Fire Up Your Business with These Commercial Charbroilers

Share

What Makes Commercial Charbroilers Essential for Restaurant Success

Charbroilers are specialized cooking equipment that use high heat (550°F and above) to quickly sear food over an open flame or heated elements, creating distinctive grill marks and imparting a smoky, char-grilled flavor that customers love.

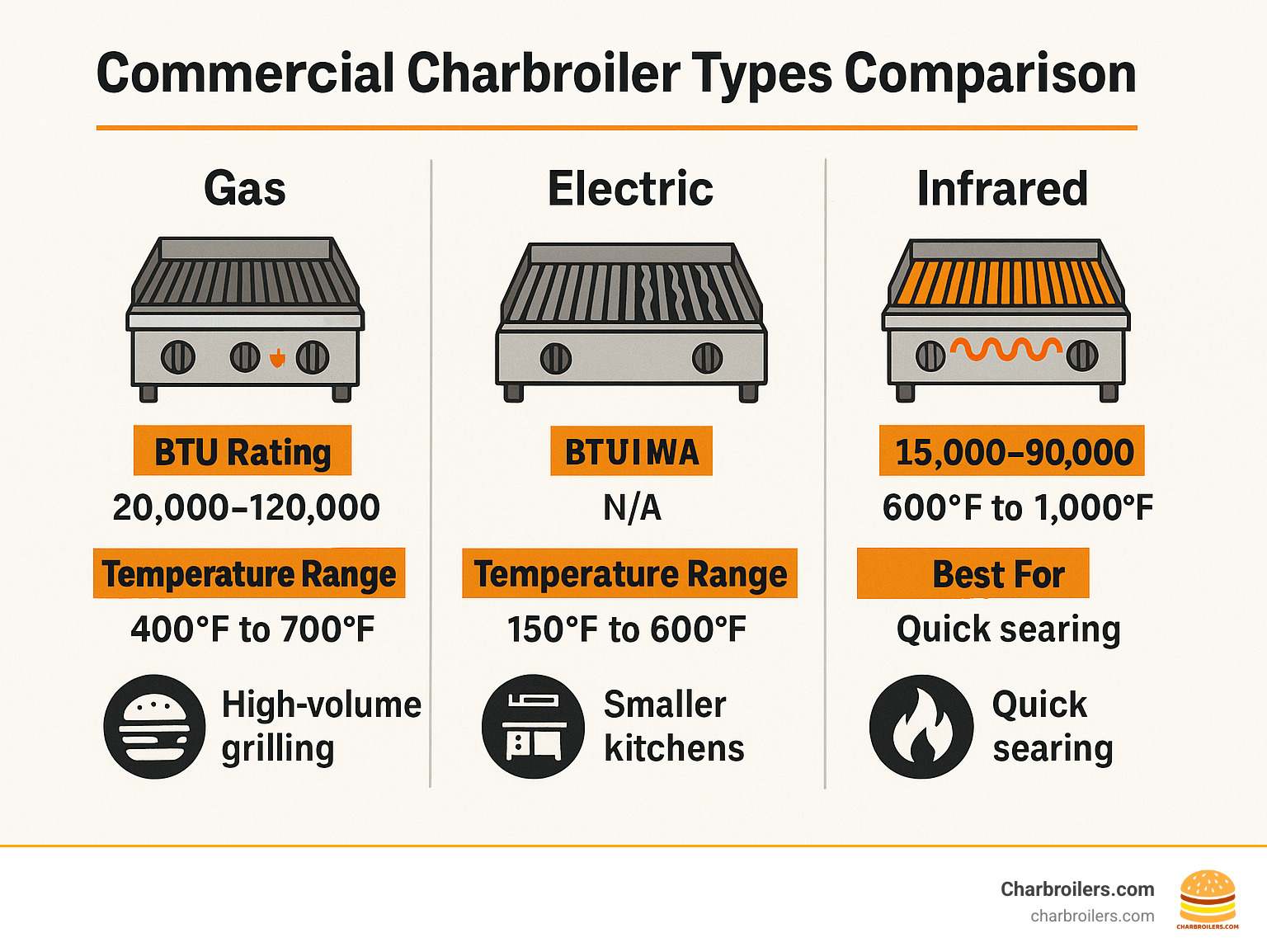

Quick Guide to Commercial Charbroilers: - Definition: High-temperature cooking equipment with grates positioned over heat sources - Main Types: Gas (most common), Electric, Infrared, Radiant, Lava Rock - Key Benefits: Distinctive flavor, visible grill marks, high-volume production - Common Uses: Steaks, burgers, chicken, fish, vegetables, sandwiches - Price Range: $400-$21,000 depending on size and features

Charbroilers take up minimal counter space while delivering industrial-sized results, making them ideal for restaurants with space constraints but high production needs. Unlike standard grills or broilers, commercial charbroilers offer more consistent cooking temperatures, better heat distribution, and the ability to handle continuous high-volume service.

