Deep Fried Decisions – Top Commercial Deep Fryers Reviewed

Share

The Power of Perfect Frying: Commercial Deep Fryers Explained

For restaurants seeking to add crispy, golden menu items, commercial deep fryers are essential kitchen workhorses that can significantly boost your profits and menu versatility. Here's what you need to know at a glance:

| Commercial Deep Fryer Basics | Details |

|---|---|

| Price Range | $79.99 (small countertop) to $21,799 (large ventless) |

| Common Capacities | 8.5-30 lbs (countertop), 40-100 lbs (floor models) |

| Power Sources | Electric (1.75-24 kW) or Gas (26,500-170,000 BTU) |

| Key Features | Temperature control, cold zones, filtration systems, safety shutoffs |

| Best For | French fries, chicken wings, onion rings, mozzarella sticks, seafood |

Commercial deep fryers are specialized kitchen equipment designed to heat large quantities of oil for consistent, high-volume food preparation. Unlike home fryers, these workhorse appliances are built to withstand the demands of busy kitchens, with temperature recovery systems that maintain consistent heat even during peak service periods.

A quality commercial fryer is often one of the most profitable pieces of equipment in your kitchen. Popular fried items like french fries, mozzarella sticks, and chicken wings typically offer excellent profit margins while requiring minimal prep time once your fryer is properly set up.

The right fryer choice depends on several factors: your menu, production volume, available space, and utility access. Electric models offer better temperature recovery and portability, while gas fryers heat up faster and can reach higher temperatures. For many restaurants, the decision often comes down to which utility is more cost-effective in your area.

I'm Sean Kearney from Charbroilers, with over a decade of experience helping restaurant owners select the ideal commercial deep fryers that balance performance, space constraints, and budget requirements. Having worked with thousands of kitchens, I've seen how the right fryer can transform a restaurant's efficiency and food quality.

How Commercial Deep Fryers Work & Key Types

Ever watched those golden fries emerge from a bath of bubbling oil? That's the magic of commercial deep fryers at work! These kitchen powerhouses transform raw ingredients into crispy delights through a beautifully simple process. When food takes the plunge into oil heated between 325°F and 375°F, the moisture inside instantly becomes steam while the exterior develops that irresistible golden crunch. Food scientists call this the Maillard reaction – I call it the reason we can't stop eating french fries!

