The Definitive Guide to Comparing Commercial Freezers

Share

Why Commercial Freezers Are Essential for Professional Food Service

Running a successful food service operation means more than perfect recipes—it requires equipment that can keep pace with relentless demand. Commercial freezers do more than chill food; they safeguard inventory, streamline workflow, and keep health inspectors satisfied.

Unlike residential units, commercial freezers feature heavy-duty compressors, reinforced stainless-steel cabinets, and precise temperature controls engineered for constant door openings and fast recovery times. They’re built to survive the daily grind of busy kitchens, protect your bottom line, and preserve food quality.

In this definitive guide, you’ll learn why commercial units outperform household models, how to choose the right type for your space, and what features truly matter for efficiency and longevity. Whether you operate a neighborhood café or a high-volume restaurant, the insights that follow will help you invest wisely and keep your operation running cold, safe, and profitable.

Why Your Business Needs a Commercial Freezer (Not a Residential One)

I've watched too many restaurant owners try to cut corners with residential freezers, thinking they'll save money upfront. Trust me, it never ends well. The difference between commercial freezers and residential units isn't just about size—it's about survival in the demanding world of food service.

When you're running a kitchen where the freezer door opens fifty times a day, where heavy stock pots get loaded onto shelves, and where a temperature spike can mean throwing away hundreds of dollars in food, you need equipment that's built for the battle.

Commercial freezers are engineered specifically for high-traffic environments. They feature powerful compressors that recover temperature quickly after door openings, stainless steel construction that withstands daily abuse, and temperature consistency that keeps your food safe and your health inspector happy.

Built for the Rigors of a Professional Kitchen

Picture this: your prep cook opens the freezer door twenty times during the morning rush, loading and unloading heavy containers. A residential freezer would buckle under this pressure, but commercial freezers are built with high-grade materials and reinforced shelving that handle this workload without breaking a sweat.

The stainless steel construction isn't just for looks—it's about durability. These units resist scratches, dents, and the harsh cleaning chemicals you'll use daily. The door hinges are built to endure thousands of openings, and the shelving won't sag under the weight of bulk storage containers.

I've seen residential freezers fail in commercial kitchens within months. The compressor burns out from constant temperature recovery cycles, door seals fail from frequent openings, and shelving collapses under commercial loads. That's not just inconvenient—it's expensive and dangerous.

The heavy-duty use design extends to every component. From the thicker insulation to the commercial-grade gaskets, every part is engineered for longevity and investment protection. You're not just buying a freezer; you're investing in equipment that will serve your business for years.

Ensuring Food Safety and Compliance

Here's where things get serious. Food safety isn't negotiable in commercial kitchens, and commercial freezers are designed to keep you compliant with health department regulations.

Consistent temperature holding is crucial for preventing foodborne illness. While residential units struggle to maintain stable temperatures with frequent door openings, commercial freezers use powerful compressors and superior insulation to prevent food from entering the temperature danger zone.

The NSF certification that comes with commercial units isn't just a nice-to-have—it's often required by health department regulations. This certification ensures your freezer meets strict standards for materials, construction, and cleanability that residential units simply don't achieve.

Easy-to-clean surfaces and bacteria resistance are built into every commercial unit. The interior materials can withstand daily sanitization with commercial-grade chemicals, while residential units often deteriorate under such conditions. This isn't just about passing inspections—it's about protecting your customers and your reputation.

For detailed information about food safety standards, check out the FDA's safe food handling guidelines. These guidelines highlight why proper equipment is essential for maintaining food safety in commercial operations.

The bottom line? Commercial freezers aren't just bigger residential units—they're purpose-built tools for professional food service. When your business depends on reliable refrigeration, there's no substitute for commercial-grade equipment.