When selecting a charbroiler for your restaurant, consider these critical factors:

- Power Source: Gas models require natural gas or propane lines but offer higher heat; electric models can be installed anywhere with appropriate outlets

- Size: Available in widths from 24" to 72" with varying depths (20" for light duty, 24" for heavy duty)

- Heating Technology: Radiant (consistent heat, protected burners), Lava Rock (mimics charcoal flavor), or Infrared (highest efficiency)

- Duty Level: Heavy-duty for all-day use, medium or light duty for occasional use

I'm Sean Kearney from Charbroilers.com, with over a decade of experience helping restaurant owners find the perfect charbroilers for their unique kitchen needs. My background in the restaurant equipment industry has taught me that the right charbroiler can dramatically improve both food quality and operational efficiency.

How Charbroilers Lift Commercial Cooking

Ever wondered why food tastes so much better when it's charbroiled? There's actually some fascinating science behind that irresistible flavor that keeps customers coming back for more.

When you fire up a charbroiler, something magical happens called the "plume effect." This creates natural hot and cold zones across your cooking surface, with temperature differences of up to 400°F! This isn't a design flaw – it's a chef's secret weapon that lets you sear steaks in one area while finishing more delicate items in another, all on the same surface.

The real star of the show is the Maillard reaction – that beautiful chemical dance that happens when proteins and sugars in food meet high heat (usually above 300°F). This isn't just browning – it's a complex process that creates hundreds of new flavor compounds that give charbroiled foods that distinctive, crave-worthy taste that's impossible to replicate with other cooking methods.

Those gorgeous grill marks aren't just for Instagram photos, either. They're actually flavor powerhouses – the places where the Maillard reaction is most intense, creating little flavor explosions in every bite. Your charbroilers achieve this through a triple-threat of heat transfer:

- Conduction: The direct sizzle when food touches those hot grates

- Convection: Hot air swirling around the food as it cooks

- Radiation: Infrared energy beaming up from the heat source below

This perfect storm of heating methods means food cooks quickly while developing deep, complex flavors. The business impact? Higher ticket prices, faster table turns, and healthier profit margins. Scientific research on Maillard reaction in grilling confirms what restaurant owners already know – customers are willing to pay more for those distinctive charbroiled flavors.

Charbroilers vs Standard Grills & Broilers

"Aren't charbroilers just fancy grills?" I hear this question all the time, and the answer is a definite no! While they might look similar at first glance, commercial charbroilers bring several key advantages to your kitchen.

For starters, temperature is a game-changer. Your standard grill might tap out at the low 500s, but commercial charbroilers comfortably operate at 550°F and beyond. That extra heat makes all the difference for proper searing and flavor development.

Direction matters too. Unlike overhead broilers (salamanders) that heat from above, charbroilers send heat upward. This smart design allows fats to drip away from the food while still creating that smoky flavor when they sizzle on the heat source below – giving you the best of both worlds.

