The Ultimate Guide to Comparing Commercial Convection Ovens

Share

Why Commercial Convection Ovens Are Essential for Professional Kitchens

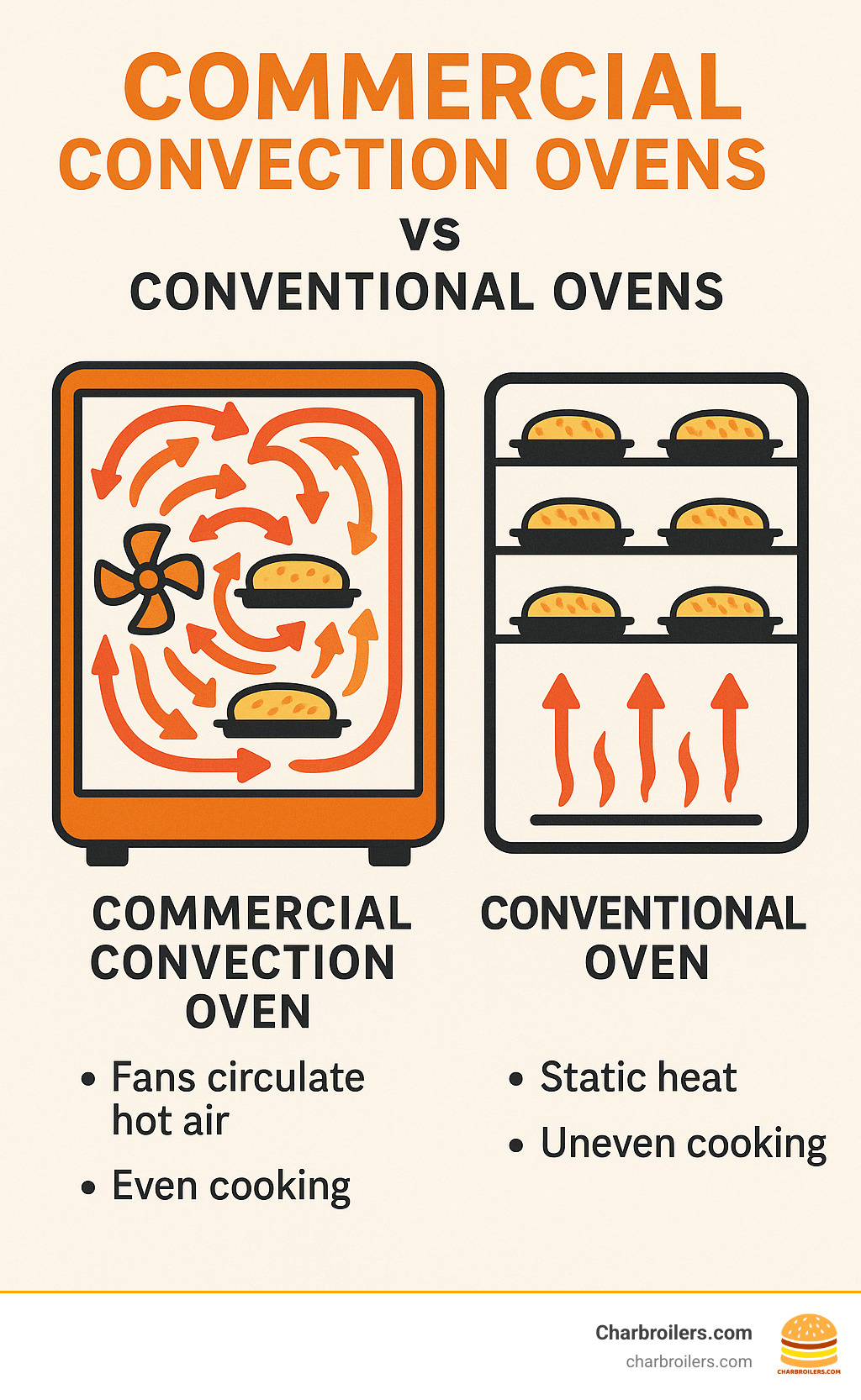

Commercial convection ovens use high-speed fans to circulate hot air, cooking food roughly 25 % faster and far more evenly than traditional radiant ovens. The result: perfectly browned pastries, juicier proteins, and lower utility bills.

