Prep Tables for Restaurant: The Ultimate Owner's Guide

Share

Walk into any great restaurant kitchen, and you'll find the unsung hero of the operation: the prep table. It’s so much more than a stainless steel surface. This is the command center, the mission control for your entire kitchen workflow. Get this one piece of equipment right, and you'll see faster ticket times, better food safety, and a team that isn't constantly running in circles.

The Hidden Engine of Your Restaurant Kitchen

Think of your kitchen like an orchestra. The chef is the conductor, the line cooks are the musicians, and the equipment is the collection of finely tuned instruments. In this symphony of controlled chaos, the prep tables for restaurant kitchens are the sheet music stands—they’re foundational, essential, and responsible for keeping everyone perfectly in sync. Without a well-chosen, strategically placed prep table, the entire performance can quickly fall apart.

This guide is about looking past the simple slab of steel and seeing how the right prep table is a strategic investment in operational excellence. It’s not just about finding a place to chop vegetables; it’s about designing an efficient, safe, and productive environment. A thoughtfully selected table can slash unnecessary steps for your staff, streamline food assembly from start to finish, and ultimately boost your bottom line by getting plates out the door faster.

A well-organized prep station is the first step toward a flawlessly executed dish. It sets the pace for the entire kitchen and ensures consistency, from the first order of the day to the last.

More Than Just a Countertop

The growing importance of this seemingly basic equipment is easy to see in the numbers. The global market for food prep tables was valued at roughly USD 1.18 billion in 2023 and is expected to climb to around USD 1.62 billion by 2029. That's not just random growth; it’s driven by the ever-increasing demands of the foodservice industry, where every second and every inch of space counts. You can discover more insights on the growing food prep table market trends and see how kitchens worldwide are prioritizing this foundational piece of gear.

So, how do you pick the right one? The only correct answer is: it depends entirely on your unique operation. We're going to give you a clear roadmap, from decoding the different types and materials to figuring out the best layout for maximum efficiency. We’ll cover:

- Essential Types: From all-purpose work tables to specialized refrigerated units.

- Sizing and Configuration: Matching the table to your space and menu.

- Materials and Durability: Understanding what makes a table last.

- Safety and Maintenance: Protecting your investment and your customers.

Let's dive in and start breaking down the core components of a truly successful kitchen setup.

What Are the Different Kinds of Prep Tables?

Choosing the right prep table for your kitchen is a lot like casting for a movie. You wouldn't hire a dramatic actor for a comedy role, right? The same logic applies here. To get your kitchen humming, you need to match the table to the task, starting with the all-purpose workhorse and moving into more specialized stars.

The most fundamental piece of the puzzle is the standard stainless steel work table. Think of this as the blank canvas of your kitchen—a simple, tough surface perfect for chopping, mixing, and general assembly. For most kitchens, this is the go-to, but its job is simply to provide a clean, flat space to work. If you're looking for that solid foundation, you can explore our collection of versatile stainless steel prep tables.

But when your menu needs ingredients to stay perfectly chilled right up until they hit the plate, you've got to look beyond the basic work table. This is where specialized prep stations really start to shine.

Specialized Stations Built for Speed and Safety

Refrigerated prep tables are absolute game-changers for both efficiency and food safety. They cleverly combine a work surface up top with cold storage down below, keeping everything you need right at your fingertips. This simple integration makes a huge difference by cutting down on how much your staff has to run around the kitchen and, more importantly, keeping food out of the temperature "danger zone."

Two main players dominate this category:

- Sandwich and Salad Prep Tables: These units are built for one thing: speed. They typically feature a cutting board running the length of the unit and a refrigerated rail on top, designed to hold pans of toppings, sauces, and greens. A busy deli can crank out sandwiches in seconds because every single ingredient is chilled, organized, and right where it needs to be.

- Pizza Prep Tables: They work on the same principle but are tailored for a different craft. These tables have a much deeper cutting board to give you plenty of room to stretch out large pizza doughs. Their refrigerated rails are also bigger to hold larger pans of cheese, sauce, and all the toppings you can imagine, turning the pizza-making process into a smooth, efficient assembly line.

You can’t overstate how crucial these cooled units are in a modern kitchen. In fact, refrigerated prep tables are a huge and growing slice of the commercial equipment market. The global market is set to climb from USD 7.67 billion in 2024 to USD 10.30 billion by 2031. This isn't just a random trend; it shows how essential these tables have become for keeping food fresh and quality high in today's fast-paced restaurants.

