Cooking Up Success with Commercial Hot Plates

Share

Powering Professional Kitchens with Commercial Hot Plates

Commercial hot plates are compact, powerful cooking units designed specifically for professional kitchen environments where space and efficiency are paramount.

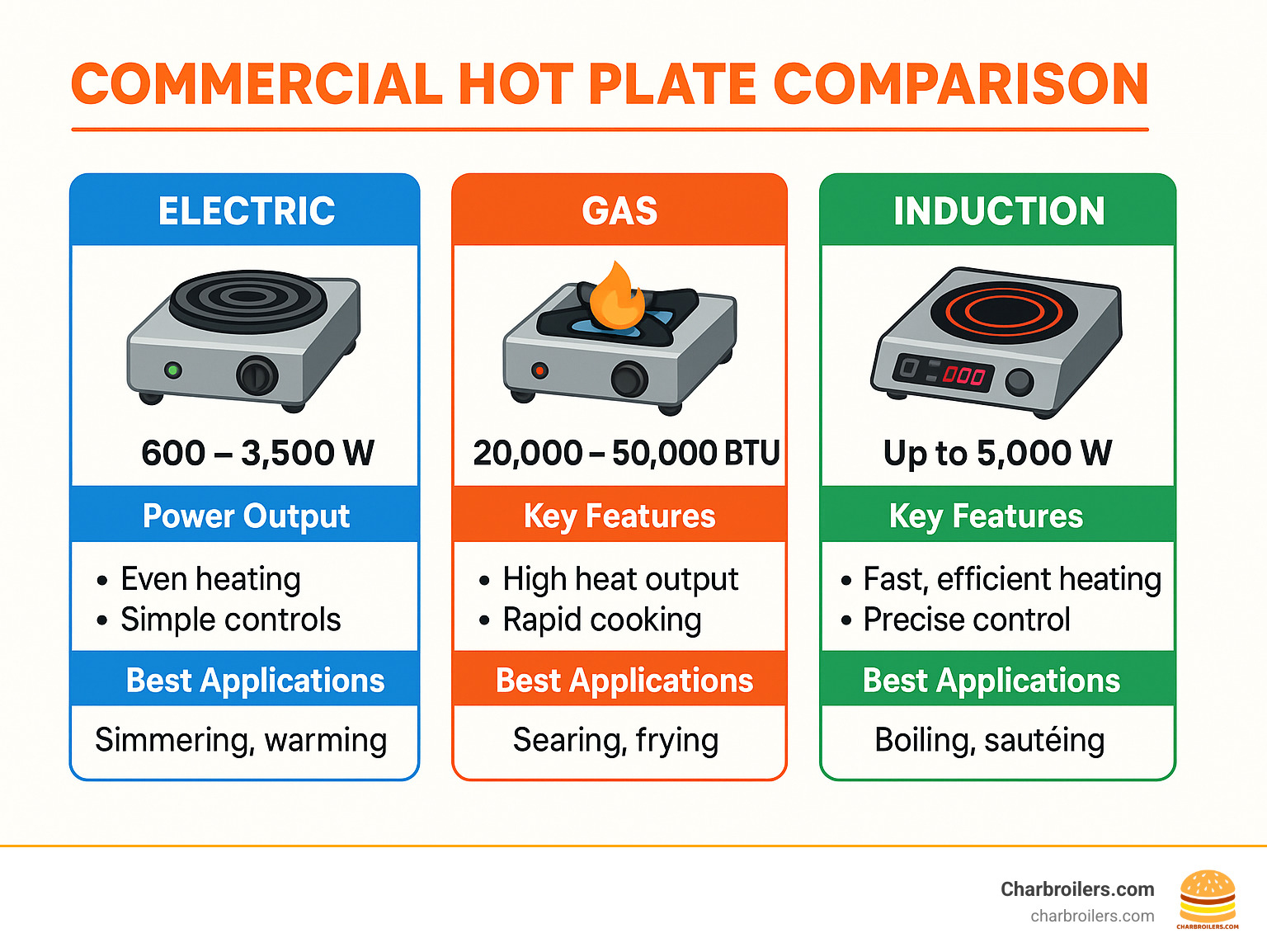

What is a commercial hot plate? - Heavy-duty electric or gas cooking appliance - Power ranges from 600W to 3500W (electric) or up to 50,000 BTU (gas) - Available in single, double, or multiple burner configurations - Built with commercial-grade materials for durability - Designed for continuous operation in high-volume settings

Commercial hot plates differ significantly from their residential counterparts through superior construction, higher power output, and precision temperature controls that can handle the demands of professional food service. They serve as versatile cooking stations that can dramatically boost production capacity in busy kitchens where every square inch matters.

