Guide to Commercial Kitchen Equipment

Share

Think of your commercial kitchen equipment as the heart of your restaurant. When all the pieces work together, you get a powerful, efficient operation that turns out incredible food. But if one part is wrong, the whole system can grind to a halt right in the middle of a dinner rush.

This guide is your blueprint for building a reliable, high-performance engine for your kitchen.

Building Your Kitchen's Engine Room

The term commercial kitchen equipment covers every single tool and appliance you'd find in a professional foodservice operation, from the massive walk-in cooler to the humble food processor. Unlike the stuff you have at home, this gear is built to take a beating day in and day out, all while meeting rigorous health and safety standards.

Choosing this equipment isn't just a shopping trip. It's about designing a cohesive system that drives your entire business. A race car isn't just a pile of fancy parts; it's a machine where the engine, chassis, and tires work in perfect harmony. Your kitchen is no different. The success of your menu hinges on how well your cooking line, refrigeration, and prep stations function as a single, well-oiled unit. The choices you make here will echo in your food quality, staff morale, and bottom line for years to come.

How We Got to the Modern Kitchen

The streamlined, stainless-steel kitchens we see today didn't just pop into existence. They’re the result of decades of problem-solving aimed at making kitchens faster, safer, and more efficient.

- The Post-War Boom (1940s-1950s): This is when things got serious. Stainless steel became the go-to material for its durability and how easy it was to clean. We also saw the birth of essential workhorses like multi-door refrigerators and modular cooking suites, designed to handle the growing appetite of post-war diners.

- The Rise of Automation (1980s-1990s): Digital controls started to replace old-school manual knobs, giving chefs a new level of precision. The microwave oven went from a novelty to a necessity, and food processors became standard issue, signaling a big shift toward saving labor and time.

- The Smart Kitchen Era (2000s-Present): Today's kitchens are all about doing more with less. We're focused on energy efficiency, multi-functionality, and even connectivity. Combi ovens that can steam, roast, and bake in one box, alongside induction cooktops that deliver instant, precise heat, are the new cornerstones of kitchen design.

This journey shows a clear path from purely functional tools to a sophisticated ecosystem that blends performance with intelligence.

A well-equipped kitchen is more than just a place to cook; it's an investment in consistency. When your team has reliable, high-performance tools, they can nail that signature dish every single time, building the kind of customer trust that forms the bedrock of a great restaurant.

Knowing this history matters. When you pick out a new piece of commercial equipment, you're not just buying a machine—you're benefiting from a long line of culinary innovation. This guide will help you think past simple spec sheets. We’ll dive into how to approach each purchase as a critical component of your kitchen's engine, covering the core principles every operator needs to understand before investing in the gear that will define their restaurant's future.

The Core Cooking Lineup You Can't Live Without

The cooking line is the beating heart of any professional kitchen. It's where raw ingredients get their big break, transforming into the signature dishes that define your restaurant. Putting this lineup together isn't just a shopping trip for shiny appliances; it's a strategic mission to select the workhorses that bring your menu to life and keep service humming.

Think of it like building a band. Every kitchen needs a solid rhythm section—like a trusty range and oven—to hold everything together. Then you bring in the lead guitarists, like a high-performance commercial charbroiler or a rapid-recovery fryer, that give your food its unique character and flavor. Every piece has to earn its spot on the line.

The market for this gear is massive and always evolving. In the U.S. alone, commercial cooking equipment is a $6.4 billion industry, and it's not slowing down. This growth is fueled by new restaurant openings and a major industry push for smarter, more energy-efficient equipment. You can get a better sense of these market trends and their impact on the industry.

The Foundation: Your Ovens and Ranges

Every great kitchen is built on a solid foundation, and that starts with your ovens and ranges. The commercial range, that classic combo of burners up top and an oven down below, is the ultimate multitasking MVP. It’s your go-to for everything from sautéing and simmering to boiling and baking, making it an absolute must-have for almost any cuisine.

But not all ovens are created equal. The type you choose can make a world of difference in your food quality, cook times, and overall output.

- Convection Ovens: These are the workhorses for baking and roasting. They use powerful internal fans to circulate hot air, cooking food up to 25% faster than a standard oven. They're perfect for bakeries churning out batch after batch of cookies or for roasting meats to a perfect, even brown.

