The Ins and Outs of Commercial Charbroilers

Share

Why Commercial Charbroilers Are Essential for Restaurant Success

Charbroiler commercial units deliver the smoky, flame-kissed flavors that keep customers coming back. These powerful cooking stations use open flames or radiant heat to sear meats, vegetables, and seafood with distinctive grill marks and rich taste profiles that regular grills simply can't match.

Quick Commercial Charbroiler Comparison:

- Gas Radiant: Fast heat-up, easy cleaning, 15,000-40,000 BTU per burner

- Lava Rock: Charcoal-like flavor, higher maintenance, excellent heat retention

- Electric: No gas lines needed, perfect for high-rises and restricted areas

- Infrared: Energy efficient, precise temperature control, minimal flare-ups

- Wood/Charcoal: Authentic smoky taste, requires ventilation and fire suppression

The choice between these types depends on your kitchen setup, menu style, and volume needs. Gas models dominate commercial kitchens because they're reliable and cost-effective, while electric units work great where gas isn't available.

Commercial charbroilers range from compact 12-inch countertop models to massive 84-inch floor units with up to 20 burners. They're essential equipment for steakhouses, diners, sandwich shops, and any restaurant wanting to add that distinctive grilled flavor and appearance to their dishes.

I'm Sean Kearney from Charbroilers.com, and I've spent over a decade helping restaurants find the right charbroiler commercial equipment after founding The Restaurant Warehouse following my time at Amazon. My experience in the restaurant equipment industry has shown me that choosing the right charbroiler can make or break a kitchen's efficiency and food quality.

Charbroiler Commercial: What It Is & How It Works

Think of a charbroiler commercial unit as your kitchen's personal campfire - but one that's been tamed and perfected for professional cooking. These aren't your backyard grills; they're precision-engineered workhorses designed to run all day, every day, delivering that perfect sear and smoky flavor that keeps customers coming back.

The secret to great charbroiled food lies in the science of heat transfer. When you place a steak on those hot grates, you're getting direct radiant heat from below - usually between 500-800°F. As the meat's juices and fats drip down onto the hot surfaces, they vaporize instantly, creating that signature smoky flavor that rises back up to infuse your food.

This high-heat cooking triggers the Maillard reaction - that magical process where proteins and sugars create complex flavors and those beautiful grill marks we all love. It's the difference between a sad, gray piece of meat and a restaurant-quality steak with a perfect crust.

The beauty of commercial charbroilers is how they manage this intense heat. Whether they use radiant panels, lava rocks, infrared elements, or electric coils, each system is designed to distribute heat evenly while managing grease and preventing dangerous flare-ups.

Main Types of Commercial Charbroilers

Radiant gas charbroilers are the workhorses of most commercial kitchens. They use ceramic or steel radiants that sit above the gas burners, creating a barrier that protects the flames from drippings while radiating consistent heat upward. These units heat up quickly and offer predictable results - perfect when you need to crank out orders during the dinner rush.

Lava rock gas charbroilers take a different approach, using actual volcanic rock to create heat and flavor. The porous lava rocks absorb and hold drippings, then vaporize them to create that authentic charcoal-like taste. Yes, you'll need to flip and replace the rocks regularly, but many chefs swear the extra flavor is worth the maintenance.

Infrared charbroilers are the high-tech option, using ceramic panels or steel emitters that glow red-hot. They're incredibly energy-efficient and give you precise temperature control with minimal flare-ups. Think of them as the sports car of charbroilers - sleek, efficient, and reliable.

Electric charbroilers solve the problem of locations where gas isn't available or allowed. They use powerful electric elements to create both radiant and conductive heat, making them perfect for basement kitchens or high-rise restaurants where gas lines aren't feasible.

Solid fuel charbroilers are for the purists who want authentic wood or charcoal flavor. These units burn real wood or charcoal in ceramic fireboxes, creating an best smoky taste and often becoming a showpiece in exhibition kitchens. Just be prepared for more complex ventilation requirements.

