Ventless Commercial Convection Ovens That'll Blow You Away (Without the Vent!)

Share

Breaking Free from Kitchen Constraints: The Ventless Revolution

If you're looking for a ventless commercial convection oven, here's what you need to know:

- What it is: A self-contained cooking system that circulates and filters air without requiring external ventilation

- Cost savings: Eliminates hood installation costs ($2,000+ per linear foot)

- Best for: Restaurants in non-traditional locations, historic buildings, food trucks, kiosks, and kitchens with limited hood space

- Top models: Professional-grade options ranging from $5,000-$20,000

- Key benefit: Can be installed virtually anywhere with proper electrical supply

A ventless commercial convection oven combines the cooking power of traditional convection with breakthrough filtration technology that eliminates the need for expensive hood systems. These innovative appliances are revolutionizing commercial kitchens by allowing operators to cook virtually anywhere with just an electrical connection. No more structural modifications, costly ductwork, or fighting with landlords over ventilation restrictions.

The technology behind these ovens is surprisingly simple yet effective. Using a combination of catalytic converters and multi-stage filtration systems, these ovens capture grease particles and convert vapors into harmless water and carbon dioxide. The EPA 202 standard requires ventless equipment to emit no more than 5.0 mg/m³ of grease-laden air, and many modern models produce less than 1.0 mg/m³.

What makes ventless ovens particularly attractive is their flexibility. Whether you're operating a food truck with limited space, renovating a historic building where traditional ductwork is prohibited, or simply trying to reduce startup costs, these ovens open up possibilities that were previously unthinkable.

Hi there, I'm Sean Kearney from Charbroilers.com, with over a decade of experience helping restaurant owners find the right equipment solutions, including ventless commercial convection ovens that can transform kitchen operations while cutting installation costs by thousands. My background in both restaurant equipment and business allows me to guide you through the practical considerations that matter most when selecting ventless technology.

What Is a Ventless Commercial Convection Oven?

Ever wished you could just plop a professional oven anywhere without worrying about complicated ventilation? That's exactly what a ventless commercial convection oven does! These ingenious appliances are changing the game for restaurants and food businesses everywhere.

Unlike their traditional cousins that need exhaust hoods pulling smoke up and out, ventless ovens handle all that messy air business internally. Think of them as self-cleaning air machines that also happen to cook your food beautifully.

The magic happens through an impressive system of components working together:

The heart of the system is the catalytic converter – similar to what's in your car, but designed for food vapors instead of exhaust fumes. These clever devices break down grease and cooking vapors into harmless water vapor and carbon dioxide.

Supporting this are multi-stage filters that catch particles of various sizes, condensate hoods that wrangle steam, heat exchangers cooling air before filtration, and self-contained collection pans that eliminate the need for drainage connections.

All this engineering ensures these ovens meet strict EPA 202 standards, which limit emissions to no more than 5.0 mg/m³ of grease-laden air. Many modern units, like Southbend's ventless models, perform even better – producing as little as 0.78 mg/m³ per cavity in their full-size units.

And yes, these ovens come with proper credentials too – look for UL KNLZ certification, which confirms they've been thoroughly tested and approved for operation without external ventilation.

