Top Restaurant Prep Tables for Efficient Kitchens

Share

Think of a restaurant prep table as the command center for your entire kitchen. It’s far more than just a slab of steel; it's the workbench where your culinary ideas come to life, from the first dice of an onion to the final, careful plating of a signature dish. The right table brings a sense of calm to the chaos of a busy service, streamlining every single move your team makes.

Why Your Prep Table Is Your Kitchen's MVP

A well-chosen prep table is one of those unsung heroes of a successful restaurant. It’s the silent partner to your culinary team, providing the dedicated, organized space needed for all the meticulous work that happens long before an ingredient even thinks about hitting a pan. This single piece of equipment dictates your kitchen's entire rhythm.

Just like a master woodworker needs a solid, reliable workbench, a chef needs a sturdy surface. A good prep table isn’t just about adding more counter space. It’s about creating an efficient environment that fuels speed and consistency, because every minute you shave off prep time means faster tickets and happier guests.

The Foundation of Kitchen Efficiency

Choosing the right restaurant prep tables is a serious business decision, one that ripples out to affect everything from food quality to staff morale. When your team has enough well-placed surfaces, they can execute their tasks without taking extra steps, which cuts down on fatigue and the potential for mistakes.

A cramped or poorly organized prep area is a recipe for disaster. It creates bottlenecks, drags down service speed, and can even become a food safety liability. Investing in the right tables is a direct investment in your kitchen’s operational backbone.

You can see just how vital these workstations are by looking at the market. The global demand for food prep tables was pegged at around USD 1.18 billion in 2023 and is expected to climb to USD 1.62 billion by 2029. This isn't just random growth; it shows how essential these tables are to the entire foodservice industry. You can learn more about the market trends for food prep tables from industry research.

Ultimately, the perfect prep table setup gives your chefs the foundation they need to execute your menu flawlessly, night after night. This guide is here to walk you through everything you need to know to pick the perfect tables that will become the true most valuable players in your kitchen.

What Are Your Prep Tables Made Of? It Matters More Than You Think.

Think of the material your restaurant prep tables are made of as their DNA. It dictates everything from your daily cleaning routine to how many years of brutal kitchen punishment they can withstand. A chef wouldn't use a paring knife to butcher a primal cut, and you shouldn't choose a prep table material that isn't up to the specific task you have in mind.

Stainless steel is, without a doubt, the king of the commercial kitchen. But here's the catch: not all stainless steel is the same. Understanding the different grades is the key to making a smart investment that pays off for years.

The Stainless Steel Showdown: 304 vs. 430 Grade

Walk into any supplier, and you'll hear two numbers thrown around: 304 and 430.

Think of 304-grade stainless steel as the all-weather, heavy-duty champion. It has a higher nickel content, which makes it incredibly tough against rust and corrosion from pretty much anything you can throw at it—salts, acidic foods, and constant moisture. This makes it the only real choice for "wet" work areas, like the space next to your sinks or where your team is prepping mountains of tomatoes and citrus.

Then you have 430-grade stainless steel. It's a more wallet-friendly option that's perfectly happy in dry environments. Use it for storing dry goods, holding countertop equipment, or as a general-purpose workhorse away from the splash zone. It's plenty durable, but it will start to show rust spots if you constantly expose it to water or corrosive stuff.

You can browse a great selection of workhorses in our collection of stainless steel prep tables.

