Top Commercial Kitchen Appliances for Your Restaurant

Share

When you get right down to it, the engine of any successful restaurant isn't the dining room—it's the kitchen. And the right commercial kitchen appliances are the foundation your entire operation is built on.

Think of your kitchen as a high-performance team. Every single piece of equipment, from the six-burner range to the walk-in freezer, has to be a reliable, powerful player that can take the intense heat of a professional environment, day in and day out.

Choosing this equipment is one of the most significant investments you'll make. It’s not just about cooking food; it’s about creating a seamless workflow that pushes efficiency, slashes costly downtime, and guarantees the same quality for every single dish that leaves the pass. Skimping on foundational pieces is like building a house on shaky ground—it might hold up for a little while, but it's destined to cause major headaches down the road.

Differentiating Professional and Residential Gear

So, what really separates the pros from the home-kitchen heroes? The core differences boil down to three key areas: durability, power, and safety standards.

Commercial appliances are built from materials like high-grade stainless steel to survive constant use, wild temperature swings, and relentless cleaning. Their power output—whether you’re measuring in BTUs for gas units or watts for electric—is leagues above residential models, built to handle the non-stop demand of a busy service.

A professional kitchen operates under immense pressure. The equipment must not only perform flawlessly but also adhere to strict health and safety codes, such as those set by NSF International, to protect both your staff and your customers.

This robust construction and strict adherence to standards are completely non-negotiable in a professional setting. You can see this reflected in market trends; the global commercial kitchen appliances market was valued at around USD 104.28 billion in 2024 and is expected to climb to USD 165.86 billion by 2033. This boom is being fueled by the expansion of quick-service restaurants and a growing demand for energy-efficient gear.

Once you've locked in your essential equipment, getting the installation right is everything. For instance, knowing the ropes of expert commercial water heater installation is just as critical as picking the heater itself, because it impacts everything from your warewashing station to your sanitation protocols.