For restaurant owners facing space constraints or looking to expand cooking capabilities without major kitchen renovations, these units offer an ideal solution. Whether you need to simmer sauces, prepare side dishes, or handle overflow cooking during peak hours, a quality commercial hot plate delivers consistent results in a compact footprint.

I'm Sean Kearney from Charbroilers.com, with over a decade of experience helping restaurant owners select the right commercial hot plates and equipment for their specific kitchen needs. Having worked with countless food service operations to optimize their cooking stations, I've seen how these versatile units can transform workflow efficiency.

What Are Commercial Hot Plates?

Commercial hot plates are the workhorses of professional kitchens – robust, powerful cooking stations built specifically to handle the demands of busy restaurants and food service operations. Unlike the hot plates you might use at home, these professional units are engineered for continuous, heavy-duty performance day in and day out.

When you walk into a professional kitchen and see these compact powerhouses, you'll immediately notice their industrial-grade construction. Electric models typically pack a serious punch, ranging from 600W for light-duty applications up to a mighty 3500W for high-volume cooking. Gas versions are equally impressive, commonly featuring burners that deliver around 25,000 BTU of cooking power – enough to rapidly bring large stockpots to a boil and maintain steady temperatures during the busiest service hours.

What really separates commercial hot plates from their residential cousins is their thoughtful design for the professional environment. They're built with stainless steel or cast iron construction that can withstand years of intense use. The heating elements or burners are engineered for consistent performance, even when they're running for 12+ hours straight. Most models feature temperature ranges from a gentle simmer (around 140°F) all the way up to scorching high heat (465°F and beyond) – giving chefs precise control for everything from delicate sauces to high-heat searing.

I've seen kitchens where these units have been in continuous operation for years without skipping a beat – something a residential hot plate simply couldn't handle. Plus, they're designed to meet the rigorous safety standards and health department regulations that professional kitchens must adhere to, offering peace of mind during those surprise inspections.

Key Benefits of Commercial Hot Plates

Ask any chef why they love their commercial hot plates, and you'll likely hear about the remarkable versatility these compact units bring to their kitchen.

The precision temperature control is a game-changer for professional cooking. Whether you're melting chocolate (where even slight overheating can be disastrous) or maintaining the perfect simmer on a reduction sauce during a hectic dinner service, these units deliver consistent, reliable heat. Some induction models even offer up to 8 different power levels for incredibly fine-tuned cooking.

Perhaps the most appreciated feature in today's tight kitchen spaces is their compact footprint. A typical double-burner unit might only take up about 20" x 13" of precious counter space while significantly expanding your cooking capacity. I've worked with restaurant owners who were able to add four new menu items simply by incorporating a quality commercial hot plate into their line setup.

These versatile units also shine during unexpected rushes. When every burner on your range is occupied and tickets keep flowing in, having supplemental cooking stations can save the day. They're perfect for handling side dishes, sauces, or special dietary requests without disrupting your main cooking line.

The portability factor cannot be overstated either. Unlike built-in equipment, commercial hot plates can easily move where they're needed most – whether that's for an off-site catering event, a cooking demonstration, or just reconfiguring your kitchen layout for a special event.

For new restaurants or those watching their equipment budget, these units offer professional-grade cooking capability starting around $300 for quality single-burner models – a fraction of what you'd invest in expanding your built-in range. And when that main range needs unexpected maintenance (always at the worst possible time, naturally), having reliable backup cooking equipment keeps service running smoothly.

In my years helping restaurants optimize their kitchens, I've seen commercial hot plates transform workflow efficiency in spaces of all sizes. Their combination of power, precision, and portability makes them indispensable tools in the professional chef's arsenal.

Main Types of Commercial Hot Plates (Pros & Cons)

Let's explore commercial hot plates together! Choosing the right fuel type for your kitchen can make all the difference in your cooking experience and operational efficiency. I've helped hundreds of chefs find their perfect match, and I'm excited to walk you through the options.

Electric Commercial Hot Plates

Electric commercial hot plates are the workhorses of many professional kitchens, and for good reason. They're incredibly user-friendly and won't have you calling your contractor for special installation.

These reliable units simply plug into standard outlets (120V or 240V) and start working their magic. What I love about electric models is their steady, predictable heat—perfect when you need to maintain that delicate simmer on your signature sauce. The cast-iron elements distribute heat beautifully across your cookware, ensuring no surprising hot spots ruin your creations.

Many kitchen managers appreciate that electric models don't require extensive ventilation systems, which can be a real blessing in tight spaces. They typically range from 1500W for single burners up to 3500W for commercial-grade double burners. The Waring WDB600, for instance, offers a smart combination of power with a 1300W large burner paired with a 500W small burner for versatility.

