Sweet Displays Ahead – Top Bakery Display Cases Reviewed

Share

Why the Right Bakery Display Case is Your Secret Ingredient for Higher Sales

Bakery display cases are essential equipment that showcase your baked goods while maintaining freshness and food safety. Here's what you need to know:

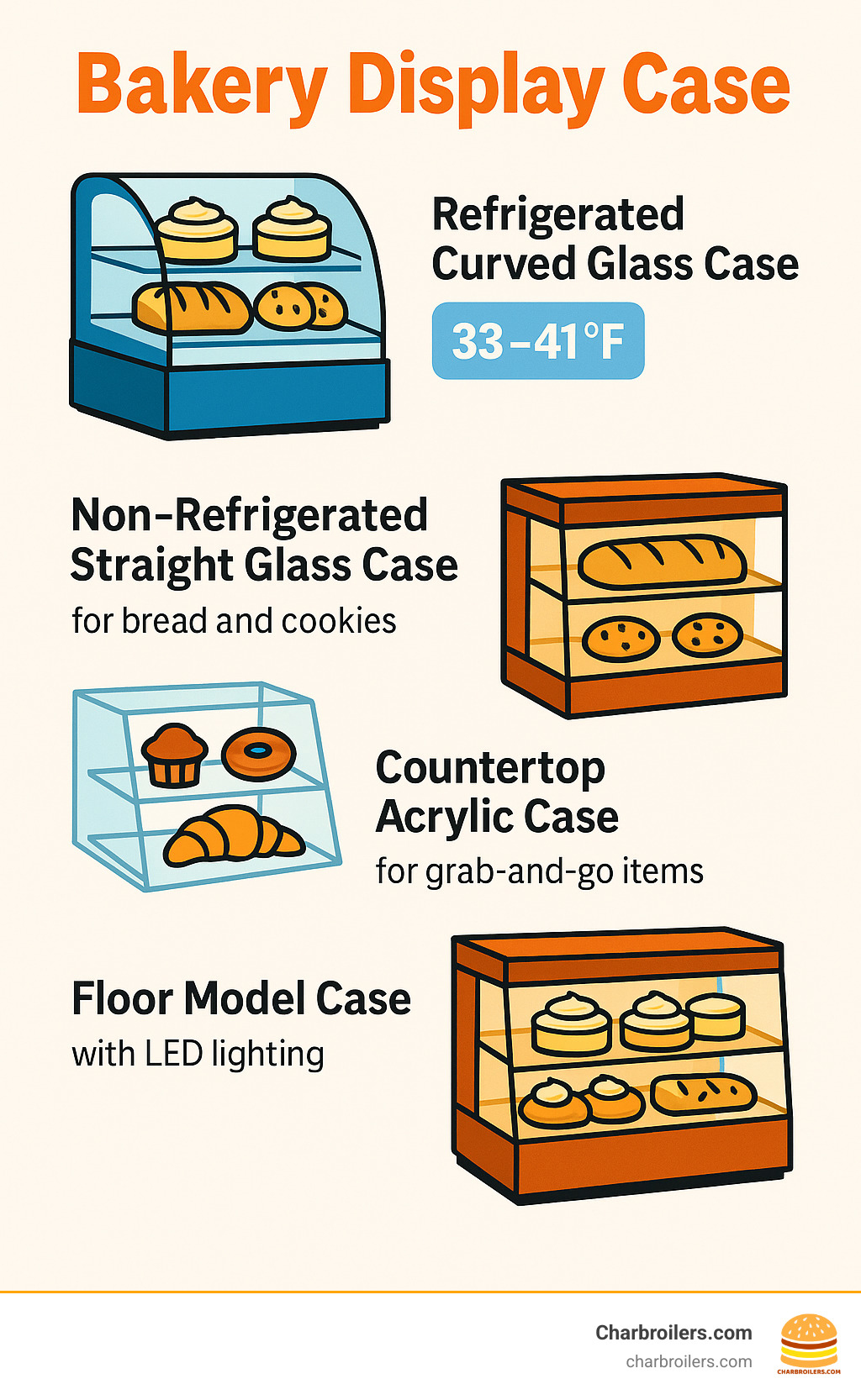

Top Types of Bakery Display Cases:

