The Right Parts for the Perfect Char: Commercial Charbroiler Components

Share

Why Commercial Charbroiler Parts Are Critical to Your Kitchen's Success

Commercial charbroiler parts are the backbone of consistent, high-quality grilling that keeps customers coming back. When these components fail, your kitchen faces costly downtime, uneven cooking, and frustrated staff trying to deliver the perfect char marks your dishes are known for.

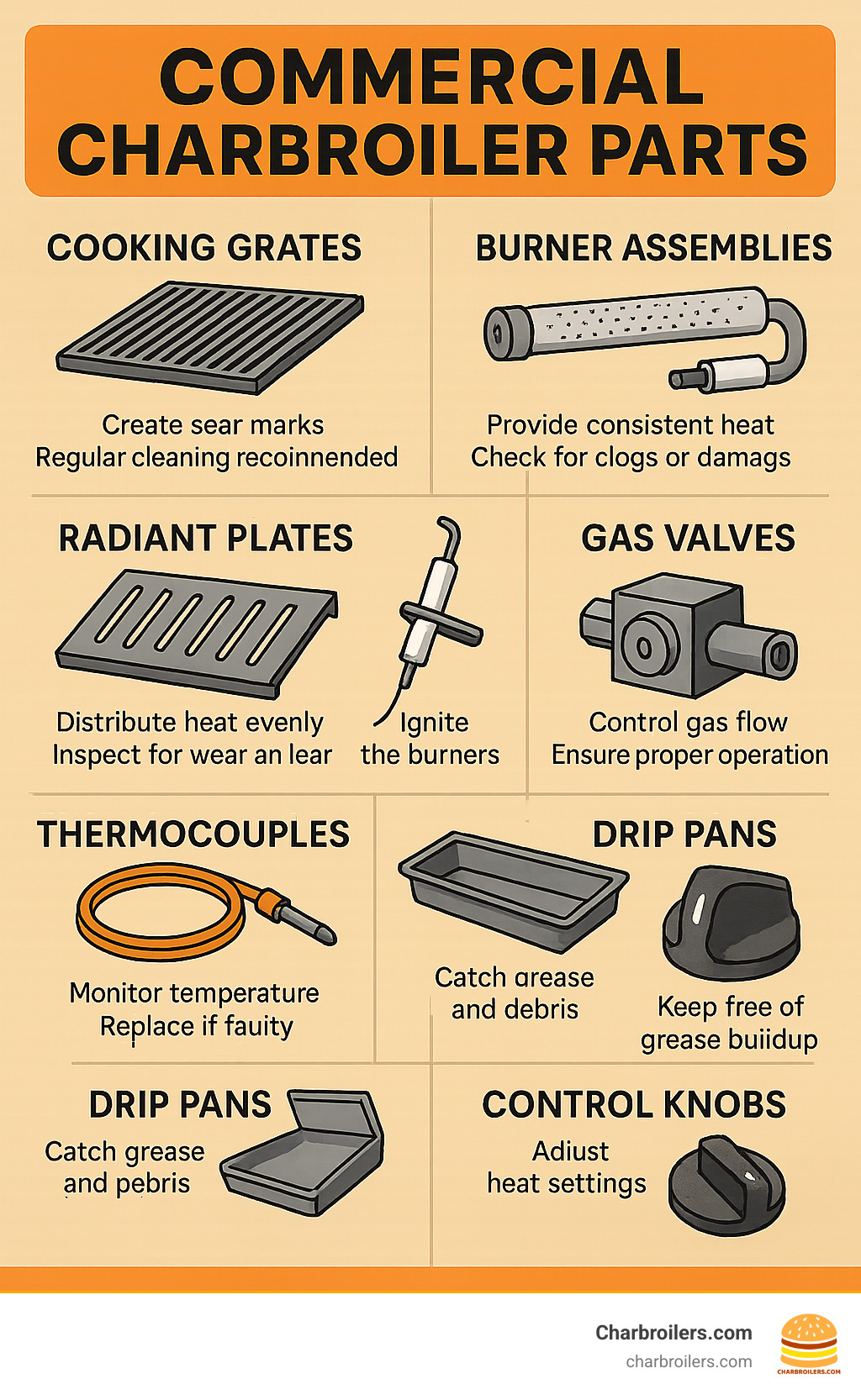

Essential commercial charbroiler parts include:

- Cooking grates (cast iron or stainless steel) - Create signature sear marks

- Burners and ignition systems - Provide consistent, reliable heat

- Radiants and heat plates - Distribute heat evenly and reduce flare-ups

- Gas valves and thermocouples - Control temperature and ensure safety

- Drip pans and grease management - Maintain cleanliness and prevent fires

The type of charbroiler you own—whether radiant, infrared, or conventional—determines which specific parts you'll need. While top-tier charbroilers are built for durability and performance, even the best equipment requires proper maintenance and quality replacement parts.