The trade-off? They're not the speediest when you need rapid temperature changes, and in some areas, your utility bill might run higher than with gas alternatives. But for consistent, worry-free cooking without open flames, electric models are hard to beat.

Gas Commercial Hot Plates

There's something viscerally satisfying about cooking with gas commercial hot plates—that immediate response when you adjust the flame, the visible heat indicator, and the impressive power they deliver.

Professional chefs often gravitate toward gas models for their ability to reach scorching temperatures quickly. With burners typically rated between 25,000 and 50,000 BTU, these powerhouses can handle everything from gentle simmering to high-heat wok cooking with impressive versatility.

I've noticed that chefs who specialize in flame-kissed dishes or Asian cuisine particularly appreciate the visual feedback of seeing the actual flame intensity. And during those unfortunate power outages that can shut down a kitchen, gas models keep right on cooking—a potential business-saver during storm season!

The downside? You'll need proper gas connections and adequate ventilation, which adds to your initial setup costs. Gas systems also require more regular maintenance to keep everything running safely and efficiently. But for many culinary professionals, the performance benefits make these considerations worthwhile.

Induction Commercial Hot Plates

If you haven't explored induction technology for your commercial hot plates, you're missing out on what many consider the future of professional cooking. These sleek units operate through electromagnetic wizardry that directly heats your cookware while keeping the cooking surface surprisingly cool to the touch.

