The Ultimate Restaurant Kitchen Equipment List

Share

A complete restaurant kitchen equipment list is your roadmap to a successful back-of-house. It covers everything from the heavy-duty cooking appliances and walk-in coolers down to the smallwares and cleaning tools that keep your operation humming. This isn't just a shopping list; it's a foundational checklist that ensures you have what you need for cooking, prep, storage, and sanitation—all critical for a smooth and compliant kitchen.

Your Definitive Kitchen Equipment Checklist

Outfitting a new restaurant or upgrading an existing one is a serious investment, and a detailed checklist is your best friend in this process. Think of this guide as your strategic plan, helping you pinpoint every single piece of equipment your kitchen needs to function at its best. By methodically working through this list, you're setting up your back-of-house for peak performance, food safety, and operational success right from day one.

The numbers don't lie. The foodservice equipment market is booming, expected to jump from USD 4.6 billion in 2025 to USD 7.3 billion by 2035. With commercial kitchen equipment making up about 68% of that market, its foundational role is crystal clear. You can dig into more of these trends in this detailed foodservice equipment report.

Prioritizing Your Major Purchases

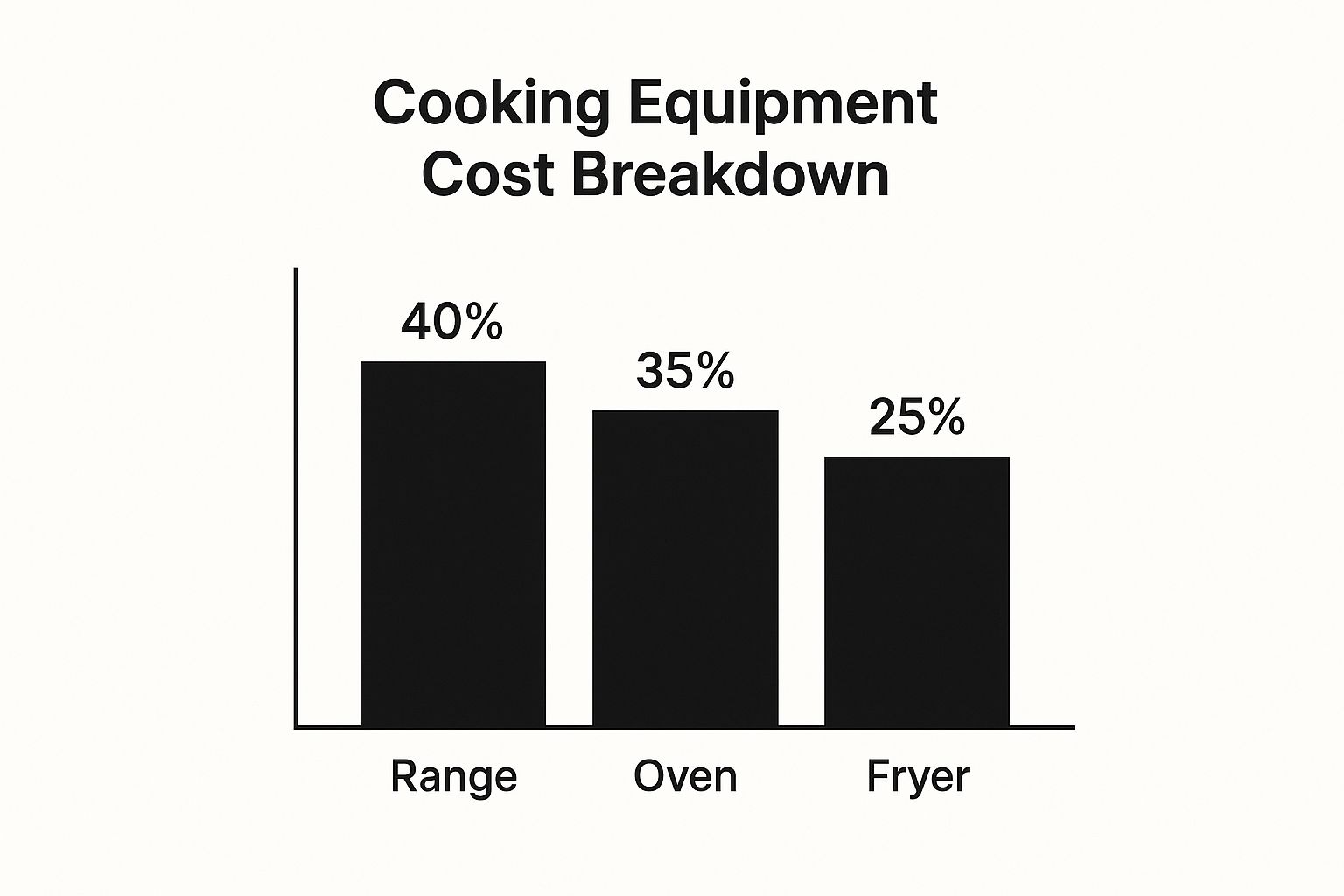

When you're mapping out your budget, the big-ticket cooking appliances will almost always represent the largest upfront cost. Knowing how that investment is typically split can help you allocate your funds without any nasty surprises.

This chart breaks down a pretty common cost distribution for your core cooking line.

As you can see, the commercial range and oven usually eat up the biggest slice of the pie. This makes perfect sense, as they are the true workhorses and the heart of your kitchen's production.

Quick-Reference Restaurant Kitchen Equipment Categories

To make your planning a whole lot easier, we’ve broken down the essentials into logical categories. This table gives you a high-level snapshot of what every professional kitchen needs and serves as a quick-reference guide for the more detailed sections to come.

| Equipment Category | Essential Items Examples | Primary Function |

|---|---|---|

| Cooking Equipment | Ranges, Ovens, Fryers, Griddles, Charbroilers | Applying heat to cook raw ingredients into finished dishes. |

| Refrigeration & Storage | Walk-In Coolers, Reach-In Freezers, Prep Tables | Preserving ingredient freshness and ensuring food safety. |

| Food Preparation | Mixers, Slicers, Food Processors, Work Tables | Preparing ingredients for the cooking process efficiently. |

| Sanitation & Warewashing | 3-Compartment Sinks, Dishwashers, Grease Traps | Cleaning and sanitizing all cookware, dishes, and surfaces. |

| Smallwares & Utensils | Knives, Pots, Pans, Cutting Boards, Tongs | Tools used directly by chefs and cooks for daily tasks. |