- Refrigerated cases - Keep cakes, custards, and cream-filled items at 33-41°F

- Non-refrigerated cases - Perfect for bread, cookies, and dry pastries

- Countertop models - Space-saving options for grab-and-go items

- Floor models - High-capacity units with maximum visibility

- Self-service cases - Let customers serve themselves safely

- Full-service cases - Staff-operated for premium presentation

Key Benefits: - Increase impulse sales by up to 30% through better product visibility - Maintain proper food safety temperatures automatically - Protect items from contamination while keeping them accessible - Available in sizes from 36" countertop units to 12-foot floor models

Is there anything as tempting as a display of baked goods, seducing customers with their golden crust and pretty decorations? The right display case turns your bakery items into irresistible impulse purchases while keeping everything fresh and safe.

Whether you're running a busy café with limited counter space or a full-scale bakery needing maximum capacity, choosing the wrong display case can hurt both your food quality and your bottom line. Get it right, and you'll see those profit margins rise along with customer satisfaction.

I'm Sean Kearney, and after over a decade in the restaurant equipment industry and founding Charbroilers.com, I've helped countless food service operators find the perfect bakery display cases for their specific needs and budgets. Let me walk you through the top options that deliver real results without breaking the bank.

What Makes a Great Bakery Display Case?

A truly great bakery display case does much more than just hold your baked goods – it's your silent salesperson working around the clock to turn browsers into buyers. After helping hundreds of food service operators choose the right equipment, I've learned that the best cases balance three crucial elements: food safety, visual appeal, and operational efficiency.

Temperature control sits at the heart of every quality display case. Your refrigerated units need to maintain rock-solid temperatures between 33-41°F to keep those cream-filled éclairs and decorated cakes safe from harmful bacteria. But here's something that surprises many bakery owners: bread and dry pastries actually go stale faster when refrigerated because the cold makes the starches crystallize. That's why your croissants and artisan breads belong in non-refrigerated cases at room temperature.

Size matters, but not always in the way you'd expect. You need a case that fits your space – widths typically run from 36 to 77 inches, with floor models reaching up to 96 inches tall. But height can be just as important as width for driving sales. Products displayed at eye level catch customer attention far more than items tucked away on bottom shelves.

The door configuration you choose affects both your daily operations and food safety. Self-service cases with customer-accessible doors work beautifully for grab-and-go operations, though they need more durable construction to handle constant use. Full-service cases where your staff retrieves items offer better contamination control and let you create premium presentations for high-value products.

Never underestimate the power of proper lighting. Modern LED systems transform ordinary baked goods into mouth-watering displays while cutting your energy costs compared to old fluorescent bulbs. The right lighting can literally be the difference between a customer walking past your case or stopping to make an impulse purchase.

When choosing between glass and acrylic construction, each material brings distinct advantages:

| Feature | Glass Construction | Acrylic Construction |

|---|---|---|

| Durability | Scratch-resistant, premium appearance | Impact-resistant, lighter weight |

| Clarity | Superior optical clarity | Good clarity, may yellow over time |

| Cost | Higher initial investment | More budget-friendly |

| Maintenance | Easy to clean, chemical-resistant | Requires gentle cleaning products |

| Safety | Can shatter if impacted | Virtually unbreakable |

Straight glass cases offer that classic, professional look with angled fronts (usually 12 degrees) to reduce glare from overhead lighting. Curved glass designs provide a more contemporary appearance and superior viewing angles from above – perfect for showing off those beautiful layered cakes and elaborate pastries.

Customization options let you match your brand identity perfectly. Many manufacturers offer custom laminate colors, brass or oak trim, mirrored end panels, and specialized lighting configurations. I've seen operators significantly boost brand recognition by coordinating their display cases with their overall décor theme.

Energy efficiency impacts your bottom line every single day. Look for units with CFC-free insulation, high-efficiency compressors, and LED lighting systems. While energy-efficient models cost more upfront, they typically pay for themselves within 18-24 months through reduced utility bills.

