Tiny Commercial Kitchen Design That Works

Share

A tiny commercial kitchen isn't just a small room where you cook. It's a professional food prep space engineered to wring every last drop of efficiency from a minimal footprint. Think food trucks, ghost kitchens, and those brilliant little urban restaurants that punch way above their weight.

This isn't about limitation; it’s about strategic optimization. It's turning tight quarters into a seriously productive culinary hub through clever design and equipment that does double or triple duty. This smart, compact approach is completely changing how profitability works in today's food scene.

Why Tiny Commercial Kitchens Are a Big Deal

The idea of a tiny commercial kitchen has officially gone from a niche workaround to a mainstream strategy. Why the shift? It’s being pushed by some powerful industry forces, namely skyrocketing urban real estate costs and the absolute explosion of the food delivery market. For a lot of new and expanding food businesses, a massive, traditional kitchen just isn't financially realistic—or even necessary anymore.

Success now hinges on making every single square inch count. A well-designed compact kitchen puts workflow ahead of sheer size. It’s all about meticulous planning where your layout, equipment choices, and daily operations are perfectly in sync.

The Rise of Delivery-First Models

The boom in cloud kitchens and delivery-only restaurants has rewritten the rulebook. These business models live and die by their efficiency and low overhead, which makes the tiny commercial kitchen their perfect home. This trend has, in turn, fueled a massive demand for specialized equipment built for tight footprints.

The global market for commercial kitchen appliances was already at USD 98.34 billion in 2024 and is on track to hit USD 149.34 billion by 2030. You can dig deeper into the growth of commercial kitchen appliances and market trends to see just how big this shift is.

A well-planned layout isn't just a nice-to-have in a small space—it's the foundation of a profitable operation. Mastering the tiny kitchen is no longer an alternative; it's a crucial skill for modern culinary entrepreneurs.

More Than Just a Small Space

At the end of the day, going with a compact kitchen is a business move rooted in efficiency and being able to adapt on the fly. It forces you to think critically about your menu, your workflow, and every piece of gear you buy.

The upsides are crystal clear:

- Lower Startup Costs: Less rent and less equipment mean a much lower barrier to entry.

- Operational Efficiency: A tight, logical workflow cuts out wasted steps and speeds up production.

- Reduced Overhead: Smaller spaces cost less to heat, cool, and light up.

This guide is here to give you the actionable advice you need to turn any small space into a true culinary powerhouse.

Designing a Workflow That Actually Flows

A cramped kitchen without a smart layout is a recipe for chaos. I’ve seen it happen time and time again. In a tiny commercial kitchen, every single step matters, and a clunky workflow means staff are constantly bumping into each other, ticket times drag, and stress levels go through the roof.

The absolute key is to map out the entire journey of your food—from the moment a delivery arrives to the second it’s handed off—before you even think about buying equipment. This isn't just theory; it's the practical blueprint for an efficient, profitable kitchen. You’re aiming for a seamless process where each station logically feeds into the next, creating a natural rhythm your team can maintain even during the Saturday night rush.

Adapting Layouts for Tight Quarters

Big, sprawling kitchens have the luxury of space, but in a compact setup, you have to be smarter. This means adapting classic kitchen designs to fit your limited footprint. I’ve found two models that work exceptionally well when you modify them for small spaces.

-

The Assembly-Line Model: This linear layout is a lifesaver for operations with a focused menu, like a ghost kitchen pumping out hundreds of burgers a night. Ingredients start at one end (prep), move straight down the cooking line (grilling, frying), and finish at the packaging station. To keep things moving, the wash station and storage are usually tucked behind the main line, so nothing interrupts that forward momentum.

-

The Zone Model: If your menu has more variety, a zone layout is probably your best bet. This approach carves the kitchen into distinct stations based on function—a salad prep zone, a grilling zone, a frying zone, you get the idea. In a small space, you create these zones using vertical shelving and under-counter units, allowing a chef to pivot between tasks without ever crossing another person's path.

The real test of any layout is how it holds up under pressure. A truly efficient flow doesn't just speed up service; it reduces physical strain on your staff, cuts down on mistakes, and directly boosts your bottom line.

Mapping Your Kitchen's Core Stations

Every commercial kitchen, no matter how small, is built around five fundamental areas. How you arrange them will make or break your operation. You can dive deeper into specific ideas for a commercial kitchen layout design in our comprehensive guide, which covers everything from ergonomics to smart equipment placement.

