How to Prevent Grease Fires in Your Kitchen

Share

When it comes to preventing a grease fire, it all boils down to one simple word: control.

You have to control the heat, contain the grease, and keep your equipment spotless. This isn't about grand gestures; it's about the small, consistent habits that stop a fire before it even has a chance to spark. Things as simple as never leaving a hot charbroiler unattended or ensuring your ventilation system is clean are your first and best lines of defense.

The Real Dangers of a Commercial Kitchen Fire

To stop a grease fire, you first have to understand how one starts. It’s never just a case of bad luck. A grease fire is a predictable, almost scientific outcome when heat, fuel, and oxygen collide in just the right (or wrong) way.

In a high-volume kitchen, that risk is everywhere. Your fuel source—grease—is a constant presence, from the charbroiler grates and deep fryer vats to the invisible film coating the inside of your ventilation hood.

Think about what happens when cooking oil gets hot. First, you see a little smoke. That's the smoke point, your visual cue that the oil is breaking down and creeping toward a dangerous temperature. If you keep heating it, the oil eventually hits its flashpoint. At this temperature, it releases enough vapor to ignite the second it meets an ignition source, like the open flame from a gas charbroiler.

The Science of a Flare-Up

Ever seen a small flare-up when a burger drips onto the grill? That’s the science in action. A single drop of fat hits the hot radiants below, vaporizes in an instant, and ignites. It’s usually small and gone in a flash, but it perfectly demonstrates just how volatile grease can be.

Now, let's replay that scenario on a dirty charbroiler. The grease trap is brimming, and a thick, carbonized layer of old grease cakes the inside. That small, manageable flare-up now has an enormous amount of fuel to feed on. It can easily climb the greasy interior walls, igniting all that built-up residue. This is exactly how a minor incident explodes into a full-blown equipment fire in a matter of seconds.

And the danger doesn't end there. An unchecked fire on your cookline can quickly spread into the building's structure, often using the ventilation system as a chimney to carry flames where you can't see them.

The Perfect Storm for a Kitchen Fire

A truly devastating kitchen fire is rarely the result of one big mistake. It's almost always a perfect storm—a series of small, seemingly minor issues that line up to create a catastrophe.

These are the things that keep fire marshals up at night:

- Inconsistent Cleaning Routines: Skipping the end-of-night charbroiler clean-out or pushing back a professional hood cleaning lets flammable grease build up to hazardous levels.

- Overworked Equipment: Pushing equipment to its absolute limit during a slammed service without giving it a chance to cool can easily push cooking oils past their flashpoints.

- Minor Staff Oversights: It’s the little things. A towel left too close to a burner, a cook getting distracted and leaving a pan unattended, or even using the wrong cleaning chemical can provide that initial spark.

The hard truth is that most kitchen fires are entirely preventable. It comes down to respecting the inherent risks of a commercial kitchen and treating every single safety protocol—no matter how small it seems—as a critical part of your defense.

This isn’t just theoretical. While we all know residential cooking fires are a common hazard, commercial kitchens operate at a completely different level of risk due to the sheer volume of cooking and intensity of the equipment. To put it in perspective, cooking fires are responsible for nearly half of all house fires, often because of unattended cooking. You can dig into these cooking fire statistics to see just how critical vigilance is.

By respecting the science and recognizing the small oversights that lead to disaster, you can build a kitchen culture where safety isn’t just a checklist—it's second nature.

Choosing and Maintaining Your Commercial Charbroiler

Let's not sugarcoat it. The data from the National Fire Protection Association (NFPA) makes it crystal clear: cooking equipment is the #1 cause of fires in restaurants. And right at the top of that list, you'll find the high-heat appliances on your cookline.

Your charbroiler is the heart and soul of the kitchen, but with all that intense heat and dripping fat, it's also a prime suspect for starting a grease fire. The good news? Selecting the right unit and maintaining it with military-like precision are the most powerful moves you can make to shut that risk down.

Modern charbroilers are built smarter and safer than ever, but they aren't all created equal. When you're looking at your options, you need to think beyond simple heat output and focus on the features that actively fight back against grease.

Selecting a Charbroiler with Safety in Mind

Your very first line of defense is choosing equipment that’s engineered to minimize risk from the get-go. As you look through our wide selection of commercial charbroilers for your restaurant, you'll notice how different designs tackle the root cause of grease fires. We offer a variety of types to fit any kitchen's needs, including infrared, gas, and electric char broilers.