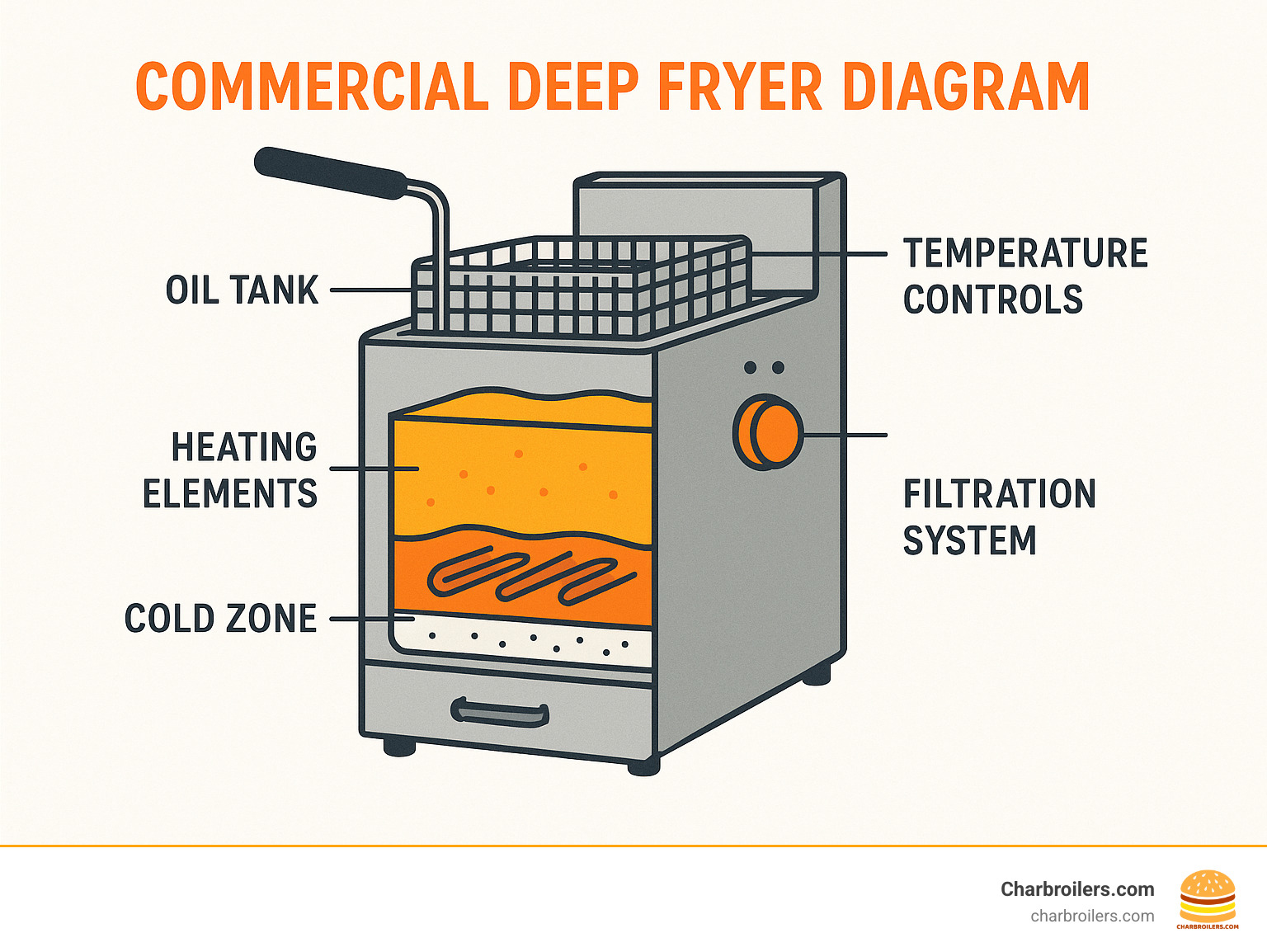

Behind this culinary change are two primary heating methods. Immersion-style electric fryers place heating elements directly in the oil, giving you lightning-fast recovery between batches. Meanwhile, tube-type gas fryers use heat tubes running through the oil with burners at one end, spreading heat evenly throughout your cooking medium.

When shopping for commercial deep fryers, you'll encounter several distinct types based on how they're installed. Countertop fryers (8.5-30 lb capacity) are perfect space-savers for small kitchens, food trucks, or as dedicated stations for specialty items. Many run on standard 120V outlets, making them incredibly versatile. For higher volume operations, floor models (40-100+ lb capacity) become your kitchen's workhorses, often featuring built-in filtration to extend oil life.

The design of your fryer dramatically affects performance too. Open-vat fryers feature wide cooking areas with V-shaped designs that maximize oil efficiency – ideal for lightly breaded or frozen foods. If you're frying heavily breaded items like fresh chicken, tube-type fryers are your friend, with their special "cold zone" at the bottom where food particles settle without burning. For delicate items like tempura, flat-bottom fryers eliminate the cold zone entirely, preventing fragile foods from getting caught in sediment traps. Need versatility? Split-pot fryers divide your frying area, letting you cook different foods simultaneously without flavor transfer – imagine crispy onion rings that don't taste like fish!

Some kitchens require specialized equipment. Pressure fryers seal food in a pressurized environment, cooking faster while locking in moisture – the secret behind many famous fried chicken recipes. Ventless fryers incorporate built-in filtration systems that eliminate the need for traditional hood vents, perfect for locations where installing ductwork isn't possible. And for the sweet-toothed among us, donut/funnel cake fryers maintain the specific temperatures and configurations these dessert items demand.

One design feature worth understanding is the "cold zone" – this cooler area at the bottom of many fryers allows food particles to settle without burning, preventing them from tainting your oil with bitter flavors. In tube-type fryers, about 20% of the oil volume serves as this cold zone, significantly extending oil life and saving you money.

Electric vs. Gas Fundamentals

The eternal kitchen debate: electric or gas? For commercial deep fryers, both options have their champions.

Electric fryers typically range from 1,600W for small countertop models to a powerful 24,000W for large floor units. They shine with superior temperature recovery between batches and more precise temperature control. Their portability is best – no gas lines needed! – making them perfect for flexible kitchen layouts or operations that might relocate. The tradeoff? Slower initial heat-up and potentially higher utility costs depending on local electricity rates.