Use this table as your starting point. It helps you quickly assess what you have and what you still need to source, ensuring no critical area gets overlooked in the hustle of opening a restaurant.

Essential Cooking Equipment and Appliances

The cooking line is the true engine room of any successful restaurant. It's where all the action happens, where raw ingredients are turned into the signature dishes that define your entire brand. Deciding on the right cooking equipment for your specific menu and expected volume is one of the most critical calls you'll make. This part of your restaurant kitchen equipment list breaks down the workhorse appliances that drive speed, consistency, and quality through every single service.

The market for these tools tells you everything you need to know about their importance. The global commercial cooking equipment space was pegged at roughly USD 13.8 billion in 2024 and is on track to hit USD 22.4 billion by 2033. That growth shows just how serious restaurants are about investing in modern, efficient gear. You can dig into other market projections to see how the industry is shifting, especially toward energy-efficient solutions that save money in the long run.

The Commercial Range and Oven

Right at the heart of most kitchen lines, you'll find the commercial range, usually with an oven built into the base. This combo is the ultimate multitasker, giving chefs the power to sauté, boil, pan-fry, and bake all at the same time. The first big choice you'll face is between gas and electric.

- Gas Ranges: Most chefs I know swear by gas. You get instant heat and the kind of precise, visual flame control that’s essential for high-volume cooking where every second counts.

- Electric Ranges: These offer a sleek, flat surface that's a dream to clean. They provide incredibly even, consistent heat, which is a game-changer for simmering delicate sauces or other finicky tasks. The induction models are particularly impressive when it comes to energy efficiency.

The oven underneath is just as critical. A standard oven base is a versatile workhorse, but specialized units like convection or combi ovens can blow your menu wide open. Convection ovens use internal fans to move hot air around, cooking food up to 25% faster and more evenly than a regular oven—a must-have for serious roasting and baking operations.

High-Capacity Deep Fryers

If you're serving anything from french fries and onion rings to fried chicken or donuts, a commercial deep fryer is completely non-negotiable. The real key here is picking a model with the right oil capacity and recovery time for your needs. A fryer that can’t keep up during a dinner rush will only produce soggy, greasy food and create long ticket times. It's a recipe for disaster.

When you're shopping for a fryer, keep these points in mind:

- Capacity: This is measured by how much oil it holds (a 40-50 lb capacity is pretty standard). You need to match this to how many fried items you realistically expect to sell.