How a Charbroiler Differs from a Grill

The biggest difference between a charbroiler commercial unit and your backyard grill isn't just size - it's reliability. While home grills are built for weekend cookouts, commercial charbroilers are engineered to maintain steady BTU output across multiple burners for hours at a time.

The grate design tells the whole story. Commercial units feature heavy-duty cast-iron or steel rod grates that are often reversible, with channels designed to direct grease into collection trays. This isn't just about cleanliness - it's about preventing dangerous flare-ups that could char your food or create smoke problems in your kitchen.

Indoor ventilation integration is another game-changer. These units are designed to work seamlessly with commercial hood systems, with specific clearance requirements and airflow patterns that keep smoke and heat under control. You won't find these features on outdoor grills because they simply don't need them.

Finally, commercial charbroilers are built for workflow integration. They're designed to fit into your kitchen's flow, with features like splash guards, easy-access controls, and removable parts that make cleaning possible even during busy service periods.

Side-by-Side Comparison of Heat Sources

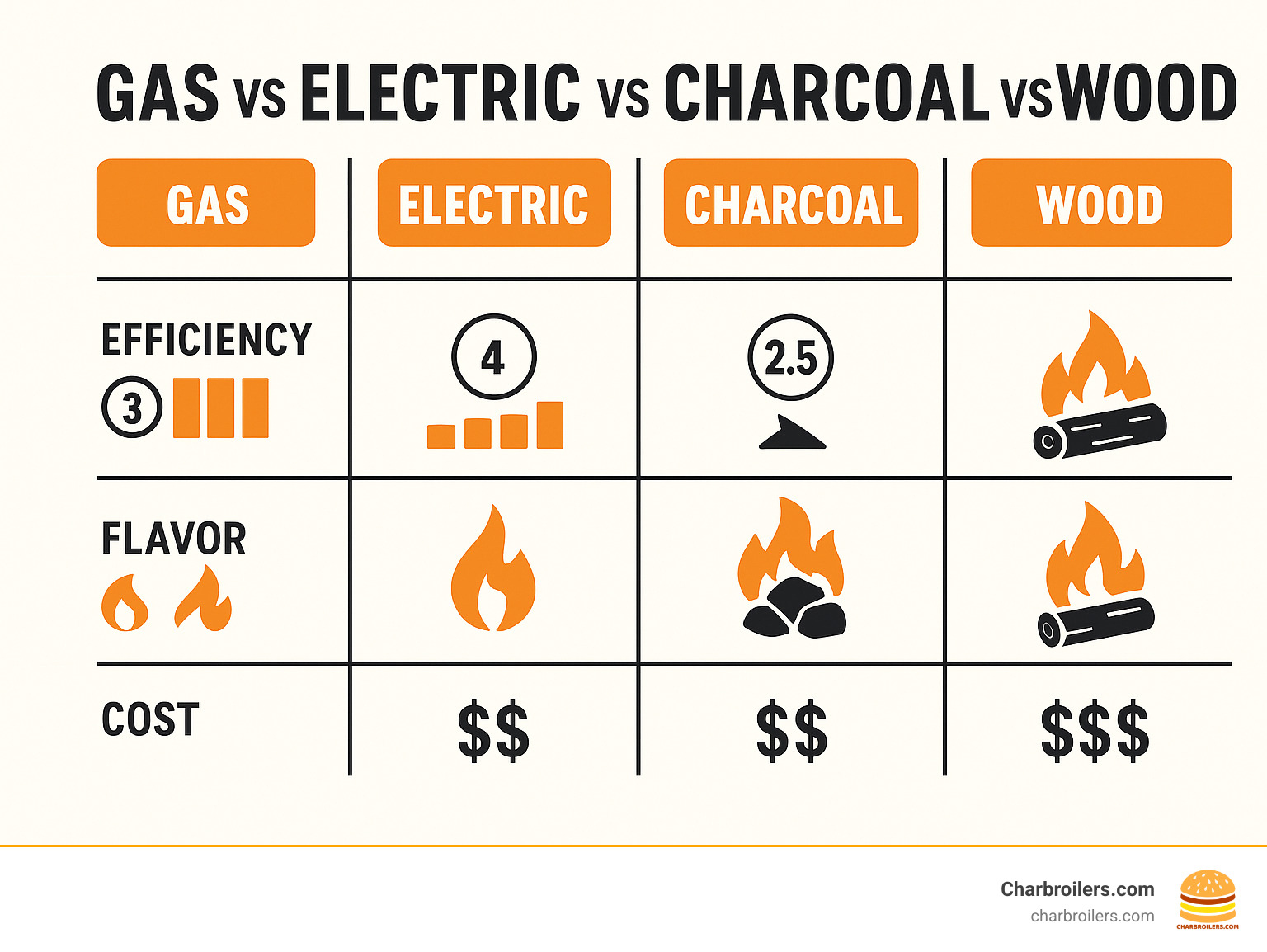

Choosing the right fuel type for your charbroiler commercial unit is like picking the heart of your kitchen operation. Each option brings something different to the table, and understanding these differences can save you thousands in operating costs while ensuring your food tastes exactly how you want it.

Gas charbroilers are the workhorses of commercial kitchens for good reason. They heat up fast, maintain steady temperatures, and give you precise control over your cooking zones. With burners pushing out 15,000 to 40,000 BTUs each, you'll have plenty of power for even the busiest dinner rush. The operating costs are predictable, and most commercial spaces already have gas lines ready to go.

Electric models become your best friend when gas isn't an option. Maybe you're in a high-rise building, or your local utility rates make electricity cheaper than gas. While they might cost more to operate in some areas, you'll save on installation since there's no gas line work needed. They're also perfect for those tricky basement kitchens where gas restrictions apply.

Wood and charcoal units are the flavor champions. There's nothing quite like the authentic smoky taste they deliver, and customers can actually smell the difference. The trade-off? You'll need more ventilation, higher labor costs, and a staff that knows how to manage real fire. But for restaurants building their reputation on authentic flavors, it's worth every penny.

