Freezing Fast: Top Commercial Blast Chillers for Every Business

Share

Why Your Kitchen Needs Commercial Blast Freezing Technology

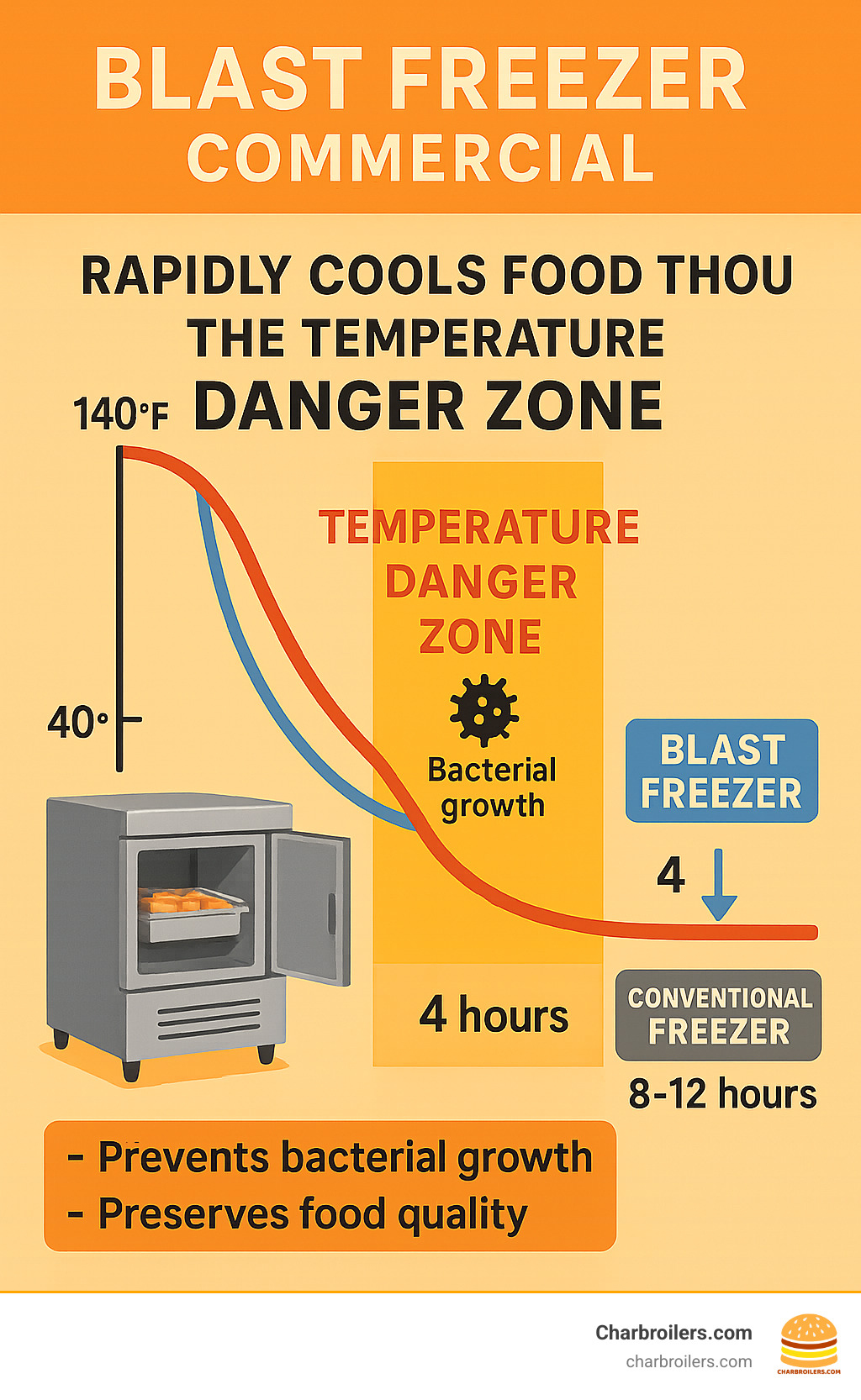

Blast freezer commercial units are specialized refrigeration equipment designed to rapidly cool hot food through the temperature danger zone (140°F to 40°F) in just 90 minutes to 4 hours, compared to conventional freezers that can take 8-12 hours or longer.