- Combi Ovens: For kitchens that demand serious versatility, combi ovens are a complete game-changer. They can operate as a convection oven, a steamer, or a precise combination of both. This gives chefs incredible control over temperature and humidity—ideal for tricky items like custards or for keeping proteins juicy while still getting that crispy, golden exterior.

Your menu dictates your oven. A high-volume pizzeria lives and dies by the intense, bottom-up heat of a deck oven. A fine-dining spot, on the other hand, will likely lean on the precision of a combi oven to flawlessly execute its complex dishes.

Delivering Signature Flavor with Charbroilers

For a huge number of restaurants, that unmistakable char and smoky aroma from a charbroiler are totally non-negotiable. Whether you're a classic steakhouse, a cool bistro, or a busy burger joint, this one piece of equipment can define your entire brand. It’s how you get that perfect sear and signature grilled flavor that keeps people lining up.

Picking the right one means matching the unit to your menu, volume, and kitchen reality. We offer a wide selection of commercial charbroilers to fit any restaurant's needs, including infrared, gas, and electric models.

Gas Charbroilers

This is the traditional choice, the one many chefs swear by for that classic open-flame grilling experience. Gas charbroilers heat up fast and give you responsive, immediate control over the flame. They’re famous for imparting that distinct smoky flavor that’s almost impossible to replicate any other way.

Electric Charbroilers

Electric charbroilers are a fantastic solution for kitchens where running a gas line just isn't an option, like in many food trucks or certain buildings with strict regulations. Don't underestimate them—modern electric char broilers deliver serious power and incredibly even heat. They’re often easier to clean and can eliminate the frustrating hot spots you sometimes get with gas.

Infrared Charbroilers

When you need pure, unadulterated power and efficiency, infrared charbroilers are in a league of their own. They use special infrared burners to blast food with intense, direct heat, cooking it faster and at lower ambient temperatures than traditional models. This technology is absolutely brilliant for searing meat, as it instantly locks in juices for an unbelievably moist product while cutting down on energy use. It's the top choice for high-volume steakhouses that demand both breakneck speed and flawless quality.

How to Choose the Perfect Commercial Charbroiler

For a lot of restaurants, the charbroiler is the heart of the kitchen. It’s the piece of commercial kitchen equipment that creates the signature sear, smoky aroma, and incredible flavor that customers crave. Whether it's anchoring a high-end steakhouse or working overtime at a busy burger joint, the right charbroiler can literally define your menu and your brand.

Picking the perfect model goes way beyond just its size. It’s really about matching the right technology to what you’re cooking, how your kitchen is laid out, and how many customers you’re serving. Let's dig into the different types of commercial charbroilers to find the absolute best fit for your restaurant.

Gas Charbroilers: The Classic Choice for Authentic Flavor

When chefs think of that classic, open-flame grilling experience, they’re picturing a gas charbroiler. These units are beloved for their incredibly fast heat-up times and the instant, responsive temperature control they provide. With a simple turn of a knob, you can go from a gentle flame for charring vegetables to a roaring fire for searing thick-cut steaks.

But it’s about more than just control. Gas models are legendary for producing that distinct, smoky flavor that's nearly impossible to get any other way. As food cooks, the drippings hit the hot radiants or briquettes below the grates and vaporize, creating a flavorful smoke that infuses right back into the food. This is what creates that authentic, backyard-grill taste that so many successful menus are built on.

Electric Charbroilers: Power and Versatility

Electric charbroilers are a fantastic and powerful option, especially in kitchens where running a gas line just isn't possible or permitted. These units have come a long way, and modern electric models pack a serious, consistent punch that can easily handle high-volume service. They are the perfect solution for food trucks, historic buildings, or basement kitchens where ventilation and gas hookups are a major challenge.

One of the biggest wins for electric charbroilers is their exceptionally even heat distribution. By using high-performance heating elements, they get rid of the annoying hot and cold spots that can sometimes be an issue with other broilers.

This consistency is your secret weapon for making sure every single item that comes off the grill is cooked perfectly from edge to edge. Plus, no open flames can make cleanup and daily maintenance routines much quicker, saving your staff valuable time.

For a closer look at specific models and features, our comprehensive guide to commercial charbroilers for your restaurant is a fantastic resource. This guide will help you narrow down your choice based on your kitchen's unique setup.