- Power Source: Gas fryers generally heat up faster and have quicker recovery times between batches. Electric models, on the other hand, can give you more precise temperature control.

- Number of Vats: A double-vat fryer is a smart move. It lets you cook different foods, like fish and fries, in separate vats to stop any flavor transfer. Nobody wants fishy-tasting french fries.

The Versatile Griddle and Charbroiler

Flat-top griddles are absolute staples for diners, cafes, and any spot churning out breakfast items like pancakes and eggs or lunch classics like Philly cheesesteaks and burgers. Their huge, flat surface lets you cook a bunch of orders at once, making them champions of efficiency.

But for that signature smoky flavor and those perfect grill marks every customer loves, a commercial charbroiler is indispensable. Unlike a griddle, a charbroiler has grates that expose food directly to the heat source. That's how you get that classic, straight-off-the-grill taste. We offer a wide selection of commercial charbroilers for your restaurant, including infrared, gas, and electric charbroilers to fit any kitchen's needs.

Pro Tip: When you're picking a charbroiler, pay close attention to the grates. Cast iron grates hold heat like nothing else, giving you deep, well-defined sear marks. Stainless steel grates, however, are much easier to clean and won't rust.

The Importance of Ventilation Hoods

We can't talk about all this hot-line equipment without discussing proper ventilation. A commercial ventilation hood isn't just an accessory; it's a critical piece of safety equipment. It’s responsible for pulling grease, smoke, heat, and other gunk out of the air.

This protects your air quality, prevents devastating fire hazards, and ensures you're up to code with local health and fire departments. Your hood system must be sized and installed correctly based on the specific equipment running underneath it—this is a crucial step you absolutely cannot afford to get wrong when designing a safe, functional kitchen.

Choosing the Right Commercial Charbroiler

When your menu calls for that signature smoky flavor and those perfect, deep sear marks, a commercial charbroiler isn't just nice to have—it's essential. This single piece of equipment is the key to delivering the authentic, straight-off-the-grill taste that brings customers back. Adding a charbroiler to your restaurant kitchen equipment list unlocks a whole new world of menu items, from juicy steaks and burgers to beautifully charred vegetables and seafood.

Unlike a flat-top griddle that cooks with surface contact, a charbroiler uses heavy-duty grates to expose food directly to a powerful heat source below. This process creates a distinct texture and flavor profile you just can't get any other way. But not all charbroilers are built the same. Our selection covers several types, and each one brings its own advantages that will directly impact flavor, cook times, and the daily workflow in your kitchen. Honestly, the right choice comes down to your menu, kitchen layout, and how many covers you do on a busy night.

Comparing Gas and Electric Charbroilers

The first and most important decision you'll face is whether to go with a gas or an electric model. Each power source offers unique benefits, and one is likely a better fit for your specific kitchen environment and cooking style.

- Gas Charbroilers: Most chefs I know swear by gas. They love the responsive and incredibly precise temperature control, which allows for instant heat adjustments on the fly. This is absolutely critical during a hectic service when you're jumping from searing a thick-cut ribeye to gently grilling delicate fish. They also tend to reach higher temperatures faster than their electric cousins.

- Electric Charbroilers: These units are a fantastic solution for kitchens where running a gas line isn't an option or is restricted by building codes. Electric models are champs at providing exceptionally consistent and even heat across the entire cooking surface. This consistency helps eliminate frustrating hot spots and ensures every single item is cooked perfectly.

Your decision here will fundamentally shape your entire grilling process. For a much deeper look into these options, you should check out this guide to commercial charbroilers for your restaurant, which really breaks down the pros and cons in greater detail.

A key thing to think about is the broiler's heat source design. Some units use metal radiants to distribute heat, while others use lava rocks. When drippings hit those hot lava rocks, they vaporize, creating a distinct smoky flavor that gets infused right back into the food.

The Power of Infrared Technology

Looking beyond the standard gas and electric models, infrared charbroilers represent a major leap forward in grilling technology. These are the high-performance machines of the charbroiler world, using ceramic plates to generate intense, direct infrared heat.

This method cooks food faster and holds a much more consistent temperature, often cutting pre-heat times down significantly. The intense heat instantly sears the outside of meats, which does an incredible job of locking in juices for a more succulent final product. On top of that, infrared technology is famous for minimizing flare-ups, which is a big win for safety and prevents that bitter taste you get from burnt drippings. They might have a higher upfront cost, but their efficiency can lead to real savings on energy bills and much faster ticket times.