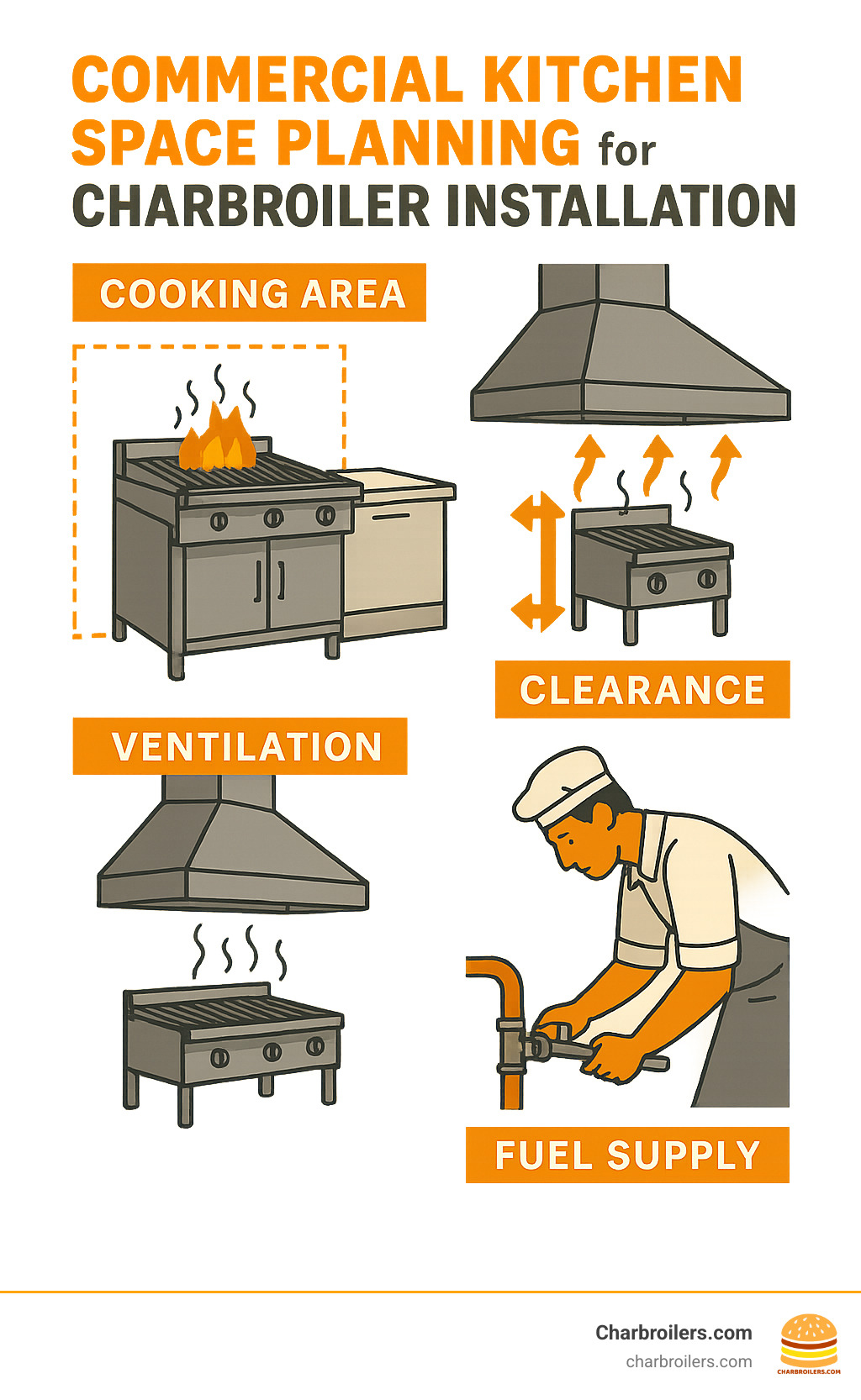

Be prepared for proper ventilation, though. The high heat and smoke production from charbroilers demand commercial hood systems with appropriate CFM ratings – more robust than what you'd need for standard grills. This isn't just about comfort; it's about safety and code compliance.

Despite their power, commercial charbroilers maintain a surprisingly efficient footprint. They're built for continuous, high-volume production with larger cooking surfaces and more powerful heating elements than standard grills, while still fitting neatly into your cookline.

Perhaps most importantly, professional charbroilers offer superior heat distribution. With burners typically spaced every 12-15 inches, they ensure even cooking across the entire surface – no more hot spots or cold corners ruining your perfectly timed orders.

At Charbroilers.com, we help restaurants and food service businesses across the USA understand these crucial differences to make equipment decisions that perfectly align with their menu, space, and production needs. The right charbroiler doesn't just cook food – it transforms your menu and your bottom line.

Main Types of Commercial Charbroilers & Their Core Parts

Let's explore the heart of what makes charbroilers tick! Understanding the different models and their components will help you make a choice you'll be happy with for years to come. I've helped hundreds of restaurant owners find their perfect match, and the right information makes all the difference.

Gas Charbroilers: Workhorse of the Line

If you peek into most busy restaurant kitchens, you'll likely spot a gas charbroiler commanding the line. These powerhouses have earned their place as the industry standard.

Gas models deliver impressive heat output—typically 15,000 to 30,000 BTU per burner—with total firepower ranging from 60,000 BTU for compact units to a whopping 390,000 BTU for those kitchen beasts handling high-volume operations.