Infrared Charbroilers: The Pinnacle of Speed and Efficiency

When your kitchen demands the absolute most in power, speed, and efficiency, infrared charbroilers are in a league of their own. Instead of just heating the air around the food, infrared technology cooks with intense, direct waves of energy. Think of it like the focused heat from the sun on a clear day—it's incredibly powerful and gets the job done fast.

This method gives you several game-changing benefits:

- Incredible Speed: Infrared charbroilers preheat and cook significantly faster than gas or standard electric models, which means you can serve more people during your busiest rushes.

- Superior Searing: The intense heat instantly creates a perfect crust on meat, locking in all the juices and moisture for an exceptionally succulent final product. This means less shrinkage and a higher-yield product for you.

- Energy Savings: Because they transfer heat so efficiently, infrared models can slash your energy consumption by up to 30-50% compared to traditional charbroilers, which lowers your utility bills over time.

These units are the undisputed champions for high-volume steakhouses and any restaurant where turning tables quickly—without sacrificing an ounce of quality—is the name of the game. By understanding what makes gas, electric, and infrared technology unique, you can choose a charbroiler that doesn’t just fit your space, but actively makes your menu better.

Keeping Your Cool With Smart Refrigeration and Prep

A world-class kitchen is more than just the fire and sizzle of the hot line. While the charbroiler might be the star of the show, its success—and the entire kitchen's—depends on the unsung heroes: smart refrigeration and efficient prep stations.

Without rock-solid refrigeration, you're not just risking spoiled inventory; you're gambling with food safety and watching profits melt away. Likewise, without the right prep tools, your labor costs will climb and your recipes will lose the consistency that keeps customers coming back. Let's shift our focus from the heat to these equally critical components that keep your operation running like a well-oiled machine.

From Bulk Storage To Line Access

Commercial refrigeration is never a one-size-fits-all game. The real secret to a smooth kitchen workflow is a smart combination of different units, each placed and used for a specific job.

Think of your walk-in cooler as the central library for your ingredients. It's the large-scale, organized hub for bulk items—cases of produce, buckets of house-made sauce, and primal cuts of meat. But during a chaotic dinner rush, no cook has time to run to the "library" for a handful of onions.

That's where reach-in refrigerators and freezers become absolutely essential. Placed strategically along the cooking line, these smaller units give your team immediate access to prepped ingredients, keeping everything they need right at their fingertips. You can also integrate specialized units like under-counter or worktop refrigerators, which brilliantly combine cold storage with valuable prep surfaces.

By mapping out your refrigeration, you create a seamless path from bulk storage to the final plate. For a closer look at choosing the right walk-in, be sure to check out our essential guide to restaurant walk-in fridges. It’s packed with insights to help you match a unit to your kitchen's unique demands.

To help visualize how these different units fit into a kitchen's workflow, here's a quick comparison of the most common types of commercial refrigeration.

Commercial Refrigeration Unit Comparison

| Unit Type | Primary Use Case | Typical Footprint | Key Selection Factor |

|---|---|---|---|

| Walk-In Coolers/Freezers | Bulk ingredient storage, long-term holding | Large (custom sizes) | Capacity, insulation (R-value), and door durability |

| Reach-In Refrigerators/Freezers | Storing prepped items on the line for quick access | Medium (2-3 doors) | Door style (solid vs. glass), shelving configuration |

| Undercounter/Worktop Units | Combined cold storage and prep space at stations | Small to Medium | Countertop material, compressor location (front vs. rear) |

| Prep Tables (Pizza/Salad) | Holding chilled ingredients for assembly lines | Medium to Large | Pan capacity, cutting board size, refrigerated base |

Each of these units plays a vital role. A well-designed system ensures ingredients are kept safe and accessible, directly boosting your kitchen's speed and efficiency.

Slashing Prep Time and Boosting Consistency

Once your ingredients are properly stored, it's time for prep—often the most labor-intensive part of any kitchen's day. Manually slicing, dicing, and mixing is not only slow but also a recipe for inconsistency. This is where modern prep equipment steps in to become your most valuable player, turning hours of tedious work into mere minutes.

A high-capacity commercial mixer is non-negotiable for any restaurant making its own dough, batters, or sauces in bulk. It guarantees every single batch has the identical texture and quality. In the same way, a powerful food processor can shred a 10-pound block of cheese, slice a case of zucchini, or whip up a perfectly smooth hummus in seconds.