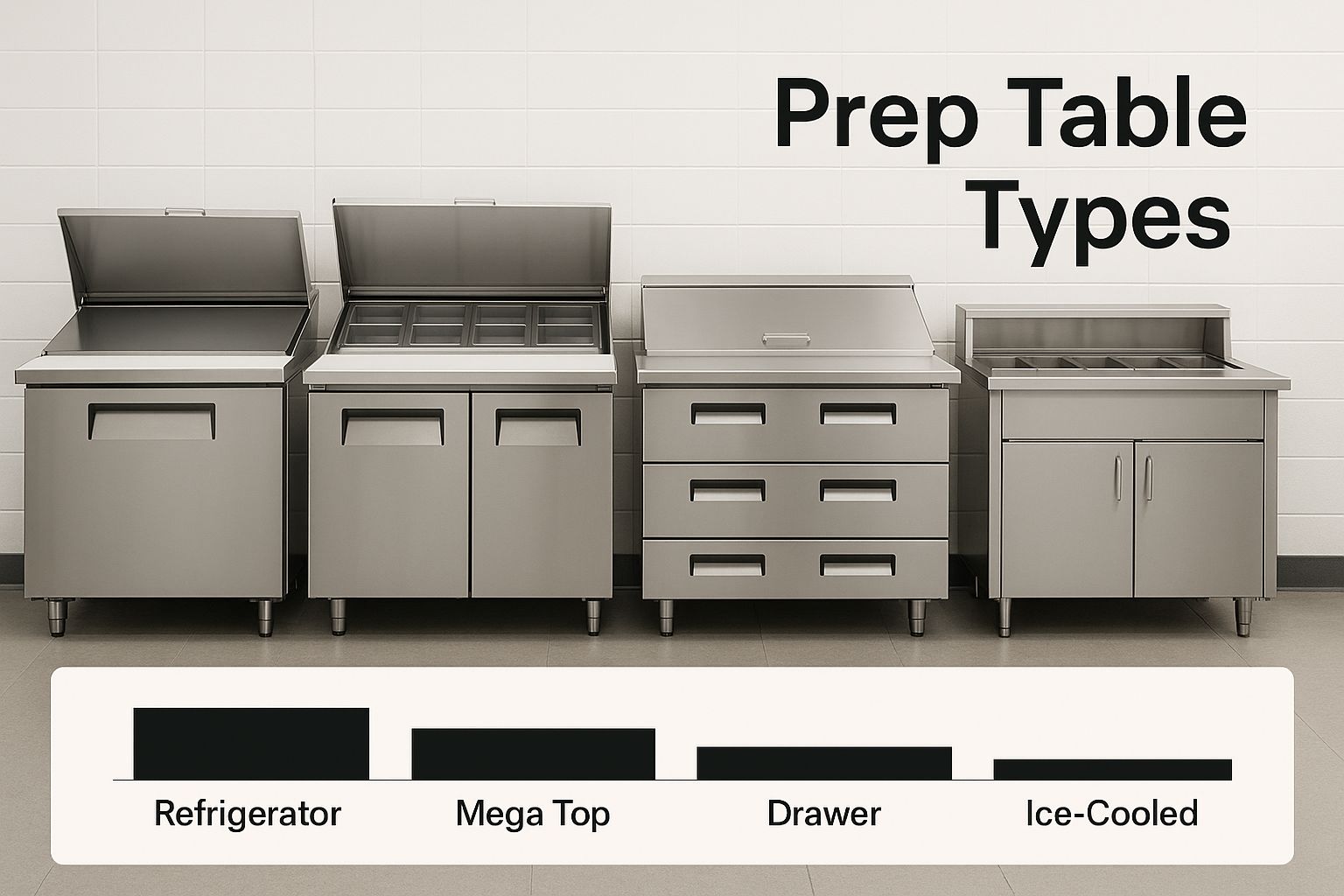

This visual guide gives you a quick breakdown of how different prep table types come together to outfit a professional kitchen.

As the image shows, the most efficient kitchens use a mix of specialized tables to create a smooth, logical workflow from station to station.

Beyond Steel: Other Materials and How They're Built

While stainless steel gets most of the glory, other materials have their own special roles to play. You'll often see a baker's table with a classic wooden top—it's just better for kneading dough and working with pastry. Some tables even come with built-in polyethylene cutting boards, giving you a dedicated, food-safe surface for all your chopping and dicing.

How the table is put together is just as crucial as the surface it's topped with.

- Welded Construction: These tables show up at your door fully assembled. The joints are welded solid, creating a rock-steady, rigid frame that won't wobble, even under intense, heavy-duty use. They are built to last.

- Knocked-Down Construction: These are the flat-pack version. They ship in pieces and you assemble them on-site. The upside is they're more affordable and way easier to get through a tight doorway. The downside? Bolts can loosen over time, making them a bit less stable in the long run.

Here’s a pro tip: always check the edge style. A table with a "marine edge" has a raised lip around the perimeter. It’s designed to contain spills and liquids, keeping them off your floor. This tiny detail is an absolute lifesaver during a chaotic service, making your kitchen safer and cleaner.