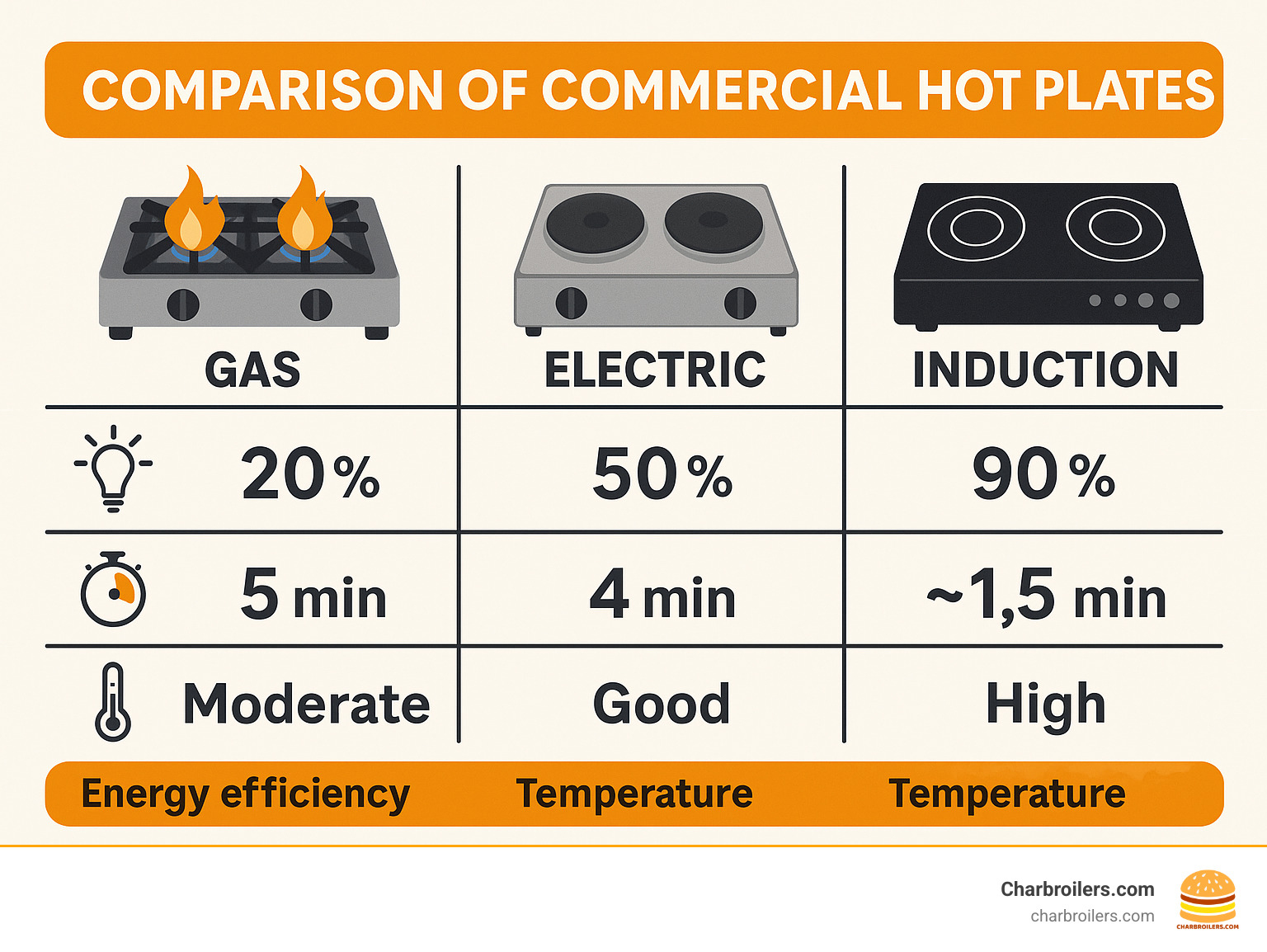

The efficiency numbers are impressive—up to 90% of the energy transfers directly to your food, compared to roughly 40% for gas flames. This translates to lower energy bills and a cooler kitchen environment (your summer staff will thank you!).

I'm particularly fond of the precise temperature control induction offers. Models like the Warmfod induction hot plate feature 8 temperature presets ranging from a gentle 140°F to a searing 465°F, giving you laboratory-like precision for delicate tasks like chocolate work or maintaining the perfect temperature for hollandaise.

The smooth glass or ceramic surface wipes clean in seconds—no more scrubbing burnt-on residue from coils or drip pans. And the safety features are outstanding, with automatic shut-off capabilities that provide peace of mind in busy kitchen environments.

The catch? You'll need magnetic-bottom cookware (a simple magnet test will tell you if yours will work), and the initial investment is higher than traditional options. But many chefs find the long-term energy savings and performance benefits more than justify the upfront cost. For more detailed information on induction efficiency, check out this latest research on induction efficiency.

When weighing these options for your kitchen, think about what matters most to your operation. Do you need the raw power of gas, the simplicity of electric, or the efficiency and precision of induction? Many successful kitchens I've worked with actually combine technologies, using different commercial hot plates for specific cooking tasks to leverage the unique strengths of each type.

Consider your menu requirements, existing kitchen infrastructure, local energy costs, and the cooking styles your team prefers. The right choice will improve your workflow while keeping both your food quality and bottom line healthy.

Choosing the Right Commercial Hot Plate for Your Kitchen

Selecting the perfect commercial hot plate for your kitchen doesn't have to be overwhelming. Think of it as finding a new team member who needs to fit your space, work with your menu, and keep up with your busiest rushes.

Sizing & Power for Commercial Hot Plates

Let's talk about finding that Goldilocks fit – not too big, not too small, but just right for your kitchen.

Start by grabbing a measuring tape and checking your available counter space. Remember to allow 6-12 inches of breathing room on all sides for proper ventilation. Those hot plates need space to stay cool! Also glance upward – if you're planning to slide it under shelving, make sure you've got enough clearance height.

Size-wise, you've got options that match your cooking needs. Single burner units (about 12-15 inches wide) work beautifully for smaller operations or as backup stations. Moving up to double burners (24-28 inches wide) gives you flexibility for medium-volume kitchens. For those high-volume operations, multi-burner setups spanning 36-48 inches wide can handle serious production demands.

Now for the muscle behind your cooking – power ratings. For electric commercial hot plates, think of it this way:

Light duty (600W-1200W) is your gentle helper, perfect for warming and light simmering. Medium duty (1300W-2000W) handles your everyday cooking and sautéing needs. When you need serious heat for rapid boiling or high-heat cooking, heavy duty models (2100W-3500W) bring the power you need.

Gas models speak a different language – BTUs. Standard commercial burners typically deliver around 25,000 BTU, while high-performance beasts can pump out 30,000-50,000 BTU for those dishes that demand intense heat.

Consider your heaviest cooking task when choosing power levels. The APW Wyott hot plate with its 1650W power and 7.5-inch diameter heating element can confidently support those massive stockpots when you're making gallons of soup for the lunch rush.

Must-Have Features & Accessories

Beyond the basics of size and power, certain features can make your commercial hot plate a joy to use rather than just another piece of equipment.

Precise temperature controls should top your wish list. Look for models with multiple heat settings or, even better, infinite control dials that let you find that perfect temperature sweet spot for delicate sauces or high-heat searing.

The kitchen can be a brutal environment, so durable construction is non-negotiable. Stainless steel bodies will stand up to the daily onslaught of spills, splashes, and cleaning chemicals far better than aluminum or painted surfaces.

Safety matters too. Indicator lights that show when the unit is powered on and when it's actively heating can prevent accidents and save energy. Non-skid feet keep your hot plate firmly planted on the counter, even when you're stirring that heavy pot of chili. And splash guards are your first line of defense against liquids reaching electrical components.