Key factors when selecting parts:

- OEM vs. aftermarket - Balance cost with guaranteed compatibility

- Material quality - Stainless steel and cast iron offer different benefits

- Proper sizing - Wrong dimensions mean wasted time and money

- Supplier reliability - Fast shipping prevents extended downtime

At Charbroilers.com, our team has experience in the restaurant equipment industry. We've helped countless operators source the right commercial charbroiler parts to keep their kitchens running smoothly, because we know that the right parts at fair prices make all the difference to your bottom line.

Commercial charbroiler parts terms you need:

Your Guide to Essential Commercial Charbroiler Parts

Think of your charbroiler as a high-performance car – it needs the right parts working together for peak performance. These commercial charbroiler parts take the most beating, and when they wear out, your kitchen feels it immediately. Understanding which parts need attention can save you from a grill failure during the dinner rush.

Every charbroiler has workhorse components that eventually need replacing. Keeping these parts in top shape isn't just about avoiding breakdowns; it's about maintaining the consistent flavor and perfect char that keeps customers returning. Let's explore the parts that matter most.

Cooking Grates

Your cooking grates create those beautiful sear marks but take a serious beating from constant heat, heavy use, and daily cleaning.

Cast iron grates are heavy hitters that hold heat exceptionally well, creating deep, professional sear marks. The downside is they require regular care to prevent rust and can crack if dropped. Many have a porcelain coating for easier cleaning and added protection.

Stainless steel grates are reliable workhorses. While they don't hold heat as long as cast iron, they are incredibly tough, resist rust, and clean up beautifully. For low-maintenance performance, stainless steel is an excellent choice.

Diamond grill grates offer a unique shape designed for specific heat patterns and distinctive brand marks, while also helping grease drain away effectively. It's like having a signature stamp for your food.

When shopping for replacement grates, consider what you cook most often, the sear marks you want, heat retention, and ease of cleaning.

Burners and Ignition Systems

Burners and ignition systems are the heart of your operation, delivering the consistent, even heat that defines professional cooking.

Tube burners and U-shaped burners are the most common styles. Stainless steel burners resist rust and corrosion far better than older porcelain steel versions, meaning they'll last longer and perform more reliably.

Your igniters and electrodes are small but crucial. When they fail, you're stuck lighting burners manually—not ideal during a busy service. Common issues include worn electrodes, damaged wires, or faulty spark generators. Some igniters have integrated ground wires, while others need separate ground wire components.

Gas valves and thermocouples are your safety and control team. Gas valves control fuel flow to the burners, while thermocouples are safety guards that shut off gas if the flame goes out. When these parts malfunction, you might notice uneven heating, lighting trouble, or dangerous gas leaks.

Keeping your burners clean and ignition components free of grease is essential for consistent performance and kitchen safety.

Replacement Parts for Charbroiler Grill

Radiants, Heat Plates, and Emitter Plates

These unsung heroes sit between the burners and cooking grates to manage heat distribution and control flare-ups.

Cast iron radiants absorb energy from the burners and radiate it back up evenly. This creates consistent cooking temperatures and eliminates hot spots that can burn food.

Heat plates (or flame tamers), typically made from stainless steel or porcelain steel, sit over the burners. They protect them from grease drips and vaporize those drippings to create smoky flavor. Remember to peel any protective vinyl coating from new heat plates before use.

Ceramic briquettes are another option for heat management. They absorb and redistribute heat while helping to vaporize drippings for extra flavor. The number needed depends on your model; for example, a 30-inch charbroiler might need 56 briquettes, while a 42-inch unit could require 84.

Emitter plates are a specialty component found in infrared charbroilers. They convert flame heat into infrared energy, allowing for incredibly high, even temperatures that sear food perfectly.

Regularly cleaning these components to remove grease and carbonized debris keeps them working efficiently and prevents dangerous flare-ups.

The Ins and Outs of Commercial Charbroilers

How Charbroiler Type Dictates Parts Needed

Finding the right replacement commercial charbroiler parts can feel like a treasure hunt because not all charbroilers are built the same. They use different heating technologies, and understanding your unit's system is the first step to getting the right components, saving you time and money.