Finding the Right Prep Table for Your Menu

Your menu is more than just a list of dishes; it’s the blueprint for your entire kitchen. It dictates every piece of equipment you need, and nothing proves this more than the humble restaurant prep table. Think of it this way: if your menu is the script, your equipment is the cast. Each piece needs to be perfectly cast for its role, or the whole performance falls flat.

Your menu is more than just a list of dishes; it’s the blueprint for your entire kitchen. It dictates every piece of equipment you need, and nothing proves this more than the humble restaurant prep table. Think of it this way: if your menu is the script, your equipment is the cast. Each piece needs to be perfectly cast for its role, or the whole performance falls flat.

Choosing a prep table isn't a one-size-fits-all game. The frantic pace of a deli cranking out sandwiches has completely different demands than a high-end bakery meticulously crafting pastries. When you match your table to your menu, you're not just buying a piece of steel—you're building an efficient, natural workflow that makes your staff’s life easier.

Matching the Table to the Task

Every kitchen needs a standard work table. It's the dependable, jack-of-all-trades performer. This simple, durable stainless steel surface is where the magic starts—chopping vegetables, portioning meat, or plating dishes. It's your go-to for any prep work that doesn't need to be chilled.

But when your menu is packed with salads, sandwiches, tacos, or anything with cold, fresh ingredients, a refrigerated prep table is an absolute game-changer. These units are brilliant, combining a workspace up top with refrigerated wells below. All your sliced meats, cheeses, and fresh greens are kept at a safe temperature, right at your fingertips. It turns a chaotic, multi-step process into a streamlined assembly line.

A refrigerated prep table is your secret weapon for both speed and food safety. Keeping ingredients consistently chilled doesn't just boost efficiency; it dramatically cuts the risk of temperature-related foodborne illness.

Specialized Tables for Unique Menus

Some menus have very specific needs that call for a specialist. A pizza joint, for instance, lives and dies by its pizza prep table. These are cleverly designed with a deep, refrigerated rail to hold all your toppings and an extra-wide cutting board. This setup lets your pizza maker slide a crust down the line, adding sauce and toppings in one fluid motion. It’s pure poetry in motion.

Other specialized tables include:

- Baker's Tables: These often have a thick wood top—usually maple—because it stays cooler than steel and its texture helps prevent dough from sticking. It’s the perfect surface for kneading bread or rolling out delicate pastries.

- Sandwich and Salad Units: A specific type of refrigerated table, these are built with integrated cutting boards and cooled ingredient rails to make building sandwiches and tossing salads as fast as humanly possible.

Of course, prep is only half the battle. Once your ingredients are ready, they head to the cook line. If you're grilling proteins or charring vegetables, pairing your prep station with the right cooking gear is critical for a smooth workflow. We offer a huge selection of commercial charbroilers to complete your setup. Whether you need the searing, even heat of an infrared charbroiler, the classic smoky flavor from a gas charbroiler, or the precise control of an electric charbroiler, we have a model to match your menu and create a truly productive kitchen.

Smart Features That Maximize Kitchen Space

Modern restaurant prep tables have come a long way from being just simple, flat surfaces. Today’s best units are smartly designed, multi-tool workstations built to solve the real problems you face in the kitchen every single day. The right features can turn a basic table into a serious productivity hub, tackling issues like tight spaces, slow workflow, and sanitation head-on.

Think of these features as a way to customize your workstation for peak performance. Even a few simple but effective add-ons can make a world of difference when your kitchen feels cramped and chaotic.

A well-equipped prep table acts as a force multiplier for your kitchen staff. Every feature that saves a step, keeps an ingredient fresh, or prevents a mess is a direct investment in a smoother, faster service.

By integrating smart design choices, you’re not just buying a piece of steel; you’re activating a part of your workflow. It’s all about making every single square inch of your kitchen work harder for you.

Practical Add-Ons That Boost Productivity

Often, the features that make the biggest impact are the most practical ones—the simple solutions to everyday kitchen headaches. These add-ons help organize your space, protect your supplies, and keep your prep area clean and safe.

- Undershelves: An open undershelf is your best friend for creating accessible storage right where you need it. It’s the perfect spot to stash frequently used pots, pans, and mixing bowls, keeping them off your main work surface but still within easy reach.

- Cabinet Bases: For items that need a bit more protection from the kitchen environment, a cabinet base is the way to go. This enclosed storage shields things like clean linens, small appliances, or dry goods from dust, spills, and splashes, making sure they stay clean and ready for action.