Don't overlook the importance of proper certifications. NSF certification ensures your equipment meets food safety standards, while UL listing confirms it won't become an electrical hazard in your busy kitchen.

Some thoughtful accessories can lift your hot plate experience. Removable drip trays make cleaning a breeze after inevitable boil-overs. Compatible pot holders provide flexibility in your cooking setup. And timer functions can free you up to multitask during busy service.

For those looking to maximize versatility, consider specialty options like the DULONG griddle hot plate. With its 22-inch cooking surface, 2000W of power, and temperatures reaching up to 572°F, it's perfect for cranking out everything from breakfast service to dinner specials on a single unit.

When making your final decision, quality pays dividends over time. A well-built commercial hot plate from a reputable manufacturer might cost more upfront, but will reward you with years of reliable service and fewer headaches. Your future self will thank you for investing in equipment that keeps performing when you need it most.

Operating, Cleaning & Maintaining for Safety and Longevity

Taking good care of your commercial hot plate isn't just about keeping it clean – it's about ensuring your investment lasts for years while maintaining peak performance. Think of it as giving your kitchen workhorse the TLC it deserves!

When starting up your hot plate each day, take a moment to ensure it's on a stable, level surface. For electric models, always check that control knobs are in the "off" position before plugging in – it's a small step that prevents big surprises! Gas model users should verify connections are secure and properly pressurized before firing up.

During the hustle of service, match your cookware to burner size for optimal heat transfer and stability. Those extra-large pots hanging over the edge? They're not just inefficient; they're tipping hazards waiting to happen. Whenever possible, use medium settings rather than cranking everything to high – your energy bill (and the planet) will thank you.

At the end of service, proper shutdown matters more than you might think. Allow your commercial hot plate to cool naturally before cleaning – that tempting shortcut of dousing hot surfaces with water can warp components and create steam burns. Trust me, those few extra minutes of cooling time pay off in equipment longevity!

Cleaning & Maintenance Routine

The daily wipe-down is your first defense against performance problems. Once your commercial hot plate has completely cooled, a damp cloth with mild detergent tackles most food residue without damaging surfaces. For electric coil models, removable drip pans make cleanup easier – just lift them out and wash separately.

Weekly maintenance takes things a step deeper. This is when you'll want to soak removable components and inspect cords for any signs of wear or damage. For gas models, checking those burner ports for food debris prevents uneven flames and wasted energy. A quick test with an infrared thermometer can confirm your unit is hitting the temperatures you're setting.

Monthly care includes tasks that prevent long-term issues, like descaling cast iron surfaces if you notice mineral buildup. Check gaskets and seals for wear – these inexpensive parts can prevent bigger problems when replaced promptly. Don't forget to clear those ventilation openings; proper airflow keeps internal components from overheating.

Induction commercial hot plates need special attention to protect their glass or ceramic surfaces. Always lift (never slide) cookware, and wipe spills immediately to prevent them from burning onto the surface. These units may cost more upfront, but their energy efficiency and surface longevity make up for it with proper care.

Safety Checks & Certifications

Safety isn't just about passing inspections – it's about protecting your staff, customers, and business. Regular safety checks should become second nature in your kitchen routine.

Electrical safety starts with the basics: Are cords intact and free from fraying? Is proper grounding in place? For kitchens with water nearby, GFCI protection is a must-have, not a nice-to-have. Gas models require their own checks – that beautiful blue flame tells you combustion is complete and efficient, while yellow or orange flames signal problems that need addressing.

When purchasing a new commercial hot plate, certifications matter more than you might realize. UL listing confirms electrical safety standards have been met, while NSF certification ensures the unit meets strict food safety requirements. For gas appliances, look for AGA certification as your assurance of gas safety compliance. These aren't just fancy acronyms – they're your proof that equipment has been rigorously tested. For more detailed information on safety checks and maintenance procedures, visit hot plates maintenance FAQ.

I recommend scheduling professional maintenance at least once yearly, more often for high-volume operations. It's like taking your car for regular service – an expert can spot potential issues before they become costly problems. Keep those service records organized; they're invaluable during health inspections and warranty claims.

Troubleshooting Common Issues

Even the best commercial hot plates occasionally act up. When your unit won't heat, start with the obvious: is it properly connected to power? Is the circuit breaker tripped? For gas models, verify the gas supply is flowing. Sometimes the solution is as simple as resetting a safety switch that tripped during a power fluctuation.

Uneven heating often comes down to physical issues – warped elements, clogged burner ports, or cookware with uneven bottoms. Clean burner ports carefully with a thin wire or specialized tool, and inspect heating elements for damage. Quality, flat-bottomed cookware makes a surprising difference in heat distribution.

