A Guide to Commercial Kitchen Fire Suppression Systems

Share

Think of a commercial kitchen fire suppression system as your kitchen's dedicated, on-duty firefighter—one that never sleeps, never takes a break, and is ready to spring into action 24/7. It's a non-negotiable safety net designed to automatically detect and kill a fire, especially a dangerous grease fire, right where it starts. This isn't just a piece of equipment; it's the single most important guardian protecting your staff, your customers, and your entire business from disaster.

Your Kitchen’s Unseen Firefighter

Let's be honest: commercial kitchens are a perfect storm for fires. You've got open flames, scorching hot surfaces, and highly flammable cooking oils and grease all packed into one fast-paced environment. A simple flare-up on the charbroiler or a grease spill near a deep fryer can escalate into a full-blown catastrophe in the blink of an eye.

This is where your automated system steps in, acting as a lifeline when seconds count. In the chaos of a real kitchen fire, you can't rely on human reaction time alone. This system is designed to be the swift, decisive first responder that stops a fire cold before it has the chance to spread.

The Anatomy of an Automated Guardian

Unlike a standard fire extinguisher that someone has to grab and operate, a suppression system is a network of components working in perfect sync to handle the threat automatically. It’s a smart, targeted response.

Here’s what makes it work:

- Heat Detectors: These are strategically placed fusible links in the ventilation hood. When temperatures spike to a specific, dangerous level, these links separate, instantly triggering the system.

- Agent Tanks: This is the heart of the operation. The tank holds a potent wet chemical agent specifically engineered to knock down grease fires, which are notoriously difficult to extinguish.

- Discharge Nozzles: Positioned directly over your high-heat appliances like fryers, griddles, and ranges, these nozzles spray the agent in a precise pattern to smother flames completely.

- Manual Pull Station: This is your manual override. It gives your kitchen crew the power to activate the system immediately if they spot a fire before the automatic detectors kick in.

The moment a fire is detected, the system unleashes a three-pronged attack. First, the wet chemical agent blankets the flames, cutting off their oxygen supply. Second, it cools the scorching hot surfaces to prevent the fire from re-igniting. And third, it’s wired to automatically shut off the gas or electrical supply to your cooking line, starving the fire of its fuel source.

According to the National Fire Protection Association (NFPA), cooking equipment is the number one cause of fires in restaurants. A properly maintained suppression system is your best defense.

This instant, multi-faceted response is what makes these systems absolutely essential. It’s a silent guardian that ensures a powerful and effective reaction every single time, protecting your people and your investment when it matters most.

When a fire kicks off over a hot appliance, water just won't cut it. Commercial kitchens are a different beast entirely—full of superheated cooking oils and grease-heavy air that can create fires that literally laugh off traditional fire extinguishers. This is precisely why wet chemical systems are the undisputed champs for protecting modern cooklines.

Instead of just spraying water, these systems unleash a powerful chemical reaction called saponification. Think of it as a firefighter’s magic trick: it instantly turns that burning, liquid grease into a thick, soapy foam that can't burn. This foam blanket pulls double duty, smothering the fire by choking off its oxygen and cooling down the scorching hot cooking surface underneath.

This one-two punch is absolutely critical for stopping the most dangerous part of a grease fire: reignition. Even after the flames are gone, the cooking oil or the appliance itself can stay hot enough to burst back into flames all on its own. The soapy barrier created by saponification stops this from happening, making sure the fire is out and stays out.

Why Other Systems Fall Short

You might see other types of fire suppression out there, but they just aren't built for the unique hellscape of a commercial kitchen fire. Understanding their weaknesses really drives home why wet chemical systems are the only choice for your cooking equipment.

-

Dry Chemical Systems: Sure, the powder they spray can knock down flames, but it does nothing to cool the superheated grease. This leaves a massive risk of the fire flaring right back up. On top of that, the fine powder is a nightmare to clean up and can easily fry sensitive kitchen electronics.