Price ranges vary dramatically based on size and features. Countertop acrylic cases start around $200-500, while premium refrigerated floor models can reach $3,000-8,000. Don't forget to factor in installation costs, especially for refrigerated units requiring electrical connections.

Health regulations mandate that refrigerated cases maintain proper temperatures and include easy-to-clean surfaces. Most jurisdictions require temperature monitoring systems and regular cleaning protocols. Scientific research on refrigerated pastry cases shows that proper case selection directly correlates with reduced food safety violations.

Key Features Checklist

Before purchasing any bakery display case, make sure you evaluate these essential features that separate great equipment from mediocre options.

Materials and construction form the foundation of long-term performance. Tempered glass construction provides safety and durability, while stainless steel or powder-coated frames ensure your investment lasts for years. Refrigerated models need CFC-free insulation, and don't overlook adjustable feet with protective rubber to prevent countertop damage.

LED lighting systems deliver energy efficiency and heat reduction that old fluorescent systems simply can't match. Look for adjustable brightness controls for different times of day, color temperature options to improve specific product types, and canopy lighting for uniform illumination that makes everything look irresistible.

Operational features that make your daily routine smoother include easy-access controls for temperature adjustment, quiet operation to maintain a pleasant customer environment, adequate ventilation for consistent temperature distribution, and removable components for thorough cleaning.

Consider your foot traffic patterns and branding needs carefully. Choose heights appropriate for your primary customer demographics, ensure sight lines don't obstruct other areas of your operation, select finish options that complement your existing décor, and plan placement for optimal customer flow.

How Bakery Display Cases Keep Products Safe & Fresh

Understanding the science behind food preservation helps you select the right case type for each product category. Bakery display cases use two primary cooling methods, and each has distinct advantages that work better for different situations.

Gravity coil systems rely on natural air circulation, creating gentle, consistent cooling without forced air movement. This method works exceptionally well for delicate items like decorated cakes or fragile pastries that might be damaged by air currents. The trade-off is that gravity systems take longer to recover temperature after door openings.

Forced-air systems use fans to circulate cooled air throughout the case, providing rapid temperature recovery and more uniform cooling. These systems excel in high-traffic environments where doors open frequently. However, the air movement can potentially dry out exposed products, making them better suited for wrapped or covered items.

Humidity control proves critical for maintaining that fresh-baked quality customers expect. High humidity gravity coils help preserve moisture content in pastries, preventing that stale, dried-out texture that drives customers away. Most baked goods perform best at 60-70% relative humidity.

Dual-zone merchandisers offer the best of both worlds, combining refrigerated and non-refrigerated compartments in a single unit. These work particularly well in coffee shops where operators want to display both cream-filled éclairs and fresh croissants in the same visual space.

Food safety extends far beyond temperature control. Proper case design includes features like sneeze guards, easy-to-clean surfaces, and adequate drainage systems. That 33-41°F temperature range isn't arbitrary – it's the sweet spot where most harmful bacteria cannot multiply rapidly while maintaining the product quality your customers deserve.

Best Bakery Display Cases of 2024 – Buyer's Roundup

Finding the right bakery display cases can feel overwhelming with so many options out there. After working with hundreds of food service operators over the years, I've learned that the best cases aren't always the most expensive ones – they're the ones that fit your specific needs and actually help you sell more product.

This year's standout models focus on what really matters: keeping your baked goods fresh, making them irresistible to customers, and holding up to daily use without constant repairs. Whether you need refrigerated cooling for cream-filled pastries or non-refrigerated display for artisan breads, there's a perfect match for your operation.

The biggest improvements I've seen lately are in LED lighting systems that make everything look more appetizing, better energy efficiency that won't shock you with utility bills, and dual-zone options that let you display different product types in one unit. Self-service designs are also getting more popular as operators look to reduce labor costs while giving customers the quick access they want.

Let me walk you through the top performers in each category, from compact countertop units perfect for coffee shops to impressive floor-model cases that can handle a busy bakery's full capacity.

Countertop Bakery Display Cases Reviewed

When counter space is tight but you still want to drive those impulse-buy sales, countertop cases deliver exactly what you need. These space-saving workhorses sit right at eye-level where customers can't miss them, turning browsers into buyers.

