Commercial Double Stack Ovens: A Comprehensive Buyer's Guide

Share

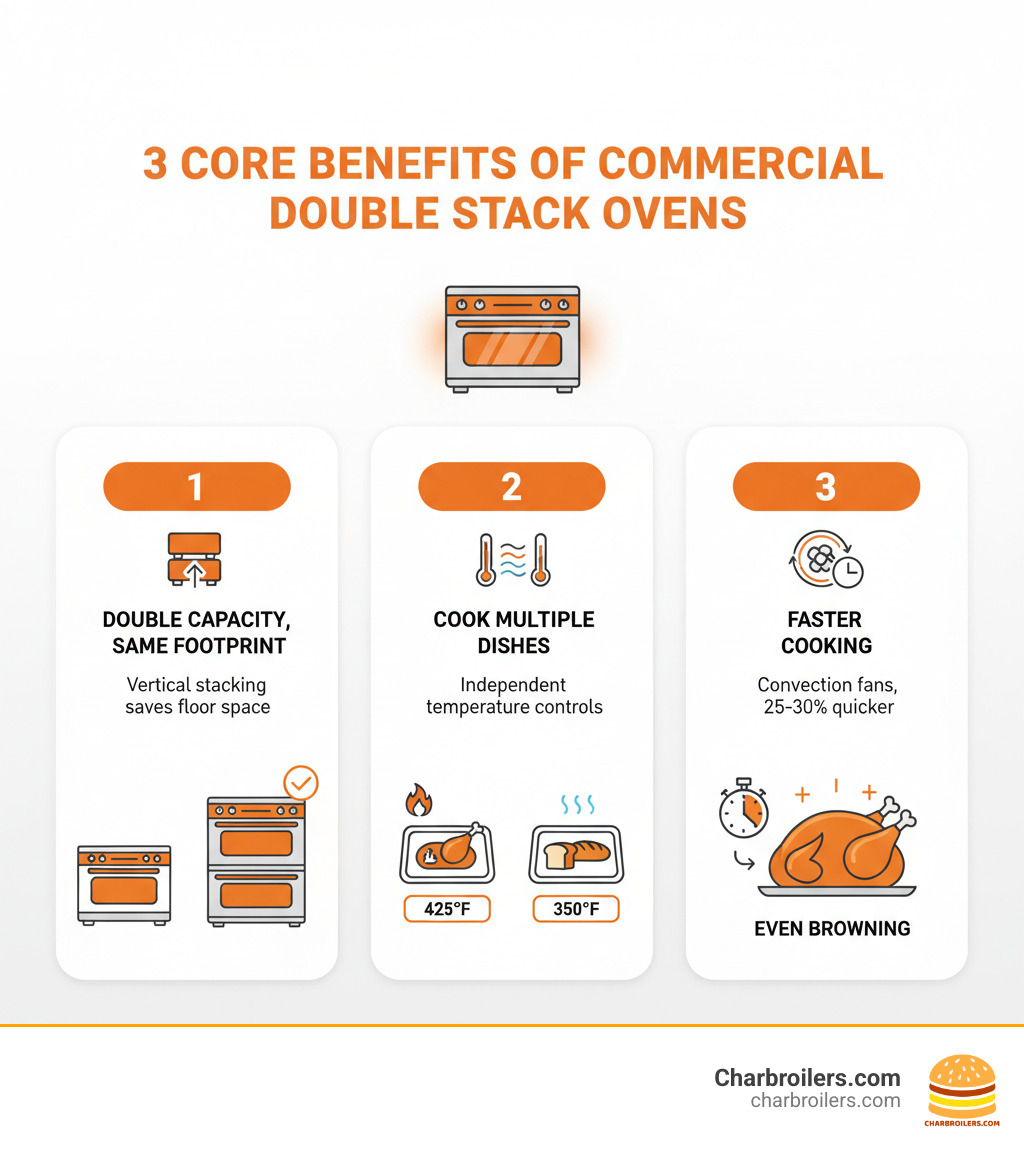

Why Commercial Double Stack Ovens Are Essential for High-Volume Kitchens

When you need to maximize cooking capacity without expanding your kitchen footprint, double oven commercial units are the solution. Here's a quick overview:

What is a Commercial Double Stack Oven?