The Core Categories of Kitchen Equipment

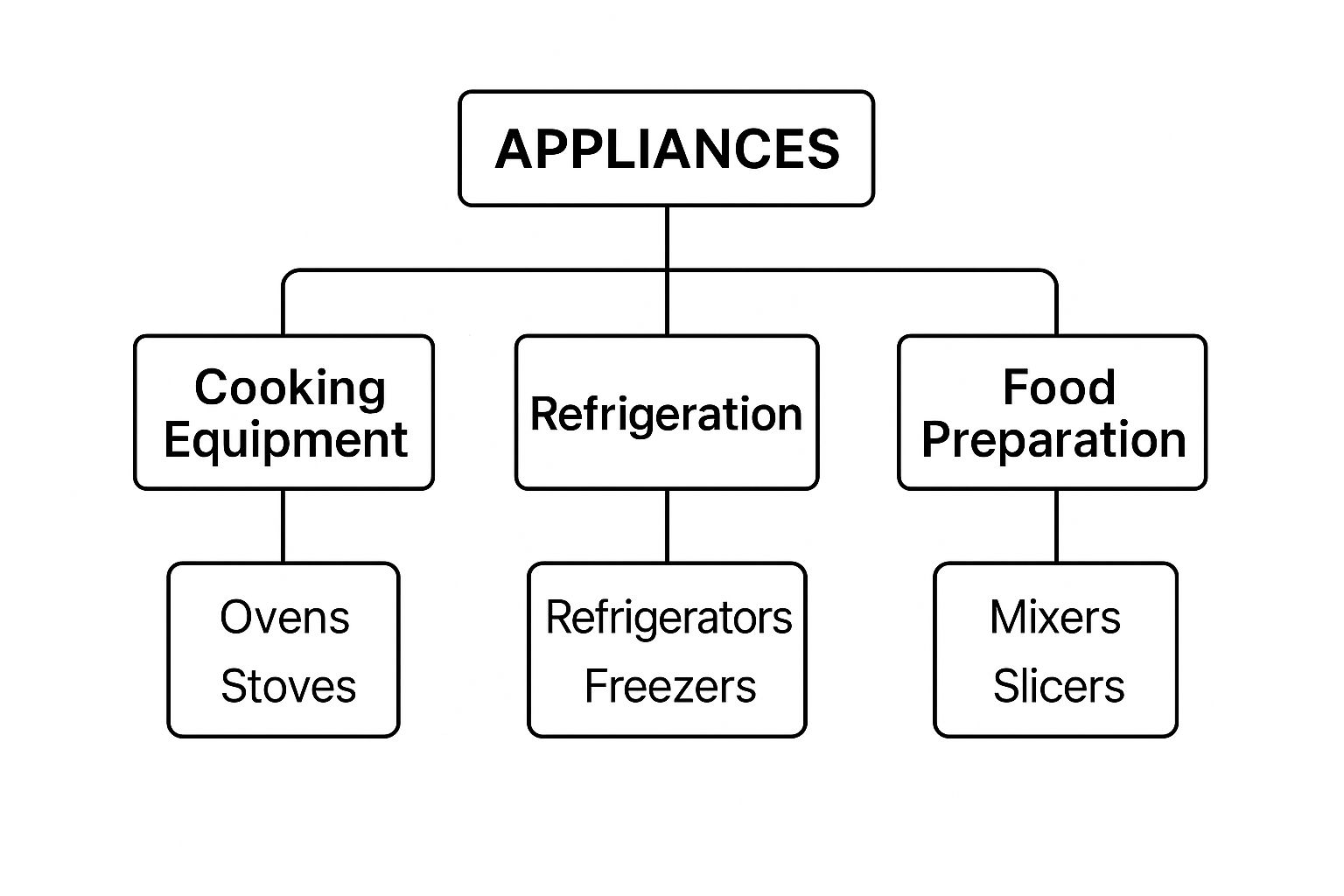

Walking into the world of commercial kitchen appliances can feel a bit overwhelming at first. To make sense of it all, I find it helps to think of a professional kitchen as being built on four main pillars. Each category has a distinct job, but they all have to work together perfectly to create a smooth, efficient operation—kind of like the different sections in an orchestra.

Getting a handle on these core groups helps you figure out what to buy first and how to design a workflow that actually makes sense. The main players are Cooking, Refrigeration, Food Preparation, and Warewashing. Each one is packed with specialized gear built for the high-volume, high-stress reality of a professional kitchen.

This simple diagram shows how everything branches out to form a complete kitchen ecosystem.

What this really shows is that a functional kitchen is a system. The cooking, cooling, and prep equipment have to be in sync. If you neglect any one of these areas, you’ll create bottlenecks that can bring your entire service to a screeching halt.

To give you a clearer picture, let's break down how these categories fit together.

Commercial Kitchen Appliance Categories at a Glance

This table provides a quick snapshot of the primary equipment categories, what they do, and where they fit in a typical foodservice operation.

| Appliance Category | Primary Function | Common Examples | Ideal For |

|---|---|---|---|

| Cooking | Applying heat to transform raw ingredients into menu items. | Ovens, Ranges, Griddles, Fryers, Charbroilers | Steakhouses, Quick-Service Restaurants, Fine Dining, Cafés |

| Refrigeration | Preserving ingredient quality and ensuring food safety. | Walk-in Coolers, Reach-in Freezers, Prep Tables | Virtually every foodservice operation, from bars to bakeries |

| Food Preparation | Slicing, dicing, mixing, and portioning ingredients. | Mixers, Food Processors, Slicers, Blenders | Pizzerias, Delis, High-Volume Kitchens, Catering Companies |

| Warewashing | Cleaning and sanitizing dishes, glassware, and utensils. | Dishwashers, Glasswashers, Pot Washers | Any business serving food on reusable dinnerware |

Understanding these roles is the first step in outfitting a kitchen that can handle the pressure of a busy service without breaking a sweat. Now, let's dive a little deeper into each one.

The Heartbeat of the Kitchen: Cooking Equipment

This is where the magic happens. The cooking category is where all your raw ingredients become finished dishes. It's the most dynamic and visible part of your kitchen, and the equipment here quite literally defines what your menu can do. From searing a perfect steak to baking delicate pastries, these are the true workhorses.

This category covers a massive range of tools, each with a specific job. You’ll find ovens, ranges, griddles, and fryers in just about any kitchen. For many restaurants, though, one specific piece of equipment becomes the star player, creating the signature flavors and textures that people line up for.

The right piece of cooking equipment doesn't just cook food—it defines your brand. The distinct char on a steak or the perfect golden-brown crisp on fries comes from specialized, high-performance appliances that are chosen with the menu in mind.