Selecting the Right Size and Grates

Finally, you have to think about the physical specs of the charbroiler itself. The size should be determined by your projected peak volume—a unit that’s too small will become a massive bottleneck in your kitchen and hamstring your service.

The material your grates are made from is another critical factor:

- Cast Iron Grates: These are the best for heat retention. If you want those deep, dark, and dramatic sear marks, cast iron is the way to go.

- Stainless Steel Grates: These are much easier to clean and are more resistant to rust, making them a durable, low-maintenance choice for a busy kitchen.

By carefully weighing the gas, electric, and infrared options right alongside the size and grate material, you can confidently pick the perfect charbroiler that truly aligns with your culinary vision and operational needs.

Commercial Refrigeration and Cold Storage

Proper cold storage is the absolute bedrock of a safe and profitable kitchen. It's not just about keeping things from going bad; your refrigeration is the unsung hero that guarantees food safety, keeps your inventory in check, and slashes waste. Without a reliable cold storage system, you're not just risking spoiled food—you're risking your reputation and your compliance with health codes.

These units are mission-critical. They are the systems that protect your ingredients from the moment they arrive until they hit the plate. A smart investment here directly translates to the quality of food you serve and the efficiency of your entire kitchen workflow. Get this part right, and everything else runs smoother.

Essential Cold Storage Solutions

To really build a bulletproof cold storage setup, you have to map out the journey your food takes, from the delivery truck all the way to the prep line. This means you need a smart mix of refrigeration types, each playing a specific role.

- Walk-In Coolers and Freezers: These are your bulk storage workhorses. A walk-in cooler is non-negotiable for holding large volumes of fresh produce, dairy, and proteins. The walk-in freezer is just as vital for all your frozen goods. They let you take advantage of bulk purchasing, which is a key strategy for managing food costs in any serious operation.

- Reach-In Refrigerators and Freezers: Think of these as the frontline soldiers. Placed right on the cooking line or in your main prep areas, they give your team instant access to ingredients during the chaos of service. That convenience is everything when you're trying to keep ticket times low and the kitchen flowing smoothly.

- Under-Counter Refrigerators: These are brilliant for maximizing every square inch of your kitchen. They tuck neatly under prep tables and counters, creating hyper-efficient workstations. They are perfect for holding frequently used items right where you need them, like at a dedicated salad or dessert station.

Specialized Refrigeration for Peak Efficiency

Once you've got your core storage covered, you can look at specialized units that seriously level up your kitchen's productivity and what you can offer on your menu. These are machines built for specific jobs that standard coolers just can't handle well.

A perfect example is the refrigerated prep table, a must-have for any place making sandwiches, salads, or pizzas. These units are geniuses of design, combining a refrigerated cabinet below with a cold rail on top that holds food pans. This keeps all your sliced meats, cheeses, and veggies perfectly chilled and right at your fingertips during assembly. For a deeper look at different models, you can keep your cool with these restaurant-ready commercial refrigerators.

Then there's the blast chiller, a true game-changer. A regular fridge cools things down slowly, but a blast chiller is engineered to rocket hot food through the temperature "danger zone" (40°F to 140°F) in a fraction of the time. This rapid cooling process is crucial for food safety, but it also does wonders for preserving the texture and flavor of prepped items, dramatically extending their shelf life.

By strategically combining walk-ins for your bulk inventory, reach-ins for line access, and specialized units like prep tables and blast chillers, you create an unbroken, efficient, and safe cold chain inside your kitchen walls.

Food Preparation and Workstation Essentials

An efficient kitchen is built from the prep station out. Long before any food hits the grill or fryer, this is where the real work happens—where raw ingredients are transformed into perfectly prepped components that make a smooth, fast service possible. Speed, consistency, and organization all start here, and having the right gear is what separates a chaotic kitchen from a high-performing one.

The numbers back this up. The global market for restaurant equipment is climbing, expected to grow from $3.88 billion in 2024 to a staggering $5.72 billion by 2029. This isn't just about replacing old gear; it's about smart investments in efficiency and food safety. You can dive deeper into these market trends on The Business Research Company to see where the industry is heading.

Core Prep Appliances

For any kitchen cranking out serious volume, doing everything by hand is a recipe for disaster. It’s a major bottleneck that slows down your entire line. A few key appliances can take over the most repetitive, time-consuming tasks, freeing up your skilled chefs to focus on what they do best: cooking and plating beautiful food.