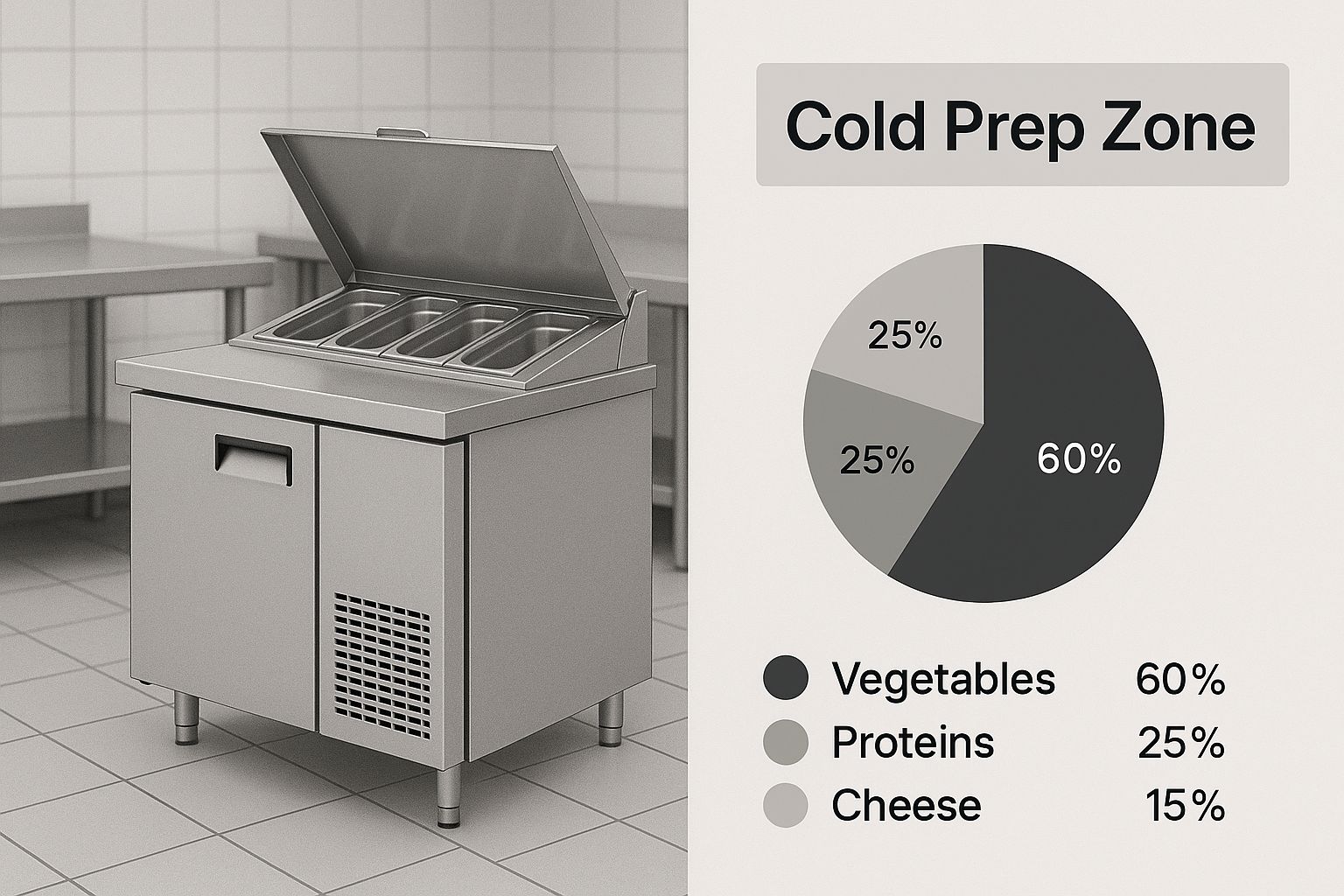

The image above really drives home the importance of a dedicated 'Cold Prep Zone' for keeping food safe and your team efficient. By building refrigerated storage right into the prep area, kitchens can slash food handling times and keep ingredients at their ideal temperature.