The clear winner for most operations is the acrylic self-service model with front and rear doors. I love this design because customers can grab what they want while your staff can restock from behind without getting in anyone's way. The heavy-duty acrylic construction looks great and handles the inevitable bumps and knocks of busy service.

These units typically run 19 to 48 inches wide, with the 27-inch size hitting the sweet spot for most coffee shops and cafés. The acrylic doors slide smoothly even after thousands of uses, and the clear construction means every muffin and cookie gets maximum visibility.

For operations selling cream-filled éclairs or decorated cupcakes, refrigerated countertop cases keep everything at that crucial 36-41°F range. The self-contained refrigeration means you just plug it in – no complicated installation or remote condensing units to worry about. The 34.5-inch refrigerated model gives you serious capacity without taking over your entire counter.

If budget is your main concern, basic glass cases with lift-up access protect your grab-and-go items and still show them off nicely. They're perfect for cookies, bagels, and other items that don't need refrigeration but benefit from protection and presentation.

Large Floor-Model Bakery Display Cases Reviewed

When you're running a high-volume operation, floor-standing cases become your silent sales team. These impressive units can hold full sheet-pan-capacity worth of products while creating the kind of visual impact that stops customers in their tracks.

Curved-glass designs are my top recommendation for most bakeries. The curved front gives customers perfect viewing angles from multiple directions, and there's something about that neat curve that makes everything inside look more appealing. These cases typically feature three adjustable wire shelves that you can customize for different product heights, plus LED-shelves that illuminate everything beautifully.

The 76-inch curved glass model offers maximum capacity while fitting most counter configurations. The tempered glass construction means safety and crystal-clear viewing, while the canopy lighting eliminates shadows that can make products look less appetizing.

For upscale bakeries where presentation justifies premium pricing, European-style cases with LED lighting systems create that boutique atmosphere customers expect. The sophisticated design aesthetic works especially well when you're positioning yourself as a premium destination rather than just another bakery.

Straight-glass cases offer a more budget-friendly path to high capacity. The sloped front design still gives customers good viewing angles, and the cantilevered shelves provide unobstructed merchandising space. When you need maximum product display within a specific budget, these practical units deliver without compromising on professional appearance.

The key with any floor-model case is making sure it fits your space and workflow. Measure twice, order once – these units are substantial investments that need to work perfectly with your existing setup.

Self-Service Bakery Display Cases for Grab-and-Go

Self-service cases are becoming essential as customers increasingly want quick, no-wait access to their favorites. These units need to be built tough since they'll see constant customer-access throughout the day.

The dual-access design with front customer doors and rear staff access solves the biggest challenge with self-service: keeping products stocked without disrupting customer flow. Sliding-doors on quality units operate smoothly even after thousands of cycles, and the robust construction handles the inevitable customer enthusiasm (and occasional carelessness).

Durability becomes critical with self-service units. Look for heavy-duty hinges, commercial-grade door seals, and materials that resist wear and scratching. The 48-inch dual-access model provides optimal capacity for most self-service applications while maintaining easy operation.

Sanitation features matter more with customer-accessible cases. Easy-to-clean surfaces, removable components for thorough washing, and materials that resist bacterial growth help you maintain health code compliance even with high customer traffic.

Revolving display refrigerators offer a unique solution for tight spaces with high product variety. These vertical units maximize display area in minimal floor space, letting customers browse multiple product categories without staff assistance. The quiet operation and smooth rotation, combined with LED lighting that follows the movement, create an almost mesmerizing display that draws attention and encourages purchases.

Setting Up & Merchandising Your Bakery Display Cases

Here's a secret that might surprise you: the way you arrange your bakery display cases can boost sales by 30% or more, without changing a single recipe. I've watched countless operators transform their revenue simply by applying smart merchandising principles.

Think of your display case as prime real estate, where location determines value. Start by creating a planogram – essentially a map showing exactly where each product belongs. Your highest-margin items deserve the penthouse suite at eye level, typically those middle shelves where customers naturally look first. That $4 specialty cake slice generates more profit than selling four $1 cookies, so give it the spotlight it deserves.