Quick Commercial Blast Freezer Guide:

- Blast Chilling: Cools food from 140°F to 40°F in under 4 hours

- Shock Freezing: Freezes food from 140°F to -10°F in under 4 hours

- Key Benefits: Prevents bacterial growth, preserves food quality, reduces waste

- Temperature Range: Can reach as low as -40°F (-40°C)

- Main Types: Countertop (15-30 lbs), Reach-in (60-240 lbs), Roll-in (480+ lbs)

- Price Range: $4,200 - $50,000+ depending on capacity and features

Every busy commercial kitchen faces the same challenge: how to safely cool large quantities of hot food without compromising quality or risking food safety violations. Traditional walk-in coolers simply weren't designed for this task - they're meant to hold cold food, not rapidly cool hot food.

Blast freezers solve this problem by using high-velocity fans and extremely cold temperatures to create small ice crystals that preserve food texture and flavor. This rapid cooling process also helps you meet HACCP requirements by quickly moving food through the bacterial danger zone where harmful pathogens multiply rapidly.

Beyond food safety, these units can transform your kitchen operations. You can prep meals days in advance, reduce food shrinkage by up to 5%, and expand your menu offerings without increasing labor costs during peak service times.

I'm Sean Kearney from Charbroilers.com, and with over a decade in the restaurant equipment industry, I've helped countless operators choose the right blast freezer commercial solution for their specific needs and budget. My experience in the e-commerce and restaurant supply sectors has shown me that the right equipment investment can dramatically improve both food safety and profitability.

Learn more about blast freezer commercial:

- commercial upright frost free freezer

- nsf ansi standard 7 commercial refrigerators and freezers

- small commercial freezer

What is a Blast Freezer and Why is it a Kitchen Game-Changer?

Picture this: it's the end of a busy dinner rush, and you've got trays of perfectly prepared food that need to be cooled and stored safely. Your regular walk-in cooler would take hours to bring those items to safe temperatures—plenty of time for bacteria to throw their own little party in your food. That's where a blast freezer commercial unit steps in like the kitchen superhero you never knew you needed.

A blast freezer commercial unit is designed to rapidly chill and freeze food at lightning speed compared to conventional freezers. While your standard freezer takes its sweet time—sometimes 8 to 12 hours—to freeze food properly, a blast freezer gets the job done in 90 minutes to 4 hours. This isn't just about convenience; it's about food safety and maintaining the highest quality standards in your kitchen.

The rapid cooling process is essential for HACCP compliance, helping you meet those strict food safety regulations that keep your business running smoothly. By quickly moving food through the Temperature Danger Zone, you're dramatically reducing food waste and protecting your customers from foodborne illness.

But here's where it gets really exciting: the speed of blast freezing creates small ice crystals instead of the large, destructive ones that form during slow freezing. Those tiny crystals are gentle on your food's cell structure, which means preserved texture and flavor that your customers will notice. No more soggy vegetables or mushy proteins after thawing—your food maintains its integrity and quality.

This translates directly to improved food quality and profitability. When your frozen items taste as good as fresh, you can expand your prep-ahead capabilities without sacrificing the dining experience.

The Science of Speed: How Blast Freezing Works

The magic happens through a combination of rapid air circulation and intense cold temperatures. Powerful fans work overtime to circulate super-cold air around your food, creating an efficient heat exchange that pulls warmth away faster than you'd think possible.

The real target here is getting food through the Temperature Danger Zone (140ºF–40ºF) as quickly as possible. This temperature range is where bacterial growth loves to happen, so the faster you move through it, the safer your food becomes.

Many units come equipped with core temperature probes that monitor your food's internal temperature in real-time. This precision takes the guesswork out of the process and ensures consistent results every time.

It's worth noting the difference between shock freezing and blast chilling. Blast chilling brings food down to refrigeration temperatures (around 40°F), while shock freezing takes it all the way down to frozen storage temperatures—often as low as -40°F. Both processes are game-changers for different applications in your kitchen.

Opening Up Major Benefits for Your Food Service Operation

Installing a blast freezer opens up a world of possibilities that can transform how your kitchen operates. Minimized preparation times become a reality when you can engage in batch cooking during slower periods, then blast freeze portions for quick service during peak hours.

This capability leads to incredible menu expansion opportunities. Want to offer house-made ice cream or delicate frozen desserts? A blast freezer makes it possible while maintaining professional quality. You can prep complex dishes days in advance without compromising on taste or presentation.

The financial benefits are equally impressive. Reduced food shrinkage happens because rapid freezing locks in moisture, preventing the weight and quality loss that occurs with slower methods. Extended shelf life means less food hits the trash can at the end of the day, directly improving your bottom line.

Meeting NSF compliance standards becomes much easier when you have equipment specifically designed to handle rapid cooling safely and efficiently.

The result? Dramatically improved operational efficiency that pays for itself over time. Your staff works smarter, not harder, your food quality stays consistent, and your profit margins get healthier. It's the kind of investment that makes you wonder how you ever managed without it.