These tools aren't just about moving faster. They're about precision and absolute reliability. When you automate repetitive tasks, you free up your skilled chefs to do what they do best: cook, create, and plate beautiful food.

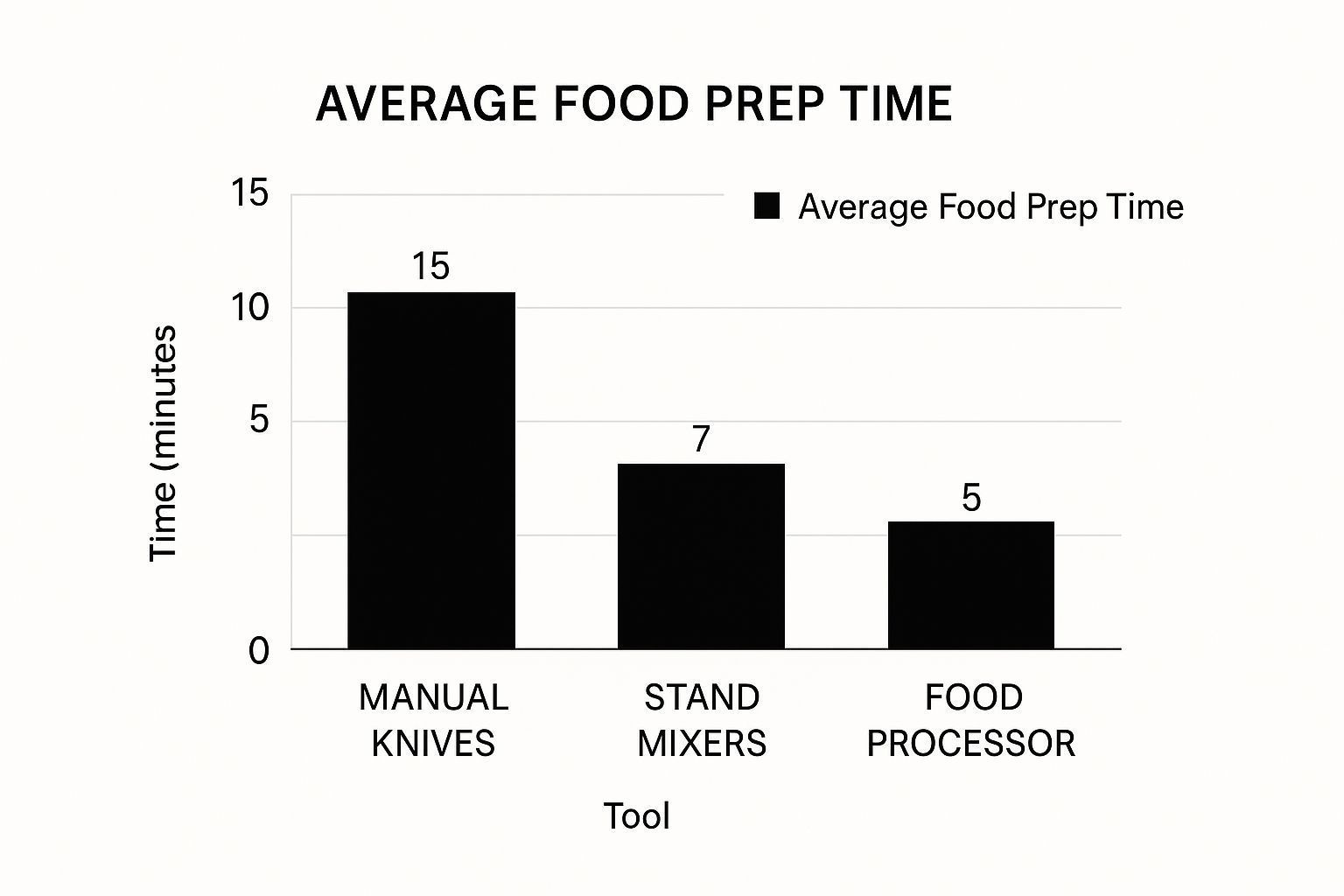

Just look at how much time these tools can save on a single, common task.

As you can see, a food processor can take a 15-minute manual task and knock it out in just five minutes. That’s a 66% reduction in prep time. Now, multiply that efficiency gain across your entire menu, every single day. The result is a dramatic drop in labor costs and a much more streamlined, less stressful kitchen.