- Backsplashes: This is a non-negotiable feature for maintaining hygiene. A backsplash acts as a barrier, preventing food bits and liquids from splashing onto the wall behind your table. This makes cleanup worlds easier and is crucial for meeting health code standards.

These additions allow you to build out stations that are perfectly tailored to specific tasks, whether it's chopping, mixing, or plating. When your stations are well-organized, your entire cooking line just operates more smoothly. To see how these organized prep stations feed into a powerful cooking line, check out our guide on commercial hot plates, which often sit right next to prep areas.

The Rise of Intelligent and Modular Designs

The evolution of prep tables is also catching up with the tech advancements we're seeing across the commercial kitchen. Modern units are becoming more than just standalone surfaces; they’re turning into integrated systems with some seriously advanced features. We're now seeing smart, connected tables that offer real-time temperature monitoring and send maintenance alerts, which is a huge boost for both food safety and operational efficiency. You can learn more about this trend by exploring these insights on the food prep tables market.

Beyond just connectivity, modularity is offering incredible flexibility. Many restaurant prep tables now have customizable designs that let you add things like integrated sinks, cutting board inserts, or specialized drawers. This means you can essentially build a workstation from the ground up that's perfectly suited to your menu and your kitchen's unique flow, squeezing every last drop of productivity out of your space.

Designing Your Kitchen for Optimal Workflow

https://www.youtube.com/embed/AEYTXONgDLA

Where you place your restaurant prep tables can make or break your kitchen's entire rhythm. It's the difference between a smooth, efficient service and one filled with frustrating bottlenecks. A smart layout isn't about cramming equipment into a room; it's about engineering a space that eliminates wasted motion and keeps your team in a state of productive flow.

It all starts with a simple tape measure. Before you even think about buying a table, map out your actual, usable space. Don’t forget to account for clearance on every side. Your crew needs room to walk, pivot, and open refrigerator doors without causing a traffic jam.

Applying the Work Triangle to a Commercial Kitchen

You've probably heard of the "kitchen work triangle," a classic design rule connecting storage, prep, and cooking. In a commercial kitchen, this idea gets scaled up to create logical "zones" that support a seamless operation. Your restaurant prep tables are the absolute heart of that prep zone.

To get that flow right, you have to be intentional about where those tables go.

- Near Refrigeration: The most logical spot for your main prep area is right next to your cold storage. This simple move means chefs can grab ingredients without trekking across the kitchen, saving precious seconds and energy with every single order. Check out our range of commercial refrigerators to find the perfect unit to pair with your new layout.

- Adjacent to the Cook Line: The journey from a prepped ingredient to a hot pan should be as short as humanly possible. Placing your prep station right next to your cooking equipment means that as soon as something is chopped, sliced, or mixed, it can be handed off instantly. This is where your entire workflow truly comes together.

A well-placed prep table creates a direct line of sight and movement between your key kitchen zones. This layout not only makes your team faster but also significantly reduces physical fatigue over a long shift—a huge factor in maintaining staff morale and performance.

From Prep to Plate Seamlessly

The final piece of this workflow puzzle is your cooking equipment. Whether your menu is built around ovens, fryers, or charbroilers, the handoff from the prep table has to be completely effortless. As you browse our selection of commercial charbroilers, think about how each one would physically integrate with your prep station.

We offer models for any kitchen configuration imaginable. You’ll find powerful infrared charbroilers for that intense, steakhouse-quality sear, versatile gas charbroilers for that classic grilled flavor, and precise electric charbroilers for more controlled cooking. By placing the right charbroiler next to a well-positioned prep station, you create a powerful, efficient work cell that moves food from raw ingredient to finished plate without a single wasted motion.

Keeping Your Prep Tables in Fighting Shape

Your restaurant prep tables are the unsung heroes of the kitchen. They take a beating day in and day out, but like any piece of essential gear, their lifespan really comes down to how well you treat them. Taking care of your tables isn't just about looks; it's about keeping food safe and avoiding those expensive, kitchen-stopping breakdowns.

Think of a solid cleaning and maintenance schedule as your insurance policy against rust, dings, and giving up the ghost too soon. A consistent routine keeps your workstations humming along as a reliable asset, not a looming liability.