Comparison of Commercial Prep Table Types

With so many options, it can be tough to see the forest for the trees. This table breaks down the most common types to help you find the perfect fit for your menu and workflow.

| Table Type | Primary Use Case | Key Features | Ideal For |

|---|---|---|---|

| Standard Stainless Steel | General prep, mixing, chopping | Durable flat surface, often has a lower shelf for storage | Any kitchen needing basic, all-purpose workspace |

| Sandwich/Salad Table | Assembling sandwiches, salads, wraps | Refrigerated top rail for pans, integrated cutting board | Delis, cafes, sandwich shops, high-volume lunch spots |

| Pizza Prep Table | Making pizzas from scratch | Deep cutting board, refrigerated rail for large topping pans | Pizzerias, Italian restaurants, any venue serving pizza |

| Worktop Refrigerator/Freezer | Light prep and cold/frozen storage | Stainless steel top over a refrigerated or freezer base | Plating stations, dessert prep, bars, appetizer stations |

Each table has its superpower. The key is knowing what you need to accomplish and picking the equipment that will make that job easier, faster, and safer.

Multi-Function Units for Today's Kitchens

Sometimes, you need gear that does more than one job, especially when floor space is at a premium. This is where multi-function units come in, bridging the gap between prepping and cooking.

A smart kitchen layout isn't just about having the best equipment; it's about making sure each piece works together to create a seamless flow from prep to plate.

Take worktop refrigerators and freezers, for instance. These units give you a durable stainless steel top for lighter prep tasks while offering refrigerated or frozen storage below. You wouldn't want to do heavy-duty butchering on them, but they're absolutely perfect for plating desserts, assembling appetizers, or holding garnishes.

And if grilling is a core part of your operation, creating a dedicated grilling zone is a must. Placing a commercial charbroiler right next to a prep station creates a high-powered production line. This setup lets a chef season and prep proteins on the table and slide them directly onto the grill. We offer a wide selection of commercial charbroilers for your restaurant, including powerful and efficient infrared, gas, and electric char broilers to fit any kitchen's needs. It’s all about maximizing speed and locking in consistency.

Choosing the Right Size and Configuration

Picking the right size for your kitchen’s prep tables is a lot like a game of Tetris. You’re not just trying to squeeze a piece into an empty spot; you're making a strategic move that sets up your entire workflow for success. A table that’s too big will choke up traffic lanes and create chaos, but one that’s too small becomes an instant bottleneck during the dinner rush.

Before you even think about length and width, grab your floor plan. Your first move is to map out how your staff actually moves through the kitchen. Trace the path from the walk-in, to the prep stations, and over to the cooking line. A well-placed table makes this flow seamless, while a bad choice forces your team into an awkward shuffle around each other.

You also have to factor in accessibility. Making sure your workspace is compliant with the Americans with Disabilities Act (ADA) isn't just about following the rules—it creates a better, more functional kitchen for your entire team. This means leaving enough clearance, typically 36 inches for walkways, to keep things moving smoothly.

Calculating Your Ideal Workspace

Once you know your spatial limits, it’s time to figure out how much actual surface area you need. This decision comes down to two things: your menu’s complexity and your peak service volume. A small café with a simple menu might get by just fine with a compact 36-inch table. On the other hand, a high-volume spot with an elaborate menu is going to need a much bigger surface to handle multiple prep jobs at once.

To get this right, think about your absolute busiest moments. How many cooks are prepping at the same time? What's the biggest batch of ingredients they need to handle? Answering these questions gives you the minimum surface area required to keep the kitchen flowing without creating clutter or compromising food safety.

A common mistake is buying for the space you have, not the workflow you need. The right prep table should dictate the layout, not the other way around. It's an active tool, not a passive piece of furniture.

Storage Configurations Under the Hood

What’s going on below the work surface is just as critical as the top itself. Your choice between undershelves, cabinets, and drawers will directly impact how organized and fast your kitchen runs. Each one plays a different role in your storage game plan.

- Open Undershelves: This is the classic, most cost-effective choice. An open shelf gives your team quick, visible access to bulky items like flour bins, big mixing bowls, and stockpots. No fumbling with doors when you need something fast.

- Cabinet Doors: If you need to store items you want to keep protected from dust and splashes, enclosed cabinets are the way to go. They create a cleaner, more streamlined look but can slow down access just a bit compared to an open shelf.

- Drawers: For all the small stuff—utensils, portion bags, and other organizational tools—drawers are a lifesaver. They keep clutter off your main workspace and help staff find exactly what they need in seconds.

Many specialized tables, especially the ones used for building sandwiches and salads, are designed to be a workspace and a storage hub all in one. This dual-function approach is all about packing maximum efficiency into a small footprint, which is a must-have for any busy kitchen. For operations that crank out subs and salads, checking out our dedicated sandwich prep tables will show you options engineered specifically for that kind of high-speed assembly line.