-

Water Mist Systems: These are great for Class A fires (think wood and paper), but spraying water on a grease fire is a recipe for disaster. It causes the burning grease to splatter violently, spreading the fire across the kitchen and turning a small problem into a full-blown catastrophe.

At the end of the day, only wet chemical agents deliver the specialized smother-and-cool combination needed to neutralize a Class K (kitchen) fire. This is especially vital for the high-heat gear we specialize in. We offer a wide selection of commercial charbroilers for your restaurant, including powerful infrared, gas, and electric char broilers that operate at extreme temperatures and pose a serious fire risk. For a closer look at proactive safety, check out our guide on how to prevent grease fires in the first place.

A wet chemical system doesn't just put out the fire; it chemically alters the fuel source. By turning flammable grease into a fire-resistant soap, it actively removes the threat of the fire restarting, providing a level of safety that other systems simply cannot match.

The Growing Importance of Advanced Protection

Demand for reliable commercial kitchen fire suppression systems is climbing, and fast. This is driven by tougher fire safety codes and a booming global foodservice industry. It’s a clear sign that restaurant owners are waking up to the huge financial and personal risks that come with kitchen fires.

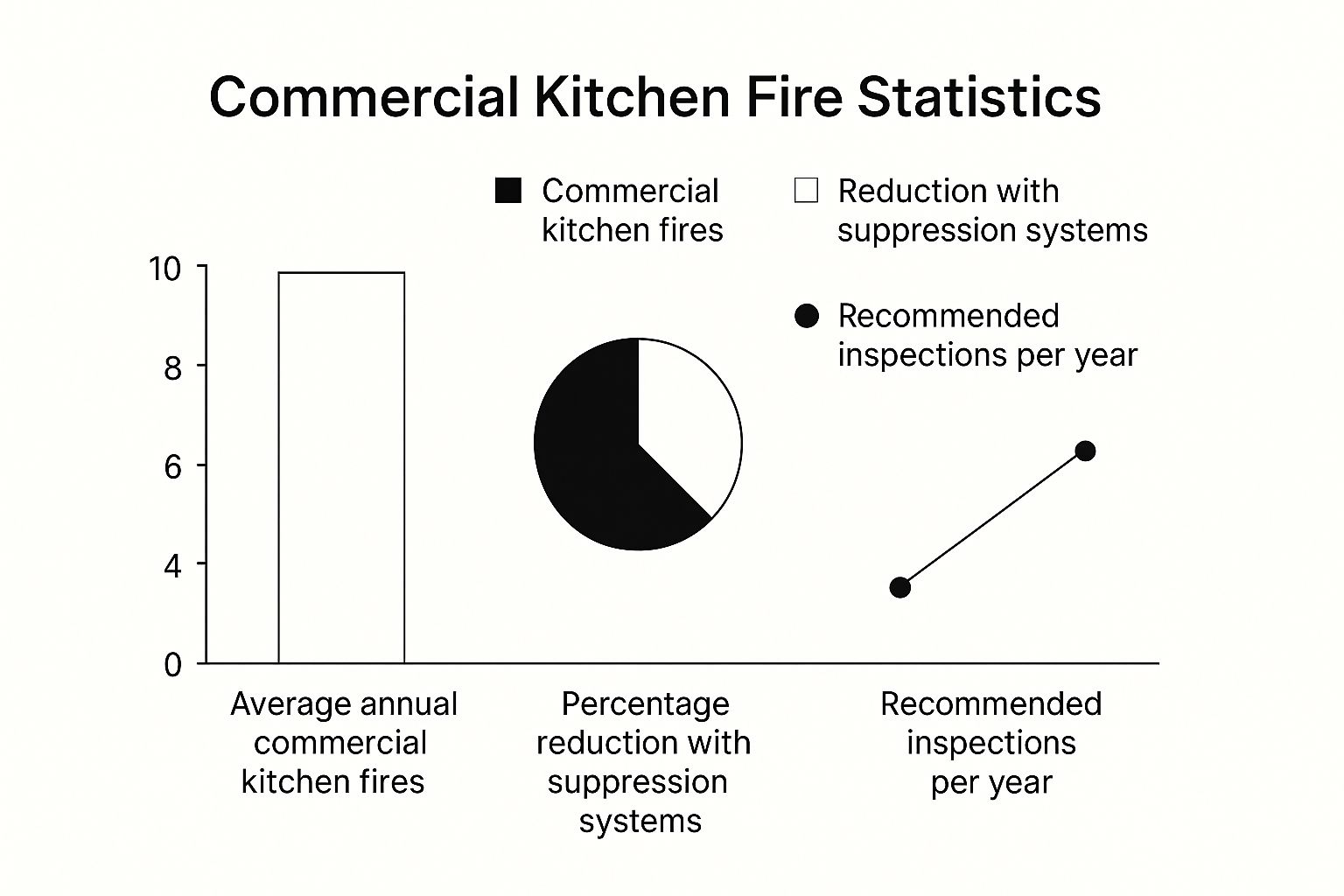

This chart really puts the reality of kitchen fires—and the power of a professional suppression system—into perspective.

The numbers don't lie. Kitchen fires happen, but a properly installed and maintained system can dramatically slash the damage they cause. This commitment to safety is fueling major market growth. The global market for these systems was pegged at around USD 1.2 billion in 2024 and is expected to more than double, hitting USD 2.5 billion by 2033. This isn't just an interesting statistic; it shows that investing in a top-notch wet chemical system is no longer just about meeting code—it's a critical business decision to protect your assets and keep your doors open.

Decoding Fire Codes and Staying Compliant

Navigating the world of commercial kitchen fire safety is more than just picking the right gear—it’s about following a strict rulebook designed to save lives and protect your business. For restaurant owners, understanding the codes that govern commercial kitchen fire suppression systems is just as critical as perfecting your signature sauce. Compliance isn't a suggestion; it's the law.