That’s where commercial charbroilers come in. They are absolutely essential for any menu featuring grilled items, delivering that smoky flavor and those beautiful sear marks that customers can’t get enough of. We offer a wide selection of commercial charbroilers for your restaurant, so you can find the perfect match for your kitchen's volume, menu, and power setup.

- Infrared Charbroilers: Our infrared models use intense, radiant heat to cook food incredibly fast and evenly, locking in juices for a perfectly moist result. They’re a dream for high-volume steakhouses that need to turn tables quickly without ever sacrificing quality.

- Gas Charbroilers: The classic choice for a reason. Our gas char broilers give you that authentic flame-grilled, traditional BBQ flavor. Their controls are super responsive, making them versatile enough for everything from burgers to delicate fish.

- Electric Charbroilers: Offering dead-on temperature control and consistency, our electric char broilers are perfect for kitchens where gas lines aren't an option or for operations that need repeatable results with minimal staff oversight.

Keeping It Cool: Refrigeration

Just as important as the heat is the cold. Refrigeration equipment is the silent guardian of your inventory, standing guard over food safety and preserving the quality of every ingredient you buy. Without solid, reliable refrigeration, food waste would skyrocket, and the risk of foodborne illness would be a constant nightmare.

This group includes everything from massive walk-in coolers and freezers for your bulk storage to smaller reach-in units and under-counter refrigerators tucked into specific prep stations. The whole point is to maintain a seamless "cold chain," making sure ingredients stay at safe temperatures from the moment they arrive at your back door until they're ready to hit the heat.

Prepping for Success: Food Preparation

Long before anything gets cooked, ingredients have to be chopped, mixed, sliced, and portioned. The food preparation category is filled with all the appliances that make these time-sucking tasks faster, more consistent, and a whole lot safer. This is the equipment that unlocks real efficiency, slashing prep time and letting your team handle much higher volumes.

The key players here are commercial mixers, food processors, meat slicers, and vegetable choppers. By automating all those repetitive tasks, this gear frees up your skilled chefs to focus on the art of cooking, which leads to a more productive and creative kitchen.

The rising demand for convenience dining and online food delivery is pushing major growth in the commercial kitchen appliance market. Projections show the market size jumping from around $108.1 billion in 2025 to $146.2 billion by 2030. This boom is directly linked to the need for more efficient prep and cooking equipment to keep up with what customers expect. You can explore more data on these market trends and their drivers.

Finding the Perfect Commercial Charbroiler

For so many restaurants, that signature smoky flavor and those perfect diamond sear marks on a steak are the main event. That kind of culinary magic doesn't happen by accident; it's the work of a high-performance commercial charbroiler. Think of a charbroiler as more than just a grill—it's the heart of your menu's identity, a machine built to deliver consistent, crave-worthy food under the intense pressure of a packed dinner service.

Picking the right model is a critical decision. It directly impacts your food quality, ticket times, and even the flow of your kitchen. Our wide selection of commercial charbroilers is designed to meet the specific needs of any operation, from a bustling steakhouse to a nimble food truck. The first step is understanding the core differences between the main types to find the perfect fit for your vision.

Infrared Charbroilers for Speed and Precision

Infrared charbroilers are the sprinters of the grilling world. Instead of using open flames to heat the grates, they use ceramic plates that radiate intense, even heat directly onto the food. This method cooks food way faster than traditional methods, often cutting cooking times by up to 50%.

That direct heat transfer also means less hot air escapes into the kitchen, which makes for a much more comfortable working environment for your team. The real game-changer, though, is moisture retention. Because infrared technology sears the outside of proteins so quickly, it locks in all the juices, resulting in exceptionally tender and flavorful menu items.

- Best For: High-volume steakhouses, seafood restaurants, and any kitchen where speed and a consistent, hard sear are top priorities.

- Key Advantage: Unmatched cooking speed and superior moisture retention in meats.

Gas Charbroilers for Authentic Flame-Grilled Flavor

When you imagine classic grilling, you’re picturing a gas charbroiler. These models are the industry standard for a reason. Chefs love them for the authentic, smoky flavor they impart when open flames and dripping juices vaporize on the heat source. That process, known as the Maillard reaction, is what creates the complex, savory crust customers expect from a perfectly grilled meal.

Gas charbroilers give chefs excellent control, allowing for quick temperature adjustments to handle a diverse menu. Whether you're charring vegetables, grilling chicken, or searing thick-cut pork chops, the responsive nature of a gas unit gives you the versatility to do it all. They are true kitchen workhorses, built for reliability and authentic taste.