| Fuel Type | Flavor Profile | Efficiency | Operating Cost | Best For |

|---|---|---|---|---|

| Gas | Clean, controllable | High | Low-Medium | High-volume operations |

| Electric | Neutral, consistent | Medium | Medium-High | Restricted locations |

| Wood | Rich, smoky | Low | High | Authentic dining experiences |

| Charcoal | Traditional BBQ | Low | High | Specialty restaurants |

Radiant vs Lava Rock Performance

The choice between radiant and lava rock systems often comes down to a simple question: do you want easier maintenance or maximum flavor? It's one of those decisions that can define your kitchen's daily routine.

Radiant charbroilers use ceramic or steel shields that sit between your food and the burners. These shields heat up evenly and protect your burners from grease drippings, which means fewer repairs and more consistent cooking. The heat distribution is wonderfully predictable - what you see is what you get across the entire cooking surface.

Lava rock systems are the flavor enthusiasts' choice. Those porous volcanic rocks catch all the drippings from your food and turn them into aromatic smoke that infuses everything with that authentic grilled taste. It's like having a charcoal grill's flavor with gas convenience.

The maintenance difference is real, though. Lava rocks need rotation every few weeks and complete replacement every 3-6 months, depending on how busy you are. Radiant systems just need regular cleaning of the shields. But here's the thing - many high-end steakhouses swear by lava rocks because the flavor difference is noticeable to customers.

Heat distribution tells its own story too. Radiant systems give you even temperatures everywhere, making them perfect for consistent results. Lava rock systems create natural hot and cool spots that experienced cooks learn to use strategically - searing steaks over the hottest areas and keeping sides warm in cooler zones.

More info about performance tips

Infrared & Electric Options for Tight Spaces

When your kitchen space is at a premium or your building has utility limitations, infrared and electric charbroiler commercial units become problem-solvers rather than compromises.

Infrared charbroilers are the efficiency champions. Those ceramic panels glow red-hot and deliver intense, focused heat that uses less fuel while cooking faster. They're perfect for kitchens trying to reduce energy costs without sacrificing performance. The heat is so even and controlled that flare-ups become rare, giving you more consistent results.