Think of fire codes as the universal safety language for kitchens everywhere. They aren't just random rules; they're built on decades of real-world fire data and safety engineering. Ignore them, and you're looking at hefty fines, forced shutdowns, or worse—a catastrophic fire that could have been stopped in its tracks. This is where your local fire marshal comes in; they’re the authority tasked with enforcing these non-negotiable standards.

The Two Pillars of Kitchen Fire Safety

When you boil it down, your kitchen's fire safety rests on two key standards from the National Fire Protection Association (NFPA). Getting a handle on these is essential for any operator.

-

NFPA 96: Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations

This is the big one—the master guide for your entire ventilation setup. It covers everything from how your hood is built and installed to the way your ductwork is routed and cleaned. It’s the first line of defense against grease buildup, which is basically fuel for a kitchen fire. For a deeper dive, check out our guide on commercial kitchen ventilation requirements. -

NFPA 17A: Standard for Wet Chemical Extinguishing Systems

This standard gets specific, focusing entirely on the fire suppression system itself. It’s the rulebook for design, installation, testing, and upkeep. This document ensures your system will actually do its job in an emergency, detailing everything from the type of wet chemical agent required to the exact placement of nozzles over your cooking line.

Translating Codes into Action

Knowing the standards is one thing, but putting them into practice is what counts. These codes translate into real, tangible requirements for your kitchen. For starters, every single piece of cooking equipment that creates grease-laden vapors—from your charbroiler to your fryers—must be protected by the suppression system. No exceptions, no gaps.

Another key piece of the puzzle is the manual pull station. This red box has to be located along a path of exit, usually near a door, so staff can easily get to it and trigger the system if they see a fire before the automatic sensors do.

But perhaps the single most important function required by these codes is the automatic shutdown of fuel sources. When that system goes off, it must instantly cut the gas or electricity to all the cooking equipment it protects. This one feature is a game-changer, starving a fire of its fuel and stopping a small flare-up from turning into a disaster.