- Infrared Charbroilers: These units often use ceramic plates to generate incredibly intense, even heat. That heat can vaporize drippings on contact, meaning less liquid grease pools up where it can ignite.

- Gas Charbroilers: Look for models with angled radiants or "flame tamers." These pieces are smartly designed to sit over the burners, catching grease and funneling it away from the open flame and into a collection tray. Fewer flare-ups, fewer heart attacks during a busy service.

- Electric Charbroilers: No open flame means one major ignition source is gone right off the bat. But don't get complacent—grease can still ignite on blazing hot electric elements, so a solid grease management system is just as vital.

No matter which type you go with, the real hero is an advanced grease management system. I'm talking deep, high-capacity drip trays that are actually easy for your crew to pull out and clean, even when things are hot. A system that's a pain to clean is a system that gets ignored, and that's when dangerous buildup happens.

Choosing a charbroiler with easy-to-clean components and a robust grease collection system is a direct investment in fire safety. The easier you make it for your staff to do daily maintenance, the more likely it will get done right, every single time.

Your Essential Charbroiler Maintenance Checklist

Buying the right piece of gear is only half the job. How you care for it day-in and day-out is what truly dictates its safety and lifespan. A rock-solid maintenance routine isn't about keeping things pretty; it's a critical fire prevention protocol. This needs to be a non-negotiable part of your kitchen's closing procedure.

The trick is to break the work down into daily, weekly, and monthly tasks. A systematic approach turns a huge job into small, manageable steps that actually get done.

Daily Cleaning Routine (End of Every Shift)

This is it. This is your most important cleaning cycle. Doing these steps every single day prevents flammable gunk from baking on and building up to dangerous levels.

- Power Down and Cool Off: First rule of thumb—make sure the unit is completely off and has cooled to a safe temperature before anyone touches it.

- Scrape the Grates: Grab a heavy-duty wire brush or grill scraper and get all the food debris and carbon off the cooking grates.

- Empty and Clean the Grease Trap: This is the big one. Carefully remove the drip tray, get rid of the cooled grease properly, and then wash the tray with hot, soapy water until it's spotless.

- Wipe Down the Exterior: Give the front, sides, and backsplash a good wipe-down to remove any splatters from the day's service.

Weekly Deep Cleaning Tasks

Once a week, your team needs to dig a little deeper to hit the hidden spots where grease loves to hide.

- Clean the Radiants: Pull the cooking grates off and give the radiants or heat deflectors a thorough scrubbing. This is a hotspot for grease buildup that can cause nasty flare-ups.

- Inspect Burners or Elements: For gas models, check that the burner ports are clear of debris. On electric units, look over the elements for any heavy buildup.

- Interior Wipe-Down: Clean the inside walls of the charbroiler. Grease vapor condenses here and can build up over time.

Monthly Inspection and Maintenance

Your monthly check-in is all about making sure the charbroiler is not just clean, but also in safe working condition.

| Maintenance Task | What to Look For | Why It Matters |

|---|---|---|

| Inspect Gas Connections | Leaks, cracked hoses, loose fittings | Prevents dangerous gas leaks, a massive fire and explosion hazard. |

| Check Electrical Wiring | Frayed cords, damaged plugs, signs of wear | Damaged wiring can lead to shorts, sparks, and electrical fires. |

| Verify Temperature Control | Thermostat accuracy, proper knob function | Ensures the unit isn't overheating, which can push oils past their flashpoint. |

| Assess Overall Condition | Warped grates, cracks in the unit body | Catches structural problems that could compromise safety and performance. |

When you commit to a schedule this rigorous, you turn your charbroiler from a potential liability into a reliable, safe workhorse. This disciplined approach to fire prevention is the bedrock of any secure and professional kitchen.

Implementing Safer Daily Cooking Practices

Real fire prevention isn't something you can buy with a new piece of gear or check off a list once a year. It's forged in the heat of a busy service, built one disciplined habit at a time by your kitchen crew. The small, consistent actions repeated every single shift are what create a real defense against disaster.

This is how you turn safety from a boring checklist item into pure muscle memory.

Master Your Temperatures

One of the most critical daily habits is mastering temperature control, especially when you're working with gallons of hot cooking oil. Every fat, from canola to lard, has a smoke point—that temperature where it starts to break down and you see that first wisp of smoke. Pushing past that isn't just bad for your food; it's the final warning bell before you hit the oil's flashpoint, where it can burst into flames.