What chefs love most is the control. Each burner section has its own knob, so you can create different temperature zones across your cooking surface. Searing steaks on one side while finishing chicken on the other? No problem!

The recovery time on these units is remarkable too. Even during your Saturday night rush, the temperature bounces back quickly between batches, keeping your kitchen moving and your tickets flying.

From an operating cost perspective, at roughly $1.00 per therm of natural gas, you're looking at about $6 to $40 daily for a 10-hour service, depending on your model's size. Most units ship configured for natural gas but include propane conversion kits for flexibility.

Electric Charbroilers: Plug-in Convenience

When gas lines aren't an option—or when you're facing strict ventilation constraints—electric charbroilers come to the rescue.

These versatile units can be installed virtually anywhere with proper electrical service, making them perfect for food trucks, pop-ups, or kitchens in buildings where gas installation is either prohibited or prohibitively expensive. I've helped several downtown Seattle restaurants in older buildings make the switch to electric with great results.

While they still require proper hood systems, electric models typically produce less smoke and fewer combustion byproducts than their gas counterparts. Their lift-up heating elements make cleaning a breeze—just raise them and wipe down underneath.

For operations looking to reduce their carbon footprint or those in spaces where gas simply isn't practical, electric charbroilers offer a compelling alternative without sacrificing too much cooking performance.

Infrared & Radiant Charbroilers: Speed & Sear

For the tech-forward kitchen, infrared and radiant charbroilers represent the cutting edge of grilling technology.

Infrared technology transforms a gas flame's energy into infrared radiation, creating an incredibly even cooking surface that virtually eliminates hot and cold spots. This consistent heat means every steak comes out perfectly, regardless of where it sits on the grill.

The special design limits oxygen to the cooking chamber, which dramatically reduces those pesky flare-ups that can char food unevenly. Many chefs are surprised to find that infrared models can slash cooking times by up to 50% while using less gas. That means higher throughput during rush periods and lower utility bills—a win-win!

Radiant models use angled metal plates above the flame to distribute heat evenly while protecting burners from drippings. Think of them as the middle ground between traditional gas and high-tech infrared options.

Lava Rock & Solid-Fuel Charbroilers: Smoke & Show

When customers are willing to pay a premium for authentic flavor, lava rock and solid-fuel charbroilers deliver in spades.

There's something almost magical about the way lava rocks capture drippings that then vaporize to create that genuine smoky flavor we all associate with perfect barbecue. In open kitchen concepts, the visible flames and aromatic smoke create a bit of culinary theater that customers love.

Our solid-fuel models at Charbroilers.com feature ceramic fireboxes that act as heat sinks, maintaining consistent temperatures throughout service. Unlike competitors using firebrick linings that deteriorate over time, our ceramic fireboxes never need replacement—a significant long-term cost saving.

These charbroilers can accommodate wood, charcoal, or a combination of fuels, allowing chefs to develop signature flavor profiles that keep customers coming back. Yes, they require more maintenance (those lava rocks need regular rotation and replacement), but for many restaurants, the distinctive flavor profile is well worth the extra effort.