The global focus on these systems is growing fast. The market for industrial cooking fire protection, which includes commercial kitchens, hit USD 38.03 billion in 2023 and is projected to climb to USD 68.46 billion by 2030. This massive growth shows a worldwide commitment to higher safety standards and proves just how essential these compliant systems are for protecting businesses everywhere.

Choosing the Right System for Your Kitchen Layout

Picking out a commercial kitchen fire suppression system isn’t like grabbing an appliance off the shelf. There’s no such thing as a one-size-fits-all solution, simply because no two kitchens are the same. The right system is more like a custom-fit suit of armor, designed piece by piece to protect your unique lineup of equipment and your specific workflow.

Just imagine trying to use the same safety blueprint for a small coffee shop and a high-volume steakhouse. It wouldn’t work. Their fire risks are worlds apart. The cafe might have a small griddle and a toaster, while the steakhouse is running multiple high-temperature commercial charbroilers, deep fryers, and salamanders. Each appliance is a different kind of fire hazard, and each one needs its own defense strategy.

This is exactly why a generic approach isn't just a bad idea—it’s dangerous. The whole point of a fire suppression system is how well it matches the specific appliances it’s protecting and the layout of the cook line.

Matching the System to Your Appliances

Your cooking equipment is the heart of the system design. The appliances that produce the most heat and grease are the main fuel sources for kitchen fires, and they demand the most powerful protection.

Here’s a look at how different equipment shapes the system design:

- Deep Fryers: These are a huge fire risk because of the large vats of highly flammable cooking oil. They need nozzles that can punch through the hot oil and lay down a thick, saponifying foam blanket over the entire surface.

- Commercial Charbroilers: It doesn't matter if you're using infrared, gas, or electric char broilers—these units throw off intense radiant heat and grease splatter. Nozzles have to be placed to cover the whole cooking surface and the areas around it to knock down any flare-ups.

- Griddles and Ranges: They might be less volatile than fryers, but their large surfaces need overlapping spray patterns to make sure no hot spots are left unprotected.

The goal here is to build a seamless shield. The number of suppressant tanks, the size of the pipes, and the types of nozzles are all calculated based on the "fire load" your specific appliances create. A smart commercial kitchen layout and design is the foundation for a truly effective fire suppression plan, making sure every high-risk spot is covered.

Customizing Nozzle Placement and Hood Design

Once you’ve got the appliances figured out, the focus turns to the ventilation hood and the exact placement of the discharge nozzles. This is where system design becomes a real science.

Think of the nozzles as sniper rifles and the fire as the target. A miss is not an option. Each nozzle must be aimed at a specific hazard zone, positioned at the correct height and angle to deliver the wet chemical agent exactly where it's needed for maximum effect.

Your cook line's layout is what dictates this placement. If your fryer is right next to your charbroiler, the nozzle setup will look completely different than if they were separated by a prep table. A certified installer will literally map out this "coverage map" to ensure there are zero blind spots, protecting every single square inch of your high-risk areas.

Vetting Manufacturers and Certified Installers

The equipment you buy and the people who install it are equally critical. Not all systems are created equal, and even the best hardware is useless if it’s installed poorly.

When you're looking for a partner, be sure to ask these questions:

- Are you certified by the manufacturer? Technicians absolutely must be factory-trained to install and service a specific brand’s system.

- Can you provide proof of insurance and licensing? This is non-negotiable. It protects you from liability.

- What is your experience with kitchens like mine? You want someone who has seen and worked on your type of restaurant and equipment before.

- Do you offer a comprehensive service plan? The job isn't done after installation. The law requires ongoing maintenance, so this relationship is a long-term one.

Doing this homework ensures you end up with a reputable pro who gets the nuances of protecting your specific business. The industry focus on this specialized protection is growing, too. The market for advanced kitchen hood fire suppression systems is a critical one, with global predictions showing it could hit nearly USD 1 billion by 2031. For more details on this growth, you can explore the full market analysis on metastatinsight.com. Investing in a professionally designed and installed system isn’t just about checking a box for the fire marshal—it's a fundamental investment in the future of your business.