1. Receiving and Storage This is where it all begins. In a tiny kitchen, this might just be a single stainless-steel table right next to your compact, reach-in coolers and freezers. The crucial part is keeping it near the entrance so delivery drivers aren't trekking through your active cooking zones.

2. Food Preparation Your prep station needs to be right next to your cold and dry storage—it just makes sense. This is where all the washing, chopping, and portioning happens. I'm a big fan of using mobile prep tables with built-in storage underneath; they give you incredible flexibility to reconfigure the space on the fly.

3. Cooking Line Here’s the heart of your kitchen. Always arrange your equipment in the order it gets used. For that burger joint example, the charbroiler and griddle would be side-by-side, immediately followed by the fryer. And let me be clear: efficient ventilation is absolutely non-negotiable here.

4. Service and Packaging For kitchens focused on delivery and takeout, this is the final handoff point. It needs to be clean, organized, and positioned for a quick, seamless pass-off to drivers, keeping them well out of the kitchen's main flow.

5. Warewashing The cleaning station, with its sinks and dish racks, has to be accessible but never in the way. A smart move is to place it near the receiving area. This can create a nice circular flow where dirty items come in one side and clean items are stored and ready for the line on the other.

Choosing The Right Commercial Charbroiler

The charbroiler is the heart of the operation for so many kitchens. It’s where you get that signature sear and smoky flavor customers line up for. But in a tiny commercial kitchen, the wrong one can be a disaster. It's not just about size—it’s the power source, the heat it throws off, and how it fits into your workflow.

Picking the wrong charbroiler can overwhelm your space, clog up your line, and push your ventilation system to its breaking point. This isn't just about cooking power; it’s about finding a unit that slots perfectly into your compact layout without becoming the kitchen's biggest problem. We offer a wide selection of commercial charbroilers for your restaurant, including powerful gas, versatile electric, and high-efficiency infrared models to suit any space or menu.