Shelf height matters more than most people realize. Each product needs breathing room to look appealing, but cramped shelves create visual chaos that overwhelms customers. Leave enough vertical space so items don't touch the shelf above, while maximizing your available capacity.

The human eye craves color contrast, and you can use this psychology to your advantage. Instead of grouping all chocolate items together, scatter them throughout the display to create visual interest. Mix light and dark colors, smooth and textured surfaces. This natural tendency to seek contrast makes individual products stand out rather than blending into a monotonous wall of similar items.

Cross-merchandising creates those profitable "add-on" sales we all love. Position your coffee cake near the coffee station, or arrange breakfast pastries adjacent to your beverage cooler. When customers see complementary items together, they're more likely to purchase multiple products.

Lighting can make or break your display's appeal. LED color temperature dramatically affects how food appears to customers. Warm white LEDs around 3000K improve those beautiful golden tones in fresh bread and pastries, making everything look more appetizing. If you're showcasing items with white frosting or cream, cooler 4000K LEDs provide that crisp, clean appearance that screams "fresh."

Mirror panels on the ends of your cases work like magic tricks – they create the illusion of having more product while bouncing light throughout the display. This technique works especially well in smaller spaces where you want maximum visual impact.

Your display case placement should work harmoniously with your entire kitchen operation. If you're planning a complete equipment layout, more info about charbroiler kitchen flow can help you optimize your entire food service setup for maximum efficiency.

Best Lighting & Arrangement Practices

The eye-level rule remains the golden standard of retail merchandising, and it applies perfectly to bakery display cases. Items positioned at average adult eye height – roughly 60 to 66 inches from the floor – receive the most attention and generate the highest sales. This prime real estate should showcase your most profitable items, regardless of how popular they might be.

Don't let popularity override profitability when arranging your display. That elaborate decorated cake might sell less frequently than simple cookies, but its higher profit margin makes it worthy of premium positioning. Use superior lighting to make these high-value items irresistible.

Seasonal rotation keeps your display fresh and gives customers reasons to return. Nobody wants to see the same arrangement week after week. Rotate seasonal items into prominent positions during their peak periods, then gracefully move them to secondary locations as trends shift.

Create visual anchors using your most photogenic products. Position elaborately decorated cakes, colorful fruit tarts, or artisanal breads at key visual points where they naturally draw customers into the display area. These show-stopping items act like magnets, pulling people closer to examine your entire selection.

Mistakes to Avoid with Bakery Display Cases

Over-stocking tops my list of display case disasters. I've seen operators cram so many items into their cases that nothing looks appealing anymore. When products are fighting for space, customers can't focus on individual items. Maintain adequate spacing between products so each one can shine on its own merits.

Wrong temperature settings can sabotage even the highest-quality products. Here's something many operators don't realize: bread and non-perishable pastries actually go stale faster under refrigeration due to starch changes. Meanwhile, cream-filled items absolutely require consistent cooling for food safety. Don't try to make one case type work for everything.

Glare problems drive customers away instead of attracting them. Poor lighting placement creates reflections on glass surfaces that make it difficult to see products clearly. Even though straight glass cases have that helpful 12-degree angle to minimize glare, proper light positioning remains crucial for creating an inviting display.

Poor cleaning practices can make even the freshest products look unappetizing. Crumbs scattered on shelves, fingerprints on glass, and food residue create an immediate negative impression. Establish daily cleaning routines and train your staff on proper sanitation procedures – your display case should sparkle as much as your products do.