Radiant and Conventional Gas Charbroilers

These are the tried-and-true workhorses in many commercial kitchens, beloved for delivering a classic, smoky charbroiled flavor.

In these traditional models, you'll find key parts like heat tents or radiant shields. These components sit over the burners, protecting them from drippings while spreading heat evenly across the cooking surface. This helps create that signature taste and beautiful sear marks. Many conventional charbroilers use these systems, sometimes with durable cast iron burners or stainless steel tube burners beneath. Their parts are built tough to handle high temperatures day in and day out.

Infrared (IR) Charbroilers

Infrared (IR) charbroilers are a different beast, using intense, direct heat for super-fast searing and incredible efficiency.

Instead of heat tents, IR charbroilers feature emitter plates. These special plates absorb heat from the burners and convert it into powerful infrared energy that directly cooks the food. This results in incredibly high temperatures, fast cooking times, and often, better gas conservation. Many leading manufacturers use this technology to boost production and save energy.

This infrared technology shines when you need a strong, even sear—perfect for steaks, burgers, and anything requiring a crisp exterior and tender interior. The direct radiant heat also means fewer flare-ups.

When hunting for commercial charbroiler parts for an IR unit, you'll need specialized emitter plates and possibly different burner designs compared to a conventional model. For example, an infrared model will have cooking grates over emitter plates, while a conventional model uses grates over heat tents. Knowing this key difference is vital for picking the correct parts.

Looking to learn more about kitchen equipment? Check out our guide on the Commercial Gas Griddle.