Designing a Kitchen That Actually Works

You can buy the best commercial kitchen equipment on the planet, but if your layout is a mess, your kitchen will never truly perform. A poorly planned space creates bottlenecks, frustrating staff and creating safety hazards, no matter how powerful your charbroiler or oven is.

Think of designing a kitchen like choreographing a complex dance—every single step and movement must be planned out for maximum speed, efficiency, and safety. This isn't just about looking organized. A smart layout is a strategic asset that directly boosts your bottom line by cutting down ticket times, minimizing accidents, and making your team's life easier—a huge win for staff retention. Your layout is the invisible force that sets the pace and rhythm during a chaotic dinner rush.

Choosing Your Kitchen's Operating System

Every great kitchen runs on a specific layout, an "operating system" built to manage the flow of food and people. The two most common setups are the assembly line and zone-based layouts, and each has its own clear advantages.

An assembly line layout is exactly what it sounds like. You arrange equipment in a logical sequence that mirrors a dish's journey, from raw ingredient to the finished plate. This is the gold standard for kitchens with a focused menu, like a high-volume sandwich shop or a pizzeria. The workflow is so linear and intuitive that training new staff becomes incredibly simple.

A zone-based layout, on the other hand, divides the kitchen into dedicated stations. You’ll have a fry station, a grill station, and a salad prep station, each working independently. This modular approach is perfect for restaurants with diverse menus, allowing multiple dishes to be fired at once without chefs tripping over each other. It empowers each station to own its part of the process before everything comes together at the final pass.

Engineering a Natural and Safe Workflow

Once you've picked a layout style, the real work begins: engineering a workflow that feels natural and keeps everyone safe. The goal is to create clear, dedicated paths for both your staff and ingredients to travel, preventing dangerous crossovers and eliminating wasted motion.

A core principle here is to minimize the number of steps a chef has to take. Every extra step during a busy service is wasted time and energy. It's simple logic: prep refrigerators should be right next to prep counters, which should be close to the main cooking line. This kind of thoughtful placement can save you countless hours over the course of a year.

The single most critical part of workflow design is preventing cross-contamination. You have to establish a one-way path for food, starting at the receiving door for raw goods and ending at the service window for finished plates. Raw ingredients and dirty dishes should never cross the path of cooked food.

This isn't just a suggestion; it's the foundation of a functional, compliant, and safe kitchen.

Planning for Essential Installation Logistics

The final piece of this design puzzle is tackling the unglamorous but absolutely vital logistics of installation. This is where your dream kitchen runs into the hard realities of building codes and physics. Skipping this part can lead to expensive retrofits, failed inspections, or even dangerous operating conditions.

-

Ventilation and Hoods: Any piece of equipment that produces heat or grease—from your fryers to your commercial charbroiler—needs a properly sized ventilation hood. This is non-negotiable for fire safety and air quality.

-

Electrical and Gas Loads: Commercial appliances are absolute power hogs. You must work with licensed electricians and plumbers to confirm your building can handle the electrical load and gas pressure your equipment lineup demands.

-

Plumbing and Drainage: Sinks, dishwashers, and ice machines all need correct plumbing. You’ll also want floor drains strategically placed in areas prone to spills to keep things safe and sanitary.

The push for high-performance, safe, and efficient kitchens is fueling a massive global market. The commercial cooking equipment market was recently valued at USD 36.04 billion and is projected to hit USD 54.35 billion by 2032. This growth is a testament to the industry's relentless drive for smarter, more productive kitchen solutions. You can dive deeper into these global commercial kitchen equipment market trends. By getting these design principles right, you can build a kitchen that’s not just up to code, but a genuine pleasure to work in.

Making a Smart and Lasting Investment

Buying commercial kitchen equipment isn't like a typical shopping trip—it’s a strategic investment in the future of your restaurant. The decisions you make right now will directly impact your kitchen’s workflow, the quality of your food, and your bottom line for years to come. This is where you move beyond the sticker price and make a truly informed choice.

It really requires a shift in thinking. You’re not just a buyer grabbing a piece of machinery; you're an investor acquiring a core asset that needs to deliver a strong return. It's all about seeing the bigger picture and understanding how each piece of equipment will contribute to your success.