Understanding Materials and Construction

The real test of a good prep table isn't how shiny it looks on day one, but how it holds up after a year of relentless chopping, spilling, and cleaning. The long-term durability of your prep tables for restaurant kitchens comes down to their bones—the materials and construction hidden beneath the surface.

Getting this right is the difference between a workhorse that lasts for years and a piece of metal that starts to warp, rust, and wobble in just a few months. When you're looking at a spec sheet, it can feel a little intimidating. But you only need to focus on two key details to understand a table's toughness: stainless steel grade and gauge. Nail these, and you're already on your way to a smart investment.

Decoding Stainless Steel Grades

The "grade" of stainless steel is just a fancy way of talking about its recipe and, more importantly, its power to fight off rust and corrosion. In the world of commercial kitchens, you'll mainly run into two players:

- Type 304 Stainless Steel: This is the undisputed champion for any surface that touches food. It’s packed with more chromium and nickel, making it incredibly resistant to corrosion from things like tomato sauce, citrus juices, and harsh cleaning chemicals. For a prep tabletop, this is what you want. No question.

- Type 430 Stainless Steel: This is a more budget-conscious option, and it's perfectly fine for the parts of the table that don't see much action, like the legs or undershelves. It’s still tough, but it's more likely to show signs of corrosion over time if it's constantly exposed to acidic foods or aggressive cleaners.

Think of Type 304 as your all-weather, heavy-duty raincoat. Type 430 is more like a reliable windbreaker—great for most days, but not what you want in a downpour.

Understanding Steel Gauge The Right Way

Now for the steel's thickness, which is measured by its gauge. Here’s the part that trips everyone up: the lower the gauge number, the thicker and stronger the steel. It feels backward, but it's crucial to remember.

Gauge is like a suit of armor for your prep table. A lower number means thicker plate, offering more protection against the dents, dings, and heavy impacts of a busy kitchen. A 14-gauge table will stand up to heavy equipment and vigorous chopping far better than a lighter 18-gauge one.

Finishing Touches That Matter

Beyond the steel itself, the design of the countertop edge might seem like a small detail, but it has a huge impact on safety and sanitation.

- Square Edge: This is a sharp, clean 90-degree edge. It’s perfect for lining up multiple tables side-by-side to create one long, seamless workspace.

- Bullnose Edge: A rounded, smooth edge that’s much more comfortable to lean against. With no sharp corners, it's a safer bet in high-traffic areas where staff are constantly moving around.

- Marine Edge: This edge is raised all the way around, like a tiny wall. Its job is to contain spills and stop liquids from running off onto the floor, which is a massive help for keeping your kitchen clean and safe.

These details become even more critical when you're looking at specialized equipment. For instance, knowing the right materials and edge style for a pizza prep table can make all the difference in a high-volume pizzeria where durability and easy cleanup are everything.

Essential Cleaning and Food Safety Habits

Your prep tables are the heart of your kitchen's action. But all that constant use means they can quickly become hotspots for bacteria and cross-contamination if you're not careful. Let's be honest: a prep table is only as good as its cleaning routine. Building rock-solid cleaning habits isn't just about keeping things shiny; it's a non-negotiable part of food safety and protecting your gear.

Think of your prep table like a surgeon’s operating table. It has to be meticulously cleaned and sanitized between every "procedure" to stop harmful bacteria in their tracks. A tiny spill or a few leftover food particles can become a breeding ground for pathogens, putting your customers and your reputation at serious risk. This is exactly why a structured cleaning schedule is so critical.

A clear, well-defined cleaning protocol takes all the guesswork out of the equation. It makes sure every single staff member knows their role in keeping the kitchen safe. By breaking down the work into daily, weekly, and monthly jobs, you create a simple but powerful system that keeps your prep stations in prime condition.

Your Daily Cleaning Checklist

Daily cleaning is the foundation of your entire food safety program. These are the essential, have-to-be-done tasks that prevent grime and bacteria from building up during a busy shift.

- Wipe Down Surfaces Constantly: After every single task—especially when you’re switching from raw to cooked foods—the surface must be cleaned and sanitized. Use a food-safe cleaner followed by a proper sanitizer to wipe out any lingering germs.

- Clean the Cutting Boards: Removable cutting boards need to go straight to the dish pit to be washed, rinsed, and sanitized. Never, ever just wipe them down in place.

- Empty and Sanitize Ingredient Pans: At the end of the night, every ingredient pan in your refrigerated prep rails needs to be emptied, washed, and sanitized. The rail itself should get a thorough wipe-down, too.