Maintenance Tips for Bakery Display Cases

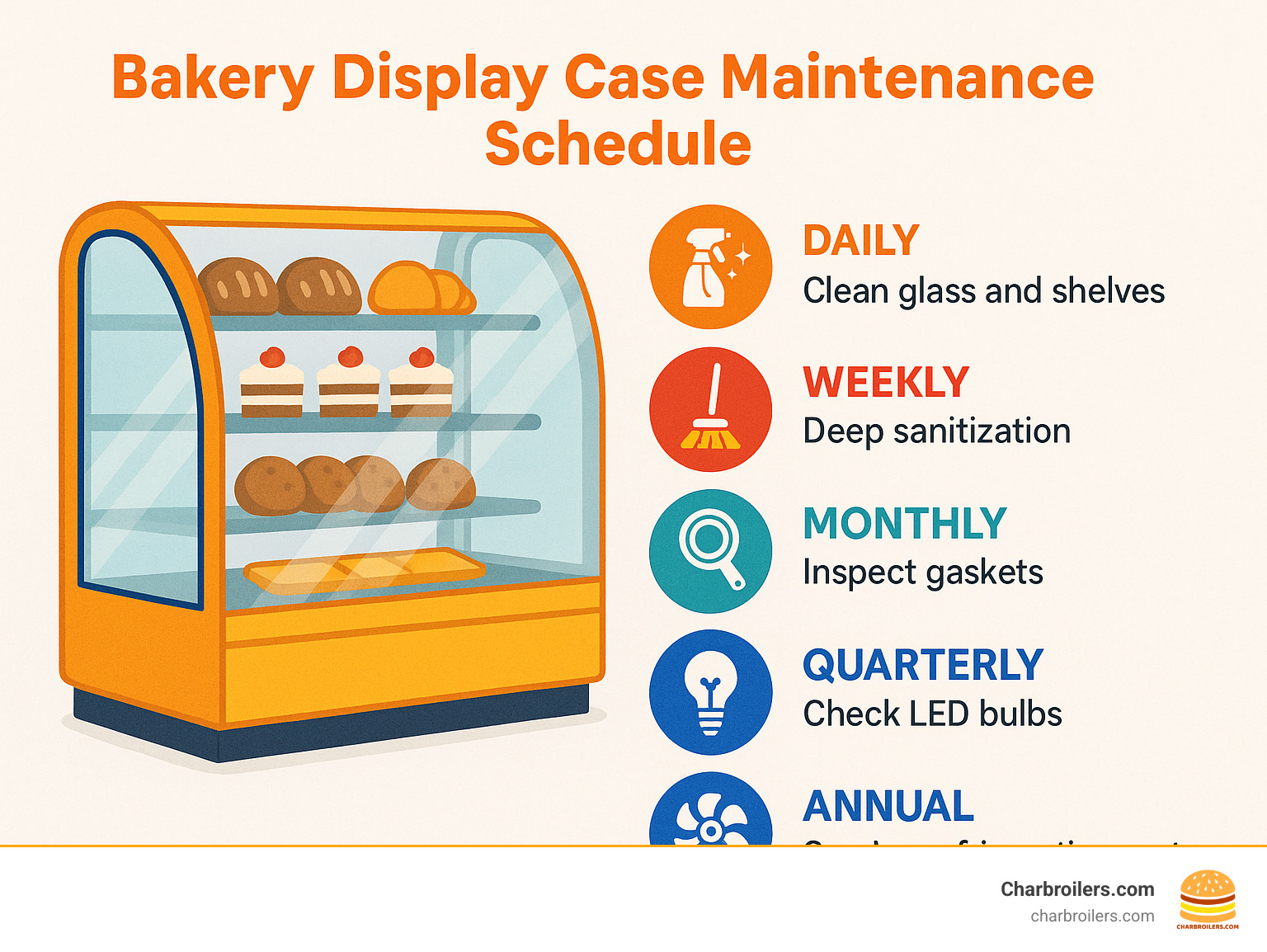

Taking care of your bakery display cases isn't just about keeping them looking good – it's about protecting your investment and keeping your customers safe. After helping hundreds of food service operators maintain their equipment, I've learned that a little daily attention prevents major headaches down the road.

Think of maintenance like brushing your teeth. Skip it for a day or two, and you might get away with it. Skip it for weeks, and you're looking at expensive problems that could have been easily prevented.

The good news? Most maintenance tasks take just a few minutes and can be done by your regular staff. Daily maintenance starts with a simple wipe-down of all glass surfaces using streak-free cleaner. Those fingerprints and smudges don't just look bad – they actually make your products less appealing to customers.

Food debris removal from shelves and drip pans should happen every single day. Crumbs and spills create breeding grounds for bacteria, and nobody wants to explain a health department violation to their insurance company. Check those temperature displays too – if something's going wrong with your refrigeration, you want to know before your expensive pastries spoil.