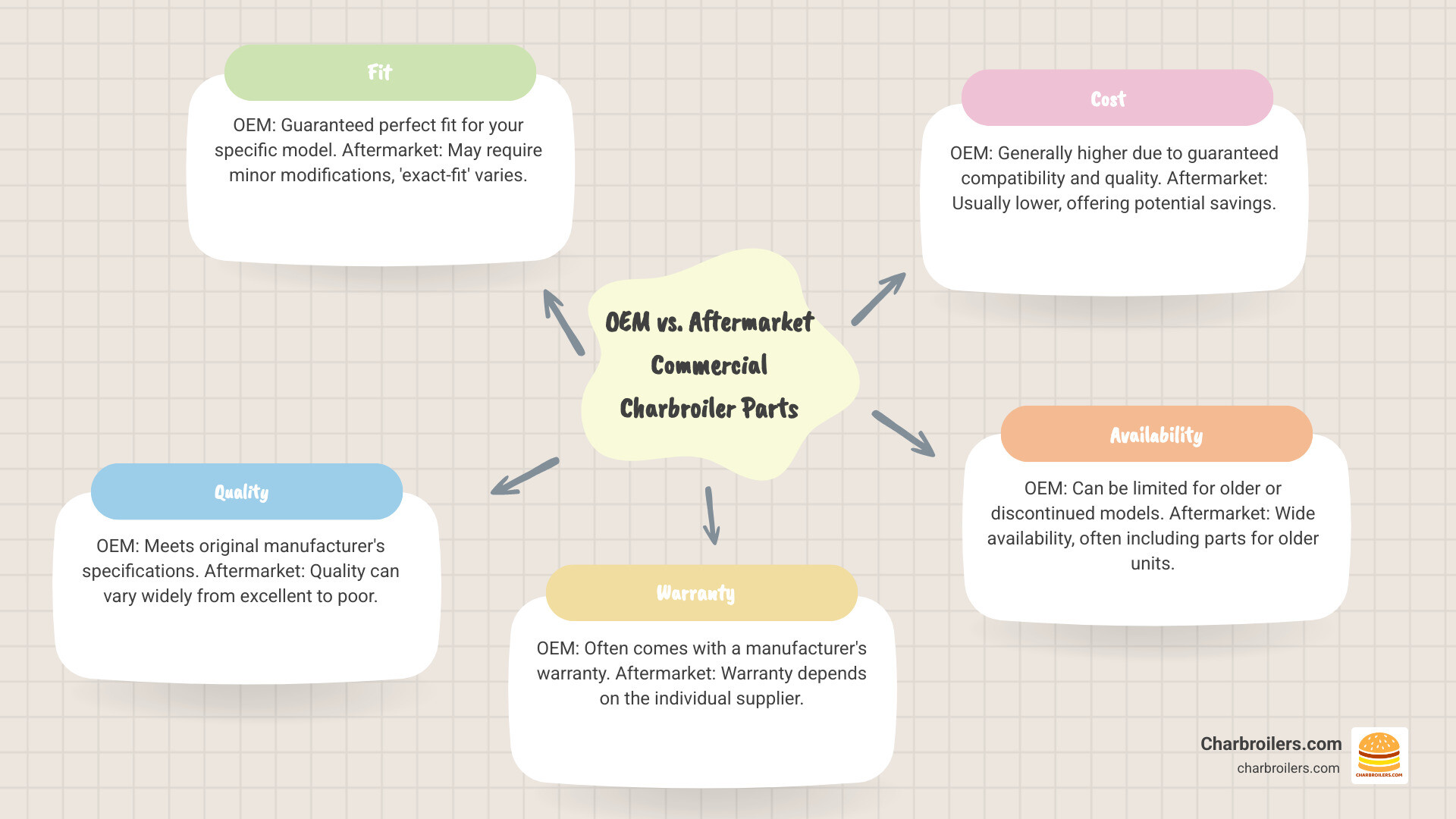

OEM vs. Aftermarket: Choosing for Durability and Performance

Deciding between Original Equipment Manufacturer (OEM) and aftermarket parts is a critical choice that balances cost, quality, and long-term performance, ensuring your charbroiler operates safely and effectively.

When your commercial charbroiler parts need replacing, you face a choice: the manufacturer's original part or a third-party alternative. This decision isn't just about cost; it's about understanding the impact on your operation's quality and longevity.

| Feature | OEM Parts | Aftermarket Parts |

|---|---|---|

| Fit | Guaranteed perfect fit, designed for your model | May require minor modifications, "exact-fit" varies |

| Quality | Meets manufacturer's original specifications | Quality can vary widely, from excellent to poor |

| Warranty | Often comes with a manufacturer's warranty | Warranty depends on the aftermarket supplier |

| Cost | Generally higher | Usually lower |

| Availability | Can be limited for older/discontinued models | Wide availability, including for older models |

The Benefits of Genuine OEM Parts

OEM parts offer guaranteed compatibility. You're getting the exact same component that was installed when your charbroiler was new.

The manufacturer warranty that comes with OEM parts provides peace of mind. If something goes wrong, the original manufacturer stands behind their product. This is especially valuable for expensive components like gas valves or specialized infrared emitter plates.

Build quality is another major advantage. OEM parts meet the equipment's exact specifications, ensuring your charbroiler maintains its performance standards—delivering the same consistent heat, efficiency, and char marks your customers expect.

For newer equipment still under warranty, using OEM parts is often required to maintain coverage.

When to Consider Aftermarket Parts

Aftermarket commercial charbroiler parts can be a smart choice, especially when dealing with cost savings pressures or hard-to-find components.

The most obvious benefit is price. Aftermarket parts typically cost less than OEM alternatives, which can make a real difference to your bottom line, especially for frequently replaced items like cooking grates.

Availability for older models is where aftermarket suppliers shine. When manufacturers discontinue parts for older charbroilers, aftermarket companies often fill the gap, specializing in keeping older equipment running.

Interestingly, some aftermarket parts offer material upgrades over the originals. For example, certain aftermarket stainless steel flame tamers are superior to original porcelain steel versions because they better resist rust and corrosion.

The key is finding reputable suppliers who stand behind their products. Look for companies with strong customer feedback and clear return policies. At Charbroilers.com, we stock both OEM and exact-fit aftermarket parts, and as a USA business based in Seattle, we stand fully behind our products and service.

Find reliable suppliers with strong customer feedback

Proactive Care: Maintenance and Troubleshooting for Longevity

Routine maintenance is the most effective way to prevent costly downtime and extend the life of your equipment. Identifying common issues early can save you from expensive emergency repairs.

Commercial charbroiler parts are tough but not invincible. A little preventive care goes a long way, as most breakdowns result from small, unaddressed problems. Staying ahead of maintenance protects your investment and ensures consistent quality.

Routine Maintenance Checklist

Creating a consistent maintenance routine is the secret weapon of successful operators.

Daily cleaning: Staff should scrape and brush cooking grates while still warm. Empty and clean the drip pan and grease tray to prevent fire hazards. A quick wipe-down of exterior surfaces helps spot potential issues.

Weekly deep cleaning: Remove and scrub the cooking grates, radiants, and heat plates with a quality degreaser. Clean around the burners, removing any grease or carbon deposits, and check burner ports for blockages that cause uneven heating.

Monthly inspections: Inspect burners for cracks or corrosion. Check igniters and electrodes for wear. Examine gas lines and connections for leaks using soapy water (never a flame). Verify that gas valves and control knobs operate smoothly and inspect the frame for stability.