Your Guide to Choosing the Right Commercial Blast Freezer

Finding the perfect blast freezer commercial unit for your kitchen doesn't have to feel overwhelming. Think of it like choosing a reliable team member—you want someone who fits your space, handles your workload, and makes your life easier every day.

The secret to making the right choice lies in honestly assessing your kitchen's specific needs. Start by asking yourself some practical questions: How much food do you need to freeze daily? Are you a cozy bakery focusing on delicate pastries, or a busy restaurant handling hundreds of pounds of proteins? Do you have plenty of floor space, or are you working with every square inch?

Your capacity needs should drive your decision. A small café might thrive with a countertop unit that handles 15-30 pounds, while a large hotel kitchen will need a roll-in model that processes 480+ pounds at once. Your kitchen footprint is equally important—there's no point falling in love with a massive unit if it won't fit through your door or leaves your staff cramped.

Temperature range capabilities matter more than you might think. While most units reach impressive lows of -40°F, some specialized operations need even more extreme temperatures. Finally, consider energy efficiency—a more efficient unit saves money month after month, making it a smarter long-term investment.

| Model Type | Capacity (Approx.) | Size/Footprint | Best Use Case |

|---|---|---|---|

| Countertop | 15-30 lbs (3-5 trays) | Small, compact | Bakeries, small cafes, specialty dessert shops, home/light commercial |

| Reach-in | 60-240 lbs (5-15 trays) | Medium, upright | Restaurants, catering, medium-sized food production |

| Roll-in | 480+ lbs (1-2 trolleys) | Large, floor-standing | Large-scale food production, commissaries, banquet facilities, hotels |

Sizing Up Your Options: Types of Blast Freezers

Commercial blast freezers come in several configurations, each designed to solve different kitchen challenges. Understanding these options helps you match the right tool to your specific workflow.

Reach-in models are the workhorses of the blast freezer world. Picture them as the reliable station wagon of commercial freezers—they look like an upright refrigerator but pack serious freezing power. These units typically accommodate 5 to 15 trays, making them perfect for most restaurants and catering operations. They fit nicely into existing kitchen layouts without demanding major renovations.

Roll-in and pass-thru models are the heavy-duty trucks of blast freezing. These large units are game-changers for high-volume operations because you can roll entire racks or trolleys of food directly inside. Imagine prepping hundreds of portions, loading them onto a trolley, and simply rolling the whole thing into the freezer. Some models handle one to two trolleys, processing hundreds of pounds at once. For truly massive operations, there are even containerized units that can freeze 20,000 pounds daily.

Countertop units prove that good things come in small packages. These compact powerhouses are perfect for specialty shops, smaller kitchens, or operations with limited space. They're ideal for bakeries focusing on pastries, ice cream shops, or restaurants that need to freeze smaller batches of meal components. Some models are even designed for light commercial use, making blast freezing technology accessible to smaller businesses.

Undercounter models offer similar capacity to countertop units but slip neatly beneath existing counters. They're space-saving champions that give you blast freezing power without sacrificing valuable prep space above.

Key Features of a Blast Freezer Commercial Model

The features packed into modern blast freezer commercial units can make the difference between a good investment and a great one. Understanding these capabilities helps you choose a unit that truly serves your operation.

Adjustable cooling cycles give you the flexibility to handle different types of food properly. Most units offer settings like soft chill for delicate items such as pastries or sauces, and hard chill for dense products or items heading into long-term storage. This versatility means one unit can handle your entire range of products without compromising quality.

Temperature probes are your precision tools for food safety. These detachable probes monitor the internal temperature of your food in real-time, ensuring everything reaches the exact safe temperature required. This precision is vital for HACCP compliance and gives you confidence that every batch meets safety standards.

Smart defrost cycles work behind the scenes to keep your unit running efficiently. Automatic defrosting prevents ice buildup that can slow performance and damage equipment. The best units optimize these cycles to use energy wisely while maintaining peak performance.

Modern units increasingly use environmentally friendly refrigerants like R290 (propane), which have lower environmental impact compared to older refrigerants. This choice reflects both environmental responsibility and often improved efficiency.

Stainless steel construction throughout the interior and exterior isn't just about looks—it's about durability and hygiene. Look for thoughtful design elements like rounded corners and removable components that make thorough cleaning straightforward and sanitary.

Digital controls transform complex processes into simple programming. Intuitive displays make it easy to set cycles and monitor progress. Advanced units even offer diagnostic features for remote monitoring of performance, helping you spot potential issues before they become problems.