- Two independent convection ovens stacked vertically in one unit

- Each oven operates separately with its own controls

- Doubles your cooking capacity while using the same floor space as a single oven

Key Benefits:

- Increased Capacity: Cook up to 10 full-size sheet pans simultaneously (5 per oven)

- Space Efficiency: Vertical stacking saves valuable floor space

- Menu Versatility: Run different temperatures in each oven at the same time

- Faster Cooking: Built-in fans circulate hot air for even, consistent results

Price Range: $3,279 to $31,027 depending on size, fuel type, and features

These workhorses are designed for high-volume foodservice businesses like busy restaurants, commercial bakeries, school cafeterias, and catering operations.

The magic is in the convection fans. They circulate hot air for even, consistent cooking, eliminating hot spots. Since each oven operates independently, you can bake bread at 350°F in the top oven while roasting chicken at 425°F in the bottom.

I'm Sean Kearney, founder of Charbroilers.com. With over a decade in the restaurant equipment industry, I know that the right double oven commercial unit can transform a kitchen's efficiency and output, especially when space and budget are tight.

Double oven commercial terms you need:

- commercial convection ovens

- how much does a commercial convection oven cost

- do commercial convection ovens need venting

Why Your Kitchen Needs a Double Oven Commercial Unit

In a busy kitchen, a double oven commercial unit is essential, not a luxury. It can be the difference between a smooth dinner service and a scramble. Instead of juggling pans in a single oven, a double stack unit doubles your output without using more floor space. This vertical design is a lifesaver when every square foot counts.

The real advantage is cooking multiple dishes at different temperatures simultaneously. Each oven has independent controls, so you can roast prime rib at 450°F in one cavity while baking croissants at 325°F in the other. This versatility improves kitchen efficiency and expands your menu capabilities.

Convection technology makes these ovens much faster than traditional models. Fans circulate hot air, eliminating the cold air bubble around food. This leads to faster preheating, cooking times up to 25-30% quicker, and more even results. The efficient heat transfer also reduces food shrinkage by locking in moisture.

High-volume establishments like restaurants, bakeries, caterers, and school cafeterias see the biggest impact. A double oven commercial unit provides the reliable, high-capacity cooking they need, letting them bake and roast twice the food at once for faster service. For more details, see our The Ultimate Guide to Comparing Commercial Convection Ovens.

Understanding Convection Performance

Unlike standard ovens that use static radiant heat, convection ovens use a fan and blower system to actively move hot air. This simple difference creates superior results. The fan and a baffle work together to eliminate hot spots, ensuring consistent browning and predictable cooking. This active air circulation allows for cooking at lower temperatures with faster results, cutting cooking times by 25-30%. This saves energy and increases output during peak hours.

Many units feature a two-speed fan for versatility. Use high speed for hearty items like roasts and casseroles that need aggressive heat. Use low speed for delicate items like cakes, custards, and pastries that could be damaged by too much air movement. Mastering this feature maximizes your investment. Learn more in our article Demystifying Commercial Convection Ovens: A Deep Dive into Their Operation.

Who Benefits Most from a Double Stack Oven?

While not for every kitchen, a double stack oven is transformative for high-volume operations that need to cook different items simultaneously.

High-volume restaurants and pizzerias are prime candidates. The ability to manage multiple dishes at different temperatures is crucial for a smooth service. Pizzerias can use them as secondary ovens for appetizers, wings, and desserts.

Commercial bakeries benefit immensely. With two independent ovens in one footprint, they can simultaneously bake different products—like cookies, breads, and pastries—at their ideal temperatures, boosting production capacity.

Hotels, resorts, and institutional kitchens (schools, hospitals) face similar demands. They must handle banquets, room service, and cafeteria meals simultaneously. The capacity and efficiency of a double oven commercial unit are essential for preparing hundreds of meals daily.

Commissary kitchens, such as KBM SEATTLE COMMISSARY KITCHEN, also rely on these ovens. They produce food for multiple clients with varied menus, making the independent cooking zones and vertical design ideal. If your kitchen juggles different temperatures, has a complex menu, or runs out of oven space during peak hours, a double stack oven is a smart investment.