Gas fryers pack serious power, ranging from 26,500 BTU to a whopping 170,000 BTU. They'll reach cooking temperature faster and can hit higher maximum temperatures than their electric counterparts. Many kitchen managers appreciate their typically lower operating costs, especially in areas with affordable natural gas. The downsides? They require permanent gas line installation, offer less precise temperature control, and once installed, they're staying put.

At Charbroilers.com, we've noticed an interesting trend: gas prices have been declining in many regions while electricity costs rise, potentially making gas fryers more economical long-term. That said, utility rates vary wildly by location, so check your local rates before deciding.

Ventilation & Hood Requirements

Safety first! Proper ventilation isn't just a good idea with commercial deep fryers – it's essential.

Most commercial kitchens require Type I hoods for fryers. These specialized ventilation systems extract grease-laden vapors, remove excess heat, and include fire suppression systems to protect your investment (and your building!). They must comply with local building and fire codes, which vary by jurisdiction.

For locations where traditional hood installation isn't practical – perhaps in a historic building or food court – ventless technology offers a clever alternative. These innovative fryers incorporate multi-stage filtration systems that remove smoke, vapor, and odors while featuring built-in fire suppression. While they cost more upfront, they save thousands on expensive hood installation. Just remember, even ventless fryers have placement limitations and require proper clearance and regular maintenance. They must also be UL-listed specifically for ventless operation.

Always consult with local authorities having jurisdiction (AHJ) before installing any fryer system. They'll ensure your setup complies with local codes, keeping your business safe and legally sound.

Choosing the Right Commercial Deep Fryers for Your Kitchen

Let's face it—picking the perfect commercial deep fryer can feel overwhelming. But I've helped hundreds of restaurant owners through this process, and I promise we can make this simple together.

Step 1: Analyze Your Menu and Volume

Think about what's going on your menu and how busy you'll get:

- Menu diversity: Will you be frying fish and french fries? Trust me, nobody wants fish-flavored fries, so you might need separate fryers for different items.

- Production volume: Those Friday night rushes can make or break your kitchen's reputation. Calculate how many pounds of food you'll need to fry during your busiest hour.

- Food type: Your breaded chicken will be happiest in a tube-type fryer, while those frozen fries will thrive in an open-pot design.

Here's a simple way to estimate your fryer's output: multiply your oil capacity by about 1.5-2.0. So your 40-pound fryer can handle roughly 60-80 pounds of food per hour. When the dinner rush hits, you'll be glad you did this math now!

Step 2: Evaluate Your Space and Utilities

Before falling in love with a particular fryer, make sure your kitchen can actually accommodate it:

Take careful measurements of your available space, including those clearances required by local codes (they're there for a reason!). Check if your electrical system can handle another appliance, or if your gas lines have enough capacity. And don't forget about ventilation—either you need space under an existing hood or you'll need to consider a ventless option.

Step 3: Consider Certifications and Safety

Quality commercial deep fryers come with important stamps of approval:

An NSF certification means your fryer meets public health standards—essential for passing those health inspections. Look for ETL or UL listings to ensure electrical safety compliance. And if you spot an ENERGY STAR rating, you might qualify for utility rebates (who doesn't love saving money?).

Step 4: Assess Advanced Features

Modern commercial deep fryers offer features that can make your life easier and your food better:

Built-in filtration systems can double your oil life—a huge cost savings when you consider how expensive oil has become. Programmable controls ensure that new hire doesn't overcook your famous calamari. Auto-lift baskets can free up your staff to handle other tasks during the rush. Oil quality sensors tell you exactly when it's time for a change, and fast-recovery heating elements keep your temperatures steady even when you're slammed with orders.

Here's how the main fryer types compare:

| Feature | Electric Fryers | Gas Fryers | Ventless Fryers |

|---|---|---|---|

| Initial Cost | $80-$5,000 | $1,200-$15,000 | $5,000-$21,799 |

| Operating Cost | Higher in most regions | Lower in most regions | Similar to electric |

| Heat-up Time | 15-20 minutes | 5-10 minutes | 15-20 minutes |

| Recovery Speed | Excellent | Good | Excellent |

| Temperature Range | Up to 375°F | Up to 400°F | Up to 375°F |

| Installation | Plug-and-play | Requires gas line | Plug-and-play |

| Mobility | Portable | Fixed | Limited mobility |

| Maintenance | Easier | More complex | Most complex |

Sizing & Capacity Calculator

Finding the right size commercial deep fryer is a bit like choosing the right vehicle—too small and you'll be constantly frustrated, too large and you're wasting money and space.