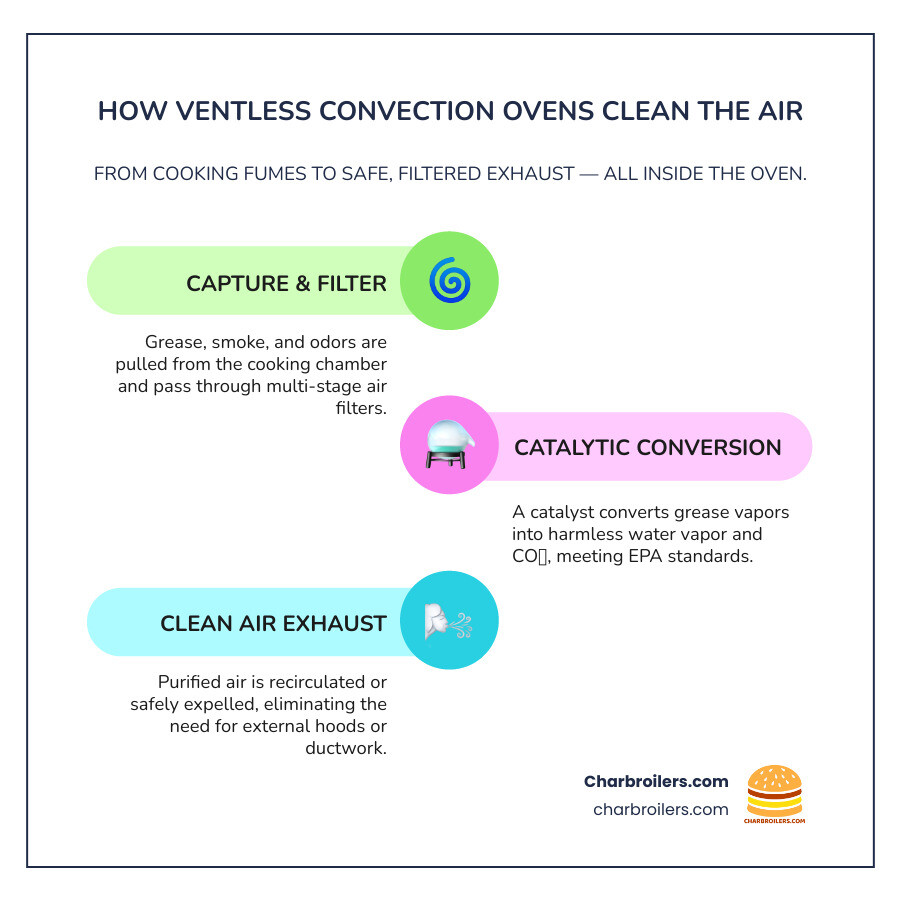

How Ventless Technology Cleans the Air

The science behind these ovens isn't just clever – it's downright fascinating!

When you're cooking, a fan pulls air through the cooking chamber where it picks up all those delicious but greasy cooking vapors. This air then travels to the oxidation catalyst – the real workhorse of the system.

The catalyst contains stainless steel fins (made from the same materials used in medical implants!) coated with catalytic materials similar to what you might find in toothpaste additives. When the grease-laden air hits this catalyst at temperatures above 500°F, a chemical reaction occurs that transforms grease vapor into water (H₂O) and carbon dioxide (CO₂) – exactly what we exhale when breathing.

After this change, the air continues its journey through a series of filters that catch any remaining particles and odors. A heat exchanger then cools everything down, condensation collects in a pan, and the now-clean air either recirculates back into the cooking chamber or gets released into your kitchen environment.

You can learn more about this fascinating catalyst science in Southbend's comprehensive brochure (PDF).

Ventless vs Traditional Vented Ovens – The Big Differences

When comparing these two approaches to commercial ovens, the differences are striking:

| Feature | Traditional Vented Ovens | Ventless Convection Ovens |

|---|---|---|

| Installation Requirements | Hood system ($2,000+ per linear foot), ductwork, roof penetration, makeup air | Simple electrical connection |

| Installation Cost | $20,000-$50,000+ for hood system | $0 (beyond oven purchase) |

| Space Requirements | Dedicated hood space, often limited to "hood line" | Can be placed almost anywhere |

| Location Flexibility | Restricted to areas with external ventilation access | Can operate in historic buildings, food courts, kiosks, multi-story buildings |

| HVAC Impact | Requires makeup air system | No impact on building HVAC |

| Energy Consumption | Higher (hood fans run continuously) | Lower (no external ventilation) |

| Maintenance | Hood cleaning, duct cleaning, fan maintenance | Filter replacement, catalyst cleaning |

| Regulatory Problems | Building permits, fire inspections, landlord approvals | Minimal (UL listed equipment) |

| Initial Equipment Cost | Lower oven cost + high hood cost | Higher oven cost, no hood cost |

The biggest win with a ventless commercial convection oven is freedom. No more being chained to a traditional hood line! These ovens open up possibilities in places that were previously off-limits – historic buildings where you can't punch holes in the ceiling, office buildings where landlords get squeamish about ductwork, food courts, kiosks, pop-up locations, and educational institutions with limited infrastructure.