What to Expect During Professional Installation

Even the most advanced commercial kitchen fire suppression system is only as good as its installation. Let’s be clear: this isn't a DIY weekend project. It’s a precision engineering job that needs to be handled by certified pros. Knowing how they work helps you understand the process and feel confident that your kitchen’s new guardian is set up right from day one.

The whole thing is a carefully planned operation that starts long before a single tool comes out of the box. It all begins with a deep dive into your kitchen's unique layout to create a solution that fits like a glove.

The Pre-Installation Blueprint

Before a single pipe gets touched, the installation team performs a thorough site survey. This is the critical first step where they map out every single detail.

Technicians will measure your ventilation hood and analyze your entire cook line. They'll identify every piece of equipment—from high-heat commercial charbroilers to deep fryers—to figure out the specific fire risks and calculate exactly how much wet chemical agent is needed. All this data goes into creating a detailed schematic, the blueprint that dictates the perfect placement for every component.

The Core Installation Phase

With the blueprint finalized, the real work begins. This is where you'll see the system physically take shape as technicians expertly integrate it into your kitchen.

Here’s what happens during this stage:

- Installing Piping and Nozzles: A network of stainless steel piping is run through and around your ventilation hood. Then, the discharge nozzles are installed, each one angled just right to give optimal coverage for the specific appliance it's protecting. No gaps, no blind spots.

- Mounting the Agent Tank and Control Head: The heart of the system—the tank holding the fire-fighting agent and the mechanical control head—is securely mounted in a spot that's both designated and easy to access.

- Connecting Detection and Pull Stations: The heat detection line, which uses heat-sensitive fusible links, is strung through the hood directly over the cooking surfaces. At the same time, the manual pull station is installed in a code-compliant location on an exit path.

This phase also involves a crucial safety integration. The system gets wired into your kitchen’s fuel supply to automatically shut off both gas and electricity to your cooking equipment the second it's activated. This is a vital step that literally starves a potential fire of its fuel.

Final Commissioning and Acceptance Testing

The installation isn't done until the system is proven to work flawlessly. This final phase, called commissioning, is the ultimate quality control check.

The acceptance test is the moment of truth. Technicians perform a "puff test," using compressed air or nitrogen to simulate a system discharge. This test confirms that all the pipes are clear, the nozzles are free of obstructions, and every mechanical part moves exactly as it should.

During the test, they’ll also verify that the fuel shut-off valves click shut correctly and that any connected alarms go off. Only after the system passes this tough test with flying colors will the technician arm it, making it live and ready to protect your kitchen.

You’ll get a signed and dated tag for the system, which documents the successful installation and serves as proof of compliance for your local fire marshal. This whole meticulous process ensures your unseen firefighter is ready for duty 24/7.

Keeping Your System Ready with Proper Maintenance

Fire protection isn't a "set it and forget it" deal. It's an ongoing commitment. Once your commercial kitchen fire suppression system is in the ground and running, it needs regular, scheduled attention to stay reliable and up to code. Think of it like a high-performance engine; skipping the tune-ups is just asking for a breakdown when you can least afford it.

This proactive upkeep is what guarantees your system will actually work when smoke starts pouring and lives are on the line.

An effective maintenance plan is really a partnership between your own staff and the certified pros. Everyone has a role to play, and both are equally important for keeping this critical safety net in perfect working order. This approach builds a powerful culture of safety right in your kitchen.

The Professional Semi-Annual Inspection

According to NFPA standards, a certified fire protection technician has to professionally service your system at least every six months. This isn't just a quick look-see; it's a mandatory, deep-dive inspection that makes sure every single component is ready for action.

During this service, the technician will:

- Inspect Fusible Links: They'll check the heat detector links for any grease buildup or damage, and double-check that they have the correct temperature rating for your specific cook line.