Countertop fryers (8-30 lb capacity) are perfect for smaller operations like food trucks or cafes. They'll typically need 11-24 inches of counter width and can produce about 15-60 pounds of food hourly. Many smaller models even run on standard 120V outlets, making them incredibly versatile.

Floor models (40-100+ lb capacity) are the workhorses for busy restaurants and hotels. They'll need about 15-36 inches of floor space per unit but can crank out 60-200 pounds of food every hour. These bigger units typically require 208-240V electrical service or a dedicated gas line.

When calculating your needs, be realistic about your peak demand. If your busiest hour requires 40 pounds of fries and 20 pounds of chicken tenders, you'll want separate fryers: a 40-pounder for fries and a 20-pounder for chicken. This prevents flavor transfer (nobody wants chicken-flavored fries either!) and ensures you can handle the rush without falling behind.

Must-Have Features Checklist

When shopping for commercial deep fryers, certain features aren't just nice-to-have—they're essential:

A precision thermostat that keeps temperatures within 2°F is crucial for consistent results. Look for a cold zone design that extends oil life by preventing food particles from burning. Safety features like high-limit shutoffs will automatically cut power if oil temperatures become dangerous.

Durable stainless steel construction makes cleaning and maintenance much easier, especially with lift-out elements or tubes. If you're going with a gas model, quick-disconnect fittings are a blessing during deep cleaning. And don't overlook the importance of insulated handles on fry baskets—your staff's hands will thank you!

For those willing to invest a bit more, auto-lift basket systems can prevent overcooking while freeing up staff. Low-oil sensors protect your equipment from damage, and computerized controls ensure consistent results regardless of who's working the station. An ENERGY STAR certification might cost more upfront but will save you money every month on your utility bills.

Looking to expand your cooking capabilities beyond frying? Learn more about our commercial charbroilers that can perfectly complement your frying station and add versatility to your menu. For more general information about deep fryers, you can also check out the Wikipedia page on deep fryers to understand their history and evolution.

Top Commercial Deep Fryers Reviewed by Category

After testing dozens of models and gathering feedback from our restaurant customers across Seattle and beyond, we've compiled our top recommendations for commercial deep fryers in various categories. Our reviews consider performance, durability, energy efficiency, and overall value.

Best Countertop Commercial Deep Fryers

Countertop commercial deep fryers are the versatile workhorses for smaller kitchens. They deliver professional results without hogging your precious floor space, making them perfect for operations where every inch counts.

For Food Trucks & Limited Space: When you're cooking in tight quarters, those 10-15 lb capacity countertop models are absolute lifesavers. I recently visited a food truck in downtown Seattle where the owner showed me how her compact fryer transforms from breakfast hash browns to afternoon mozzarella sticks with just a quick oil filtering in between. These space-saving units typically heat up in about 15-20 minutes to reach that perfect 350-370°F sweet spot, and many run on standard 120V circuits so you don't need special electrical work.

What makes these models truly shine is their adaptability. Many feature dual tanks that let you fry different products simultaneously without flavor transfer. As one food truck owner told me with a laugh, "It's like having two fryers in the footprint of one. My customers can get both french fries and churros without either tasting like the other!"

For Higher Volume Needs: If you need more output without surrendering floor space, the larger 20-30 lb countertop models bridge the gap perfectly. These beefier units recover temperature faster between batches and can pump out up to 60 pounds of product per hour. They typically require 208-240V operation, but that extra power means you won't slow down during the lunch rush.

These larger countertop units have become particularly popular in ghost kitchens and limited-menu operations. One of our customers running a delivery-only wing concept told me their 25 lb countertop model handles Friday night rushes with ease, all while taking up just 24 inches of counter width.

Best Floor-Model Commercial Deep Fryers

When volume is your priority, floor model commercial deep fryers deliver the capacity and durability needed for continuous service. These are the tanks that keep pumping out product hour after hour during your busiest shifts.

Tube-Type Gas Fryers: For heavily breaded items like fried chicken, tube-type gas fryers are the undisputed champions. With oil capacities ranging from 50-100 lbs and BTU ratings from 100,000-170,000, these powerhouses can handle whatever your kitchen throws at them. Their specialized cold zone design captures about 20% of the oil volume, collecting food particles before they burn and taint your oil.