For most commercial electric deep fryers, this means keeping the oil well under 400°F, with a sweet spot usually between 350-375°F. Using a calibrated thermometer and never, ever leaving a fryer or a hot pan of oil unattended are non-negotiable rules of the line.

If you see smoke, it's a blaring alarm to kill the heat. It’s that simple. Getting this right stops a grease fire before it even has a chance to start.

Keep Your Cooking Station Clear and Organized

A cluttered cookline is a dangerous cookline. The area around your charbroiler, griddle, and fryers needs to be a hard "no-go zone" for anything flammable. It sounds like common sense, but you'd be surprised what you see during the chaos of a dinner rush.

Make these firm rules:

- No Towels: Stacks of side towels or cleaning rags have no business sitting on countertops near open flames or hot surfaces.

- No Cardboard: Keep all boxes—from produce to protein—far away from the cookline. Cardboard is basically kindling.

- No Chemicals: Cleaning chemicals, especially aerosol cans, belong in their designated storage area, far from any heat.

This discipline has to be part of your workflow. An organized station doesn't just make you faster; it slashes the risk of accidents, like bumping a pot of hot oil or not being able to find a pan lid when you need one to smother a flare-up.

The single most effective habit is a 'clean-as-you-go' mindset. Wiping up a small spill now prevents it from becoming a slick of fuel for a fire later. A clean station is a safe station.