Key Features to Consider Before You Buy

Choosing a double oven commercial unit is a major investment. To find the right match, consider these essential features: fuel source, dimensions, controls, power requirements, and certifications. Getting these details right avoids costly mistakes. For a full financial picture, see our guide on Budgeting for Bake-Offs: How Much Does a Commercial Convection Oven Set You Back?

Fuel Type: Gas vs. Electric

Your first decision is fuel type: gas or electric. This choice impacts operating costs and heat response time. Both have their advantages in professional kitchens.

| Feature | Gas Ovens (Natural Gas/LP) | Electric Ovens |

|---|---|---|

| Upfront Cost | Often lower | Often higher |

| Operating Cost | Typically lower (depending on local utility rates) | Typically higher (depending on local utility rates) |

| Heat Response | Quick to heat up, good recovery | Very consistent, dry heat |

| Installation | Requires gas line connection, often 120V for controls/fan | Requires specific voltage (208/240V, 480V) & phase (1 or 3) hardwiring |

Gas ovens are popular for their fast heat-up and temperature recovery. Running on natural gas or propane, their power is measured in BTUs (e.g., the Southbend BGS/23SC has 80,000 total BTU). Most require a 120V connection for fans and controls. Learn more in our article on Unlock Efficiency: The Power of Gas Convection Ovens.

Electric ovens provide exceptionally consistent, dry heat, which is ideal for baking. They require a high-voltage (208V, 240V, or 480V) single- or three-phase electrical connection and must be hardwired. A model like the Vulcan VC44ED might draw 25 kW. For more on electric options, see our guide Power Up Your Kitchen: The Best Commercial Electric Ranges with Convection Ovens.

Your local utility rates may decide for you. Gas is often cheaper to operate, but electric is more practical if your building lacks gas infrastructure.

Size, Depth, and Capacity

A double oven commercial unit must fit your kitchen's physical space and cooking volume. Consider the overall footprint and interior capacity. Most units are 30-38 inches wide and 66-74 inches tall. Always measure your space and account for clearance for door swing and maintenance access.

Interior dimensions determine cooking capacity, based on standard 18" × 26" full-size sheet pans. A standard depth oven has a ~22-inch interior, fitting pans side-to-side. Most hold 5 pans per cavity, for a total of 10. Bakery depth ovens are deeper, allowing you to load pans front-to-back. This can improve airflow and ergonomics for bakers.

Also check rack positions. More positions provide flexibility for items of different heights. For more on space, read Maximize Your Space: Understanding Full-Size Commercial Countertop Convection Ovens.

Controls and Technology

The control panel should match your team's skill level and cooking style. Options range from simple and durable to sophisticated and feature-rich.

Solid-state controls with manual dials are the reliable workhorses of commercial kitchens. They are simple to use, durable, and easy for training staff. They offer precise temperature control, typically from 150°F to 500°F, and are ideal for kitchens that value simplicity.

Computer or programmable controls add automation, allowing you to store recipes with multi-stage cooking sequences. This ensures consistency, reduces guesswork, and is great for kitchens with standardized menus or less experienced staff.

Touchscreen controls are the most advanced, offering intuitive graphical interfaces, recipe management, and diagnostic alerts. These controls offer the highest precision and are ideal for complex operations.

Certifications and Energy Efficiency

Certifications on a double oven commercial unit are your assurance of safety, sanitation, and cost savings.

ENERGY STAR certification is a must-have. Certified ovens meet strict EPA efficiency guidelines, leading to lower utility bills and potential cash rebates from utility companies.

NSF certification guarantees the oven meets public health and sanitation standards. It means the unit is designed for easy cleaning, helping you maintain a hygienic kitchen.

UL or ETL Listed certifications confirm the oven meets electrical safety standards, having been tested by a third-party lab. Always look for these non-negotiable safety marks to protect your staff and business.

Review spec sheets for full technical details and certifications. You may need a PDF viewer like Adobe Acrobat software to open them.

Installation, Maintenance, and Accessories

Proper installation, maintenance, and accessories are key to maximizing the life and performance of your double oven commercial unit. These fundamentals ensure your oven serves you reliably for years. Start by reviewing our Don't Get Burned: Follow These Convection Oven Safety Guidelines.