I'll never forget visiting a busy chicken restaurant where the owner proudly patted his 75 lb tube-type fryer and said, "This baby handles 30 pounds of chicken in an hour with consistent quality. It's been running 9-11 hours a day for two years with minimal issues. Best investment I ever made."

Open-Pot Fryers: If frozen foods like french fries and onion rings are your staples, open-pot fryers deliver exceptional results. Their V-shaped design maximizes oil efficiency, and without tubes to work around, cleaning is much faster. The excellent heat distribution ensures every basket comes out with consistent crispiness.

Split-Pot Floor Models: For menu diversity, split-pot models offer the best of both worlds. With separate temperature controls for each section, you can simultaneously cook items requiring different temperatures without flavor transfer. One seafood restaurant owner told me her split-pot fryer was "like having two completely separate fryers in one footprint," allowing her to fry fish in one section and french fries in the other.

The real game-changer with modern floor models is their integrated filtration systems. One multi-location restaurant group we work with reported a 40% reduction in oil costs after upgrading to floor models with built-in filtration. "The systems paid for themselves within the first year," their operations manager told me. "Plus, the oil quality is more consistent, so our food tastes better."

Best Specialty & Ventless Commercial Deep Fryers

Sometimes standard fryers just won't cut it. For unique cooking needs or challenging installation environments, specialty and ventless commercial deep fryers offer custom solutions that can transform your menu possibilities.

Pressure Fryers: If you've ever wondered how certain chicken chains get that incredibly juicy meat with the perfectly crispy exterior, the secret is pressure frying. These specialized units seal in moisture while creating crispy exteriors by cooking under pressure. They operate at lower oil temperatures (325°F versus the standard 350°F) and can reduce cooking times by up to 30%. As a bonus, they minimize oil absorption, resulting in a slightly healthier product.

Donut/Funnel Cake Fryers: Bakeries and concession stands have unique frying needs, and that's where specialized donut fryers come in. With their flat-bottom design, delicate pastries won't get caught or damaged during frying. These units typically operate at lower temperature settings (around 325°F) and feature wider, shallower tanks for easier product handling. Instead of traditional baskets, many use special screens for gentler handling of your delicate treats.

Ventless Fryers: Perhaps the most development in recent years has been the perfection of ventless fryer technology. These units have been absolute game-changers for operations in historical buildings, high-rises, and other locations where installing traditional ductwork is either structurally impossible or would cost a small fortune.

While ventless models do come with a higher price tag (ranging from $5,000 to over $21,000), they can save tens of thousands in hood installation costs. Their multi-stage filtration systems effectively remove smoke, vapor, and odors, while built-in fire suppression systems ensure safety compliance.

I recently visited a cafe in a historic Seattle building where the owner showed me her ventless fryer with pride. "This was our only option given the building restrictions," she explained, "but it's performed flawlessly for two years. We can now offer fried items that were impossible before, and our customers love them."

Maintenance, Cleaning & Safety for Long Fryer Life

Taking good care of your commercial deep fryers isn't just about keeping them clean—it's about protecting your investment, ensuring food quality, and maintaining a safe kitchen. While most fryers are built to last 7-10 years, I've seen well-maintained units still going strong after 15+ years in busy kitchens.