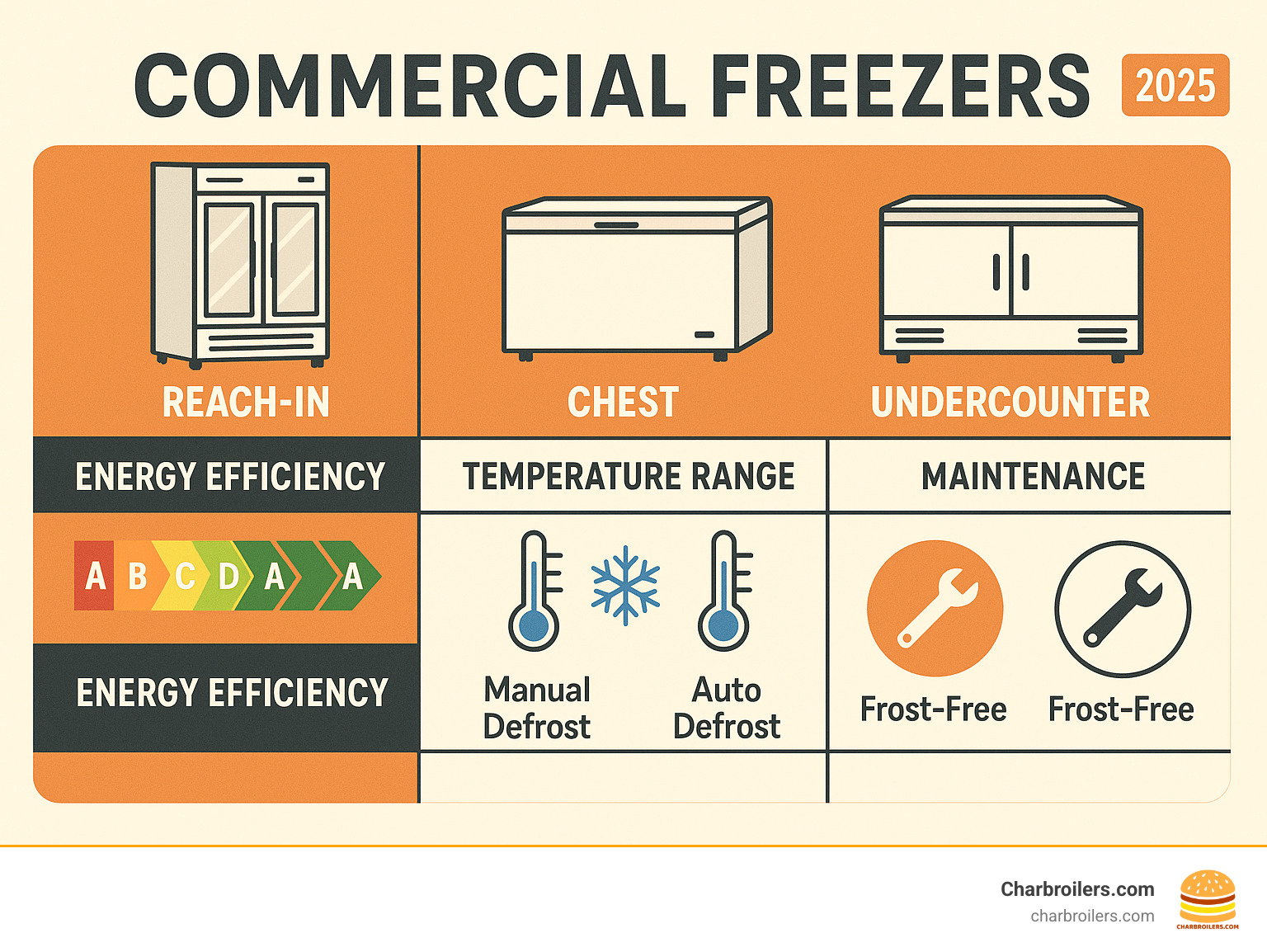

A Breakdown of Commercial Freezer Types

Selecting the right commercial freezer isn't just about capacity—it's about matching the equipment to your kitchen's workflow and space constraints. After years of helping restaurants optimize their setups, I've learned that the wrong freezer type can create bottlenecks that hurt efficiency, no matter how good the food is.

Let me walk you through the main types and when each one makes the most sense for your operation.

Upright & Reach-In Freezers

These vertical units are the backbone of most commercial kitchens, and for good reason. Upright freezers pack impressive storage capacity into a compact footprint, which is crucial when you're paying premium rent for kitchen space.

You'll find these units in sizes ranging from 23 to 72 cubic feet, with single, double, or triple door configurations. The adjustable shelving is a game-changer for organization—you can customize the interior layout as your menu changes or inventory needs shift.

The real decision comes down to solid doors versus glass doors. Solid door models offer better insulation and lower energy costs, making them perfect for back-of-house storage where staff knows what's inside. Glass door units shine in front-of-house applications or busy prep areas where quick visual inventory checks save time and prevent unnecessary door openings.

The vertical design means everything stays at eye level or within easy reach. No more digging through layers of frozen products like you would with a chest freezer. For keeping these workhorses running smoothly, our guide on Commercial Upright Frost-Free Freezers That Keep Their Cool covers the essential maintenance tips.

Chest Freezers

Chest freezers are the marathon runners of the freezer world—they're built for long-term storage and energy efficiency. The top-loading design works with physics instead of against it. Cold air naturally wants to settle at the bottom, so when you open the lid, you're not letting all that expensive cold air pour out onto the floor.