The appeal of a gas charbroiler is its ability to deliver that classic, flame-kissed flavor profile. It's the go-to for chefs who believe true barbecue character comes from the interplay of fire, smoke, and food.

Electric Charbroilers for Consistency and Convenience

Electric charbroilers are a powerful solution for kitchens where gas lines are impractical or just not an option. These units provide exceptionally precise and consistent temperature control, making them ideal for delicate items like fish or for operations that depend on standardized recipes and repeatable results. With no open flame, they can also be a safer choice in certain kitchen environments.

Another huge advantage is the ease of use and cleanup. Electric models often have fewer complex parts and don't produce the same level of combustion byproducts as gas units, which really simplifies daily maintenance. For mobile setups like food trucks or kitchens in historic buildings with ventilation restrictions, electric charbroilers provide professional grilling power without the logistical headaches of gas.

To help you sort it all out, here’s a quick comparison of the three main types:

| Feature | Infrared Charbroiler | Gas Charbroiler | Electric Charbroiler |

|---|---|---|---|

| Heat Source | Radiant Heat Panels | Open Flame Burners | Electric Heating Elements |

| Cooking Speed | Fastest | Moderate | Moderate to Fast |

| Flavor Profile | Intense Sear, Juicy | Authentic, Smoky | Clean, Consistent |

| Best For | Steaks, High Volume | Burgers, All-Purpose | Fish, Precise Cooking |

| Installation | Requires Gas or Electric | Requires Gas Line | Requires Electrical Outlet |

Ultimately, matching a charbroiler to your menu, kitchen infrastructure, and daily volume is key. An infrared model excels at high-speed searing, a gas unit delivers that classic flavor, and an electric charbroiler provides unmatched precision and convenience. When you invest in the right one, it stops being a simple appliance and becomes a true culinary asset.

How to Select the Right Appliances

Choosing the right commercial kitchen appliances is one of the biggest money moves you’ll make for your business. It's a decision that goes way beyond the sticker price, hitting everything from your daily workflow and utility bills to your long-term bottom line. Think of this as your practical buyer's guide—we’re focused on the total cost of ownership to help you make a smart investment that lasts.

To get it right, you need to see your kitchen as a complete system. Every single appliance has to fit, not just physically, but functionally. It needs to slide right into your workflow and make sense with your menu. Let's walk through the critical factors that will help you pick equipment that works as hard as you do.

Evaluate Your Kitchens Space and Layout

Before you even glance at models and brands, grab a tape measure. Seriously. The physical size of your kitchen is the first, non-negotiable limit you’re up against. An appliance is totally useless if you can't get it through the door, so measure the space, your doorways, and any hallways it needs to travel down.

And don't just measure the unit's footprint. Commercial equipment needs to breathe. Most appliances require several inches of clearance on all sides for proper ventilation and safe operation. You also have to leave enough room for your crew to move around the gear safely and efficiently, even when you're slammed.

Choose Between Gas and Electric Power

Ah, the great gas versus electric debate. It’s a classic for a reason, and the right answer really boils down to your menu, budget, and what your building is already set up for. Each power source brings its own performance quirks and operating costs that will absolutely impact your finances.

-

Gas Appliances: Chefs often swear by gas for its responsive, immediate heat control. Gas ranges and grills let you make instant temperature tweaks, which is a dream for things like sautéing and searing. In many places, gas is also cheaper, but installation can be a bigger job that requires a professional to hook up the gas lines.

-

Electric Appliances: These are known for delivering consistent, even heat, making them the go-to for baking and frying. Modern electric gear, especially induction cooktops, are incredibly energy-efficient and offer pinpoint temperature control. While they might cost more upfront, they're generally easier to install and a breeze to clean.

While both have their pros, the best choice often depends on the specific appliance. When it comes to something like deep frying, for instance, the differences are huge. You can get a much deeper look at this in our guide on the top commercial deep fryers reviewed to see exactly how power sources change the game.

Prioritize Energy Efficiency for Long Term Savings

That price tag on the appliance? That's just the down payment. The real cost comes from the energy it sucks up every single day. Energy consumption is a sneaky operational expense that adds up fast, which is why those energy efficiency ratings are your best friend.

Keep an eye out for equipment with the ENERGY STAR certification, a program run by the U.S. Environmental Protection Agency. Appliances with this seal have been proven to perform just as well as—or even better than—standard models while using way less energy.