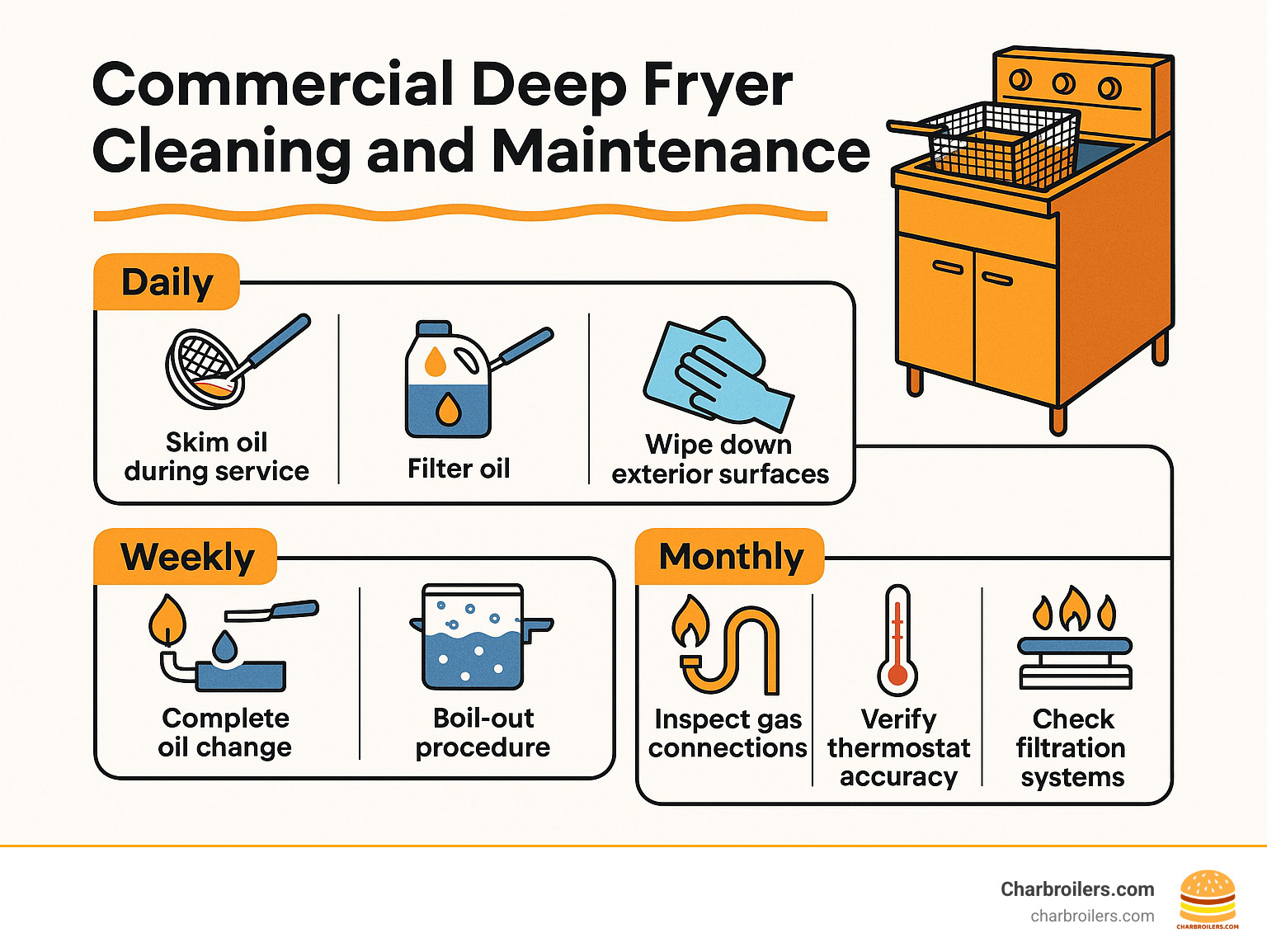

Daily Maintenance:

Think of your fryer like a car that needs regular oil changes. Throughout your service day, use a fine mesh skimmer to remove floating bits of food. This simple 10-second task prevents those particles from burning and tainting your oil. For busy restaurants, filtering your oil at least once daily (ideally during that mid-afternoon lull between lunch and dinner) can make a world of difference.

Don't forget to wipe down those exterior surfaces too! Oil splatter doesn't just look messy—it can become a sticky fire hazard when left to build up. And always keep an eye on your oil quality. Fresh oil should look clear with a light golden hue. When it starts looking like motor oil (dark and cloudy), it's telling you something!

Weekly Maintenance:

Depending on how busy your kitchen is, you'll need to completely change your oil every 3-7 days. But before adding fresh oil, give your fryer a proper bath with a "boil-out" procedure:

First, make sure the oil is completely cool before draining it (safety first!). Then fill the fryer with hot water and a commercial fryer cleaner. Heat this solution to about 200°F for 15-20 minutes, which helps loosen all that stubborn gunk. Now comes the elbow grease—scrub thoroughly with a proper fryer brush, paying special attention to those heating elements or tubes where carbon likes to hide.

After draining and rinsing thoroughly, dry the fryer completely before adding fresh oil. Any water left behind will cause dangerous splattering when you add hot oil!

Monthly Maintenance:

Once a month, take some time for deeper maintenance. If you have a gas fryer, carefully check those connections for leaks (never with an open flame—use soapy water or a proper leak detector). Verify your thermostat accuracy with a reliable thermometer, as even small temperature discrepancies can affect food quality and oil life.