Temperature control problems might indicate it's time for thermostat calibration. If your sauce is burning at "medium" or barely simmering at "high," your controls may need adjustment. Digital models sometimes display error codes – keep that manual handy to decode them, or bookmark the manufacturer's support page for quick reference.

For simple fixes like cleaning components or tightening connections, a confident kitchen manager can often handle the job. But when it comes to gas systems or internal electrical components, please call in the professionals. The money you save attempting DIY repairs isn't worth the safety risk or potential equipment damage.

Preventive maintenance is always less expensive than emergency repairs – especially when those repairs might happen during your busiest service! By following these care guidelines, your commercial hot plate will remain a reliable partner in your kitchen operations for years to come.

Commercial Hot Plates and Kitchen Workflow Efficiency

Ever watched a busy kitchen during the dinner rush? It's like a choreographed dance where every step and station matters. Adding commercial hot plates to this dance can transform your kitchen's rhythm and productivity in surprising ways. These versatile units aren't just cooking tools—they're problem solvers that can help your team work smarter, not harder.

Optimizing Kitchen Layout

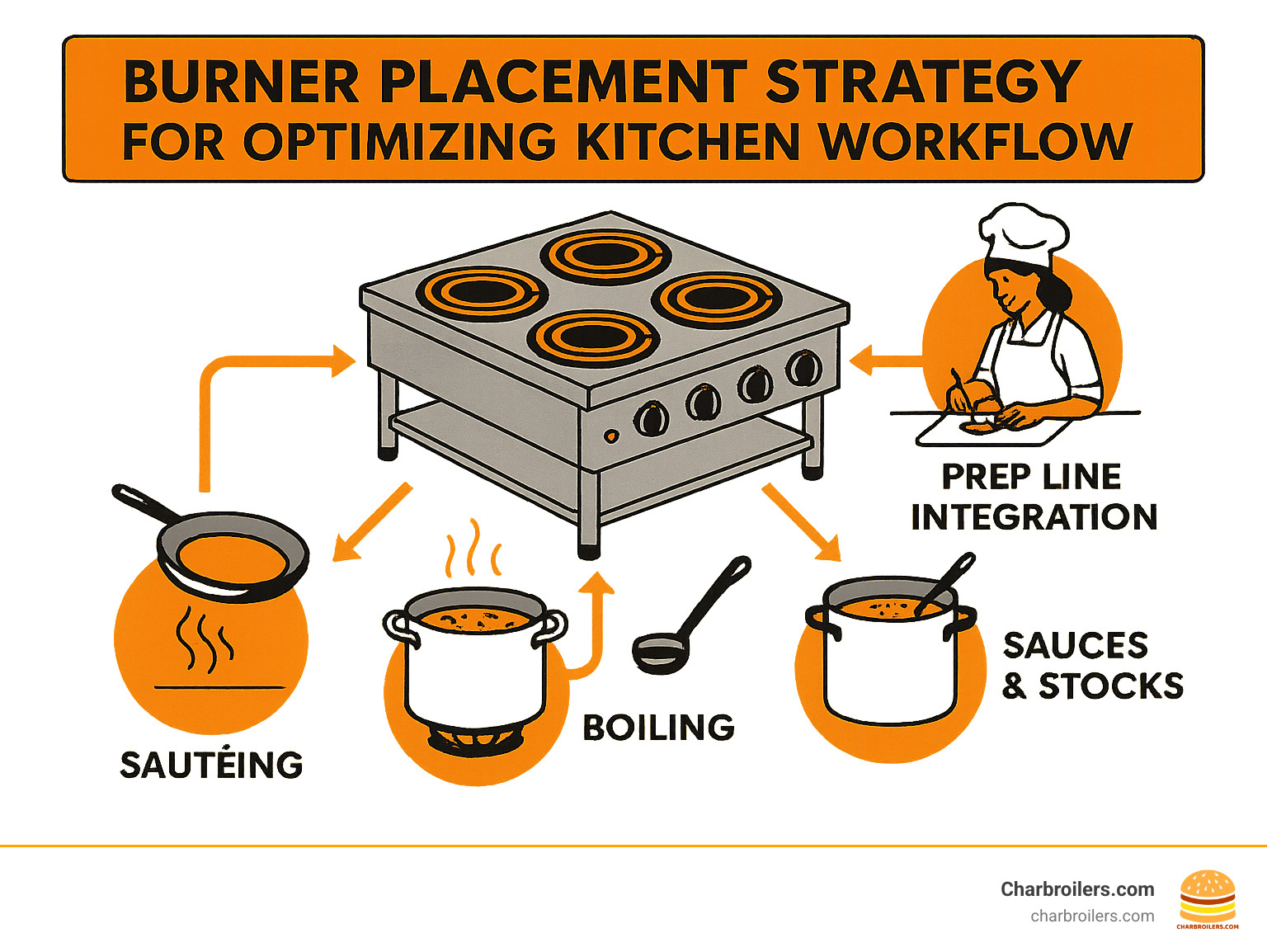

Think of your kitchen layout as a river—you want ingredients and dishes to flow smoothly from preparation to plate. Commercial hot plates can eliminate bottlenecks in this flow when strategically placed.