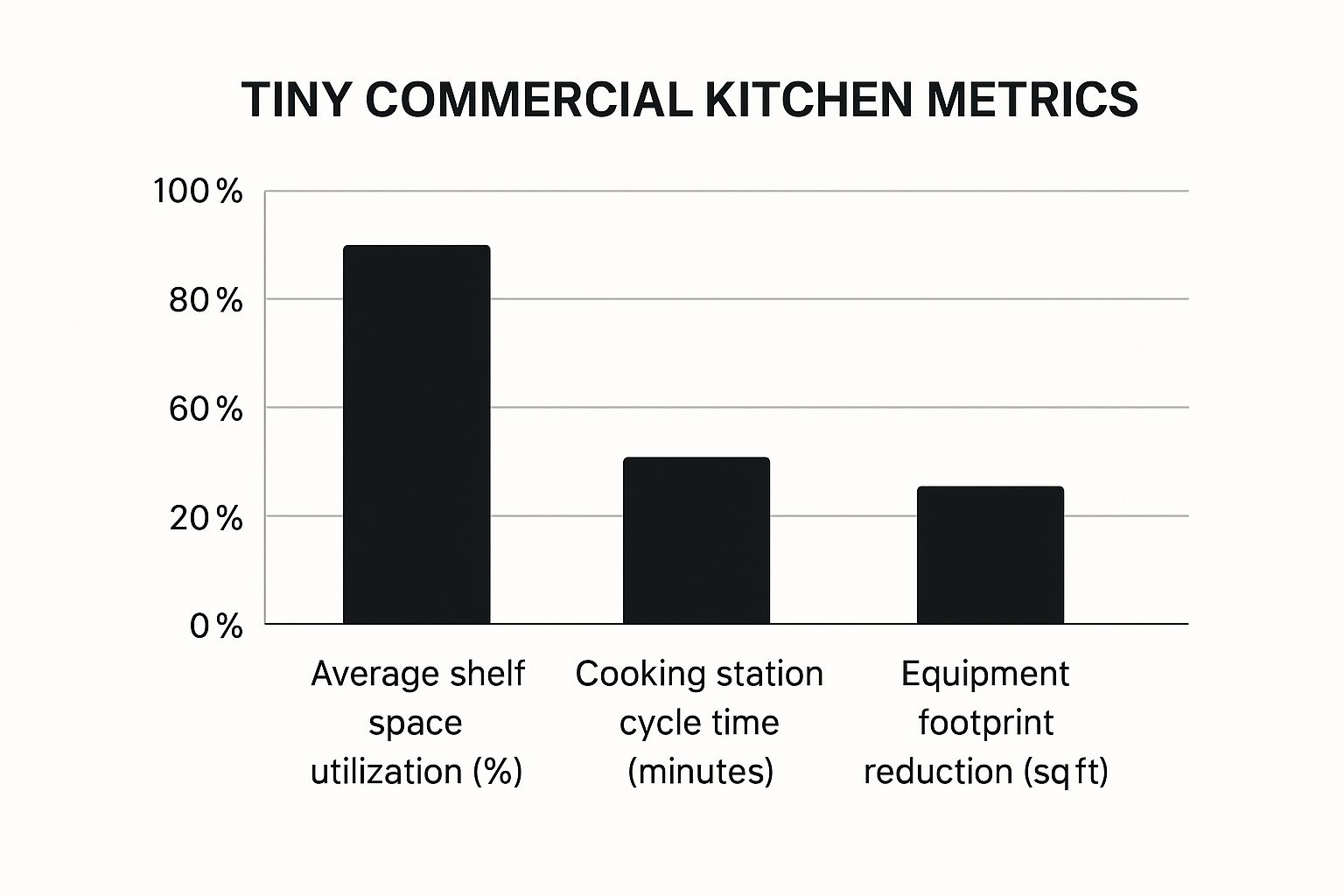

As the data shows, smart equipment choices have a massive impact. They can seriously shrink the physical space you need and cut down order times, which is a direct boost to your bottom line.

Gas Charbroilers: Raw Power in a Small Frame

For a lot of chefs, there's just no substitute for the raw, adjustable power of a gas charbroiler. They fire up fast and give you pinpoint control over the heat. This makes them perfect for high-volume spots—like a busy food truck grilling burgers and steaks back-to-back—where you can't afford to wait.

While they used to be massive, manufacturers are now making narrow-footprint gas models designed for exactly these kinds of tight spots. Just remember, they still need a dedicated gas line and some serious ventilation. That infrastructure has to be part of your plan from day one. Those open flames kick out a ton of heat and smoke, so a powerful hood system isn't optional.

The real trade-off with a gas charbroiler in a tiny kitchen is space versus power. If your menu is heavily grill-focused, dedicating the necessary square footage and ventilation budget for a compact gas unit is often a smart investment.

Electric Charbroilers: Plug-And-Play Simplicity

Electric charbroilers are the champions of simplicity and flexibility. Being plug-and-play means you can often skip the expensive, complicated installation of a gas line. That’s a huge win for pop-ups, small cafes, or any kitchen in a building with gas restrictions.

They deliver consistent, even heat, though you might have to wait a little longer for them to preheat compared to gas. Their biggest advantage? A cleaner cooking process that produces less ambient heat and fewer emissions, which puts less strain on your ventilation. For a small cafe adding grilled paninis to the menu, a countertop electric charbroiler is a perfect, low-impact choice. For more details, our guide to commercial charbroilers for your restaurant offers a deeper dive into different models.

Infrared Charbroilers: Intense Heat and High Efficiency

Infrared charbroilers are a major leap forward in grilling tech. They use intense, direct heat to cook food faster and way more efficiently. These units use radiant heat to sear the surface of food in a flash, locking in all the juices and cutting down on those pesky flare-ups. This efficiency also means they use a lot less energy—we’re talking 30-50% less than traditional models.

That speed and efficiency make them a fantastic choice for a tiny kitchen that needs to turn tickets around fast. Think about a ghost kitchen specializing in high-end grilled chicken bowls. A compact infrared charbroiler can deliver perfectly cooked, juicy results in a fraction of the time, keeping the orders flying out the door during a rush. Plus, they produce less ambient heat, which makes life a lot more comfortable for your crew.

To help you decide, let's break down how these three options stack up in a small-space scenario.

Commercial Charbroiler Comparison for Tiny Kitchens

Choosing the right charbroiler often comes down to weighing the pros and cons of each power source against your specific needs—menu, volume, and kitchen constraints. This table lays it all out.

| Feature | Gas Charbroiler | Electric Charbroiler | Infrared Charbroiler |

|---|---|---|---|

| Heat Up Time | Very fast (5-10 mins) | Moderate (15-20 mins) | Extremely fast (2-5 mins) |

| Temperature Control | Excellent, instant response | Good, consistent heat | Excellent, precise control |

| Installation | Requires gas line & heavy ventilation | Simple plug-in, lighter ventilation | Gas or electric models available |

| Footprint | Compact models available, but needs clearance | Countertop models are very space-efficient | Compact and highly efficient |

| Energy Efficiency | Moderate | Good | Excellent (up to 50% savings) |

| Best For... | High-volume, grill-heavy menus | Pop-ups, cafes, kitchens with gas limits | Quick-service, high-efficiency operations |

Ultimately, the "best" charbroiler is the one that fits your operation like a glove. A gas unit gives you raw power, an electric one offers unmatched simplicity, and an infrared model provides cutting-edge speed and efficiency.