This makes chest freezers incredibly cost-effective for operations that store large quantities of frozen proteins, vegetables, or prepared items that don't need frequent access. The deep storage cavity can handle bulk storage like nobody's business.

The downside? Organization can feel like a treasure hunt. Items at the bottom tend to get forgotten, and it's easy to lose track of what you have. Smart operators use baskets or dividers to create zones within the chest, making inventory management much more manageable.

Chest freezers work best when you need to store large quantities of items for extended periods, have lower initial cost requirements, and don't need frequent access to frozen inventory.

Undercounter & Worktop Freezers

These space-saving units are all about putting frozen ingredients exactly where you need them. Instead of walking across the kitchen every time you need frozen toppings or ingredients, you have everything within arm's reach at your prep station.

Undercounter freezers typically range from 16 to 32 cubic feet and slide perfectly under prep tables or work surfaces. Some models even feature worktop surfaces that give you additional prep space—it's like getting two pieces of equipment in one footprint.

The magic happens in the workflow. Pizza stations with frozen toppings at hand level, prep areas with frozen ingredients right there, bar back areas with frozen garnishes and mixers—these units create point-of-use storage that dramatically improves kitchen efficiency.

For compact kitchens where every square inch counts, undercounter units can be the difference between a cramped, frustrating workspace and a smooth-running operation.

Walk-In Freezers

When you need maximum capacity for large-scale operations, walk-in freezers are in a league of their own. These aren't just big freezers—they're refrigerated rooms with insulated panels, proper doors, and remote compressor systems that keep the noisy, heat-generating equipment outside your kitchen.

Walk-ins are measured in square footage rather than cubic feet, with common sizes ranging from 6x6 feet to 12x16 feet or larger. The ability to actually walk inside makes inventory management and organization infinitely easier than trying to reach into even the largest upright unit.

These units are essential for large restaurants with high volume, catering businesses that need to store massive quantities for events, and any operation requiring pallet storage. The remote compressor system is a bonus—it reduces noise in your kitchen and takes the heat load off your HVAC system.

Walk-in freezers represent a significant investment, but for operations that need serious storage capacity, they're often the most cost-effective solution per cubic foot of storage space.

Key Features to Look for When Buying Commercial Freezers

When you're investing in commercial freezers, understanding the technical specifications makes all the difference between a purchase that serves your business well and one that becomes a costly headache. Let me walk you through the features that really matter for performance, efficiency, and your bottom line.

Calculating the Capacity for Your Commercial Freezers

Getting the capacity right is like finding the perfect pair of shoes—too small and you'll be cramped, too large and you're wasting money. The old rule of thumb suggests 1.5 to 2 cubic feet of freezer space per restaurant seat, but that's just a starting point.

Your menu complexity plays a huge role here. A pizza place with lots of frozen toppings needs different capacity than a steakhouse that primarily stores proteins. If you're getting deliveries twice a week instead of daily, you'll need extra space to bridge those gaps.

Think about your prep-ahead volume too. Do you batch-prep items for the week? That requires significantly more freezer space than operations that prep fresh daily. And don't forget about seasonal variations—holiday catering or summer ice cream sales can double your storage needs.

Before you fall in love with a specific unit, measure your available space carefully. Most commercial freezers need at least 6 inches of clearance on the sides and back for proper airflow. Skimp on this, and you'll have efficiency problems from day one.

Defrost Systems: Manual vs. Auto

The defrost system might seem like a minor detail, but it dramatically affects your maintenance routine and energy bills. Let's break down your three main options:

| Defrost Type | Energy Use | Maintenance | Temperature Consistency | Best For |

|---|---|---|---|---|

| Manual | Lowest | High (requires regular defrosting) | Good when properly maintained | Low-budget operations with dedicated maintenance staff |

| Auto/Cycle | Medium | Medium (some manual intervention) | Very Good | Most commercial operations |

| Frost-Free | Highest | Lowest (minimal manual intervention) | Excellent | High-volume operations prioritizing convenience |

Manual defrost systems are the most energy-efficient but require your staff to regularly scrape away ice buildup. It's like having a car with a manual transmission—more work, but you have complete control.

Auto-cycle defrost systems handle most of the work automatically but occasionally need some manual help. Think of it as a good compromise between efficiency and convenience.

Frost-free systems do everything automatically but use more energy running fans and defrost cycles. They're perfect for busy operations where staff time is more valuable than the extra energy cost.

If you're considering frost-free systems, check out our troubleshooting guide: Fixing Common Issues with Imperial Frost-Free Commercial Freezers.

