Decoding Ovens: A Guide to Conventional and Convection Cooking

Share

Understanding Conventional and Convection Ovens: What's the Difference?

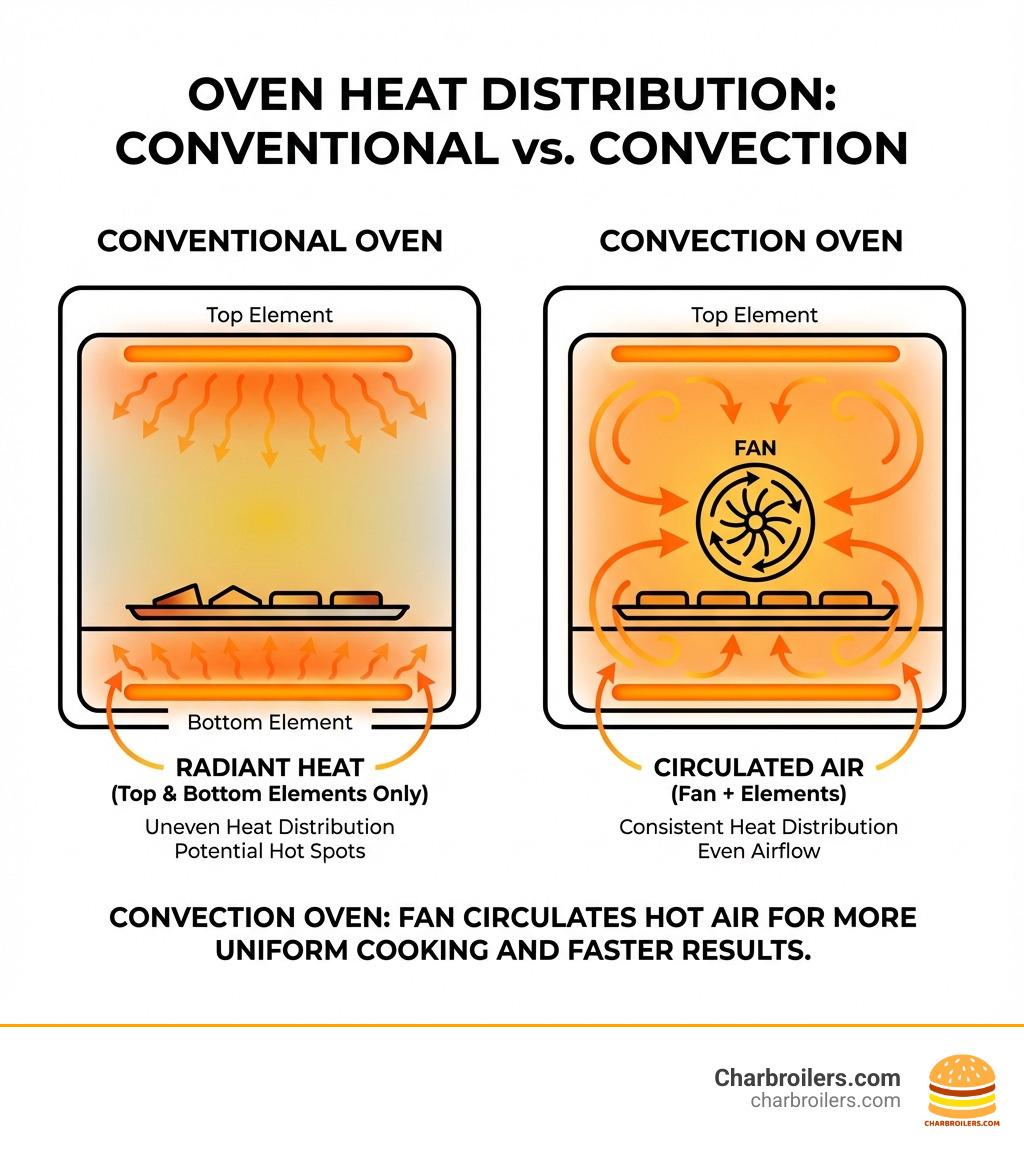

Conventional ovens are the traditional workhorses found in most kitchens, using top and bottom heating elements to cook food through radiant heat. Unlike convection ovens, they don't circulate air with a fan, which means heat rises naturally and can create hot spots.