Deep cleaning needs to happen weekly, and yes, that means removing everything and giving the case a thorough scrub-down. Use only food-safe sanitizers and make sure everything's completely dry before restocking. This is also when you'll want to pay special attention to door seals and gaskets where bacteria love to hide.

Here's something many operators miss: gasket inspection should happen monthly, not just when they're obviously failing. Damaged door seals are energy vampires, letting warm air sneak in and forcing your refrigeration system to work overtime. Replace worn gaskets promptly – it's much cheaper than the energy waste they cause.

Health codes aren't suggestions, they're requirements. Most jurisdictions demand documented cleaning schedules and temperature logs. Create these systems from day one, not after an inspector shows up. Your future self will thank you when you can hand over pristine records instead of scrambling to explain missing documentation.

Don't forget about warranties either. Most manufacturers require proof of proper maintenance for coverage. Keep detailed records of cleaning, repairs, and part replacements. That documentation protects your investment and ensures warranty claims get honored instead of denied.

When calculating ROI on different models, factor in maintenance costs. Higher-quality units often cost less to maintain over their lifespan, making them smarter investments despite higher upfront prices. Scientific research on acrylic durability shows that proper care dramatically extends equipment life while maintaining appearance and functionality.

Cleaning Schedule for Bakery Display Cases

Creating a cleaning schedule removes guesswork and ensures nothing gets forgotten. Daily tasks include wiping glass surfaces, removing debris, emptying drip pans, recording temperatures, and sanitizing customer contact points like door handles.

Weekly deep cleaning involves removing products and shelving for thorough sanitization. Clean all interior surfaces with food-safe sanitizer, wash removable components, inspect door seals, and clean exterior surfaces and base areas.

Monthly tasks focus on prevention: inspect and replace gaskets as needed, check LED bulbs for dimming, clean condenser coils on refrigerated units, verify temperature accuracy with a calibrated thermometer, and review cleaning logs for completeness.

Longevity & Energy-Savings

LED retrofit options can slash your energy consumption by 40-60% compared to traditional fluorescent lighting while providing better illumination. Most retrofit kits pay for themselves within 12-18 months through reduced utility costs alone.

Night covers for refrigerated cases work like blankets, reducing energy consumption during closed hours by minimizing heat infiltration. These simple additions can cut refrigeration costs by 15-20% while extending compressor life.

Compressor care centers on keeping condenser coils clean and ensuring adequate ventilation around refrigerated units. Dirty coils force compressors to work harder, increasing energy consumption and shortening equipment life. Schedule professional maintenance annually to keep everything running smoothly.

The bottom line? Proper maintenance isn't an expense – it's an investment that pays dividends through lower energy bills, fewer repairs, and equipment that lasts years longer than neglected units.

Frequently Asked Questions about Bakery Display Cases

How much space do I need for a display case?

The space you'll need depends entirely on which type of bakery display case you choose and how your customers move through your space. Let me break this down in a way that actually helps you plan.

For countertop units, you're looking at anywhere from 19 to 48 inches of counter width. But here's what most people forget – you also need room for those doors to swing open without smacking into something (or someone). I've seen too many operators squeeze a case into a tight spot, only to find their staff can barely open it during the morning rush.

Floor models are a different beast entirely. These units need 36 to 77 inches of floor space, but that's just the beginning. You'll want at least 36 inches of aisle space in front so customers can actually see what you're selling without feeling cramped. Think about it – nobody wants to squeeze past other customers just to check out your chocolate croissants.

Traffic flow around your case makes or breaks the whole setup. Your staff needs to restock without blocking customers, and customers need to browse without creating bottlenecks. I always tell our clients to walk through their space during their busiest hours and imagine where the case will go.

Refrigerated units add another wrinkle – they need breathing room. Plan for at least 6 inches of clearance on all sides so the cooling system can work properly. Cramped refrigeration equipment works harder, costs more to run, and breaks down sooner.

Don't forget about height clearances either. Make sure your ceiling is high enough for doors to open fully, and consider how the case looks from different angles in your space.