- Commercial Food Processors: Forget the one you have at home. These are built like tanks, designed to dice, slice, shred, and puree huge batches of vegetables, cheese, or anything else you throw at them in seconds. The result is perfect, uniform cuts every single time.

- Heavy-Duty Mixers: If you’re making your own dough, batters, or sauces from scratch, a planetary or spiral mixer is non-negotiable. These machines handle dense, heavy loads without breaking a sweat, giving you consistent results whether you're making pizza dough or a delicate cake batter.

- Precision Slicers: A must-have for delis and sandwich shops, but just as critical for any kitchen needing perfectly uniform slices of meats and cheeses. It delivers a level of speed and precision that’s simply impossible to match with a knife.

- Immersion Blenders: Often called stick blenders, these are one of the most versatile tools you can own. Blend soups and sauces right in the pot, saving a ton of time and cutting down on the mountain of dishes you have to wash later.

The Foundation of Your Workspace

While appliances do the heavy lifting, your physical workspace is where the magic really happens. Your workstations are the command centers for prep, and they need to be tough, hygienic, and ridiculously organized to keep things flowing smoothly.

A well-designed prep station is more than just a table; it's a system. The goal is to create a setup where a chef can access everything they need with minimal movement, creating a smooth and ergonomic workflow that reduces fatigue and speeds up service.

Stainless steel work tables are the gold standard for a reason. They're incredibly tough, non-porous (so they don't harbor bacteria), and a breeze to clean and sanitize—all things your health inspector loves to see. When you're shopping for tables, look for models with built-in undershelves. That extra storage is invaluable for keeping your work surface clear and organized. To get the full picture, check out our guide on setting up your restaurant prep tables.

And finally, you can't have a prep station without a solid set of color-coded cutting boards. This simple system is the bedrock of food safety, making it easy to prevent cross-contamination between raw meats, poultry, seafood, and fresh produce. It’s a small, easy-to-implement practice that has a massive impact on your kitchen’s overall hygiene.

Sanitation and Warewashing Systems

In any restaurant, incredible food is only half the battle. Impeccable cleanliness is the non-negotiable foundation of every successful kitchen, and this section breaks down the critical systems you need for warewashing and maintaining absolute sanitation. These tools are your first line of defense in protecting your customers, your reputation, and making sure you sail through every health inspection.

From workhorse dishwashers that chew through mountains of plates to the humble (but legally required) three-compartment sink, every piece plays a part. A well-designed sanitation setup doesn't just guarantee a steady stream of clean dishes; it creates a safer, more organized workflow for your entire crew.

Commercial Dishwashers: High-Temp vs. Low-Temp

A commercial dishwasher is a true labor-saving hero in any busy kitchen. Your main decision will be between a high-temperature and a low-temperature model, and each comes with its own set of rules for operation.

- High-Temperature Dishwashers: These machines use a built-in booster heater to blast dishes with a final rinse of at least 180°F, which is hot enough to sanitize everything without chemicals. They cost more upfront and need a proper vent hood, but your dishes dry almost instantly and come out free of any chemical residue.

- Low-Temperature Dishwashers: These models rely on chemical sanitizers (like chlorine or iodine) to do the heavy lifting, using water between 120°F and 140°F. They're cheaper to buy and don't need a special hood, making them a great fit for smaller budgets or tight spaces. Just remember to factor in the ongoing cost of the sanitizing chemicals.

The Essential Three-Compartment Sink

Even if you have the most powerful dishwasher on the market, a three-compartment sink isn't optional—it's legally required in almost every commercial kitchen. This is your go-to station for manually washing, rinsing, and sanitizing all the bulky pots, pans, and utensils that just won't fit in a machine.

A correctly set up three-compartment sink is a cornerstone of food safety. It provides a systematic, code-compliant method for cleaning that prevents cross-contamination and ensures every item is properly sanitized before its next use.

Getting the setup right is simple but absolutely critical:

- Wash: The first compartment gets hot water (at least 110°F) and a good dose of cleaning detergent.

- Rinse: The middle sink is filled with clean, warm water to rinse off all the soap suds.

- Sanitize: The final compartment holds a chemical sanitizing solution, mixed to the correct concentration, where items are fully submerged for a specific amount of time.