- Test Detection and Actuation Lines: The tech makes sure the lines running from the detectors to the control head are tight and clear, guaranteeing an instant response when triggered.

- Verify Nozzle Placement: They confirm every nozzle is aimed perfectly over your appliances—including your infrared, gas, and electric char broilers—and that the protective caps are in place to stop clogs.

- Check the Suppressant Agent: The agent tank gets checked for proper pressure, and the agent itself is inspected to make sure it hasn't expired or been compromised.

This semi-annual service is your ultimate peace of mind. When they're done, the technician updates the system's service tag. That tag is the proof the fire marshal wants to see, showing your equipment is compliant and ready to go.

A fire suppression system is only as good as its last inspection. The National Fire Protection Association (NFPA) found something alarming: in nearly one-third of restaurant fires where suppression systems failed to activate, the cause was simply a lack of proper maintenance.

Empowering Your Staff with Monthly Checks

While the pros handle the heavy lifting, your own kitchen staff are the system's first line of defense. Giving them a simple, monthly checklist can catch small issues before they snowball into major failures. This quick walk-through should be a non-negotiable part of your safety protocol.

During this monthly check, your team should verify that:

- Gauges are in the green and show proper pressure.

- Nozzles are clear and not blocked by equipment or caked-on grease.

- The manual pull station is easy to get to and its safety seal is intact.

- The system shows no obvious signs of damage, rust, or tampering.

This kind of consistent attention creates a proactive safety culture. It takes fire protection from an "out of sight, out of mind" concept and makes it a shared, active responsibility. When you combine professional servicing with diligent in-house checks, you make sure your kitchen’s unseen firefighter is always ready for duty.

Of course, here is the rewritten section, designed to sound like it was written by an experienced human expert.

Answering Your Top Questions About Kitchen Fire Safety

Even with a detailed guide, it's the real-world questions that pop up when you're thinking about something as critical as your restaurant's fire safety. I get these all the time from restaurant owners, so let's tackle the most common ones head-on.

So, What's a New System Going to Cost Me?

I wish I could give you a single number, but the honest answer is it depends. A new system can run anywhere from $2,500 to over $10,000.

That’s a huge range, I know. The final price tag isn't a flat fee; it's custom-built for your kitchen's specific needs. The biggest factors are the size of your ventilation hood and the number of appliances that need protection—especially high-risk gear like commercial charbroilers. A small food truck will be on the low end of that range, while a large restaurant with a long, complex cook line will naturally be on the higher end.

What Actually Happens When the System Goes Off?

It's a fast, powerful, and totally automated sequence of events that unfolds in seconds. The moment the system is triggered—either automatically by a sudden spike in heat or manually when someone pulls the station—a few things happen almost at once.

First, a loud alarm blares to get everyone's attention. At the exact same time, the system kills the gas or electric supply to all your cooking equipment, cutting the fire's fuel source. Immediately after, the wet chemical agent shoots out from the nozzles positioned over your appliances. It blankets the fire, rapidly cools the hot surfaces, and smothers the flames to stop it from re-igniting.

Think of it as a coordinated, lightning-fast response designed to neutralize a fire at its source before it has a chance to grow. It’s a decisive action that protects your people and your property when every single second counts.

Do I Really Need to Update the System if I Just Swap Out an Appliance?

Yes. One hundred percent, yes. Any time you change your cook line, you need a professional to re-evaluate your fire suppression system.

Whether you're adding a new deep fryer, rearranging your griddles, or upgrading your infrared, gas, or electric char broilers, your fire risk has changed. Your system was designed for a very specific layout. Moving or changing appliances means the nozzles might not be pointing in the right places anymore, leaving you with dangerous blind spots. It's a critical step to ensure your kitchen remains fully protected and compliant.

At Charbroilers, we know that high-performance cooking equipment requires professional-grade safety to match. Build a powerful and secure cook line by exploring our wide selection of commercial charbroilers and other essential kitchen gear. Head over to https://charbroilers.com to find the perfect equipment for your restaurant.