Energy Efficiency and Refrigerants

Energy efficiency isn't just about being environmentally responsible—it's about protecting your profit margins. ENERGY STAR certified models can slash your energy consumption by 10-20% compared to standard units. Over a commercial freezer's typical 10-15 year lifespan, that adds up to thousands in savings.

Modern eco-friendly refrigerants like R290 (propane) offer excellent efficiency while reducing environmental impact. These natural refrigerants are becoming the industry standard as older, less efficient options get phased out.

The quality of insulation and gasket seals makes a huge difference in efficiency. Look for units with thick polyurethane foam insulation and magnetic door gaskets that seal completely. Well-insulated doors with minimal thermal bridging keep the cold in and your energy bills down.

For a complete database of certified energy-efficient models, visit ENERGY STAR's commercial freezer listings.

Construction and Safety Features

Stainless steel construction isn't just about looking professional—it's about durability, cleanability, and food safety. Look for 18-gauge or thicker stainless steel on high-wear areas like door handles and edges. Thinner materials will dent and scratch, creating places for bacteria to hide.

Essential features that make daily operations smoother include digital temperature displays for easy monitoring and door locks for security. Self-closing doors prevent accidental openings that waste energy and compromise food safety.

LED lighting provides better visibility while using less energy than traditional bulbs. Adjustable legs or casters make cleaning underneath easier and help you level the unit on uneven floors.

These features might seem like nice-to-haves, but they become essential when you're dealing with the daily demands of a busy kitchen.

Maintaining Your Investment: Longevity and Food Safety

Your commercial freezer is a significant investment that should serve your business for 15 years or more with proper care. I've watched too many restaurant owners learn this lesson the hard way—neglecting routine maintenance leads to premature failures, costly repairs, and food safety violations that could have been easily prevented.

The good news? Most freezer maintenance is straightforward and can be handled by your staff with minimal training. It's really about building good habits and staying consistent.

Essential Maintenance Practices

Think of freezer maintenance like changing the oil in your car—skip it, and you'll pay dearly later. Here's what needs to happen regularly to keep your unit running smoothly:

Weekly interior cleaning with approved sanitizers prevents bacteria buildup and keeps your freezer compliant with health codes. This isn't just about wiping down shelves—pay attention to corners, drainage areas, and any spots where food debris might accumulate.

Daily gasket cleaning might seem excessive, but those rubber door seals are your freezer's first line of defense against temperature loss. Food particles and grease can prevent proper sealing, forcing your compressor to work harder and driving up energy costs.

Monthly condenser coil cleaning is perhaps the most important task many operators skip. Dirty coils can't release heat efficiently, causing your freezer to work harder and potentially leading to compressor failure. A simple brush or vacuum usually does the trick.

Quarterly temperature monitoring with an independent thermometer ensures your built-in display is accurate. Temperature drift happens gradually, so regular checks catch problems before they compromise food safety.

Proper airflow maintenance means keeping vents clear and maintaining the manufacturer's recommended clearances around your unit. We've seen units fail simply because someone pushed them too close to a wall or stacked boxes on top.

Annual professional servicing is your insurance policy against major breakdowns. A qualified technician can spot worn components, refrigerant leaks, and electrical issues before they become expensive emergencies.

Troubleshooting Common Issues

Most commercial freezer problems give you warning signs before they become serious. Learning to recognize these early indicators can save you thousands in repair costs and prevent food loss.

Temperature fluctuations are often the first sign something's wrong. Before calling for service, check if your condenser coils need cleaning, examine door gaskets for damage, and make sure you're not overloading the unit. These simple fixes solve the majority of temperature issues.

Excessive frost buildup usually points to air leaks or defrost system problems. In manual defrost units, this might simply mean it's time for routine defrosting. For automatic systems, check that door gaskets are sealing properly and that nothing is blocking the defrost drain.

Strange noises shouldn't be ignored, but don't panic either. Sudden changes in sound often indicate loose components, worn fan motors, or compressor stress. While some operational noise is normal, new or louder sounds warrant investigation.

Door sealing problems compromise both efficiency and food safety. These issues usually stem from worn gaskets, damaged hinges, or improper leveling. Most are relatively inexpensive fixes if caught early, but they can lead to compressor failure if ignored.

For specific troubleshooting guidance on popular models, check our article on the Haier Commercial Frost-Free Freezer: The Coolest Kid on the Block.

A well-maintained commercial freezer not only lasts longer but also operates more efficiently, saving you money on energy costs while keeping your food safe and your health inspector happy.

Frequently Asked Questions about Commercial Freezers

How do I determine the right size freezer for my business?