Key Benefits

- Speed – up to 25 % quicker cook times

- Even heat – no hot or cold spots

- ENERGY STAR® efficiency – reduced operating costs

- Menu flexibility – from croissants to roast beef

- Space-saving designs – countertop, single-deck, and double-deck

- Fuel options – gas or electric to match your utilities

Popular Sizes

- Countertop (≈1.5–3.5 cu ft): cafés, food trucks, test kitchens

- Single deck (≈5–7 cu ft): most full-service restaurants

- Double deck (≈10–14 cu ft): high-volume bakeries, caterers

Choosing the right capacity, power source, and features keeps service running smoothly and protects your food margins.

I’m Sean Kearney of Charbroilers.com. After 10+ years outfitting kitchens, I’ve seen first-hand how the right convection oven can cut ticket times and boost consistency almost overnight.

Need more details? Check out our in-depth guides:

- Used commercial convection oven deals near you

- Buying used commercial convection ovens

- Ventless commercial convection ovens

How Convection Ovens Revolutionize Professional Kitchens

Convection technology is simple: built-in fans keep hot air moving so heat reaches every surface of your food. This steady airflow eliminates hot spots, shortens cook times, and promotes superior browning by whisking away surface moisture.

Why It Matters to Your Bottom Line

- 25 % faster output lets you serve more guests without extra labor.

- Consistent doneness means fewer comps and happier customers.

- Better caramelization & crust formation lift flavor and plate appeal.

- Lower temps + shorter cycles = energy savings that show up on your utility bill.

The Core Advantages for Your Business

- Increased productivity – handle the dinner rush without adding staff.

- Improved food quality – even heat produces uniform, repeatable results.

- Menu versatility – bake pastries at 7 a.m., roast chickens at 7 p.m.

- Reduced shrinkage – proteins keep more moisture, boosting yield.

- Energy savings – many models cut gas or electric use 20–30 % compared to legacy ovens.

A Breakdown of Commercial Convection Oven Types

Choosing a model starts with matching capacity to demand, not guessing. Track how many sheet pans you load during a peak hour and select the smallest oven that comfortably covers that number.

Countertop – up to 4 half-size pans; perfect for satellite prep, bars, or bakeries needing overflow capacity.

Single deck – the "standard issue" for most restaurants; handles 5–7 full-size sheet pans without hogging floor space.

Double deck – two ovens stacked; same footprint as a single deck but double the output for caterers or high-volume concepts.

Gas vs. Electric: The Core Choice

| Feature | Gas | Electric |

|---|---|---|

| Upfront cost | Lower | Higher |

| Typical operating cost | Lower in most regions | Higher but stable |

| Heat recovery | Very fast | Moderate, very even |

| Install requirements | Gas line + hood | 208–480 V service |

Gas excels at quick recovery during nonstop service. Electric shines for precision baking or sites without gas infrastructure.

Stacking options let you boost capacity vertically if floor space is tight.

Key Features to Compare in Commercial Convection Ovens

Focus on the features that save labor, boost consistency, or cut costs. Everything else is a luxury.

Controls

- Analog dials – fool-proof, inexpensive, great for simple menus.

- Digital panels – precise temps & timers, easier staff training.

- Programmable recipes – one-touch consistency across shifts.

- Gentle-bake / low-fan modes – protect custards, cakes, and delicate pastries.

Construction Basics

- Stainless steel exterior & porcelain interior – durable, easy to scrub.

- Double-pane glass doors – monitor food without heat loss.

- Independent doors on double-deck units – open one cavity without dropping temp in the other.

- 11+ rack positions – maximum flexibility for odd-sized pans.

Helpful Modern Add-Ons

- Reversing or variable-speed fans – eliminate lingering hot spots.

- Heat-recovery insulation – recapture waste heat, lowering utility spend.

- Humidity control or steam injection – glossy breads, juicier roasts.

Pick the options that align with your menu; skip the rest to keep pricing in check.

Sizing, Efficiency, and Cost-Saving Strategies

Oversizing wastes energy; undersizing bottlenecks service. Track your busiest hour, count required sheet pans, and size one step above that figure—no more.

Right-Sizing in Three Quick Steps

- Menu audit – list every oven item, noting pan size and quantity.

- Peak-hour tally – how many pans sit inside simultaneously when you’re slammed?