Quick Comparison:

| Feature | Conventional Oven | Convection Oven |

|---|---|---|

| Heat Source | Top and bottom elements only | Elements plus internal fan |

| Heat Distribution | Radiant, can be uneven | Circulated, more consistent |

| Best For | Delicate cakes, custards, quick breads | Roasting meats, multi-rack baking, crisping |

| Cooking Speed | Standard timing | 25% faster on average |

| Cost | Generally lower | Higher upfront investment |

If you run a busy commercial kitchen, understanding the difference between these two oven types matters. Conventional ovens work well for traditional baking and dishes that need a still environment, while convection models excel at high-volume roasting and achieving crispy, evenly browned results.

The key difference comes down to airflow. Conventional ovens rely on heat radiating from stationary elements at the top and bottom of the cavity. This creates distinct heat zones—hotter near the elements, cooler in the middle. That's why recipes often call for rotating pans halfway through cooking.

Convection ovens add a fan and sometimes a third heating element to circulate hot air throughout the cavity. This moving air eliminates cold spots, speeds up cooking, and helps achieve consistent browning across multiple racks—a huge advantage when you're cooking at scale.

I'm Sean Kearney from Charbroilers.com, and I've spent over a decade helping restaurant owners select the right equipment for their kitchens, including conventional ovens and convection models that deliver consistent results under demanding commercial conditions. Whether you're upgrading your baking station or expanding your prep line, choosing the right oven type directly impacts your cooking efficiency and food quality.

Terms related to conventional ovens:

The Anatomy of an Oven: Conventional vs. Convection

Understanding how an oven generates and distributes heat is fundamental to mastering its use in a commercial kitchen. Both conventional ovens and convection ovens achieve high temperatures, but their methods of heat transfer create distinct cooking environments.

At its core, any oven works by dispersing heat throughout an oven compartment to accomplish various cooking tasks, from crisping pastries to melting cheese, browning meats, or baking tender cakes. The heat source—whether gas or electric—is crucial, but it's the method of distribution that truly defines the oven type.

How Traditional Conventional Ovens Work

A conventional oven, sometimes referred to as a traditional, regular, thermal, or radiant oven, operates with heating elements typically located at both the bottom and the top of the oven cavity. These elements generate heat directly, which then radiates throughout the oven. This is primarily a static heat environment, meaning the air inside the oven largely remains still.

The primary heating mechanisms are:

- Bottom Element (Bake Element): This is the main workhorse for most baking and roasting. Heat radiates upwards from this element, gently enveloping food. It's excellent for cooking items from the bottom up, providing a solid base heat.

- Top Element (Broil Element): Positioned at the top of the oven, this element provides intense, direct heat from above. It's designed for broiling, quickly browning, charring, or searing the top surface of dishes. Think of achieving a crispy gratin topping or perfectly seared fish.

Because heat primarily radiates and rises in a conventional oven, it naturally creates different heat zones. The areas closest to the active heating elements will be hottest, leading to what we call "hot spots." This can result in uneven cooking, where the dish closest to an active heating element may cook the fastest or brown more quickly. This inherent characteristic means that careful rack placement is essential, and rotating dishes halfway through cooking is often recommended to ensure uniform results.

The Convection Difference: A Fan-Powered Approach

In contrast to the static heat of conventional ovens, convection ovens introduce a dynamic element: airflow. A convection oven incorporates an internal fan and an exhaust system that actively circulates hot air around the oven cavity. This fundamental difference is what allows convection ovens to cook more evenly and often more quickly.

The fan system works to distribute heat uniformly, eliminating the hot and cold spots common in conventional ovens. This constant movement of hot air helps to:

- Even Heat Distribution: Ensures that every part of the food, and every dish on every rack, receives consistent heat.

- Faster Cooking: Circulating hot air transfers heat more efficiently to the food, reducing overall cooking times.

- Improved Browning and Crisping: The moving air helps to quickly evaporate moisture from the food's surface, promoting superior browning and crisping, which is ideal for roasted meats and vegetables.

Some advanced convection ovens, known as "True Convection" or "European Convection" models, take this a step further by including a third heating element located near the fan. This additional element preheats the air before it's circulated, ensuring even more precise and consistent temperatures throughout the oven. This is particularly beneficial for multi-rack cooking, allowing you to bake multiple batches of cookies or roast several pans of vegetables simultaneously without needing to rotate them. Our team at Charbroilers.com can confirm that for high-volume commercial kitchens, the efficiency and consistency of convection can be a game-changer. For a deeper dive into how these systems operate, you might find our guide on Demystifying Commercial Convection Ovens: A Deep Dive into Their Operation insightful.