Installation Essentials for Your Double Oven Commercial Unit

Installing a double oven commercial unit is not a DIY project. It requires professional attention to placement, ventilation, and utility connections to ensure safety and prevent future problems.

For placement and clearance, follow the manufacturer's manual for required clearance on all sides. This ensures proper air circulation and prevents heat damage to walls and other equipment.

Ventilation requirements are critical. Most gas ovens require a Type I hood to remove heat, smoke, and grease. Some electric models may use a Type II hood. Always check your local fire codes, as they have the final say. Learn more in our article, Commercial Convection Ovens: Unpacking Venting and Hood Requirements.

Utility connections must be handled by licensed professionals. A certified gas fitter is needed for gas ovens, and a licensed electrician is required to hardwire electric units to the correct voltage and phase. Improper installation can damage the oven, create hazards, and void your warranty.

Maintenance and Cleaning Best Practices

Regular maintenance is an insurance policy for your double oven commercial unit. Daily and weekly cleaning prevents costly repairs, ensures peak efficiency, and results in better-cooked food.

Daily cleaning involves wiping down the exterior and glass doors to prevent grease buildup. Clean interior spills immediately before they bake on and become difficult to remove.

For weekly cleaning, remove and soak the racks in a commercial degreaser. Clean the interior, noting that porcelain interiors and coved corners make this task easier. Use a commercial oven cleaner in a well-ventilated area, rinse thoroughly to remove residue, and then reinstall the racks.

Schedule professional servicing annually or semi-annually. A technician should inspect the fan, motor, door gaskets, and utility connections. This preventative maintenance catches small issues before they become major problems.

Essential Accessories for Your Double Oven Commercial Unit

The right accessories improve functionality and safety for your double oven commercial unit. Extra oven racks allow for continuous cooking, while stainless steel stands provide ergonomic height and easier cleaning. Drip pans catch spills, and heat-resistant gloves are essential for safety. Always use commercial-grade cleaners for heavy-duty grease. Some units can be fitted with casters for mobility, and options like Kosher-friendly controls are available for specific needs.

Frequently Asked Questions about Commercial Double Ovens

When you're considering a double oven commercial unit, it's natural to have questions about how these workhorses perform in real-world kitchen conditions. Let me address the most common questions we hear from restaurant owners and kitchen managers.

How does a double deck convection oven cook food faster than a standard oven?

A convection oven's internal fans circulate hot air, stripping away the insulating layer of cool air that forms around food in a standard oven. This forced air movement transfers heat more efficiently, allowing food to cook up to 25-30% faster and at lower temperatures. The result is faster, more even cooking.

Can I cook two completely different dishes at the same time?

Yes. This is a key advantage of a double oven commercial unit. Each oven has independent controls for temperature and time. This allows you to roast a chicken at 375°F in the top cavity while baking cookies at 325°F in the bottom, without compromising the quality of either dish. This flexibility is invaluable for complex menus.

What is the difference between a standard depth and a bakery depth oven?

The difference is how they accommodate full-size (18" × 26") sheet pans. A standard depth oven fits pans side-to-side. A bakery depth oven is deeper, fitting pans front-to-back. This orientation can improve airflow and is often preferred by bakers for ergonomic reasons. While bakery depth models have a slightly larger footprint, a standard depth double oven commercial unit is sufficient for most general restaurant use.

Conclusion

Investing in a double oven commercial unit is a transformative step for any high-volume kitchen. These ovens double your cooking capacity in the same footprint, allow for simultaneous cooking at different temperatures, and use convection technology to cook 25-30% faster with consistent results.

When choosing, consider your menu, kitchen space, and utility access. The right fuel type, depth, controls, and certifications will ensure you get the perfect unit for your needs.

Your investment extends beyond the purchase. Proper installation, regular cleaning, and professional servicing are crucial for long-term performance and safety. The right accessories will further streamline your operations.

At Charbroilers.com, we understand that quality equipment is the backbone of a successful kitchen. While a double oven commercial unit handles your baking and roasting, ensure your grilling station is just as efficient by exploring our guide to commercial charbroilers for your restaurant.

A double stack convection oven delivers the capacity, efficiency, and versatility your kitchen needs to succeed.