Choosing the right size commercial freezer feels overwhelming at first, but it's actually pretty straightforward once you know what to consider. Start with the classic rule of thumb: 1.5 to 2 cubic feet of freezer space per restaurant seat. A 50-seat restaurant typically needs 75-100 cubic feet of freezer capacity.

But here's where it gets interesting—your specific operation matters more than any formula. A pizza place using lots of frozen toppings needs different capacity than a steakhouse with fresh proteins. Think about your menu complexity and how much frozen inventory you actually carry.

Your delivery schedule makes a huge difference too. If trucks arrive twice weekly, you can get by with less storage than operations receiving weekly deliveries. Seasonal variations also matter—ice cream shops need extra capacity for summer, while soup kitchens might need more during winter months.

Always measure your available kitchen space carefully, including that crucial 6-inch clearance for ventilation. We've seen too many perfect freezers that couldn't fit through doorways or didn't have proper airflow once installed.

What is the difference between a solid door and a glass door freezer?

The choice between solid and glass doors comes down to energy efficiency versus convenience. Solid door freezers are the energy champions—their superior insulation keeps temperatures more stable and reduces operating costs. They're perfect for back-of-house storage where you don't need to see what's inside.

Glass door models sacrifice some efficiency for visibility, but that trade-off often makes sense. Staff can see contents without opening the door, which actually saves energy in high-traffic situations. No more opening three different freezers to find the right ingredient during a busy dinner rush.

Glass doors shine in front-of-house applications like grab-and-go displays or bar back areas where quick visual inventory matters. They're also great for training new staff who are still learning where everything is stored.

The energy difference isn't dramatic with modern glass door technology, but it's worth considering for operations focused on minimizing utility costs.

How often should a commercial freezer be professionally serviced?

Annual professional servicing is the minimum for most commercial freezers, but think of it as insurance rather than expense. A yearly tune-up ensures your compressor, condenser, and electrical components are working correctly before small issues become expensive problems.

High-volume operations or units in harsh environments benefit from twice-yearly service. If your freezer gets opened constantly or operates in a particularly hot kitchen, the extra maintenance pays for itself in prevented breakdowns.

The timing matters too. Schedule service during slower periods when you can afford brief downtime. Many operators choose spring maintenance to prepare for busy summer months.

Professional service catches problems your daily maintenance might miss—things like refrigerant levels, electrical connections, and compressor efficiency. The cost of preventive maintenance is always less than emergency repairs or premature replacement, especially when you factor in lost inventory from unexpected failures.

A well-maintained commercial freezer can last 15 years or more, while neglected units often fail within 5-7 years. That annual service call is protecting a significant investment in your operation's future.

Conclusion

Investing in the right commercial freezer isn't just about buying equipment—it's about setting your business up for long-term success. After helping hundreds of food service operations choose their freezers, I've seen how the right decision can transform a kitchen's efficiency and profitability.

The most important lesson? Never cut corners by using residential units in commercial settings. What seems like a money-saving decision upfront almost always becomes an expensive mistake. Commercial-grade equipment pays for itself through reliability, efficiency, and compliance with health codes.

When selecting your commercial freezer, focus on matching the equipment to your actual needs. A small café doesn't need a massive walk-in freezer, just like a high-volume restaurant can't rely on a single undercounter unit. Size your freezer based on your menu complexity, delivery schedule, and growth plans—not just the space you have available.

Energy efficiency deserves serious consideration too. An ENERGY STAR certified freezer might cost more initially, but it'll save you money every month for the next 10-15 years. With rising energy costs, those savings add up quickly.

Don't forget about maintenance. The best commercial freezer in the world won't serve you well if it's not properly maintained. Set up a routine maintenance schedule from day one to protect your investment and ensure consistent performance.

At Charbroilers.com, we know that purchasing commercial equipment represents a significant investment for any food service operation. That's why we offer financing options specifically designed for restaurants and food service businesses. You shouldn't have to choose between quality equipment and healthy cash flow.

Whether you're opening your first restaurant or upgrading an existing kitchen, the right freezer will serve your business reliably for years to come. For detailed insights on specific models and their real-world performance, check out our review of the Frigidaire Frost-Free Commercial Upright Freezer Keeps Your Business Chill.

Making an informed decision now prevents costly problems later. Your food stays at optimal quality, your staff works more efficiently, and you avoid the headaches that come with equipment failures. Most importantly, you'll have the peace of mind that comes with knowing your frozen ingredients are stored safely and compliantly.

Your customers deserve the best, and that starts with having the right equipment in your kitchen. Invest in proper commercial-grade freezers from the start—your business will thank you for it.