Beyond location flexibility, you'll also enjoy energy savings by eliminating those power-hungry hood fans that constantly suck conditioned air out of your building. That's good for both your utility bills and the planet!

Ventless Commercial Convection Oven Roundup: Find Your Perfect Fit

Now that we understand how ventless technology works, let's explore some of the best options available for different foodservice operations. At Charbroilers.com, we've helped countless restaurant owners find their perfect ventless solution - and trust me, there's something for every kitchen!

Countertop & Small-Footprint Winners

Best for: Food trucks, kiosks, cafés, small restaurants, satellite locations

When space is at a premium but cooking quality can't be compromised, countertop ventless convection ovens shine. These compact powerhouses are perfect for tight spaces while still delivering professional results.

Picture this: a food truck serving gourmet pastries or a small office café delivering fresh-baked cookies without massive kitchen infrastructure. That's the magic of these small-footprint winners.

Most countertop models accommodate 3-5 half-size sheet pans (13" x 18") in a footprint under 30" wide. What makes them truly special is their plug-and-play convenience - just connect to a standard 208/240V outlet and you're cooking!

Many operators start with a single unit, then stack a second one as their business grows. It's like doubling your kitchen capacity without using an extra inch of floor space. The three-stage filtration systems in these compact units ensure clean operation even in customer-facing environments.

When shopping for a small-footprint model, pay attention to preheat times (typically 10-15 minutes to 350°F), recovery times after door openings, and filter replacement intervals. ENERGY STAR qualified models will save you money over time, especially in operations where the oven runs continuously.

High-Volume Powerhouses (Conveyor & Impingement)

Best for: Pizza operations, high-volume QSRs, stadiums, schools, ghost kitchens

Need to crank out serious volume without a traditional hood? Ventless conveyor and impingement ovens are your new best friends. These specialized units use high-velocity air jets to cook food rapidly while maintaining consistent quality.

The production capacity is truly impressive. Some models can cook up to 60 twelve-inch pizzas per hour - perfect for busy stadium concessions or ghost kitchens focused on delivery. Imagine serving perfectly consistent pizzas during a packed game without the massive infrastructure traditionally required!

What makes these systems particularly valuable is their flexibility in challenging environments. Split belt options let you cook different items simultaneously, while stackable designs (up to three high) maximize output in minimal floor space. The smart voltage sensor technology adapts to your electrical supply, and idle mode conserves energy between rush periods.

All-Purpose Workhorses for Bakeries & Schools

Best for: Bakeries, schools, healthcare facilities, full-service restaurants

When you need versatility across a wide menu, full-size ventless commercial convection ovens truly shine. These dependable workhorses typically hold 5-10 full-size sheet pans and deliver consistent results whether you're baking delicate pastries or roasting savory proteins.

What separates these units from basic models is their sophisticated airflow management. Features like soft-air mixing technology and two-speed bi-directional fans ensure even heat distribution throughout the chamber, eliminating hot spots and producing uniform results across every rack position.

Bakeries particularly appreciate the precise temperature control (typically 150-550°F) and programmable recipe storage (50-100 recipes), which ensures consistency across shifts and locations. School foodservice directors love the higher capacity and simple three-color indicator light system that makes filter maintenance foolproof even for non-technical staff.