Placing hot plates directly at prep stations means your team can immediately cook components without walking across the kitchen. Imagine your prep cook being able to quickly sauté mushrooms right where they're chopping them—no waiting for range space, no carrying ingredients across a busy floor.

During my visit to a Seattle bistro last month, I watched how they created dedicated stations for specific menu items. Their sauce station, equipped with two induction commercial hot plates, allowed them to maintain perfect temperatures for five different sauces simultaneously—something their previous setup couldn't handle.

The beauty of these units is their flexibility. When the Tuesday night rush differs from Saturday's dinner service, you can reconfigure your cooking stations to match the demand. This kind of adaptability is simply impossible with fixed cooking ranges.

For restaurants that plate complex dishes, positioning a commercial hot plate near the pass means components stay hot until the final touches are applied. No more lukewarm sauces or rapidly cooling vegetables while waiting for the protein to finish cooking.

Energy and Cost Efficiency

Let's talk money—because that's what keeps the doors open. Commercial hot plates can be surprisingly gentle on your utility bills when used thoughtfully.

Induction models are the efficiency champions, converting about 90% of energy directly to heat compared to gas's 40% efficiency. One restaurant owner I worked with switched three stations to induction commercial hot plates and saw her electricity bill drop noticeably, even with increased production.

Smart placement reduces another hidden cost—staff movement. Every step your team takes during service costs time and energy. By positioning hot plates where they're needed most, you're essentially buying back precious minutes during rush periods. Those minutes add up to happier customers and potentially more covers per service.

I love watching the change when restaurants maximize their space with these units. A café in Portland doubled their breakfast production by adding two double-burner commercial hot plates to their previously underused counter space. They didn't need to renovate or expand—just work smarter with the space they had.

Adaptability for Different Service Models

The world of food service keeps evolving, and commercial hot plates are perfect companions for this constant change.

For catering operations, these portable powerhouses are game-changers. Imagine being able to finish dishes on-site with the same precision you'd have in your main kitchen. Your risotto stays creamy, your sauces fresh, and your reputation for quality intact—even when cooking in a tent at an outdoor wedding.

Testing a pop-up concept? Commercial hot plates let you create a functioning kitchen with minimal investment. I recently helped a chef launch a weekend ramen pop-up using just three induction units in a shared space. The low startup cost meant less financial pressure while they tested their concept.

These units also shine in educational settings. Cooking schools can create individual student stations where everyone gets hands-on experience without the expense of multiple full ranges. Demonstrations become more interactive when participants can immediately try techniques themselves.

A restaurant I consulted with in Chicago increased their production capacity by 30% during weekend rushes by strategically adding three double-burner commercial hot plates to their line. This simple change allowed them to accept more reservations during prime dinner hours without expanding their kitchen footprint—turning potential turned-away customers into actual revenue.

The modest investment in quality commercial hot plates often pays for itself quickly through increased capacity, lower energy costs, and the ability to say "yes" to opportunities that would otherwise be beyond your kitchen's capabilities.

Frequently Asked Questions about Commercial Hot Plates

How do I calculate the right BTU or wattage for my menu?

Figuring out the right power for your commercial hot plate doesn't have to be complicated. Think of it as matching the right tool to your cooking style.

For electric models, think of it this way: If you're just keeping sauces warm or doing light simmering, 600W-1000W will do the trick. For everyday cooking tasks like preparing vegetables or making sauces, look for something in the 1000W-1800W range. When you need serious heat for boiling large pots or high-heat stir-frying, you'll want to step up to 1800W-3500W models.

Gas models follow a similar pattern. Light-duty cooking needs about 15,000-20,000 BTU, medium-duty cooking requires 20,000-30,000 BTU, and heavy-duty applications call for 30,000-50,000 BTU burners.

To nail down your specific needs, start by identifying your most demanding cooking task. Are you constantly boiling large pots of pasta water? You'll need at least 2500W or 30,000 BTU for that. Also consider how much food you're cooking at once, how quickly you need to recover between batches, and even your location's altitude (higher elevations actually require more power to achieve the same cooking results).