Do bakery display cases require special electrical hookups?

This is where things get interesting, and honestly, a bit more complicated than most people expect when they're shopping for their first bakery display case.

Non-refrigerated cases are pretty straightforward – they typically just need standard 110V power for their lighting systems. These plug right into regular outlets, so no special electrical work required. Easy enough, right?

Refrigerated cases are where you might need to call an electrician. Larger floor models often require 220V connections, especially if they have serious refrigeration systems. You'll likely need a dedicated electrical circuit to handle the power load without tripping breakers or overloading your existing setup.

Here's something that catches people off guard – many manufacturers actually require professional installation to keep your warranty valid. I know it's tempting to save a few bucks and try to hook things up yourself, but trust me, it's not worth voiding your warranty over.

Energy costs are worth factoring into your planning too. Most refrigerated cases consume between 3 and 8 kilowatt-hours per day, which translates to roughly $30 to $80 added to your monthly electric bill in most markets. It's not huge, but it's real money that adds up over time.

The smart move is to have an electrician evaluate your space before you buy, especially for refrigerated units. They can tell you exactly what you'll need and what it'll cost, so there are no surprises when your new case arrives.

Can I mix dry and refrigerated items in one case?

Short answer? Not in a standard case, and you really don't want to try. Here's why this matters more than you might think.

Regular bakery display cases are designed to operate at either room temperature or refrigerated temperatures – not both at the same time. When you try to mix product types, you end up compromising both food safety and product quality. Your cream-filled éclairs won't stay safe, and your artisan bread will go stale faster in the cold.

Dual-zone merchandisers solve this exact problem, and they're pretty clever. These specialized units give you separate refrigerated and non-refrigerated compartments in one case. You can display both your delicate cream pastries and your fresh croissants in the same visual space while keeping each at the right temperature.

If dual-zone units aren't in your budget, the next best solution is positioning separate cases right next to each other. This creates the appearance of one unified display while maintaining proper temperature control for each product category. It's not quite as sleek, but it works.

Think about your actual product mix when you're making this decision. If you regularly sell both refrigerated and room-temperature items, investing in the right setup from the start saves you headaches (and potentially money) down the road. Trying to make do with the wrong equipment usually backfires.

The bottom line? Food safety isn't worth compromising over, and your products will taste better when stored at their optimal temperatures. Your customers will notice the difference, even if they don't realize why.

Conclusion & Next Steps

Choosing the right bakery display cases isn't just about storing your baked goods – it's about turning every croissant, cake, and cookie into a silent sales ambassador. When you see that 30% boost in impulse purchases, you'll understand why smart bakery owners consider display cases one of their most important investments.

We've walked through everything from temperature control basics to advanced merchandising techniques. The main takeaway? Match your case to your products. Refrigerated units for cream-filled delights, dry cases for crusty breads, and dual-zone models when you need both. It sounds simple, but getting this right makes all the difference between products that sell themselves and inventory that just sits there.

Your display case becomes part of your team – the employee that never calls in sick and works every single hour you're open. Whether you start with a compact countertop unit to test the waters or go all-in with a stunning curved glass floor model, you're making an investment that pays dividends every day.

Financing shouldn't hold you back from getting quality equipment. At Charbroilers.com, we've structured our financing options specifically for food service operators who understand that the right equipment pays for itself. Too many owners settle for budget alternatives that end up costing more through higher energy bills, constant repairs, and lost sales opportunities.

The beauty of professional bakery display cases lies in their simplicity. Set them up correctly, maintain them properly, and they'll boost your sales while keeping your products fresh and safe. No complicated training, no steep learning curves – just reliable equipment doing what it's designed to do.

Ready to transform your bakery's sales potential? Our team has helped hundreds of food service operators find the perfect display solutions for their unique situations. We know which units work best in tight spaces, which models handle high-volume operations, and how to maximize your return on investment.

More info about display solutions offers additional insights into creating a complete food service setup that works seamlessly together. When you're ready to take that next step, we're here to help you choose equipment that grows your business rather than just filling space.

Contact us today and let's discuss how the right display cases can become your bakery's secret weapon for higher profits and happier customers.