Looking Beyond the Price Tag

The initial cost is just the tip of the iceberg. A much smarter way to look at it is by calculating the Total Cost of Ownership (TCO). This framework helps you see the true, long-term cost of an appliance over its entire working life.

Think of it like buying a car. You might save a few thousand bucks upfront on a cheaper model, but if it guzzles gas and is constantly in the shop, it's going to cost you way more in the long run than a slightly more expensive but reliable vehicle. The exact same principle applies to your kitchen.

The global market for commercial cooking equipment is booming, valued at around USD 13.8 billion and on track to hit USD 22.4 billion by 2033. This isn't just a random number; it shows how critical it is for foodservice businesses to invest in reliable, high-performing gear to stay competitive.

To make the right call, you have to weigh these critical long-term factors:

- Energy Consumption: How much is this unit going to add to your utility bill every single day? An ENERGY STAR certified appliance can cut those costs by 10% to 30%, which adds up to massive savings over its lifespan.

- Maintenance Needs: What’s the real story on repairs? Some brands are built like tanks and rarely need a service call, while others can become a constant source of headaches and expenses.

- Expected Lifespan: A cheap unit that gives up the ghost in five years is a terrible investment compared to a slightly pricier one that runs smoothly for a decade.

- Warranty and Support: A solid warranty isn't just a piece of paper. It’s your safety net against those unexpected, wallet-draining breakdowns that always seem to happen at the worst possible time.

Your Final Investment Checklist

Before you sign on the dotted line, use this final check-in to make sure everything lines up—your menu, your budget, and the physical realities of your kitchen. By pulling together everything you've learned, you can make a purchase that's both smart and sustainable. For an even more thorough guide, our detailed commercial kitchen equipment checklist will walk you through every step.

Answering these questions puts you in the driver's seat, ready to select equipment that delivers a powerful return on your investment. This methodical approach ensures you're not just filling a space; you're adding a valuable, profit-driving machine to your operation.

Common Questions About Commercial Kitchen Equipment

Diving into the world of commercial kitchen equipment can feel like learning a whole new language. Whether you're a first-time owner mapping out your dream kitchen or a seasoned chef ready for an upgrade, getting straight answers is the first step toward making a smart investment. Let's tackle some of the questions we hear all the time.

What Is the Most Essential Piece of Kitchen Equipment?

This is the million-dollar question, and the honest answer is: it completely depends on your menu. While you could make a strong case for the range and oven combo as the classic workhorse, or a high-quality refrigeration unit as the backbone of food safety, the real answer is more personal.

The "most essential" piece is whatever your signature dish can't live without. For a steakhouse, it's the charbroiler. For a bakery, it's a convection oven. Pinpoint the single piece of equipment that truly defines what you do, and start there.

How Do I Choose Between Gas and Electric Equipment?

This classic kitchen debate usually boils down to three things: your cooking style, what your building can handle, and your local utility costs.

Many chefs are loyal to gas because it gives you that instant, responsive heat. You turn the knob, the flame jumps, and you're in direct control. It’s perfect for the fast-paced, on-the-fly adjustments needed for sautéing or wok cooking.

On the other hand, modern electric equipment—especially induction and infrared models—has come a long way. It can be incredibly energy-efficient and offers rock-solid, even temperatures. If your building isn't piped for gas, electric is your go-to. The real question to ask is: does my menu demand immediate heat changes, or is precise, consistent temperature more critical to my food's success?

What About Commercial Charbroilers?

When you need that unmistakable flame-kissed flavor and those perfect grill marks, nothing beats a charbroiler. We live and breathe this stuff, and we have a wide selection of commercial charbroilers to fit any kitchen's needs.

- Gas Charbroilers: These are the traditional choice, prized for delivering that authentic, smoky flavor that comes from an open flame.

- Electric Char Broilers: Don't have a gas hookup? No problem. These units provide powerful, consistent heat to get the job done right.

- Infrared Charbroilers: For high-volume kitchens, infrared is a game-changer. It uses intense, focused heat to cook food faster, sealing in the juices and cutting down on energy use.

The right one for you depends entirely on your menu, how many covers you do, and your kitchen's setup. Each type gives your cooking line a unique edge to help you nail those signature grilled items every single time.

At Charbroilers, our whole world revolves around providing the high-performance cooking gear your restaurant needs to knock it out of the park. Come explore our full lineup of charbroilers and other kitchen essentials.

Find your perfect fit at https://charbroilers.com.