Performance and Efficiency: A Head-to-Head Comparison

When equipping a commercial kitchen, understanding the performance and efficiency differences between conventional ovens and convection ovens isn't just about cooking methods—it's about operational costs, consistency, and speed. Let's stack them up.

| Feature | Conventional Oven | Convection Oven |

|---|---|---|

| Cooking Speed | Standard timing; can be slower due to hot spots. | Up to 25% faster; circulating air transfers heat more efficiently. |

| Temperature Accuracy | Can have hot spots and uneven heating. | More consistent temperatures throughout the cavity due to fan circulation. |

| Energy Efficiency | Generally less efficient; longer cook times, heat loss. | More energy-efficient; lower temperatures and shorter cook times, better insulation. Many are ENERGY STAR® rated. |

| Cost | Lower upfront purchase price. | Higher upfront cost due to added technology (fan, sometimes third element). |

| Best Use Cases | Delicate baked goods, custards, soufflés, slow cooking. | Roasting meats/vegetables, multi-rack baking, crisping, sheet pan dinners, dehydrating. |

Cooking Speed: A key advantage of convection ovens is their speed. The fan-forced air circulates hot air directly around the food, transferring heat more effectively than the static radiant heat of a conventional oven. This means dishes cook faster—often up to 25% quicker. For a busy restaurant, this can significantly improve kitchen throughput and reduce wait times for customers. As our experts at Charbroilers.com know, every minute counts in a commercial setting.

Temperature Accuracy and Consistency: In a conventional oven, heat radiates from the elements, creating a less uniform temperature environment. You'll often find hotter spots near the elements and cooler spots elsewhere. This necessitates rotating pans for even cooking. Convection ovens, with their circulating air, maintain a far more consistent temperature throughout the cavity, ensuring uniform cooking and browning across all racks. This consistent cooking is a major benefit for quality control in a professional kitchen.

Energy Efficiency: While conventional ovens are simpler in design, convection ovens often prove more energy-efficient in the long run. Their ability to cook at lower temperatures (typically 25°F less than a conventional oven) and for shorter durations means less energy consumption per dish. Many commercial convection ovens are also designed with advanced insulation and sealed cooking chambers, further contributing to energy savings. We often see ENERGY STAR® rated convection models that help businesses reduce their utility bills. Understanding how different ovens work, including their energy consumption and heat transfer methods, is vital for any business owner. For a broader technical overview of oven operation at the consumer level, you can also review how ovens work to cook food.

Cost Comparison: Generally, conventional ovens have a lower upfront purchase price. Their simpler construction and fewer mechanical parts make them more budget-friendly initially. Convection ovens, with their added fan mechanisms and sometimes a third heating element, tend to have a higher initial investment. However, when considering the total cost of ownership for a commercial operation, the energy savings and increased efficiency of a convection oven can often offset the higher purchase price over time. This makes the decision a balance between immediate budget and long-term operational efficiency.

The Culinary Decision: When to Use Conventional Ovens

Choosing between a conventional oven and a convection oven isn't about one being inherently "better" than the other; it's about selecting the right tool for the culinary task at hand. Just like a skilled chef knows when to use a charbroiler versus a griddle, knowing your oven's strengths is key.

While convection ovens boast speed and evenness, there are specific dishes and cooking methods where the still, radiant heat of a conventional oven truly shines. The key is understanding how the heat interacts with different food textures and structures.

Best Dishes for the Still Heat of Conventional Ovens

The gentle, undisturbed environment of a conventional oven is often preferred for dishes that are delicate, rely on slow, steady heat, or require a specific rise without being dried out or skewed by circulating air. Here’s where conventional ovens truly excel:

- Delicate Cakes and Quick Breads: For items like angel food cakes, soufflés, custards, and quick breads, the still air prevents the delicate structure from being disturbed, allowing them to rise evenly and set properly without drying out the surface too quickly. Recipes that rely on the expansion of air bubbles to rise, like yeast breads, often fare better in this tranquil environment.

- Custards and Soufflés: These delicate mixtures benefit from the humid, even heat that doesn't agitate their structure, preventing cracks or uneven setting.