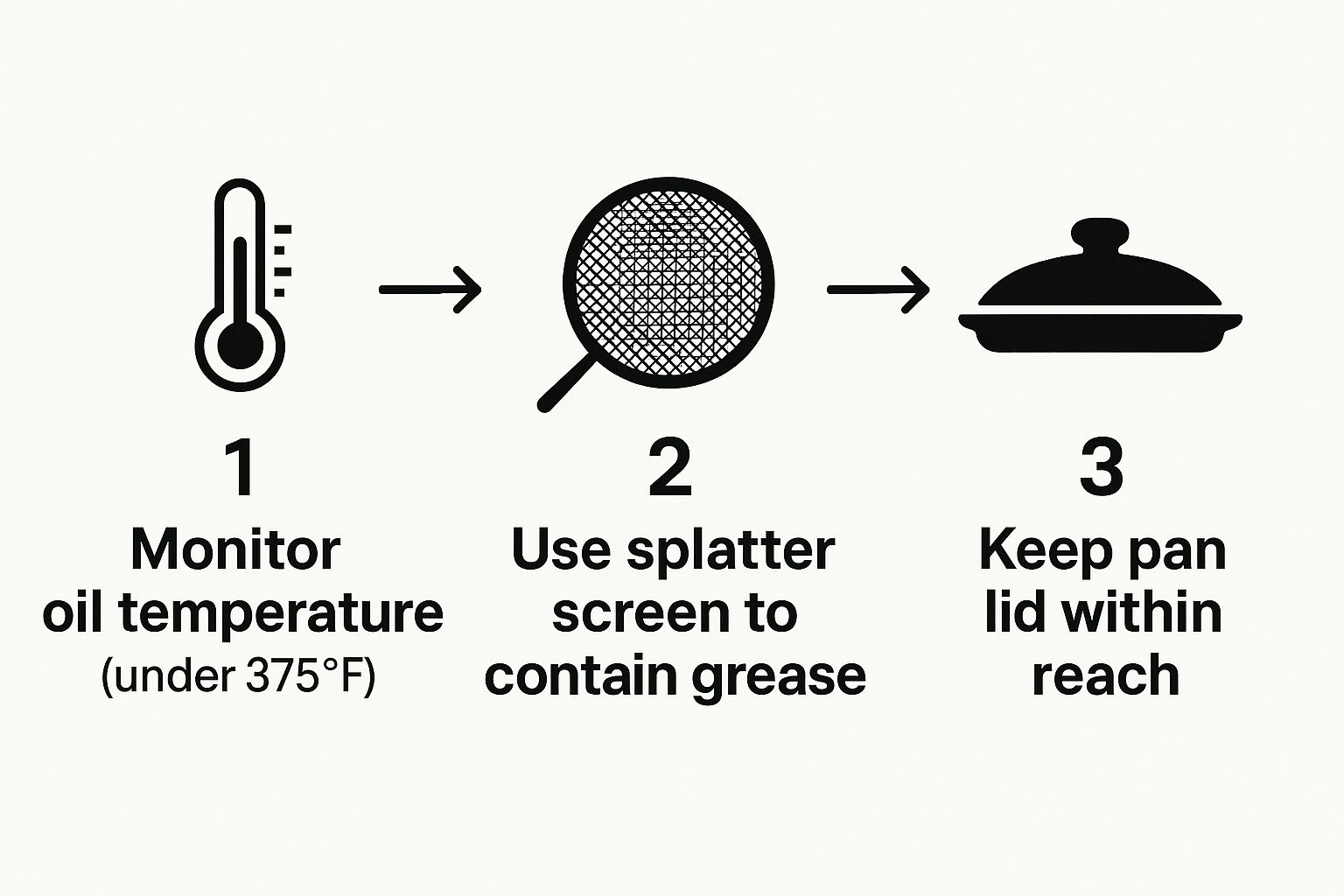

This image breaks down the core principles of safely handling hot oil—it's all about control.

Controlling the temperature, preventing splatter, and knowing how to cut off oxygen are the fundamentals for stopping a grease fire in its tracks.

The danger here is very real. Between 2017 and 2021, cooking was the leading cause of home fires in the U.S. A shocking 66% of those fires started with cooking materials like grease or fat catching fire, a stark reminder of how quickly things can go wrong.

Unsafe vs Safe Commercial Cooking Practices

In every kitchen, there are risky habits that can creep in over time. The key is to spot these common mistakes and actively replace them with professional, safety-first alternatives. The table below lays out some of the most common high-risk practices I've seen in kitchens and shows you the safer, professional way to get the job done.

| High-Risk Practice | Safer Professional Alternative | Why It Matters |

|---|---|---|

| Overfilling Fry Baskets/Pots | Fill baskets only halfway and gently lower them into the oil. Never fill a pot more than two-thirds full. | This stops hot oil from boiling over and spilling onto the burner or floor, which can cause a massive, fast-spreading fire. |

| Using Wet or Icy Food | Pat food completely dry before it goes into hot oil. Fully thaw frozen items according to safety guidelines first. | Water makes hot oil pop and splatter violently. This can cause severe burns or spray hot grease onto nearby flammable materials. |

| Leaving the Cookline Unattended | Enforce a "never turn your back" rule for any active fryer, burner, or charbroiler. Always have a cook monitoring the line. | Unattended cooking is the #1 cause of kitchen fires. A serious fire can erupt in less than a minute. |

| Using Makeshift Tools | Use the correct, manufacturer-approved tools. Always keep a tight-fitting metal lid within arm's reach of your pans. | The wrong tool can slip or break, leading to spills. A proper lid is the fastest and safest way to smother a small pan fire. |

By making these safer practices a mandatory part of your kitchen's daily routine, you systematically eliminate the very conditions that allow grease fires to happen. This turns your entire team into your best and most reliable line of defense.

Your First Line of Defense: Ventilation and Suppression

While your kitchen crew is the active defense against grease fires, you’ve got systems working tirelessly behind the scenes providing a constant, passive layer of protection. Think of them as your automated guardians—the ventilation pulling dangerous vapors away and the suppression systems ready to act in a split second.

Ignoring them is like leaving the back door of your restaurant unlocked overnight. It’s an open invitation for disaster.

The kitchen hood and ventilation system are so much more than just exhaust fans. They're the lungs of your kitchen, specifically engineered to pull hot, grease-laden vapor up and away from ignition sources like your charbroiler. When this system works correctly, it dramatically cuts down the risk of fire by keeping that flammable gunk from settling on walls, ceilings, and other equipment.

But when that system is neglected, it quickly flips from a powerful asset into a serious liability.

Recognizing a Failing Ventilation System

You don’t need to be an HVAC expert to spot the warning signs of a ventilation system that's on the ropes. A system choked with grease simply can't do its job, and the evidence will be all over your kitchen.

Keep an eye out for these tell-tale signs:

- A Smoky Kitchen: If the air doesn’t clear out quickly during a busy service, your exhaust fan isn't pulling hard enough. It’s losing the fight.

- A Greasy Film: Notice a sticky, yellowish film building up on walls, shelves, or even the floor? That’s all grease that should have gone straight up the hood.