What cookware is compatible with induction commercial hot plates?

The magic of induction cooking comes with one important caveat: it's picky about cookware. Since induction works through magnetic fields, your pots and pans need to have magnetic properties to work.

Commercial hot plates using induction technology work beautifully with cast iron (an absolute champion on induction), carbon steel (another excellent performer), magnetic stainless steel, and enameled cast iron. Even some multi-ply cookware works well if it contains ferrous layers.

On the flip side, pure aluminum, copper, glass, non-magnetic stainless steel, and ceramic cookware will just sit there cold, no matter how high you crank the heat.

Not sure if your existing pots will work? Here's a simple test: grab a refrigerator magnet and touch it to the bottom of your pan. If it sticks firmly, you're good to go. If it barely clings or doesn't stick at all, that pan won't work on induction.

For professional kitchens making the switch to induction, investing in quality induction-compatible cookware with heavy, flat bottoms is worth every penny. You'll gain better heat transfer, more durability, and significantly improved energy efficiency that pays off in the long run.

Are there energy-efficient or eco-friendly commercial hot plate options?

Absolutely! Today's commercial hot plates offer several eco-friendly options that can reduce both your carbon footprint and your utility bills.

Induction technology leads the pack in energy efficiency, converting up to 90% of energy into heat (compared to just 40% for gas and 70% for conventional electric models). Beyond using less energy, induction units cook faster, lose minimal heat to the surrounding environment, and keep your kitchen cooler – which means your AC doesn't have to work as hard.

Look for Energy Star certified models where available. These units meet strict efficiency guidelines and typically use 10-30% less energy than standard models, which adds up to significant savings over time.

Some newer commercial hot plates come with smart power management features like automatic shut-offs, programmable timers, and power-sharing technology in multi-burner units. These intelligent features prevent wasted energy when units aren't actively cooking.

Even the manufacturing process is becoming more sustainable, with some companies using recycled materials and implementing eco-friendly production practices. When shopping, consider not just how the unit performs but also its end-of-life recyclability.

In our experience, restaurants typically recover the higher initial investment of energy-efficient commercial hot plates through utility savings within 1-2 years of regular use. Plus, you'll enjoy the bonus benefits of faster cooking times and a more comfortable kitchen environment for your staff.

Conclusion & Next Steps

Investing in commercial hot plates can transform your kitchen's efficiency without breaking the bank or requiring major renovations. These powerful little workhorses offer professional performance in a compact package that fits nearly anywhere.

Throughout this guide, we've seen how these versatile cooking stations can revolutionize your workflow. From high-powered gas burners that deliver intense heat for wok cooking to precision-controlled induction units that save energy while protecting your staff from burns, there's a commercial hot plate solution for virtually every kitchen challenge.

What makes these units so valuable in today's competitive restaurant environment is their remarkable flexibility. Need to expand cooking capacity during your weekend rush? Add a double-burner unit to your line. Catering an off-site event? Pack a portable induction model. Testing a new menu concept? Try it out without committing to expensive permanent equipment.

When selecting your ideal commercial hot plate, remember to match the power and features to your specific needs. Consider your menu items, cooking techniques, available space, and utility connections. Quality construction from reputable manufacturers pays dividends through years of reliable service under demanding conditions.

At Charbroilers.com, we've helped countless restaurant owners find the perfect equipment solutions for their unique challenges. Our team understands that no two kitchens operate exactly alike, which is why we focus on understanding your specific operational needs before recommending equipment.

To get the most from your investment, establish regular cleaning routines (daily wipe-downs are essential!), train staff thoroughly on proper usage, and address minor issues before they become major headaches. With proper care, your commercial hot plate will serve as a reliable kitchen companion through thousands of busy service periods.

Ready to boost your kitchen's capabilities? Here's how to get started:

First, take a critical look at your current workflow to spot bottlenecks where additional cooking stations could help. Measure your available counter space and check your electrical capacity or gas connections. Review your menu items to determine specific power requirements, and consider how portable cooking stations might improve your catering or special event offerings.

New equipment is an investment in your business's capacity and efficiency. Many of our customers find that financing options allow their new equipment to essentially pay for itself through increased production and sales.

For more insights on equipping your commercial kitchen for success, check out our detailed guides on complementary equipment:

- Deep Fried Decisions: Top Commercial Deep Fryers Reviewed

- Guide to Commercial Charbroilers for Your Restaurant

With the right equipment in place, your kitchen can achieve new levels of efficiency and consistency while giving your culinary team the tools they need to shine. We're here to help you steer the options and find the perfect solution for your unique operation.