Smart Equipment Choices Beyond the Charbroiler

Sure, the charbroiler is a star player, but a genuinely slick small kitchen operates like a special forces team—every piece of gear is multi-talented and pulls its weight. When every square inch is gold, each appliance has to do the job of two or three traditional units to earn its spot. This isn't about buying more; it's about investing in a curated collection of equipment that makes your small space punch well above its weight.

The mission is to hunt down and eliminate any single-purpose machine that’s just hogging counter space and getting in the way. Instead, you'll focus on compact, high-performance units that keep your whole operation lean and nimble.

Embracing Multi-Functional Powerhouses

For many small kitchens I've worked with, the absolute game-changer is the combination oven. This single piece of equipment can steam, roast, bake, and even proof bread. It effectively replaces a standard convection oven, a steamer, and a proofer, all within one compact footprint.

Think about a small bakery-cafe. Instead of carving out separate areas for baking pastries and steaming vegetables for soups, a combi oven handles both tasks effortlessly. This move alone frees up priceless floor and counter space, which you can then use for a better prep area or more cold storage. The sheer versatility lets you get creative and expand your menu without having to knock down a single wall.

In a tiny commercial kitchen, the philosophy is simple: buy equipment for the menu you have and the menu you want. Multi-functional gear provides the flexibility to adapt and grow without a costly renovation.

This smart approach is exactly why the market for this gear is booming. The global commercial kitchen appliances market was valued at roughly USD 104.3 billion in 2024. It’s projected to climb all the way to USD 165.9 billion by 2033, driven by the intense demand for energy-efficient appliances that boost productivity. You can dig into more commercial kitchen market statistics to see just how big this industry-wide shift is.

Maximizing Vertical and Under-Counter Space

Let's be real: your countertops and floors are finite resources. The smartest small kitchen operators I know learn to build up and down to reclaim that precious territory.

-

Under-Counter Refrigeration: Tucking refrigerators and freezers directly under your prep tables is one of the best moves you can make. It puts chilled ingredients right where your chefs need them, cutting out wasted steps and keeping the main walkways clear of traffic.

-

Vertical Storage Solutions: Get that clutter off your counters with wall-mounted shelving, magnetic knife strips, and overhead pot racks. It’s not just about creating more workspace; it’s about improving safety and organization, making essential tools easy to spot and grab in a hurry.

-

Slimline and Countertop Models: Always be on the lookout for slimline mixers, countertop fryers, and half-size convection ovens. A food truck that specializes in fried chicken, for instance, can get by with a compact countertop fryer instead of a monster floor model, leaving just enough room for an extra prep station.

When you start combining these strategies, you create a kitchen that feels and functions as if it’s twice its actual size. The key is to see every empty wall and unused cabinet not as a limitation, but as an opportunity for smarter, more efficient operation.

Navigating Health, Safety, and Efficiency

A well-designed tiny kitchen is a thing of beauty, but a great one is also safe, clean, and up to code. When you're working in tight quarters, things like ventilation and sanitation aren't just boxes to check—they're the very foundation of your operation. Getting this stuff right from the beginning is how you build a business that lasts.

Take your charbroiler, for instance. That powerhouse is going to kick off a serious amount of heat and greasy smoke. Without a top-notch ventilation system, you’re creating a dangerous work environment and a massive fire risk. Proper airflow isn't just a suggestion; it’s a critical requirement for keeping your crew safe and the health inspector happy.

Mastering Food Safety in Close Quarters

When your prep space is limited, the danger of cross-contamination skyrockets. The only way to combat this is by creating strict, clearly defined zones for different tasks. It's a simple discipline, but it’s one of the most effective ways to keep your food safe.

Think of these zones as invisible walls that protect your ingredients and, ultimately, your customers. Here’s a practical way to set this up:

- Color-Coded System: This is a classic for a reason. Use different colored cutting boards and knives for raw meats, poultry, seafood, and ready-to-eat produce. It’s a simple visual cue that prevents deadly mix-ups, even when the kitchen is slammed.

- Designated Prep Zones: Even if it’s just a few feet of counter space, dedicate specific areas for raw food prep and another for ready-to-eat items. Make it a hard-and-fast rule that these zones never, ever overlap.