The airflow design might not be visible, but it's crucial for performance. Units with well-engineered evaporator fan systems and adjustable airflow ensure uniform cooling across all food products, even those that might typically resist heat removal.

Some premium units feature automatic changeover capabilities that switch between blast freezing and holding modes automatically. This prevents over-processing delicate items and can reduce operating costs by optimizing energy use.

Maximizing Your Investment: Operations and Maintenance

A blast freezer commercial unit is a significant investment, and like any valuable piece of equipment, it requires proper operation and diligent maintenance to ensure its longevity, efficiency, and continued contribution to your kitchen's success.

Think of your blast freezer as a high-performance athlete—it needs the right fuel, proper care, and regular check-ups to perform at its peak. While these units do work harder than conventional freezers during their rapid cooling cycles, smart operation can keep your energy costs manageable and your equipment running smoothly.

Energy consumption becomes much more efficient when you follow proper loading techniques. The golden rule? Don't pack your blast freezer like you're playing Tetris. Overloading restricts airflow, forcing the compressor to work overtime and slowing down the entire freezing process. Instead, distribute food evenly on trays, leaving space for air to circulate freely around each item.

Cleaning procedures aren't just about keeping things looking nice—they're essential for both food safety and equipment efficiency. Daily wipes of interior surfaces and trays prevent buildup that could harbor bacteria or create unpleasant odors. But the real maintenance heroes are often overlooked: gasket checks and condenser cleaning.

Those rubber door seals might seem minor, but damaged gaskets can turn your precision freezing unit into an energy-guzzling disappointment. Check them weekly for cracks or wear, and replace them promptly when needed.

Condenser coil maintenance is where many operators drop the ball. A dirty condenser is like trying to run a marathon while breathing through a straw—everything becomes harder and less efficient. Dust and debris on these coils can dramatically increase your energy bills and lead to unexpected breakdowns.

Here's your simple weekly maintenance routine that takes just minutes but saves you thousands:

- Wipe down interior and exterior surfaces with food-safe cleaner

- Check door gaskets for cracks, tears, or signs of wear

- Clean the condenser coil using a brush or vacuum to remove dust and debris

- Inspect temperature probes for damage and cleanliness

- Verify drains are clear and free of blockages

- Review temperature logs to ensure consistent performance

Ensuring Food Safety and HACCP Compliance

Your blast freezer commercial unit isn't just about convenience—it's your frontline defense against foodborne illness. This means treating temperature logging and critical control points with the seriousness they deserve.

Every batch of food that goes through your blast freezer should tell a complete story through documentation. Record the food's starting temperature, when it entered the unit, what core temperature it reached, and when you removed it. This isn't just paperwork for the sake of paperwork—it's your proof that you're following proper food safety protocols and meeting HACCP requirements.

The magic number for preventing cross-contamination is moving food through the danger zone (140°F to 40°F) within four hours. Your logs should consistently reflect this timeline, giving you confidence during health inspections and peace of mind about the safety of every dish you serve.

Staff training makes all the difference between a blast freezer that improves your operation and one that becomes a liability. Your team needs to understand proper loading techniques, cleaning procedures, and why these protocols matter. When everyone knows the why behind the what, compliance becomes second nature rather than a chore.

Even the best-maintained equipment can occasionally hiccup. When issues arise, having a troubleshooting plan helps you address problems quickly before they impact your service. For comprehensive guidance on common freezer problems and solutions, check out our detailed guide on Fixing Common Issues with Commercial Freezers.

Maintenance for Your Blast Freezer Commercial System

A well-maintained blast freezer commercial system is like a reliable kitchen team member—it shows up every day, performs consistently, and rarely causes headaches. Achieving this reliability requires a three-tier approach: daily cleaning, weekly checks, and professional servicing.

Daily cleaning sets the foundation for everything else. After each use, wipe down interior and exterior surfaces, removing any food spills immediately. This simple habit prevents odors from developing, stops bacterial growth in its tracks, and keeps your unit looking professional. Think of it as brushing your teeth—a small daily effort that prevents much bigger problems down the road.

Your weekly checks are where you catch small issues before they become expensive repairs. Beyond the checklist mentioned earlier, pay special attention to your auto-defrost function. Ice buildup isn't just unsightly—it reduces efficiency and can damage internal components. A properly functioning auto-defrost system should keep ice formation minimal without running constantly.

Professional servicing is your insurance policy against unexpected breakdowns. Schedule periodic maintenance with a qualified technician who can perform deeper cleaning, check refrigerant levels, inspect electrical components, and spot potential problems with an experienced eye. This proactive approach typically costs a fraction of emergency repairs and keeps your unit operating at peak efficiency.