- Casseroles and Pasta Bakes: For dishes that need to cook through slowly and develop a rich, bubbly top, conventional ovens are perfect. The radiant heat ensures the interior is thoroughly cooked while the top browns gradually.

- Braising and Slow Cooking: When you want to tenderize large cuts of meat or slowly cook stews, the consistent, gentle heat of a conventional oven provides a stable environment for long cooking times, allowing flavors to meld beautifully. The slightly more humid interior of a conventional oven can also be beneficial for keeping these dishes moist.

The primary advantage here is the lack of forced air, which means less risk of drying out delicate items or causing uneven rising. For many traditional recipes, particularly those passed down through generations, a conventional oven remains the gold standard, providing the familiar results we've come to expect.

When Convection Cooking is the Superior Choice

On the flip side, when you're aiming for speed, crispness, or cooking multiple items at once, convection is your go-to.

- Roasting Meats and Vegetables: The circulating hot air creates a delicious, crispy exterior on roasted chicken, turkey, or vegetables, while keeping the interior juicy. It's fantastic for achieving that perfect golden-brown finish.

- Sheet Pan Dinners: Convection allows for even cooking across an entire sheet pan, ensuring all ingredients are cooked through and beautifully caramelized, without having to rotate the pan.

- Multiple Batches of Cookies/Pastries: If you're baking large quantities, a convection oven can cook several trays at once, with consistent results across all racks, saving significant time and effort.

- Dehydrating and Air Frying: The drier, circulating heat of a convection oven is ideal for dehydrating fruits or making crispy "air-fried" items with little to no oil. Many modern convection ovens even include dedicated air fry settings.

The key takeaway is that while conventional ovens are indispensable for certain culinary tasks, convection offers undeniable advantages in efficiency and achieving specific textures, particularly in a high-volume commercial kitchen environment.

Key Features to Consider Before You Buy

Choosing the right oven for your commercial kitchen in Seattle, WA, USA, is a significant investment. Whether you lean towards conventional ovens or convection models, there are several key features to evaluate to ensure you select equipment that meets your operational needs and budget. Our goal at Charbroilers.com is to help you make an informed decision that will serve your business for years to come.

- Oven Capacity (Cubic Feet): This is perhaps the most critical factor. Commercial ovens come in various sizes, from half-size to full-size, and single or double-deck configurations. Consider your typical batch sizes and peak hour demands. Do you primarily bake small pastries, or are you roasting large turkeys? We've seen capacities ranging from 4.2 cu. ft. for single wall ovens up to 6.7 cu. ft. for double oven ranges. For example, a 5.3 cu. ft. oven might be sufficient for a smaller cafe, while a larger restaurant might need a 6.0 cu. ft. double oven gas convection range.

-

Fuel Type (Gas vs. Electric):

- Gas Ovens: Often preferred for their responsive heat and slightly more humid cooking environment, which can be beneficial for certain baked goods. They require a dedicated gas line.

- Electric Ovens: Tend to offer a drier heat, excellent for crisping and browning. They are generally easier to install as they don't require gas lines, offering more flexible placement. Most commercial kitchens are set up for a 240-volt electric connection.

- Dual Fuel Ovens: Some ranges combine a gas cooktop with an electric oven, offering the best of both worlds.

- Self-Cleaning Functions: Commercial kitchens are busy, and cleaning can be a chore. Many modern ovens, including conventional ovens, come with self-cleaning features. These typically use very high heat to turn food residue into ash, which can then be easily wiped away. Some also offer steam-clean settings for lighter cleaning, which is a chemical-free way to loosen food soils.

- Smart Features and Programmable Controls: In today's connected world, smart ovens offer incredible convenience. Features like Wi-Fi connectivity, remote monitoring via mobile apps, and even voice control can streamline kitchen operations. Programmable controls allow for precise temperature and time settings, often storing favorite recipes for consistent results every time. Some models even offer "no preheat mode" to save time.

- Construction and Durability: For a commercial environment, durability is non-negotiable. Look for models with stainless steel construction, reinforced doors, and heavy-duty cooking racks. These features ensure the oven can withstand the rigors of constant use.

- Installation Type: Will you need a freestanding range, a slide-in range, or a built-in wall oven? Freestanding ranges are versatile, while slide-in models offer a more integrated look. Wall ovens are often paired with separate cooktops, allowing for flexible kitchen design. Some electric convection ovens even offer ventless options, which can be a huge advantage for kitchens without traditional hood systems, expanding placement possibilities.