Electric charbroilers shine in challenging locations. High-rise restaurants, basement kitchens, or anywhere gas lines are impractical or prohibited can still deliver great grilled food. The newer models generate both radiant heat from above and conductive heat from the cooking surface, giving you versatility that rivals gas units.

Many electric models feature lift-up cooking plates that make cleaning a breeze - something that becomes important when you're dealing with the higher maintenance needs of electric elements. They're also quieter than gas units, which can be a bonus in open kitchen designs where noise matters.

Powered by GDPR Cookie Compliance plugin

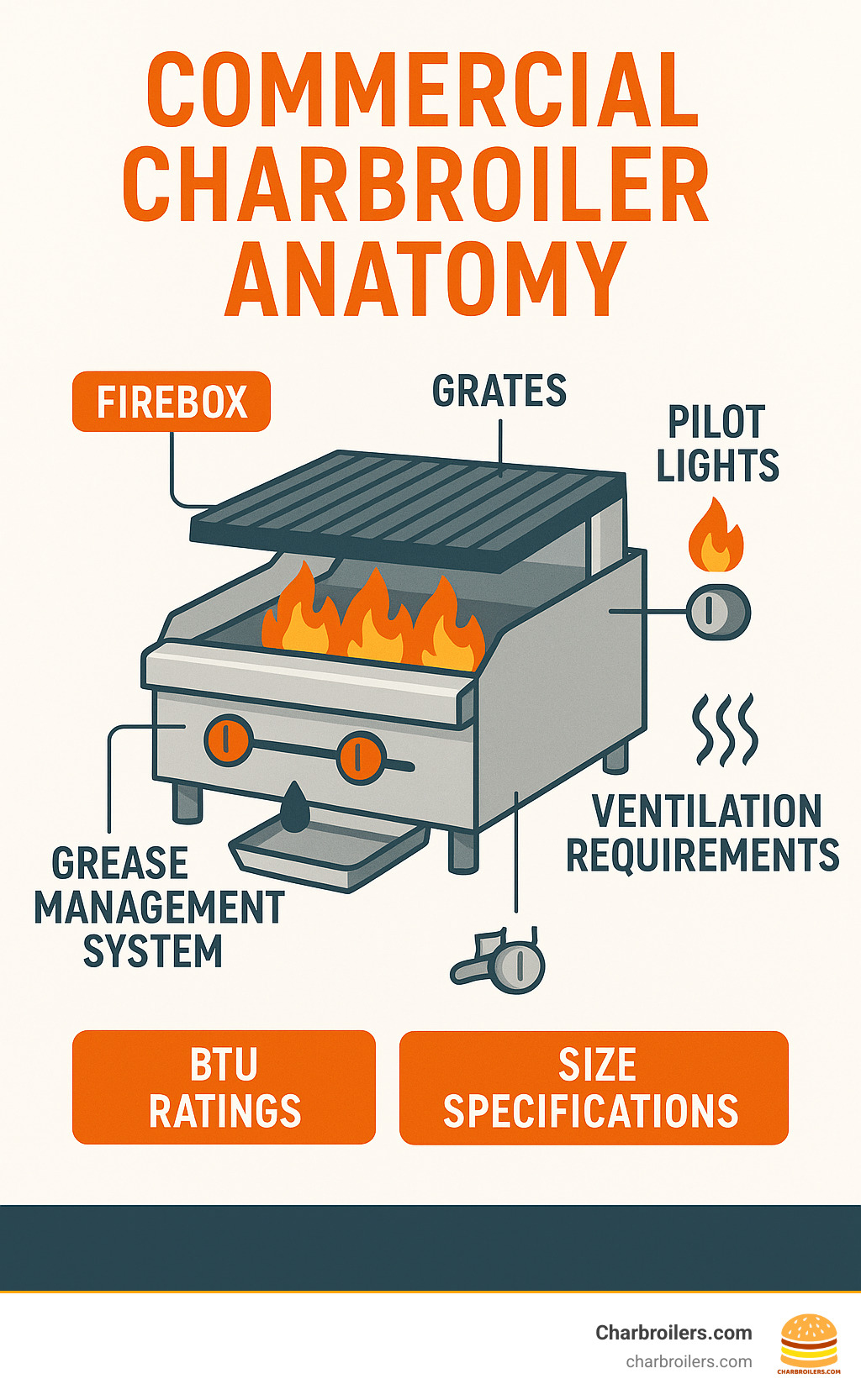

Critical Buying Factors: Size, BTUs & Ventilation

Getting the right size charbroiler commercial unit can make the difference between smooth service and kitchen chaos. I've seen too many restaurants struggle with undersized equipment during rush hours or waste money on massive units they never fully use.