- Plan modest growth – add ~15 % capacity for new menu items, not 50 % "just in case."

Cut Your Utility Bill

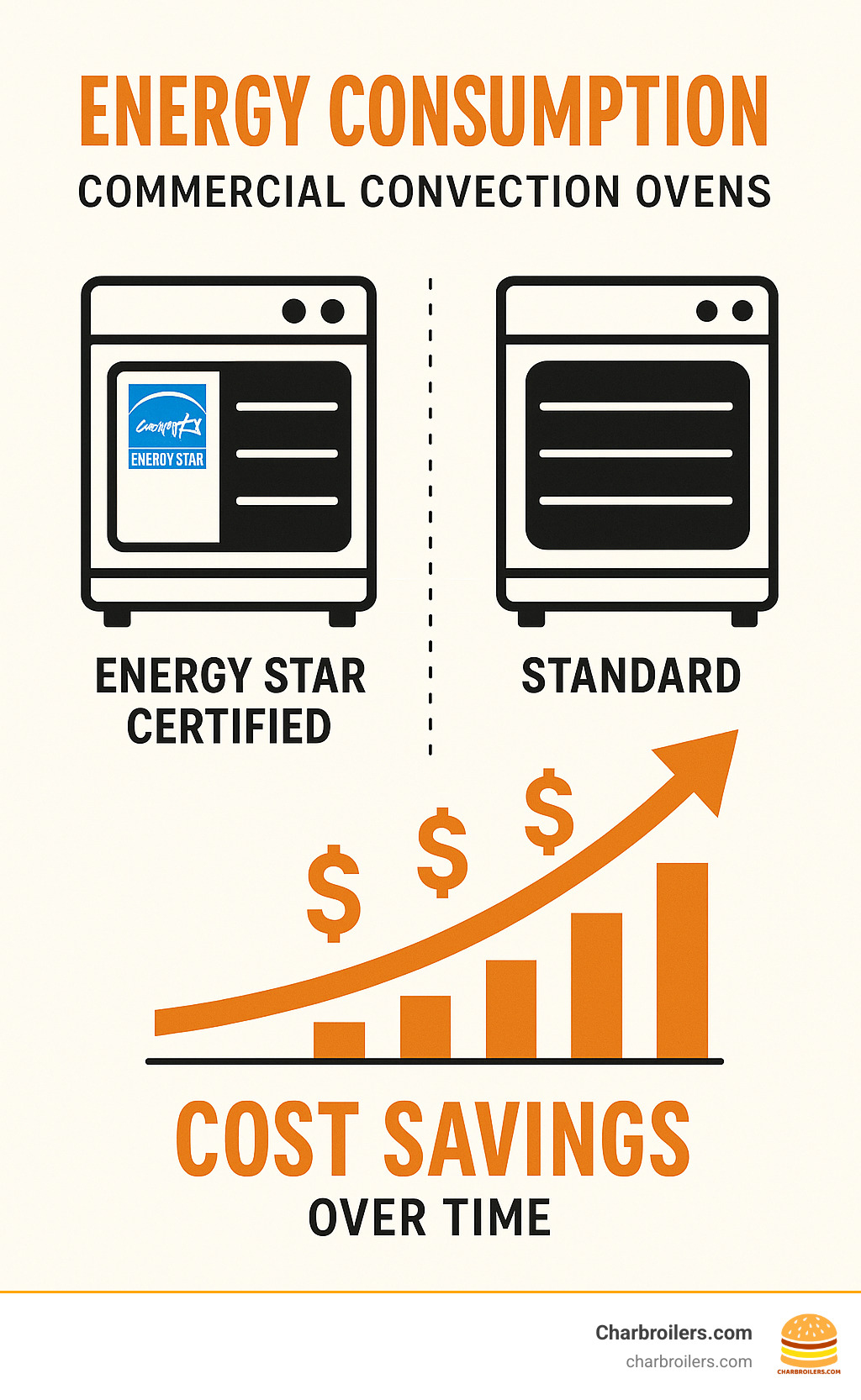

- Choose ENERGY STAR® certified models – they can trim energy use 15–30 %. You can browse the official specification sheets at the ENERGY STAR product finder to see exactly how much you could save.

- Keep door gaskets tight and clean to prevent heat loss.

- Use built-in timers and only preheat when necessary.