The right ventless commercial convection oven can transform your operation, whether you're running a tiny kiosk or a busy school cafeteria. The best part? You'll get professional results without the headache and expense of traditional ventilation systems. At Charbroilers.com, we're here to help you steer all the options and find your perfect match.

Buying Guide: Costs, Codes, and Installation Tips for Ventless Success

Let's talk money and logistics - because while a ventless commercial convection oven might seem like kitchen magic, you'll still need to plan carefully for success. I've helped hundreds of restaurant owners steer this transition, and the financial picture is typically quite rosy once you look at the complete equation.

Up-Front vs Lifetime Costs

The sticker price on ventless ovens might make you do a double-take at first. Countertop models start around $5,000, while those impressive high-end full-size or conveyor units can reach $20,000 or more. But here's where the math gets interesting.

Traditional hood systems will set you back about $2,000+ per linear foot installed - and that's just the beginning. When you factor in building modifications, roof penetrations, and makeup air systems, you're often looking at a $20,000-$50,000 project before you've even purchased your actual cooking equipment!

"The hood system was going to cost us more than all our cooking equipment combined," one café owner told me recently. "Going ventless literally made our downtown location possible."

From an operational standpoint, you'll save in surprising ways too. Without energy-hungry hood fans constantly sucking conditioned air out of your building, your utility bills will thank you. You will need to budget for filter replacements - typically $200-600 annually depending on your usage and model. The good news? Most catalytic converters are designed to last the lifetime of the oven with proper maintenance.

When we crunch the numbers with clients, we typically see ROI periods of less than 18 months. One quick-service restaurant owner expanded to three new locations in the time it would have taken to build just one with traditional ventilation!

Site-Planning & Regulatory Checklist

Before you get too excited about all that money you'll save, let's make sure your site is ready for ventless technology. First, check your electrical service. Most full-size models need 208/240V, 3-phase power, while smaller countertop units might work with 208/240V single-phase. Either way, you'll need dedicated circuits.

Space planning is straightforward but critical. Most manufacturers recommend 2-10 inches of clearance around the unit. If you're stacking units (a popular space-saving move), verify your ceiling height can accommodate the full stack. And don't forget about workflow - make sure staff can comfortably load and unload the oven and fully open doors without creating bottlenecks.

The regulatory landscape varies by location, and this is where some homework pays off. While ventless technology is widely accepted, some jurisdictions have specific requirements. Always verify that your chosen model has proper UL KNLZ certification, and check with both local building authorities and your insurance carrier before purchase.

"We thought we were good to go until the fire marshal visited," a food hall vendor shared with me. "Thankfully, our oven had all the right certifications, and we just needed to adjust its positioning slightly."

For installation day, position your oven away from other heat-producing equipment, ensure your floor can support the weight (especially important for stacked units), and plan for easy filter access. Many savvy operators also install interlock systems that prevent operation if the ventless system fails - a small investment for peace of mind.

Running a kitchen in a unique environment like a cruise ship or offshore platform? Look for specialized marine-rated ventless ovens that handle vibration and resist corrosion.

At Charbroilers.com, we've guided countless restaurant owners through this process, from initial site assessment through financing options that make these energy-efficient solutions accessible even for startups. The right planning turns what could be a complex project into a smooth transition that opens up exciting new possibilities for your business.

Operating, Maintaining & Maximizing Your Ventless Oven

Proper operation and maintenance are essential to getting the most from your ventless commercial convection oven. Following these best practices will ensure optimal performance, longevity, and food quality.