Footprint considerations start with measuring your available space carefully. Countertop models begin at just 12 inches wide and work perfectly for small operations, while floor units can stretch up to 84 inches for high-volume kitchens. Remember to account for required clearances - most units need at least 6 inches on each side and 18 inches behind for proper ventilation.

BTU output determines how fast and hot your charbroiler can cook. Most commercial units feature burners rated between 15,000 to 40,000 BTU each. A busy steakhouse might need multiple 40,000 BTU burners for quick searing, while a sandwich shop can handle lunch rushes with 20,000 BTU burners just fine.

The grate material affects both your cooking results and daily maintenance routine. Cast-iron grates retain heat beautifully and create those perfect sear marks customers love, but they require seasoning and careful cleaning. Stainless steel rods clean up easier and resist corrosion, making them popular for high-volume operations where speed matters.

Adjustable grate positions give you flexibility to create different heat zones - perfect for cooking various proteins simultaneously. Some models offer reversible grates with different channel patterns, letting you switch between fine sear marks and bold grill patterns depending on your menu needs.

Ventilation planning often gets overlooked until installation day, which can be a costly mistake. Gas units typically require Type I commercial hoods with adequate make-up air systems to handle the heat and combustion byproducts. Electric models might work under lighter ventilation, but always check your local codes first.

Smoker drawer accessories can transform a standard charbroiler into a flavor powerhouse, adding wood chips for authentic smoky taste without the complexity of a full wood-fired system.

Matching Charbroilers to Restaurant Concepts

Steakhouses need the heavy artillery - units with 30,000+ BTU burners that can sear thick cuts quickly while maintaining juicy interiors. Lava rock systems work particularly well here because they create the intense, smoky flavors that steak lovers expect from a premium dining experience.

Diners and casual restaurants typically find their sweet spot with mid-range radiant gas charbroilers. These units balance cooking performance with maintenance simplicity, helping ensure your weekend brunch cook gets the same results as your experienced dinner chef.

Sandwich shops can often meet their needs with compact countertop models that still deliver those appealing grill marks on chicken breasts and vegetables. The key is choosing a unit that handles your peak lunch volume without overwhelming your limited kitchen space.

Food truck operations present unique challenges where every inch and BTU counts. Portable gas models with excellent heat retention work best, letting you cook efficiently while managing limited propane supplies and tight quarters.

Exhibition kitchens offer exciting opportunities to make your charbroiler part of the dining experience. These setups work beautifully when built into stone or brick surrounds, creating visual drama while maintaining full cooking functionality.

Key Features Checklist

When you're evaluating different charbroiler commercial options, focus on features that will make your daily operations smoother. Pilot ignition systems with cross-over tubes ensure reliable startup across all burners - no more frantically trying to light individual burners during prep time.

Splash guards and back panels protect your surrounding equipment from grease splatter and heat damage, potentially saving thousands in repairs down the road. Removable drip trays make grease management much easier, helping you maintain sanitation standards without wrestling with built-in collection systems.

Stainless steel construction throughout the unit ensures durability and makes cleaning easier for your staff. Insulated fireboxes improve heat retention while reducing energy waste - a feature that pays for itself over time through lower fuel costs.

Caster wheels might seem like a small detail, but they're invaluable for thorough cleaning or rearranging your kitchen layout. Look for heavy-duty casters that can handle the weight of a fully loaded commercial charbroiler.

Upkeep, Safety & Cost of Ownership

Your charbroiler commercial investment pays off when you maintain it properly. Think of it like a car - regular care keeps it running smoothly and prevents expensive breakdowns that could shut down your kitchen during peak hours.