Investing in ENERGY STAR certified commercial kitchen appliances can save a typical restaurant thousands of dollars a year on utility bills. It's a smart play that cuts your overhead and shrinks your environmental footprint without compromising on performance.

Inspect for Quality Construction and Durability

Let's be real: commercial kitchens are brutal environments. Your appliances have to be tough enough to handle constant use, crazy high temperatures, and daily scrub-downs. The build quality is a dead giveaway for how long a piece of equipment is going to last.

When you're checking out potential gear, get hands-on and look closely at the materials. High-grade stainless steel (like types 304 or 430) is the industry gold standard because it's tough and doesn't rust. Look for solid, well-put-together components—heavy-duty knobs, welded seams instead of screws, and reinforced doors. A well-built machine won't just last longer; it'll save you a fortune in service calls and killer downtime.

Designing a Smarter Kitchen Workflow

Top-of-the-line commercial kitchen appliances are only half the story. The real secret to a high-performing kitchen is how you arrange them. A smart layout can completely change the game for your team, turning the usual dinner rush chaos into a smooth, synchronized dance.

It all comes down to creating a logical path that mirrors how food moves, from the delivery truck all the way to the customer's plate. This means setting up dedicated work areas to cut down on wasted steps, eliminate dangerous traffic jams, and keep your staff from burning out. When every piece of equipment is right where you need it, your whole operation gets faster, safer, and a lot more profitable.

Proven Kitchen Design Principles

Every restaurant is different, with its own menu and vibe, so there’s no single "best" layout that fits everyone. But the most successful kitchen designs all borrow from a few core principles. Getting these concepts down will help you pick the right structure for your unique needs.

Three of the most popular and effective setups are:

- Assembly Line Layout: This is the gold standard for places with a standardized menu, like a pizzeria or a busy sandwich shop. Stations are lined up in order—prep, cooking, finishing, service—letting dishes flow seamlessly from one end to the other.

- Zone Layout: This approach groups similar tasks into their own little neighborhoods. You might have a sauté station, a fry station, and a grill station, each with its own gear and prep space. It's a fantastic setup for restaurants juggling a diverse menu.

- Island Layout: Here, the main cooking equipment—like ranges, ovens, and charbroilers—sits in a central block, with other stations arranged around the outside. This layout is a favorite in many high-end kitchens because it makes communication between chefs a breeze.

Creating a Logical and Efficient Flow

The whole point of a good layout is to create an unbroken workflow from the back door to the front of the house. This journey starts the second a delivery truck pulls up. Your receiving and storage areas, especially your coolers, need to be right near the back door to get perishable ingredients into a safe temperature zone ASAP. You can check out our guide to find the perfect restaurant-ready commercial refrigerators to anchor this critical first step.

From storage, ingredients make their way to the prep stations. These should be placed logically right between your storage and the main cooking line. Finally, the cooking area needs a clear, direct path to the pass or service window, keeping servers out of the hot, busy cooking zone.

Speaking of cooking equipment, it’s a massive market. Valued at USD 13.3 billion in 2025, it's expected to hit USD 26.5 billion by 2035. Part of that growth is driven by the need for kitchens to meet tough food safety standards—something a well-planned workflow makes a whole lot easier.

A well-designed kitchen layout isn’t a luxury; it’s a strategic asset. By minimizing movement, you maximize speed and safety, allowing your team to focus on producing high-quality food consistently.

To really dial in your kitchen's flow and tackle common headaches like spills, think about adding specialized drainage rubber mats. Placing them in high-traffic spots like the dish pit or prep areas is a simple move that makes a huge difference in safety and cleanliness for your staff.

Maintaining Your Equipment for Longevity

Your commercial kitchen appliances are a massive investment, and just like any high-performance machine, they need regular TLC to keep running at their peak. Protecting that investment is one of the smartest things you can do for your bottom line.

Think of it like this: you can either perform routine oil changes on your car or wait for the engine to seize. One is a small, manageable task. The other is a catastrophic, business-halting failure. A simple preventative maintenance schedule is your best defense against those unexpected breakdowns that always seem to happen during the Saturday night dinner rush.

This proactive approach doesn't just stretch the lifespan of your valuable gear. It also ensures it runs efficiently, keeps food safety standards high, and delivers the consistent results your customers expect every single time.