Daily Operation Best Practices

- Proper Preheating: Always preheat your oven thoroughly before cooking (typically 10-15 minutes)

- Even Loading: Distribute food evenly across racks for optimal air circulation

- Door Management: Minimize door openings to maintain temperature and reduce filter load

- Temperature Setting: Use the lowest effective temperature to reduce emissions

-

Filter Monitoring: Pay attention to filter status indicators - most modern units use a simple three-color system:

- Green: System operating normally

- Orange/Yellow: Order replacement filters

- Red: Replace filters immediately (some units will not operate when this light is on)

Maintenance Schedule

Daily:

- Wipe down exterior surfaces

- Clean door gaskets

- Remove and clean racks and rack guides

- Empty condensate collection pan if applicable

Weekly:

- Deep clean interior cavity with manufacturer-approved cleaner

- Check filter indicator lights

- Inspect door seals for damage

Monthly:

- Inspect fan operation

- Clean or replace grease baffle filters if needed

- Check electrical connections

Quarterly:

- Professional inspection of catalytic converter

- Deep cleaning of all components

- Verification of emissions compliance

Filter Replacement Procedure

Most modern ventless ovens make filter replacement straightforward:

- Wait for the oven to cool completely

- Locate the filter access panel (typically on top or back of unit)

- Remove the panel according to manufacturer instructions

- Slide out the old filter(s)

- Insert new filter(s) in the correct orientation

- Replace the access panel

- Reset the filter monitoring system if required

Always keep spare filters on hand - when the orange/yellow light illuminates, order replacements immediately to avoid downtime.

Workflow & Kitchen Design Boosts

One of the greatest advantages of ventless ovens is their ability to transform kitchen workflow and design. Here are some strategic ways to leverage this technology:

Reclaim Valuable Hood Space:

- Move high-volume items like baked goods out from under the hood

- Repurpose hood space for items that absolutely require it (open flames, high-smoke items)

- Create more efficient workflow with strategic oven placement

Add Points-of-Service:

- Install ventless ovens in satellite locations for made-to-order items

- Create finishing stations near service areas for last-minute items

- Reduce kitchen traffic by decentralizing cooking operations

Line-Side Installation:

- Position ventless ovens directly on the line for immediate access

- Reduce steps and improve efficiency during service

- Create dedicated stations for specific menu categories

Common Limitations & How to Solve Them

While ventless ovens offer tremendous advantages, they do have some limitations. Here's how to work around them:

Challenge: Cooking Raw, Fatty Proteins

- Solution: Par-cook proteins under the hood, finish in ventless oven

- Alternative: Use leaner cuts or pre-rendered proteins

- Workaround: Incorporate more plant-based or pre-cooked protein options

Challenge: Heavy Smoke Items

- Solution: Adjust recipes to reduce initial smoking (lower initial temperature)

- Alternative: Reserve traditional hood space for these specific items

- Workaround: Use smoking techniques before cooking in the ventless oven

Challenge: Filter Saturation

- Solution: Implement a proactive filter replacement schedule

- Alternative: Install multiple units to distribute the load

- Workaround: Adjust menu mix to reduce heavily greasy items during peak periods

Frequently Asked Questions about Ventless Commercial Convection Ovens

Do ventless ovens really meet safety and environmental regulations?

Yes! Your ventless commercial convection oven isn't just convenient—it's designed to meet rigorous safety standards. When shopping for your oven, look for that crucial UL KNLZ certification, which tells you the equipment has been thoroughly tested and approved to operate without external ventilation.

The EPA sets a clear standard: ventless equipment must emit no more than 5.0 mg/m³ of grease-laden air. Here's the impressive part—many modern ovens blow past these requirements with flying colors. Southbend's models, for instance, produce as little as 0.78 mg/m³ in their full-size units during testing.

And these aren't easy tests! Manufacturers put these ovens through their paces using notoriously greasy foods like raw chicken. The catalytic technology effectively transforms those grease particles into harmless water vapor and carbon dioxide—pretty amazing science at work in your kitchen.

One quick heads-up, though: while these ovens meet national standards, it's always smart to check your local codes. Some cities or counties might have their own specific requirements about ventless equipment. A quick call to your local building department can save headaches down the road.

How often do I need to replace filters or catalysts?

This is like asking how often you need to change your car's oil—it depends on how you drive! Your filter replacement schedule will vary based on what and how much you're cooking.