Weekly and Monthly Deep Cleaning

While daily habits are crucial, a deeper clean on a regular basis is what tackles the grime you can’t always see. These tasks also keep your equipment running smoothly and help it last a whole lot longer.

Preventative maintenance is always smarter—and cheaper—than making emergency repairs. A few minutes of weekly care can save you from a costly equipment failure right in the middle of a dinner rush.

Weekly Tasks:

- Inspect and Clean Gaskets: The rubber door seals on your refrigerated units are magnets for food debris and mold. Wipe them down with a damp cloth and look for any cracks or tears that could break the seal. A bad seal makes the compressor work overtime, which just wastes energy and money.

- Remove and Clean Shelves: Pull out all the undershelves and any internal shelves from refrigerated units. Give them a good wash to get rid of any spills or buildup that’s accumulated over the week.

Monthly Tasks:

- Clean Condenser Coils: Dust and grease are the enemies of a refrigerated prep table. When they clog the condenser coils, the unit has to work way too hard to stay cool. Gently brush or vacuum the coils to keep the air flowing and prevent the motor from overheating.

- Check and Calibrate Thermometers: Make sure the thermometers on your refrigerated units are giving you an accurate reading. If they’re off, your ingredients could be sitting in the temperature danger zone—that’s anything between 41°F and 135°F.

By sticking to this simple schedule, you turn essential maintenance from a chore into a seamless part of your kitchen’s workflow. It’s the key to making sure your prep tables for restaurant use stay safe, efficient, and reliable for years to come.

Optimizing Your Kitchen Layout for Peak Flow

Your prep tables for restaurant kitchens are so much more than just furniture. Think of them as the strategic anchors of your entire operation. Where you place them dictates how your staff moves, how fast orders get out, and just how calm—or chaotic—your kitchen feels during a dinner rush. When you start thinking about the big picture, you can turn a simple prep station into the heart of a seriously productive kitchen.

The goal is to create a seamless path, taking ingredients from storage all the way to the final plate. Don't see your kitchen as a collection of separate stations; it's a single, interconnected machine. Every single step a cook takes is a potential slowdown. Smart placement cuts those steps down, creating a smooth workflow that shaves precious seconds off every order.

This is where classic concepts like work triangles and assembly lines really prove their worth. A well-designed kitchen lets a cook pivot between their prep table, the walk-in, and the cooking line with barely a step. This logical flow prevents those frustrating kitchen traffic jams and keeps everything moving forward, from prep to pan to plate.

Creating Efficient Work Zones

The first step is pairing your prep tables with the right equipment. A prep station for searing steaks needs to be right next to your cooking line, creating a powerful one-two punch for speed and consistency. This lets a chef season and prep proteins on the table and immediately slide them onto a hot surface.

For that kind of high-heat workflow, proximity is everything. Our wide selection of commercial charbroilers is designed to integrate perfectly into these zones. We offer a variety of models to fit any kitchen's needs, ensuring you always have the right tool for the job.

- Gas Charbroilers: The industry workhorse. They’re known for intense heat and quick recovery times, perfect for high-volume steak and burger joints.

- Electric Charbroilers: A fantastic option for kitchens where you can't run a gas line. They offer consistent, even heat and are often a breeze to clean.

- Infrared Charbroilers: These advanced units use intense infrared heat to cook food faster and more evenly, locking in moisture for unbelievably juicy results.

By placing the right charbroiler next to a dedicated protein prep table, you build an incredibly efficient grilling station that can handle even the craziest dinner service with ease.

A great kitchen layout doesn't just make work faster—it makes it easier and safer. When you cut down on unnecessary movement, you minimize the risk of collisions, spills, and staff burnout, creating a much better work environment for everyone.

Layouts for Different Restaurant Types

The perfect layout is never one-size-fits-all; it has to match your specific menu and service style. A pizzeria, for instance, is all about a linear assembly line: dough prep, to the pizza prep table, and straight into the oven. A fine-dining kitchen, on the other hand, might use a "zone" approach, with separate, self-contained stations for appetizers, entrées, and desserts, each with its own prep tables and gear.

Thinking through these workflows before you place a single piece of equipment is the secret to unlocking peak efficiency. By positioning your prep tables for restaurant use with a clear purpose, you create a kitchen that just flows, making every shift smoother and more productive.

Ready to build the ultimate grilling station? At Charbroilers, we provide the high-performance equipment that turns a good kitchen layout into a great one. Explore our complete collection of commercial charbroilers and other essential cooking equipment by visiting us at https://charbroilers.com today.