When making your choice, the right oven is an integral part of your culinary success. For a broader perspective on selecting industrial kitchen equipment, our Industrial Oven Buying Guide: Find Your Perfect Heat Treat Solution offers additional insights.

Frequently Asked Questions About Oven Types

We often get questions from our customers about the nuances of oven operation, especially when comparing conventional ovens with their convection counterparts. Let's address some of the most common queries to help you cook with confidence.

Do I need to adjust recipes for a convection oven?

Yes, absolutely! This is one of the most frequent questions we encounter. Recipes are typically written for conventional ovens, which means they assume static, radiant heat. When using a convection oven, the circulating hot air cooks food faster and more evenly. If you don't adjust, you risk overcooked or dried-out dishes.

A general rule of thumb, often referred to as the "25/25 rule," is to:

- Reduce the temperature by 25°F (15°C): If a recipe calls for 375°F in a conventional oven, set your convection oven to 350°F.

- Reduce the cooking time by 25%: Start checking for doneness about 20-25% earlier than the recipe suggests. For example, if a recipe says 60 minutes, check at 45 minutes.

For meats, you might only need to adjust the checking time, not necessarily the temperature, to ensure they cook through without drying out. Many modern convection ovens offer an "Auto Conversion" setting that automatically adjusts the temperature for you, simplifying the process. Always keep an eye on dishes when first using a convection oven, as every oven can behave slightly differently.

Can a convection oven be used as a regular oven?

Yes, most convection ovens are designed with versatility in mind and can indeed be used as conventional ovens. This is a fantastic feature for commercial kitchens that need flexibility.

Typically, you can simply deselect the convection setting or fan function on your oven's control panel. When the fan is turned off, the oven will operate using only its top and bottom heating elements, just like a traditional conventional oven. This allows you to create the still, radiant heat environment needed for those delicate cakes, soufflés, or custards that might be adversely affected by circulating air.

Many modern ovens are "hybrid" models, offering both convection and conventional settings. This gives chefs the best of both worlds, allowing them to choose the optimal cooking method for each dish. If you're unsure, always refer to your oven's user manual for specific instructions on how to activate or deactivate the convection fan.

How does rack placement matter in conventional ovens?

Rack placement is far more critical in conventional ovens than in convection models, primarily due to the static nature of their heat distribution. Since heat radiates from the top and bottom elements, different parts of the oven cavity will have varying temperatures, creating distinct "heat zones."

- Proximity to Elements: Food placed closer to the bottom element will receive more intense heat from below, promoting browning on the bottom. Conversely, food closer to the top element will brown more quickly on top, ideal for broiling or achieving a crispy crust.

- Top Rack: Best for browning, broiling, or cooking items that need a crispy top, such as gratins or certain pastries.

- Middle Rack: The most versatile position, offering the most even heat for general baking and roasting in a conventional oven. It's usually the recommended placement for most recipes.

- Bottom Rack: Ideal for items that need a solid, browned bottom crust, like pizzas or certain breads, or for slow-cooking dishes that benefit from steady, indirect heat.

Because of these heat zones, dishes in a conventional oven often need to be rotated halfway through cooking to ensure even browning and doneness. Without the circulating air of a convection oven, you'll need to be more strategic about where you place your food and how you manage it during the cooking process. Mastering rack placement in a conventional oven is a skill that comes with practice, but it's essential for achieving consistent and delicious results.

Conclusion

Choosing the right oven for your commercial kitchen is a pivotal decision that impacts everything from food quality to operational efficiency. We've explored the fundamental differences between conventional ovens and convection ovens, delving into their heating mechanisms, performance, and ideal culinary applications.

While conventional ovens remain invaluable for their static, radiant heat, perfect for delicate baked goods and slow-cooked casseroles, convection ovens offer undeniable advantages in speed, consistency, and browning capabilities, especially crucial in a high-volume commercial setting. Understanding these distinctions allows you to harness the full potential of your kitchen equipment, ensuring that every dish you serve is perfectly cooked.

At Charbroilers.com, we understand the demands of the restaurant industry in Seattle, WA, USA. Whether you're upgrading an existing setup or outfitting a new establishment, selecting the appropriate oven is key to meeting your culinary goals and satisfying your customers. We're here to help you steer these choices, ensuring you find the equipment that best suits your needs.

Explore our complete guide to commercial charbroilers for your restaurant.