Annual professional servicing: A certified technician can check gas pressure, calibrate controls, and identify issues untrained eyes might miss. Consider it an insurance policy for your equipment.

Getting Fired Up About Commercial Charbroilers

Troubleshooting Common Commercial Charbroiler Parts Failures

Even with perfect maintenance, parts wear out. Recognizing the warning signs is key.

Uneven heating: This common complaint is often caused by clogged burner ports, warped heat plates or radiants, or a failing burner. A thorough cleaning often solves it. If not, inspect heat distribution components for damage.

Burner problems: If a burner won't light, you may have a clog, a faulty igniter/electrode, a bad gas valve, or a gas supply issue. If it lights but burns unevenly, the ports are likely blocked or the burner is damaged.

Ignition issues: No spark usually means a worn-out igniter, a loose wire, a faulty spark generator, or a dead battery. Delayed ignition is dangerous and points to similar problems. When replacing an ignitor, you may need a separate ground wire part if the old one had it integrated.

Excessive flare-ups: This is almost always caused by grease buildup on radiants, heat plates, or the drip pan. Damaged flame tamers can also be the culprit. A deep clean and replacement of worn commercial charbroiler parts is the solution.

Grease buildup and corrosion: These are not just cosmetic issues; they cause hot spots and can weaken components, leading to gas leaks. Upgrading from porcelain steel to stainless steel parts can improve longevity.

Most failures stem from a lack of cleaning, heat stress, and corrosion. Address these proactively to save time, money, and stress.

Ensuring a Perfect Fit: How to Order the Correct Parts

Ordering the wrong part wastes time and money. A simple verification process ensures you get the right component on the first try, getting your kitchen back to full capacity faster.

When it comes to commercial charbroiler parts, precision matters. Getting the right component the first time is about minimizing downtime. A simple verification process is your roadmap to ordering exactly what you need.

Finding Your Model and Serial Number

Your charbroiler's model and serial number are its unique fingerprint, telling you exactly which parts will fit your equipment.

Locating the data plate is your first mission. Most charbroilers have a metallic sticker or plate on the back, side, or inside a door panel. This plate is worth its weight in gold.

The model number is your best friend when ordering. Even charbroilers from the same manufacturer can use different components. For example, a manufacturer's infrared and conventional models often require distinct parts, even if they look similar.

Once you have the model number, parts diagrams become incredibly helpful. Many suppliers offer detailed exploded views online, showing each component with its part number.

Cross-referencing part numbers adds another layer of verification. If you have the old part, look for any stamped numbers. Always double-check compatibility with your model number, as part numbers can change. When in doubt, measuring your old parts and comparing dimensions can confirm you're getting the right replacement.

The golden rule is to always provide your model and serial number to your supplier to ensure accuracy.

Where to Find Reliable Commercial Charbroiler Parts

Finding the right part is only half the battle; you also need a supplier you can trust for quality, availability, and prompt service.

Authorized dealers are a good choice for OEM parts. They source directly from manufacturers and guarantee authenticity, which provides peace of mind for critical safety components.

Specialist suppliers like Charbroilers.com offer deep expertise and an extensive inventory. We focus on commercial kitchen equipment, so we understand the urgency when a unit goes down. Our warehouse is stocked with parts for many appliances, and we ship most items quickly. Many in-stock parts can ship within 3 business days or less.

Verifying compatibility should always be part of your ordering process. A good supplier will ask for your model number to confirm the fit and should explain the differences between OEM and aftermarket options to help you make an informed decision.

At Charbroilers.com, we're more than just a parts supplier; we're your partners in keeping your kitchen running. Based in Seattle, WA, we stand behind our products and service. Our experienced team can help you find the correct commercial charbroiler parts for your model. We also offer financing options for food service operations, making it easier to get the parts you need without straining your cash flow.

The bottom line: shopping by model number and working with knowledgeable suppliers makes all the difference.

Conclusion

Investing in high-quality, correct-fitting commercial charbroiler parts is about more than just repairs; it's about maintaining the heart of your kitchen where incredible, smoky flavor is born.

From the cooking grates that create signature sears to the burners that deliver perfect heat, every component plays a vital role. Together, they help you create the delicious, perfectly charred dishes that your customers love.

Understanding your equipment, following a routine maintenance schedule, and making smart choices when sourcing commercial charbroiler parts are essential. By doing so, you protect a valuable investment and ensure your charbroiler continues to fire up profits and delight diners for years to come.

For a comprehensive look at selecting the perfect equipment for your business needs, be sure to explore our complete guide. We're here to help you every step of the way.