Building a Practical Maintenance Routine

Look, creating a maintenance plan doesn't need to be some overly complicated affair. The real key is breaking tasks down into simple daily, weekly, and monthly checklists your crew can actually follow. Consistency is way more important than complexity here.

Start by zeroing in on the workhorses of your kitchen—the fryers, ranges, and griddles. These pieces take the most abuse and get the biggest benefit from a little regular attention.

- Daily Tasks: These are the quick, simple actions that stop problems before they start. We're talking wiping down surfaces, emptying grease traps on fryers, brushing down grill grates, and double-checking fridge temperatures.

- Weekly Tasks: This is where you get a bit more in-depth. It involves things like de-liming dishwashers, boiling out fryers, and giving oven interiors a deep clean to get rid of that stubborn carbon buildup.

- Monthly Checks: These tasks are all about inspection and calibration. You’ll want to check the gaskets on your refrigeration units to make sure they’re sealing tight, calibrate your oven thermostats for accuracy, and inspect all gas hoses and electrical cords for any signs of wear and tear.

For certain equipment, like griddles, a specific cleaning process is absolutely essential to prevent flavor transfer and keep that perfect non-stick surface. To really get that down, check out our ultimate guide to cleaning a commercial stainless steel griddle.

A well-maintained kitchen is a profitable kitchen. Studies show that a structured preventative maintenance program can slash the risk of equipment failure by as much as 70%. That translates to thousands saved in repair and replacement costs over the life of an appliance.

Simple Troubleshooting for Common Issues

You'd be amazed how many service calls you can avoid just by empowering your staff with some basic troubleshooting skills. It can solve minor headaches before they ever disrupt service.

For instance, if a pilot light on a gas range won't stay lit, the problem might just be a small blockage in the gas tube that someone can carefully clear out. If a walk-in cooler isn't holding temp, the very first step should be checking and cleaning the condenser coils. Dust and grease buildup are the usual suspects.

To keep your investment humming along, a good commercial appliance parts and service guide is an invaluable resource. Having something like this handy helps you identify the right parts and understand when a problem is big enough to actually require a professional. By adopting these practices, you turn your team into the first line of defense, protecting your equipment and your profits.

Frequently Asked Questions

Stepping into the world of commercial kitchen equipment can feel a bit overwhelming, especially when you're about to make a major investment. I get it. To help you cut through the noise, I’ve put together some straightforward answers to the questions I hear most often from chefs and restaurant owners.

What Is The Main Difference Between Commercial And Residential Appliances?

It really boils down to three things: durability, power, and safety standards. Think about it—your home oven might run for an hour a day, but a commercial range is a workhorse that runs for 12 hours straight.

Commercial gear is built for that kind of abuse, using heavy-gauge stainless steel that can take a beating. They're also packed with much more powerful heating and cooling systems to keep up with the relentless pace of a professional kitchen. Most importantly, they have to be certified by organizations like NSF International to meet public health codes—something your home dishwasher was never designed to do.

How Do I Choose Between Gas And Electric Commercial Appliances?

This is a classic kitchen debate, and the right answer often comes down to your building's hookups, your menu, and your budget.

Gas has a reputation for a reason. Chefs love it for the instant, responsive temperature control—perfect for sauté stations and charbroilers where you need to go from a roaring flame to a gentle simmer in a second. In many places, it can also be cheaper to run.

On the other hand, modern electric appliances, especially induction and convection models, are champions of precision and even heating. This makes them a dream for delicate tasks like baking or for holding consistent temperatures in a fryer. Plus, they're often easier to clean and can be more energy-efficient. You'll need to weigh the upfront cost against your long-term utility bills and decide which cooking style best serves your food.

How Often Should My Commercial Kitchen Equipment Be Serviced?

While every piece of equipment is different, a solid maintenance routine is non-negotiable. Daily cleaning is the baseline for everything—it’s just good practice for hygiene and performance.

For the heavy lifters like your fryers, ranges, and refrigerators, you absolutely need a professional service plan. I recommend getting a technician in at least twice a year. They can check connections, clean out hard-to-reach components, and calibrate thermostats to keep things running smoothly.

Always, always check the manufacturer’s recommendations. Following their guide not only helps your equipment last longer but also keeps you from accidentally voiding your warranty.

Ready to find the perfect charbroiler to anchor your menu? At Charbroilers, we offer a wide selection of infrared, gas, and electric models designed for professional performance. Explore our collection today and start grilling with power and precision.