The daily routine is simple but crucial. After service, let your charbroiler cool down completely before starting any cleaning. Scrape those grates while they're still warm (but not scorching hot), and empty the grease collection trays. This prevents buildup that can create nasty flavors or even fire hazards.

Weekly deep cleaning is where you really protect your investment. Remove the grates completely for thorough washing, and give your radiants or lava rocks a good inspection. If you're running a lava rock system, rotate those rocks weekly - they'll last longer and cook more evenly.

Lava rock charbroilers need extra attention, and that's just part of the deal. Those porous rocks that give you amazing flavor also absorb grease and food particles. Plan on replacing them every 3-6 months depending on how busy you are. Yes, it adds to your costs, but it's non-negotiable for food safety and performance.

Monthly inspections should cover the big picture items. Check that pilot lights are working properly, inspect gas connections for any leaks, and look over the overall structure for wear and tear. Schedule annual professional service calls for comprehensive safety checks and calibration - it's cheaper than emergency repairs.

If you've invested in a ceramic firebox unit, you're in luck. These single-piece fireboxes are built to last and rarely need replacement, unlike modular firebrick systems that may require periodic rebuilding. The upfront cost pays dividends in lower maintenance over time.

Maintenance Best Practices for charbroiler commercial Units

Smart maintenance starts with proper grease management. Clean grease traps daily and never let them overflow. Built-up grease isn't just gross - it's a fire waiting to happen. Keep spare grease collection containers on hand so you're never stuck with a full tray during busy periods.

Grate seasoning might sound fancy, but it's just treating your cast-iron grates like a good cast-iron pan. After cleaning, apply a thin layer of high-heat cooking oil and heat the grates briefly. This prevents rust and creates a better cooking surface.

Burner shield care is often overlooked but critical for even cooking. Clean these regularly to prevent grease buildup that can cause hot spots or flare-ups. Replace damaged shields immediately - they're inexpensive compared to the problems they prevent.

Temperature calibration matters more than most people realize. If your charbroiler is running too hot or too cool, you're wasting fuel and getting inconsistent results. Most units have adjustment screws for fine-tuning, but don't guess - use a proper thermometer to check temperatures.

Regulations, Ventilation & Safety Gear

NFPA 96 compliance isn't optional - it's the law. This standard governs commercial kitchen ventilation and fire suppression, and your local fire marshal takes it seriously. Most charbroiler commercial installations need Type I hoods with proper capture velocity and make-up air systems.

Hood filters need regular cleaning and replacement. Grease-laden filters reduce efficiency and create fire hazards. Many restaurants run two sets of filters so they can swap them out for cleaning without shutting down operations.

Fire suppression systems are typically required for gas and solid fuel charbroilers. These automatic systems detect excessive heat and deploy suppression agents before small problems become big disasters. Test them regularly and keep inspection records - your insurance company will thank you.

CO monitoring may be required in your area, especially for high-BTU installations or kitchens with limited ventilation. Carbon monoxide is invisible and deadly, so don't skip this safety measure if it's required.

Staff training is your best defense against accidents. Make sure everyone knows how to operate the equipment safely, what to do in emergencies, and how to recognize potential problems. A well-trained team prevents most accidents before they happen.

Financing options can help spread the cost of quality equipment over time, making it easier to invest in proper safety features and maintenance programs. Many restaurants find that monthly payments for reliable equipment cost less than emergency repairs on cheap units.

Warranty terms vary significantly between manufacturers. Some offer parts-only coverage, while others include labor and even preventive maintenance. Factor warranty coverage into your total cost of ownership - it can save thousands over the life of your equipment.

Frequently Asked Questions About Charbroiler Commercial Equipment

How does a charbroiler commercial deliver smoky flavor indoors?

The secret to that amazing smoky flavor lies in what happens when your food meets the flames. As meats and vegetables cook, their natural fats and juices drip down onto the hot surfaces below - whether that's ceramic radiants, lava rocks, or steel shields.

When these drippings hit surfaces heated above 400°F, they instantly vaporize and create aromatic compounds that rise back up to infuse your food. It's like having a tiny flavor factory working underneath every burger and steak.