Critical Sanitation Support Systems

Beyond the main warewashing stations, a few other systems are vital for keeping your entire kitchen environment clean and safe. A grease trap is a crucial plumbing device that catches fats, oils, and solids before they can get into the main sewer lines, saving you from disastrous clogs and hefty fines.

You'll also need dedicated handwashing stations, fully equipped with hot water, soap, and single-use towels, placed conveniently for all staff. And don't forget a well-stocked janitorial closet with mops, buckets, brooms, and the right cleaning chemicals—it's the backbone of your daily cleaning routine, ensuring your entire operation stays spotless from floor to ceiling.

Frequently Asked Questions

Putting together a new kitchen is a huge undertaking, and it's completely normal to have questions when you start building out your restaurant kitchen equipment list. Getting solid answers on budgeting, what to buy, and what you really need can help you make smart choices and avoid those costly rookie mistakes. This FAQ tackles the most common hurdles restaurant owners run into.

My goal here is to give you the practical, real-world knowledge you need to invest with confidence. When you understand the key variables, you can pick equipment that not only fits your budget but also sets you up for long-term success.

What Is the Most Important Equipment for a New Restaurant?

While every single kitchen has its own unique quirks, a few pieces are non-negotiable right out of the gate. The heart of your operation is always the cooking line—think a commercial range, oven, and fryer. Just as critical is your refrigeration. You absolutely need reliable cold storage, like a walk-in cooler and a few reach-in units, to handle inventory and meet food safety laws.

From that core, your equipment list will grow based on what's on your menu. But pretty much every functional kitchen starts with this foundation:

- Cooking Line: A range, oven, fryer, griddle, or charbroiler forms your primary cooking setup.

- Refrigeration: You'll need a walk-in cooler, a reach-in refrigerator, and a freezer at a minimum.

- Prep Stations: Stainless steel work tables are your workhorses, along with essential tools like food processors.

- Sanitation: A three-compartment sink for washing and a commercial dishwasher are required for health code compliance.

These items are the backbone of any kitchen that's built to last.

Should I Buy New or Used Kitchen Equipment?

This is the big one, the question every new operator grapples with because it hits your startup budget hard. Both new and used equipment come with serious pros and cons, and you have to weigh them carefully against your finances and how much risk you're willing to take on.

Buying new gives you the comfort of a manufacturer's warranty, the latest in energy efficiency, and gear that’s in perfect condition. On the flip side, used equipment can cut your initial costs by a massive 50-70%, which frees up a ton of cash. The trade-off? No warranty and the very real possibility of higher repair bills down the road.

My advice? The right call often depends on the piece of equipment. For complicated gear with lots of moving parts like an ice machine or a combi oven, buying new is almost always the safer bet. For simple, sturdy items like stainless steel tables or sinks, used is a perfectly smart way to save money.

Deciding between new and used gear is a critical step for any restaurant owner. Here’s a table to help you compare the key factors side-by-side, so you can see which path makes more sense for your specific situation.

New vs Used Equipment Purchase Considerations

| Factor | New Equipment | Used Equipment |

|---|---|---|

| Upfront Cost | Highest initial investment. | Significantly lower initial cost. |

| Warranty | Comes with manufacturer warranty. | Typically sold "as-is" with no warranty. |

| Reliability | Highest reliability and latest tech. | Higher risk of breakdowns and repairs. |

| Lifespan | Full expected operational lifespan. | Lifespan is already partially used up. |

| Energy Efficiency | Often meets modern efficiency standards. | Older models can have higher utility costs. |

Ultimately, this decision is about balancing upfront savings against long-term risk. A hybrid approach—buying new for critical, complex equipment and used for simpler, durable items—often provides the best of both worlds.

How Do I Create a Budget for My Kitchen Equipment?

Building a realistic budget always, always starts with your menu. Your menu is the blueprint that dictates every single piece of cooking, prep, and storage equipment you'll need. Once you have that final equipment list, start researching costs for both new and used options to get a clear picture of the price range you're working with.

A solid rule of thumb is to set aside 10-15% of your total startup capital for kitchen equipment. Critically, you need to add a contingency fund of at least 15-20% on top of that equipment budget. This buffer is your safety net for the inevitable—unexpected shipping fees, surprise installation costs, or that one last-minute item you forgot about.

At Charbroilers, we offer a wide selection of commercial charbroilers designed for performance and durability. Whether you need an infrared, gas, or electric model, we have the right equipment to perfect your menu. Explore our collection and find the ideal charbroiler for your kitchen.