- Excessive Heat: A properly ventilated kitchen should manage ambient heat pretty well. If your kitchen feels unusually hot and stuffy, poor airflow is a likely culprit.

These aren't just minor annoyances; they are flashing red lights that your primary fire prevention system is compromised. For a deeper dive into the specific codes and requirements that govern this critical equipment, you can learn more about commercial kitchen ventilation requirements in our detailed guide.

The Role of Automated Fire Suppression

Even with perfect cleaning and cooking habits, accidents happen. That's exactly where an automated fire suppression system comes into play. This network of nozzles, usually installed directly in the hood right over your high-heat equipment, is designed to detect and extinguish a fire automatically—no human intervention needed.

When the system detects a fire (typically via a fusible link that melts at a specific temperature), it unleashes a wet chemical fire retardant. This stuff is specifically formulated for grease fires. It smothers the flames and saponifies the hot oil, turning it into a non-flammable, soap-like substance. It's a one-two punch that cools the fuel source and prevents reignition.

According to NFPA 96 standards, these systems aren't optional—they are a requirement for commercial kitchens and must be inspected by a certified professional every six months. A passed inspection means your system is armed and ready to go.

During these inspections, the technician makes sure the nozzles are correctly positioned over your charbroilers and fryers, ensuring the chemical agent will hit its target. Any time you rearrange your cookline, you absolutely must have the system re-evaluated to maintain proper coverage.

Hands-On Defense: The Class K Fire Extinguisher

Your final layer of defense is the one you can hold in your hands. Commercial kitchens are required to have Class K fire extinguishers, and for very good reason. Unlike a standard ABC extinguisher, which can dangerously splash burning grease and make things worse, the Class K model uses a wet chemical agent similar to what's in your suppression system.

Proper placement is key. Extinguishers need to be easily accessible, no more than 30 feet from the cooking equipment, and never, ever blocked by carts or boxes. Your staff has to know exactly where they are and, just as importantly, be trained on how to use them effectively.

The importance of having the right tools at hand cannot be overstated. A Class K extinguisher is what stops a small flare-up from becoming a full-blown catastrophe.

Empowering Your Team with Fire Safety Training

You can have the most advanced charbroiler, a spotless ventilation system, and a top-of-the-line fire suppression setup. But at the end of the day, the single most important safety feature in your entire kitchen is a confident, well-trained team. When a grease fire kicks off, it’s not the equipment that has to make a split-second decision—it’s your people. Giving them the right knowledge and practice is how you build a kitchen that can handle anything.

Effective fire safety training is so much more than handing out a pamphlet during onboarding. It has to be practical, it has to be memorable, and it absolutely has to be ongoing. The real goal here is to build muscle memory, so when the stress is high, your staff doesn't freeze up. They act.

Conducting Training That Actually Sticks

Getting everyone together once a year for a fire safety meeting is a start, but it's not enough. Real learning happens through regular, hands-on reinforcement. People forget procedures they don’t use every day, especially in a fast-paced kitchen environment. To make safety training truly stick, it needs to become a living part of your kitchen culture.

Instead of a long, boring meeting, try running short, 10-minute "safety huddles" during your pre-shift meetings once a month. One huddle could be a quick game of "where's the Class K extinguisher?" Another could be a verbal quiz on the first three steps to take if a sauté pan ignites.

The key is repetition. A calm, well-rehearsed response to an emergency is not an accident; it's the direct result of consistent and practical training that makes safety protocols second nature to every single person on your team.

This approach keeps safety front and center without feeling like a lecture. It turns everyone—from your executive chef to the brand-new dishwasher—into a proactive guardian of the kitchen.

Immediate Do's and Don'ts When a Fire Starts

When a grease fire erupts, those first 30 seconds are everything. Your team's immediate actions will be the difference between a minor flare-up that's handled in seconds and a full-blown catastrophe. Your training needs to hammer home these simple, non-negotiable rules.

The Absolute "DOs":

- Kill the Heat: The very first move, always, is to turn off the burner, fryer, or charbroiler. Fire needs heat to live. Cut off its fuel source.

- Cover It: For a small fire in a pan, calmly slide a metal lid over it to completely cover the flames. This starves the fire of oxygen. Leave it covered until it's completely cool.

- Use Baking Soda: For tiny, contained flare-ups, you can dump a large amount of baking soda on them. It works by smothering the flames.