For gas fryers, inspect and clean those burner assemblies to ensure efficient heating. And don't forget to check your filtration systems—clean or replace components as needed to keep them working properly.

Extending Oil Life & Reducing Costs

Let's talk money—specifically, how to save it! Oil is one of your biggest ongoing expenses with commercial deep fryers, but there are smart ways to make it last longer.

Regular filtration is the single most effective strategy. By filtering hot oil daily, you can literally double its lifespan. Many of our customers at Charbroilers.com have seen dramatic improvements—like the fast-casual spot that cut oil costs by 35% just by implementing twice-daily filtration.

Keep an eye on those temperatures too. Oil breaks down much faster above 375°F, so resist the temptation to crank up the heat for faster cooking. And here's a simple tip that makes a big difference: cover your fryer vats during off hours. This prevents both contamination and oxidation, which can significantly extend oil life.

I always tell restaurant owners to add salt after frying, not before. Salt accelerates oil breakdown, so season your beautiful crispy creations after they come out of the fryer. And remember that cold zone at the bottom of your fryer? It's designed to collect food particles before they burn—but it only works if you keep it clean!

A busy sports bar I worked with extended their oil change interval from every 3 days to every 5-7 days simply by using covers overnight and filtering properly. That's real money back in their pocket!

Essential Safety Tips When Operating Commercial Deep Fryers

Let's be honest—commercial deep fryers can be dangerous if not respected. They combine extremely hot oil, electricity or gas, and busy kitchen environments. That's why proper training is non-negotiable.

Burn prevention starts with proper equipment. Heat-resistant gloves aren't optional when working with fryers. Always lower and raise baskets gently to prevent splashing, and maintain proper oil levels—overfilled fryers are splash hazards waiting to happen.

Fire safety deserves your full attention. Never leave fryers unattended while heating, and always keep a Class K fire extinguisher (specifically designed for kitchen grease fires) within easy reach. Make sure everyone knows how to activate your hood suppression system in an emergency. And remember the golden rule: never, ever put water on an oil fire—it will create a dangerous explosion of flaming oil.

The area around your fryers should have slip-resistant floor mats and excellent drainage. Oil spills become dangerous slipping hazards in seconds, so clean them immediately.

When it comes to loading your fryer, never fill baskets more than halfway. Lower food into the oil slowly and deliberately to prevent splashing. And always shake excess ice from frozen products before frying—ice causes oil to violently bubble and potentially overflow.

At Charbroilers.com, we provide our customers with detailed safety checklists and can help you develop training materials specific to your equipment. After all, a safe kitchen is a productive kitchen!

Frequently Asked Questions about Commercial Deep Fryers

What certifications should my commercial deep fryer have?

When shopping for a commercial deep fryer, you'll notice various certification symbols that might look like alphabet soup at first glance. Let me break down what these actually mean for your business:

The NSF certification is essentially your health inspector's seal of approval. The National Sanitation Foundation tests equipment to ensure it meets strict public health and sanitation standards. Without this, you might face challenges during your health inspections.

For safety, look for either an ETL or UL listing. These aren't just random letters – they're proof that independent organizations (Underwriters Laboratories or Intertek) have thoroughly tested your fryer to make sure it won't turn into a fire hazard during the lunch rush!

If you're watching utility bills (and who isn't these days?), an ENERGY STAR rating is worth considering. While not mandatory, this certification might qualify you for utility rebates, and the energy savings can add up substantially over time.

Gas fryer shoppers should also look for AGA or CSA certification marks, which confirm the equipment meets gas appliance safety standards – crucial for preventing leaks or other hazardous situations.

One special note about ventless fryers: make sure they specifically carry a UL listing for ventless operation. This is a separate, more stringent certification than standard electrical safety approval, and skipping this verification could lead to serious code violations.

How much do commercial deep fryers cost?

The price tag on commercial deep fryers varies widely – kind of like the difference between a basic family sedan and a luxury sports car. Let me walk you through what you can expect to pay:

For countertop electric models, you're looking at anywhere from $79.99 for a basic single-tank starter model up to $5,000 for premium dual-tank systems with all the bells and whistles. Most restaurants find their sweet spot in the $500-$1,500 range for mid-sized 15-20 lb models that balance quality with affordability.

Floor model gas fryers start around $1,200 for entry-level 40 lb units and can climb to $15,000 for high-capacity 100 lb commercial workhorses. The most popular models tend to fall in the $3,000-$7,000 range, offering that middle-ground of durability and features without breaking the bank.

