazard. Wiping down the fryer's exterior, handles, and the surrounding floor keeps your station safe and sanitary.

- Fire Safety First: Every kitchen needs a Class K fire extinguisher within arm's reach of the fry station. Make sure every single team member knows where it is and exactly how to use it in an emergency.

By weaving these operational habits and safety rules into your daily routine, you'll run a fryer station that's not only more profitable and efficient but also a whole lot safer. It's all about protecting your investment and your most important asset—your team.

The Future of Frying Technology

The world of commercial electric deep fryers is changing fast. We're moving way beyond simple temperature dials into an era of smart, automated, and incredibly efficient technology. These aren't just sci-fi concepts; they are real-world solutions hitting the market right now.

The world of commercial electric deep fryers is changing fast. We're moving way beyond simple temperature dials into an era of smart, automated, and incredibly efficient technology. These aren't just sci-fi concepts; they are real-world solutions hitting the market right now.

These new fryers are designed to solve the biggest headaches in modern kitchens—from labor shortages and soaring utility bills to the growing demand for more sustainable operations.

This next generation of fryers is being built to think. Imagine a fryer using AI-powered cooking cycles to automatically tweak the time and temperature for whatever you're cooking, hitting that perfect golden-brown crispness every single time with minimal staff help. That level of automation is here, helping kitchens deliver consistently great food, even with a less experienced crew.

This jump in technology is a huge reason the market is growing. Forecasts show the electric commercial deep fryer market is on track to grow from USD 1.8 billion in 2025 to USD 2.6 billion by 2035. That's some serious growth, all fueled by the demand for smarter, more efficient kitchen gear. If you want to dive deeper into the market trends, you can explore more insights about these advancements in frying technology.

Smart Features Redefining Kitchen Workflow

The biggest leaps forward are happening in automation and energy management. These features are designed to take the guesswork out of frying and seriously cut down your operating costs, making your kitchen more profitable and a whole lot less wasteful.

Here are a few key innovations to keep an eye on:

- Fully Automated Filtration: I'm talking about systems that filter the oil all by themselves on a preset schedule, no staff required. This not only makes your oil last longer but also frees up your team for more important tasks.

- Ultra-Efficient Energy Designs: Next-gen heating elements and better insulation are cutting energy use by as much as 30-40% compared to older fryers. That's a direct hit to your monthly utility bills.

- Integrated Data and Connectivity: Smart fryers can now link up with kitchen management software, giving you real-time data on oil life, cooking cycles, and maintenance alerts for better oversight.

Investing in future-focused technology isn't about chasing shiny new objects. It's a strategic move to future-proof your kitchen. These advancements deliver a clear return on investment through savings on labor, energy, and oil.

Preparing for a Smarter, More Efficient Kitchen

By understanding where frying technology is going, you can make a much smarter investment today. A fryer with automated features and energy-saving designs won’t just meet your current needs—it will keep your kitchen competitive and lean for years to come.

As you think about your next equipment upgrade, consider how these forward-thinking features line up with your long-term business goals. And if you're looking to build out your entire cookline, don't forget we offer a wide selection of commercial charbroilers. Our inventory includes advanced infrared, traditional gas, and efficient electric char broilers to match any restaurant's needs.

Common Questions About Electric Fryers

Picking out a new commercial electric deep fryer is a big move, and it's totally normal to have a few last-minute questions. Getting solid answers on things like power, upkeep, and what it'll cost to run is the key to making a smart investment that’ll serve your kitchen well for years. We’ve pulled together some straight-to-the-point answers for the questions we hear most often.

A big one right off the bat is installation. Unlike gas fryers, you don't need to worry about gas line hookups, which gives you a lot more freedom in where you can place an electric model. But, be aware that the heavy-duty floor models often demand specialized high-voltage outlets. It's always a good idea to have an electrician check out your kitchen's wiring before you buy.

Power Needs and Daily Care

A question I get all the time is about power: "Can I just plug it into my regular outlets?" While some small countertop fryers might use a standard 120V plug, almost all commercial units—especially the floor models—need 208V or 240V three-phase power. This is what gives them the muscle for quick heating and fast recovery times. Always, always double-check the electrical specs on the product page.

As for daily upkeep, the best habit you can get into is simple: filter your oil at the end of every single day. This one step works wonders. It stops food particles from building up, makes your oil last way longer, and keeps your food tasting great. For a more thorough clean, a weekly "boil out" using a special cleaning solution will keep your fry pot in prime condition.

The old electric vs. gas fryer debate often boils down to what you'll spend in the long run. Gas might be cheaper upfront in some places, but electric fryers are far more efficient with their energy, since nearly all of it goes directly into heating the oil. This efficiency often evens out the score, and in many cases, can even make electric the cheaper option on your monthly utility bill.

The whole commercial fryer market is a busy and competitive field. In fact, market forecasts predict the industry will swell to USD 798.24 million by 2032, thanks to manufacturers who are always pushing for better designs. This growth is great news for you, as it means new models will keep getting more efficient and packed with useful features. You can dive into the full commercial deep fryer market analysis to see what trends are shaping the future of frying.

At Charbroilers, we offer information on our wide selection of commercial charbroilers for your restaurant, including high-performance infrared, gas, and electric models to complete your cooking line. Explore our full range of professional kitchen equipment to find the perfect tools for your business at https://charbroilers.com.