The Daily Clean-Down: Your First Line of Defense

A daily wipe-down is completely non-negotiable. It’s what keeps your stainless steel sanitary and stops rust before it can even think about starting. After every single shift, your team needs to run this simple playbook:

- Clear the Decks: Get all the food scraps, tools, and cutting boards off the surface. A soft plastic or rubber scraper is your best friend here—it gets the gunk off without scratching the steel.

- Wash It Down: Grab a soft cloth or sponge, some warm water, and a mild detergent. Give the entire table a good wash, hitting the backsplash, all the edges, and the legs.

- Rinse and Sanitize: Use clean water to rinse off every bit of soap. Then, follow up with a food-safe sanitizer, making sure to follow the manufacturer's directions to kill off any lingering bacteria.

- Dry, Dry, Dry: This is the one step you can't skip. Use a clean, dry towel and wipe down every single inch of the table. Standing water is stainless steel's mortal enemy and the number one cause of rust and ugly water spots.

Simple Maintenance Checks That Save Big Headaches

Beyond the daily scrub, a little preventative maintenance can save you from massive problems later. Giving your tables a quick once-over helps you spot small issues before they turn into big, expensive ones. For instance, keeping your cook line equipment clean is just as important—it stops grease and grime from migrating over to your prep areas. A well-maintained charbroiler station means less mess everywhere else.

Just like you wouldn't neglect your high-powered cooking equipment, you can't ignore your prep surfaces. We have a huge range of commercial charbroilers perfect for any kitchen, including powerful infrared charbroilers, workhorse gas charbroilers, and precise electric charbroilers. Keeping both your cooking and prep stations in top shape makes for a safer and more efficient kitchen.

A few quick checks go a long way. Tighten any leg bolts that have started to wobble—a stable table is a safe table. Take a peek at the casters to make sure they're free of debris and damage. These simple habits keep your restaurant prep tables steady, secure, and always ready for service.

Still Have Questions About Prep Tables?

Choosing the right restaurant prep table can feel surprisingly complicated, and it’s easy to get lost in the details. A few clear answers can help you pick the perfect workstation for your kitchen without spending hours on research. Here are some of the most common questions I hear from restaurant owners when they're on the hunt.

What’s the Best Grade of Stainless Steel?

For any area where you're handling food directly, 304-grade stainless steel is the undisputed champion. It’s built to resist the rust and corrosion that comes from constant contact with salts, acidic foods like tomatoes or citrus, and moisture. That durability makes it a breeze to keep sanitary and is absolutely worth the investment for any "wet" work zone.

Now, 430-grade steel is a solid, more budget-friendly choice. It’s best kept to dry applications, like holding equipment or storing dry goods. If you expose it to moisture day in and day out, you’re likely to see rust start to form.

Pro Tip: Think of 304-grade as your frontline soldier, right in the thick of food prep. The 430-grade is your reliable support staff, perfect for holding down the fort with dry storage and equipment stands.

Should I Get an Undershelf or a Cabinet Base?

This one comes down to your kitchen's workflow and what you need to store. An open undershelf is perfect for grabbing things you use all the time, like mixing bowls, pots, or bulk ingredient containers. You can see everything at a glance, it helps with airflow, and it's simple to clean underneath.

A cabinet base, on the other hand, gives you enclosed storage. This is ideal for protecting supplies from dust, splashes, and the general chaos of a busy kitchen. It's the perfect spot for stashing sensitive items like clean linens, small appliances, or extra disposables, though you will have to put in a bit more effort to clean inside the cabinet.

How Do I Pick the Right Table Height?

Most commercial prep tables are a standard 34-36 inches high, which is a comfortable, ergonomic height for the average person. But you really should think about the main job that will happen at that specific station.

For heavy-duty, forceful work like chopping dense root vegetables, a slightly lower table can give your chefs better leverage and reduce shoulder strain. On the flip side, for delicate work like intricate pastry decorating or careful plating, a slightly higher surface can prevent your team from hunching over and straining their backs. If you want maximum flexibility, look for models with adjustable legs to suit different tasks and staff members.

At Charbroilers, we know every single piece of equipment has to pull its weight for your kitchen to succeed. That’s why we offer a huge selection of commercial charbroilers to complete your cook line, from powerful infrared and versatile gas models to precise electric units. Find the perfect match for your menu and workflow at https://charbroilers.com.