Lava rock charbroilers take this process to the next level. The porous volcanic stone catches and holds these drippings, creating even more surface area for that flavor-producing vaporization. That's why many chefs swear by lava rock systems for delivering the most authentic grilled taste indoors.

Solid fuel charbroilers burning wood or charcoal add another layer of complexity, with the fuel itself contributing smoke compounds that penetrate the food. It's the closest you can get to outdoor barbecue flavor in a commercial kitchen setting.

What space and ventilation do I need for a charbroiler commercial?

Space planning for a charbroiler commercial unit involves more than just the footprint of the equipment itself. Most local fire codes require 6 to 18 inches of clearance on all sides for proper airflow and safety access.

The real challenge usually comes with ventilation requirements. Gas-fired charbroilers typically need 100 to 150 CFM per square foot of cooking surface under a Type I commercial hood. That means a 36-inch charbroiler might require 750-1,125 CFM of exhaust capacity.

Higher BTU units demand even more ventilation. A heavy-duty charbroiler pumping out 200,000+ BTUs will need substantial make-up air systems to replace all that exhausted air. Without proper make-up air, your kitchen can develop negative pressure that affects cooking performance and comfort.

Electric charbroilers offer more flexibility here. Many qualify for lighter ventilation requirements, and some smaller units can operate under Type II hoods in certain jurisdictions. This makes them perfect for spaces where installing major ventilation systems isn't practical.

How often should I replace lava rocks or ceramic radiants?

The replacement schedule for charbroiler components depends heavily on how hard you work your equipment. Lava rocks need the most attention - they should be rotated weekly to ensure even wear and replaced every 3 to 6 months in busy kitchens.

High-volume operations might need fresh lava rocks even more frequently. The porous stone gradually fills with grease and food particles that can't be cleaned out, eventually affecting heat distribution and flavor quality.

Ceramic radiants are much more durable, typically lasting 2 to 5 years with proper maintenance. They're designed to withstand the thermal cycling of commercial kitchens, but they can crack or chip if subjected to thermal shock from cold water hitting hot surfaces.

Steel radiants fall somewhere in between, usually needing replacement every 1 to 3 years in high-volume operations. They're less expensive than ceramic but don't retain heat as well or last as long.

The real champions for longevity are single-piece ceramic fireboxes found in premium units. These are engineered to last the entire life of the charbroiler, making them a smart investment for restaurants planning to stay in business for years to come.

Conclusion

Choosing the right charbroiler commercial equipment isn't just about buying a cooking appliance - it's about investing in your restaurant's flavor profile and customer satisfaction. The distinctive grill marks and smoky taste that only a quality charbroiler can deliver often become the signature elements that keep diners coming back.

Whether you've decided on gas radiant for its reliability and easy maintenance, lava rock for that authentic charcoal-like flavor, or electric for those tricky installations where gas isn't an option, the most important thing is finding equipment that matches your kitchen's workflow and volume needs.

At Charbroilers.com, we've spent years helping restaurant owners steer these decisions. From the busy steakhouse needing a heavy-duty 60-inch gas model to the small sandwich shop perfect for a compact countertop unit, we've seen how the right charbroiler transforms both kitchen efficiency and food quality.

The restaurant equipment industry keeps evolving, and today's charbroiler commercial units offer better energy efficiency, smarter heat distribution, and improved safety features compared to older models. Ceramic fireboxes last longer, infrared technology saves fuel costs, and modern pilot systems provide more reliable ignition.

By choosing quality equipment from the start and following proper maintenance schedules, you're making a future-proof investment. A well-maintained commercial charbroiler can serve your restaurant reliably for decades, paying for itself many times over through consistent food quality and customer satisfaction.

Our financing options are specifically designed for food service operations, making it easier to get the equipment you need without straining your cash flow. We understand that restaurants operate on tight margins, and the right financing can make the difference between settling for adequate equipment and getting exactly what your kitchen needs.

Ready to find your perfect charbroiler setup? Our team is here to help you sort through the options and find equipment that fits both your cooking needs and your budget.