Keeping this discipline is non-negotiable. For a full breakdown of how to keep every corner spotless, our commercial kitchen cleaning checklist lays out all the daily and weekly tasks you need to stay on top of.

In a tiny kitchen, compliance isn't just about passing inspections. It's about building a sustainable, safe, and efficient operation that can thrive under pressure. Every protocol you establish is a direct investment in your business's health.

Building a Sustainable and Cost-Effective Operation

Beyond the immediate safety concerns, long-term efficiency is what keeps you profitable. This is where smart equipment choices and sustainable habits directly impact your bottom line. Choosing ENERGY STAR certified appliances, for example, might cost a bit more upfront, but they can dramatically lower your utility bills month after month.

This shift toward sustainability is happening across the entire industry. Market forecasts show the global commercial cooking equipment market is expected to jump from $37.44 billion in 2024 to $54.35 billion by 2032. A huge driver of that growth is the demand for eco-friendly gear that cuts down on fuel consumption and emissions.

By doing things like setting up smart waste sorting and picking energy-efficient equipment, you’re not just being a responsible business owner—you're making a sharp financial move that will pay off for years to come.

Your Tiny Kitchen Questions Answered

Alright, let's tackle those nagging questions that pop up right when you think you’ve got your tiny kitchen all figured out. You've mapped the workflow and picked the big-ticket items, but it's the little details that can keep a chef up at night. This is where we get straight to the point with answers to the most common questions we hear from operators just like you.

Think of this as your cheat sheet for those final, crucial decisions. We’re diving into the real-world problems that come with making every single square inch of your space work as hard as you do.

What Is the Minimum Size for a Commercial Kitchen?

There’s no single magic number here—your local health department always has the final say. But from what I've seen on the ground, most successful ghost kitchens and food trucks are rocking it in spaces as compact as 100 to 200 square feet.

The real secret isn't the total square footage; it's how cleverly you use it. A brilliantly designed 150-square-foot kitchen with a logical flow and multi-use equipment will run circles around a chaotic 300-square-foot space any day of the week. Your main goal is to meet the code for clearance around your gear and create a workflow that’s safe and efficient, not just small.

The question shouldn't just be "how small can I go?" but rather "how efficiently can I organize the space I have?" A tiny commercial kitchen succeeds based on smart design, not just minimal dimensions.

How Can I Manage Grease and Odor Effectively?

When you’ve got a charbroiler roaring in a tight space, taming grease and odor isn't just a good idea—it's absolutely essential. Your number one investment, without a doubt, is a powerful, correctly sized commercial vent hood. Don't even think about cutting corners here; this is a critical piece for safety, compliance, and keeping the air breathable.

Once you have the right hood, a few smart habits will keep things running smoothly:

- Regular Maintenance: Get a professional crew in to clean your hood and ductwork on a set schedule. A clean ventilation system is an effective one.

- Baffle Grease Filters: Make the switch from mesh to baffle filters. They’re way better at trapping grease and are a breeze to clean, which is a lifesaver in a busy kitchen.

- Smart Placement: Line up your heavy hitters—like the charbroiler and fryer—right under the center of the hood. This ensures maximum capture where you need it most.

Great ventilation keeps your crew happy, your kitchen clean, and your neighbors from complaining. It’s the foundation of a well-run operation.

What Are the Best Flooring and Wall Materials?

In a compact kitchen, everything gets more intense: the heat, the spills, the foot traffic. You need surfaces that are tough as nails and incredibly easy to clean, because you don’t have time for high-maintenance materials.

When it comes to surfaces, stick with the tried-and-true industry champs:

- Flooring: Quarry tile with a non-slip finish is the undisputed king. It’s nearly indestructible, stands up to grease and stains, and gives your team the grip they need when things get hectic.

- Walls: For the hot zone right behind your cooking line, nothing beats stainless steel panels. For the other walls, Fiber-Reinforced Plastic (FRP) is a fantastic, budget-friendly choice that’s non-porous and super easy to wipe down.

Spending a little more on the right materials upfront will save you a ton of time, money, and headaches on cleaning and repairs down the line. It's a one-time investment in the long-term health and safety of your kitchen.

At Charbroilers, we get the unique challenges of building a tiny commercial kitchen. We carry a wide selection of commercial charbroilers built to deliver maximum output without dominating your limited space. Check out our collection of high-efficiency infrared, powerful gas, and versatile electric charbroilers to find the perfect heart for your kitchen. Find the right equipment to bring your menu to life at https://charbroilers.com.