The Absolute "DON'Ts":

- NEVER Use Water: This is the golden rule, the one you can't forget. Tossing water on a grease fire creates a violent fireball that will spread flaming oil everywhere. Instantly.

- NEVER Move a Burning Pot: Trying to be a hero and carry a burning pan to the sink is a recipe for disaster. You are almost guaranteed to splash burning grease on yourself, someone else, or something flammable.

- NEVER Use Flour or Sugar: Unlike baking soda, these powders are combustible. Throwing them on a fire will make things much, much worse.

Mastering the Class K Fire Extinguisher

If the fire is too big to smother with a lid, the Class K fire extinguisher is your go-to tool. Every single employee needs to know how to use one, and the easiest way to remember is the P.A.S.S. method.

- Pull: Pull the pin at the top of the extinguisher. It's there to prevent accidental discharge.

- Aim: Aim the nozzle at the base of the fire. Don't spray the flames; you need to hit the fuel that's burning.

- Squeeze: Squeeze the lever slowly and evenly to release the wet chemical agent.

- Sweep: Sweep the nozzle from side to side, covering the entire area of the fire until it's completely out.

This is one area where you can't cut corners. Investing in hands-on training with a professional fire safety company is worth every penny. Letting your staff actually pull the pin and discharge an extinguisher—even a training unit—builds the confidence they'll need when the adrenaline is pumping. That experience ensures they won't hesitate when every second counts.

Grease Fire Safety FAQs

Even in the best-run kitchens, questions about fire safety pop up. Getting clear, practical answers is the best way to keep your team sharp and confident on the line. Here are a few of the most common things restaurant owners and kitchen managers ask about preventing grease fires.

What’s the Single Most Important Thing I Can Do to Prevent a Grease Fire?

If I had to pick just one thing, it's rigorous and consistent cleaning. Hands down. Grease is the fuel for almost every kitchen fire, so stopping it from building up is your number one defense.

This goes way beyond a quick wipe-down at closing time. It means a serious commitment to daily cleaning of your charbroilers and fryers. It also means sticking to a strict professional cleaning schedule for your kitchen hoods and ventilation system. A clean kitchen is a safe kitchen.

Can I Use a Regular ABC Fire Extinguisher on a Grease Fire?

Absolutely not. Let me be clear: never, ever use a standard ABC extinguisher on a commercial kitchen fire. They aren't designed for cooking oils and will make a bad situation terrifyingly worse.

The force from an ABC extinguisher will splash burning grease everywhere—across the cookline, onto your staff, you name it. Commercial kitchens are required by law to have Class K fire extinguishers. These deploy a wet chemical agent that smothers the flames and performs a neat chemical trick called saponification, turning the grease into a non-flammable soap to cool everything down.

How Often Does My Fire Suppression System Need to Be Inspected?

According to the NFPA 96 standards, your commercial kitchen fire suppression system has to be professionally inspected every six months. This isn't optional; it's a critical requirement for both safety and staying compliant.

During this biannual check-up, a certified technician makes sure the whole system is ready to go. They’ll check that the nozzles are clear and pointed correctly at your cooking equipment and that every component is in good working order. Think of it as essential insurance—making sure your automated system will actually work when you need it most.

Do Newer Charbroilers Actually Help Prevent Grease Fires?

Yes, they really do. Many modern commercial charbroilers are designed with advanced safety features built right in. When you're shopping for new gear, look for designs that actively manage grease to cut down on your fire risk.

Today's charbroilers—whether they're infrared, gas, or electric—often come with:

- Smarter Grease Management: Look for units with large, easy-to-remove drip trays. The easier they are to clean, the more likely your staff is to do it frequently.

- Angled Radiants: These are designed to channel grease away from direct flames and into the collection tray, which dramatically reduces those dangerous flare-ups.

- Easy-to-Clean Designs: Stainless steel construction and thoughtfully designed components just make daily deep cleaning faster and more effective.

Of course, the charbroiler is only half the battle. Managing the grease it produces is just as important. For a deeper dive, check out our guide on why a clean kitchen grease trap is a vital part of your total safety plan.

Upgrading your equipment is a direct investment in a safer, more efficient kitchen. At Charbroilers, we carry a huge selection of commercial charbroilers designed with your restaurant's safety and performance as top priorities. Explore our range of advanced infrared, powerful gas, and efficient electric char broilers to find the perfect fit for your operation. Visit https://charbroilers.com to enhance your kitchen's safety and capabilities today.