Specialty and ventless fryers command premium prices, typically $5,000 to $21,799, with pressure fryers starting around $5,000 and fully automatic ventless systems reaching the upper end of that range.

Remember though, the sticker price isn't the whole story. I've worked with restaurant owners who initially balked at higher prices but later realized the value in considering the total cost of ownership. Installation costs (especially for gas models), ventilation requirements, energy consumption, oil usage, and maintenance needs all factor into the true cost.

Many of our customers at Charbroilers.com take advantage of our financing options to get the higher-end models that save them money in the long run through reduced operating costs. It's like investing in a more fuel-efficient car – higher upfront cost, but lower expenses down the road.

Can commercial deep fryers replace air fryers in a pro kitchen?

The air fryer versus commercial deep fryer debate reminds me of comparing a bicycle to a motorcycle – they might seem similar at first glance, but they serve very different purposes in a professional setting.

While air fryers have become the darling of home kitchens, they simply can't replace traditional fryers in a commercial environment. The volume alone is a deal-breaker – even the largest commercial air fryer can't match the output of a standard deep fryer during a busy service.

Then there's the matter of texture and taste. Let's be honest – there's a certain magic that happens when food hits hot oil that air fryers can't quite replicate. That distinctive crispy exterior paired with a moist interior is what customers expect from their favorite fried foods. I've had restaurant owners tell me their customers can immediately tell the difference between traditionally fried items and air-fried alternatives.

Recovery time is another crucial factor. Commercial fryers are built to maintain consistent temperatures even when you're dropping in basket after basket during the dinner rush. Air fryers typically need time to recover between batches – a luxury few busy kitchens can afford.

That said, I've seen smart operators incorporate commercial-grade air fryers as companions to their traditional fryers. They're great for offering "lighter" menu options, handling overflow during peak periods, or preparing items that actually perform well in air fryers (like reheating pre-fried frozen items).

The wisest approach for most restaurants is viewing air fryers as teammates rather than replacements for their commercial deep fryers – each has its strengths, but they play different positions on your kitchen team.

Conclusion

Selecting the right commercial deep fryer is truly one of the most significant equipment decisions you'll make for your restaurant or food service business. I've seen how the perfect fryer becomes more than just equipment—it transforms into a genuine profit center, consistently delivering those golden, crispy items that keep your customers coming back for more.

After helping hundreds of restaurant owners find their ideal fryer setup, I've noticed that success comes down to a few key considerations:

Match your fryer's capacity to your actual needs, thinking about both your typical service and those crazy-busy Friday nights when orders are flying in. Tube-type fryers excel with breaded items like chicken, while open-pot designs work wonders with frozen foods like french fries.

Your utility situation matters too—gas fryers heat up faster, while electric models offer more precise temperature control. In many areas we serve, gas costs have been trending downward, making them increasingly economical, but your local utility rates should guide this decision.

Don't underestimate the value of good filtration systems. Yes, they add to the upfront cost, but the savings in oil (which can easily run $40+ per container) quickly offset that investment. One restaurant owner I worked with cut their oil expenses by nearly 40% after upgrading to a model with built-in filtration.

Proper ventilation isn't just about compliance—it's about creating a comfortable working environment. Whether you go with traditional hood systems or opt for newer ventless technology, ensuring proper air quality protects both your equipment and your staff.

Speaking of staff, even the best fryer won't perform well without proper training. Take the time to thoroughly train your team on safe operation and maintenance procedures. The small investment in training pays huge dividends in safety, food quality, and equipment longevity.

At Charbroilers.com, we take pride in serving restaurants throughout Seattle and beyond with quality commercial deep fryers backed by genuine expertise and support. Our team doesn't just sell equipment—we help you steer the selection process, arrange financing that works for your budget, and ensure your installation goes smoothly.

Whether you're launching a new concept, replacing aging equipment, or expanding your menu to include more fried offerings, choosing the right fryer makes all the difference in your kitchen's efficiency and your food's consistency. While premium equipment requires a larger initial investment, the reliability and lower lifetime operating costs make it the smarter financial decision in the long run.

Ready to lift your fried food game? Browse our selection of commercial deep fryers or reach out to our team for personalized recommendations custom to your specific kitchen needs. For more expert insights on commercial kitchen equipment, check out our blog for additional resources.