- Batch similar foods to maximize each firing cycle.

Looking for budget-friendly options? Our guide to buying used commercial convection ovens walks you through spotting quality second-hand equipment.

Essential Maintenance for Longevity and Performance

Taking care of your commercial convection ovens isn't just about keeping them clean—it's about protecting your investment and ensuring consistent performance for years to come. I've seen well-maintained ovens running strong after 15 years, while neglected units start failing within just a few years of purchase.

The good news is that most maintenance tasks are straightforward and can become part of your daily routine. The key is consistency and knowing when to handle things yourself versus when to call in the professionals.

DIY Cleaning and Upkeep

Your daily cleaning routine sets the foundation for long-term oven health. Start with the basics while your oven is still warm but not hot—this makes cleaning much easier as grease and food particles haven't had time to harden.

Wipe down all exterior surfaces with appropriate commercial cleaners, paying special attention to control panels and door handles that get touched frequently. The interior surfaces clean up much easier when you tackle them right after cooking, before any spills have a chance to bake on.

Remove and clean oven racks in your dishwasher or pot sink. This prevents grease buildup that can affect air circulation and create unpleasant odors. While the racks are soaking, check and clean the door seals for any food debris that might prevent proper sealing.

Don't forget to empty and clean drip pans if your oven has them. These often-overlooked components can become breeding grounds for bacteria if left uncleaned.

Your weekly deep cleaning routine goes beyond the daily basics. Remove all racks and clean the interior thoroughly, including the walls, ceiling, and floor of the oven chamber. This is when you'll tackle any stubborn buildup that daily cleaning missed.

Cleaning the fan area requires special attention and care. Some models allow you to remove screws to access the fan housing for thorough cleaning. This step is crucial because grease buildup around the fan can affect air circulation and create serious fire hazards. Always follow your manufacturer's instructions for this task.

Take time to check and clean air intake and exhaust areas to ensure proper ventilation. Inspect door hinges and lubricate them if needed to prevent binding and ensure smooth operation. Finally, test temperature accuracy with an oven thermometer to catch any calibration issues early.

When it comes to cleaning agents, stick with non-abrasive cleaners designed specifically for commercial ovens. Harsh chemicals might seem more effective, but they can damage seals, interior surfaces, and even affect the taste of your food. Your oven manufacturer's recommendations are your best guide here.

When to Call for Professional Service

While daily and weekly maintenance keeps your ovens running smoothly, some issues require professional expertise. Motor problems top the list of issues that need expert attention. If you notice unusual noises, reduced air circulation, or complete fan failure, it's time to call a qualified technician. Fan motors in heavily used ovens typically need replacement after several years of service—this is normal wear and tear, not a sign of poor quality.

Thermostat calibration should be checked annually by a professional. While some temperature variance is normal, if your oven temperatures consistently don't match the control settings, professional calibration ensures your cooking remains accurate and consistent.

Electrical problems always require professional service—no exceptions. Issues with heating elements, control systems, or wiring should never become DIY projects in commercial kitchens. The risks to both safety and equipment are too high.

Gas leaks demand immediate professional attention. If you smell gas around your oven, shut off the gas supply immediately and call a qualified technician. Don't attempt to diagnose or fix gas-related issues yourself—this is strictly professional territory for safety reasons.

Frequently Asked Questions about Commercial Convection Ovens

How much faster do they cook?

Plan on about 25 % faster than a conventional oven. Start by reducing recipe temps 25 °F and times 20–25 %, then fine-tune.

Do I need special ventilation?

- Gas ovens – almost always require a Type I hood.

- Electric ovens – may qualify for a cheaper Type II hood; some small ventless models include built-in filtration. Always verify with local codes before buying.

Can I bake delicate cakes and custards?

Yes. Use gentle-bake or low-fan settings, solid pans, center rack placement, and drop the temperature 25–50 °F. Your soufflés will thank you.

Conclusion

A well-chosen convection oven can cut ticket times, raise food quality, and chip away at utility costs—all while fitting the footprint you already have. Match capacity to your busiest hour, pick gas or electric based on utilities, and stick to features that earn their keep.

Charbroilers.com offers flexible financing so you can upgrade today and pay over time. Ready to round out your cook line? Explore our complete guide to commercial charbroilers and see how the right gear turns kitchen chaos into controlled performance.