Understanding your specific model's quirks and requirements makes maintenance much easier. Every manufacturer provides detailed instructions for their equipment, and following these guidelines ensures you don't void warranties or miss critical maintenance steps.

The bottom line? Proper maintenance isn't an expense—it's an investment that protects your larger investment and keeps your kitchen running smoothly. When your blast freezer commercial system is well-maintained, it becomes one less thing to worry about during busy service periods, letting you focus on what matters most: serving great food to happy customers.

Frequently Asked Questions about Commercial Blast Freezers

After helping countless kitchen operators choose the right equipment, I've noticed the same questions come up again and again about blast freezer commercial units. Let me share the answers to the most common ones that might be on your mind too.

What is the main difference between a blast freezer and a conventional freezer?

Think of it this way: a conventional freezer is like taking a leisurely stroll through a park, while a blast freezer is like sprinting to catch the last train. The speed makes all the difference.

A blast freezer commercial unit uses powerful fans to circulate extremely cold air at high velocity, freezing food in a matter of hours rather than the 8-12 hours a conventional freezer might take. But here's where it gets really interesting - this speed isn't just about convenience.

When food freezes slowly in a conventional freezer, large ice crystals form inside the food cells. These big crystals are like tiny bulldozers, bursting through cell walls and causing serious damage. That's why your frozen strawberries turn mushy when thawed, or why that beautiful piece of fish becomes dry and flaky.

A blast freezer creates small ice crystals that slip between cells without causing damage. The result? Your food maintains its original texture, flavor, and nutritional value. It's the difference between food that tastes fresh when thawed versus food that clearly tastes "previously frozen."

How cold does a commercial blast freezer get?

While your typical home freezer might reach 0°F (-18°C) and call it a day, commercial blast freezers are in a completely different league. Most blast freezer commercial units can reach temperatures of -40°F (-40°C), and some specialized models can go even colder.

This extreme cold is what makes the magic happen. Combined with those high-velocity fans I mentioned, these ultra-low temperatures enable the rapid "shock freezing" process that's essential for maintaining food safety and quality.

The exact temperature your unit reaches will depend on the model and manufacturer, but rest assured - they're all designed to get cold enough to freeze food faster than you ever thought possible.

Can a blast freezer be used for chilling as well?

Here's some great news: most modern units are actually combination blast chillers and freezers, making them incredibly versatile workhorses in your kitchen.

These smart machines come with different settings to handle whatever you throw at them. Need to rapidly cool delicate pastries or sauces without freezing them solid? Use the "soft chill" setting. Working with dense items like roasts or thick stews that need aggressive cooling? Switch to "hard chill" mode.

And of course, when you need that deep-freeze function for long-term storage, it's ready to go. This versatility means one blast freezer commercial unit can handle multiple tasks - from preparing ingredients for immediate service to preserving them for busy periods ahead.

It's like having three pieces of equipment rolled into one, which is especially valuable when kitchen space is at a premium.

Conclusion

Investing in a blast freezer commercial unit represents a turning point for your food service operation. It's not just another piece of equipment taking up space in your kitchen—it's your secret weapon for changing how you handle food safety, quality, and efficiency all at once.

Think about it: every time you rapidly cool food through that critical temperature danger zone, you're doing three powerful things simultaneously. You're preserving the food's natural texture and flavor by creating those tiny ice crystals we talked about earlier. You're extending shelf life dramatically, which means less food heading to the dumpster at the end of the week. And perhaps most importantly, you're meeting those strict HACCP standards that keep your customers safe and your business protected.

The ripple effects on your daily operations are remarkable. Suddenly, you can prep tomorrow's specials during today's slow period. Your kitchen staff isn't scrambling during the dinner rush because half the work is already done. You can say "yes" to that catering order that seemed impossible before, or finally add those delicate desserts to your menu that you've been dreaming about.

All of these improvements add up to something every food service operator cares about: better profitability. When you reduce waste, speed up service, and expand what you can offer, your bottom line notices.

We know that taking the leap on commercial equipment can feel like a big decision. That's exactly why we've structured our financing options to work with the realities of running a food service business. We want to make it easier for you to get the tools that will make your operation more successful.

Ready to explore what a blast freezer commercial unit could do for your kitchen? We're here to help you find the perfect fit for your space, volume, and budget. And while you're planning your equipment upgrades, don't forget to explore our guide to commercial upright freezers for even more ways to keep your ingredients at their peak.

Your customers deserve the best quality food you can serve, and you deserve equipment that makes that goal achievable every single day.