Most modern ventless commercial convection ovens make this easy with a traffic-light style indicator system:

- Green means you're good to go

- Yellow/orange is your warning to order replacements

- Red means it's time for immediate replacement

For typical operations, plan on replacing filters every 3-6 months. If you're cooking greasy items all day in a busy kitchen, you might need changes every 1-3 months instead. The good news? The catalytic converter itself—the heart of the ventless system—is built to last the lifetime of the oven with proper care.

I always tell our customers to keep spare filters in stock. There's nothing worse than seeing that red light come on during your busiest week of the year with no replacement on hand! When you see that yellow warning light, that's your cue to place your next order.

Can a ventless oven match the cooking speed of my current equipment?

Not only can a ventless commercial convection oven match your current equipment's speed—in many cases, it might actually cook faster! The technology has come a long way, with several speed options available:

Standard convection models cook at similar speeds to their traditional counterparts, while high-speed impingement and rapid cook hybrid technologies can significantly outpace conventional ovens.

Take TurboChef's High h Conveyor 2020, which can churn out an impressive 60 pizzas per hour. Or consider that some ventless models can toast a perfect sandwich in just 60-90 seconds, and have those chicken wings ready in under 5 minutes.

What makes the difference? It comes down to air circulation (some models blast air at up to 50 mph!), heating element power (typically 7.5-11 kW in commercial units), and the specific technology used. The right ventless oven can keep pace with your busiest service periods while offering all the flexibility of hood-free installation.

When you're ready to make the switch, our team at Charbroilers.com can help match you with the perfect model for your specific volume and menu needs. We'll make sure you don't sacrifice speed while gaining all the benefits of ventless technology.

Conclusion & Next Steps

The rise of ventless commercial convection ovens marks a true game-changer in commercial kitchens. These innovative appliances do more than just cook food—they open doors to possibilities that were once blocked by costly ventilation requirements and structural limitations.

Think about what this technology means for your business. You could slash your startup costs by eliminating that $20,000+ hood installation. You might finally expand into that historic building downtown where traditional ductwork was prohibited. Perhaps you've been dreaming of adding a satellite location or food kiosk but couldn't justify the ventilation expense—until now.

The beauty of ventless technology lies in its simplicity and flexibility. With just an electrical connection, you can create a fully-functional cooking operation almost anywhere. No more structural modifications, no more negotiating with landlords about roof penetrations, and no more watching your HVAC costs soar from all that conditioned air being pulled out of your building.

For startups, the math is compelling. The initial investment in a ventless oven pays for itself quickly when you factor in the eliminated hood costs. For established operations, these ovens represent a path to expansion that bypasses many traditional problems. Schools and healthcare facilities find they can add cooking capacity in locations previously limited to reheating or no cooking at all. And for food trucks and mobile operations? The compact power of ventless technology creates cooking possibilities that transform limited menus into culinary trips.

Here at Charbroilers.com, we've helped countless foodservice operators steer the transition to ventless cooking. Our Seattle-based team understands that choosing the right equipment isn't just about specifications—it's about how that equipment will serve your unique business goals. We're ready to help you explore options with:

- Personalized consultations to match ventless technology to your specific needs

- Competitive pricing that respects your budget realities

- Flexible financing packages designed specifically for foodservice businesses

- Guidance through the installation process

- Ongoing support to ensure your equipment performs at its best

The foodservice landscape is evolving, and ventless technology is helping lead that evolution. Kitchens are becoming more flexible, more efficient, and more adaptable to changing consumer demands. By embracing this technology now, you position your business to thrive in this new environment.

Ready to explore how a ventless commercial convection oven could transform your operation? Our team is just a conversation away, ready to provide the insights and solutions that will help your business grow.

For more information about other commercial kitchen equipment solutions, check out our guide to commercial charbroiler solutions or learn about cooking up success with commercial hot plates.