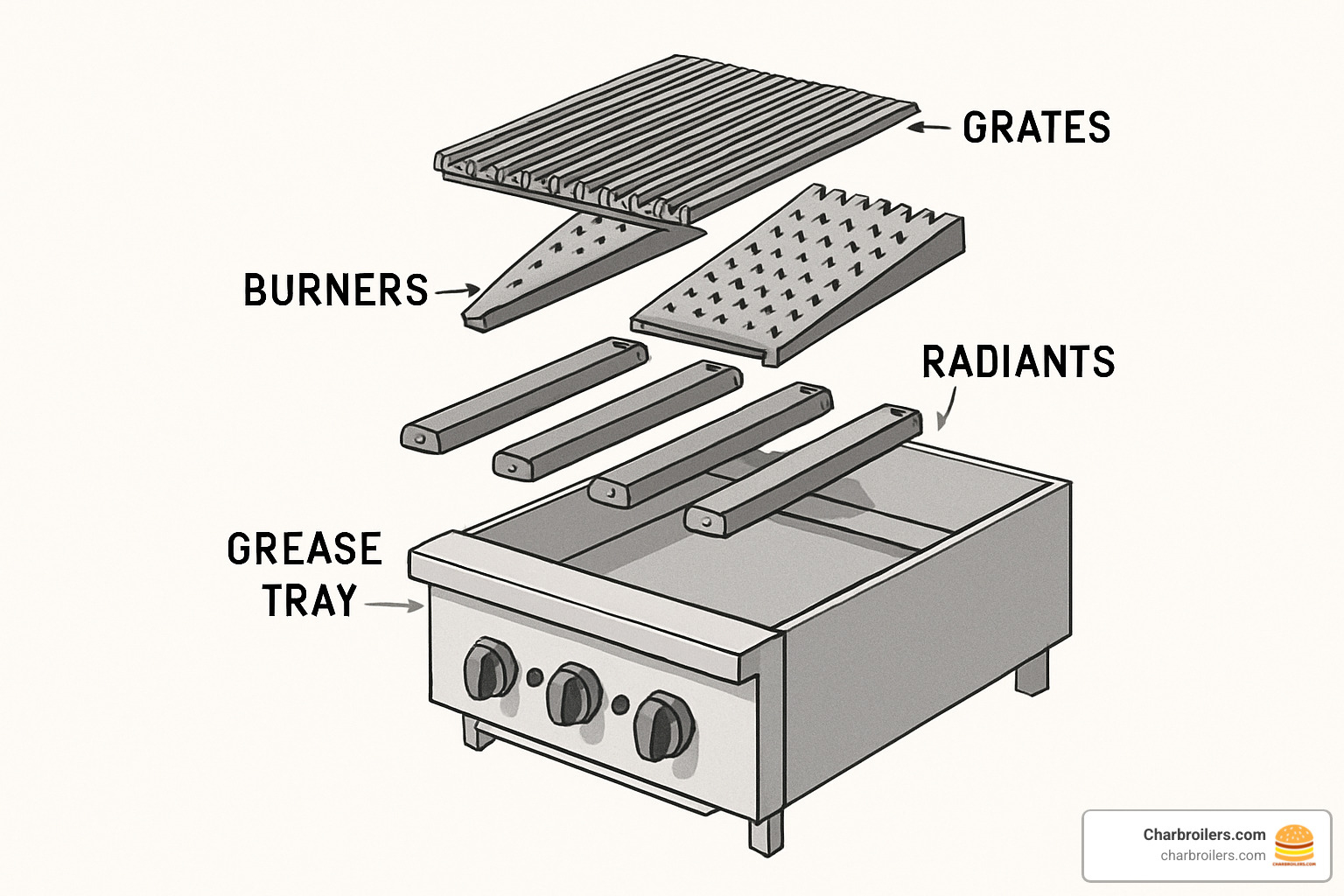

Key Components Every Buyer Should Know

No matter which type catches your eye, understanding the key components will help you make a smarter purchase and keep your equipment running smoothly for years.

Burners form the foundation of any gas charbroiler. In heavy-duty models, you'll find them spaced every 6 inches for maximum heat coverage, while light and medium-duty units typically space them every 12-15 inches. This spacing directly impacts temperature consistency and recovery time.

Radiants sit above the burners and come in several forms: metal plates, lava rocks, or ceramic briquettes. Each material distributes heat differently and contributes to the final flavor profile of your food.

Grates are where the magic happens—and you've got options! Cast iron grates offer superior heat retention and create beautiful sear marks, but require more maintenance. Stainless steel grates resist corrosion better but don't hold heat quite as well. Many of our models feature reversible grates with different bar widths on each side, giving you flexibility for different foods. For delicate items like fish, we offer specialized "seafood grates" with closely spaced bars.

Heat deflectors might seem like a minor component, but they play a crucial role in extending grate life and optimizing heat distribution throughout your cooking surface.

The grease management system—including troughs and collection trays—captures drippings to reduce flare-ups and simplify cleaning. A well-designed system can significantly reduce your end-of-shift cleanup time.

At Charbroilers.com, we understand that equipment downtime can be devastating to your business. That's why we stock a comprehensive range of replacement parts for all these components, ensuring your investment continues performing at its best through years of busy service.

Choosing the Perfect Charbroiler for Your Menu & Space

Selecting the right charbroiler involves careful consideration of your menu requirements, production volume, available space, and budget. Here's how to make the best choice for your operation:

Sizing Your Charbroiler

Size is one of the most critical factors in selecting a charbroiler. Too small, and you'll struggle during peak service; too large, and you're wasting valuable kitchen space and energy.

Key Sizing Considerations: * Burners-per-foot rule: Heavy-duty models typically feature one burner per 6 inches, while light/medium-duty units have one per foot * Standard width increments: Most models come in 12-inch modules, with common widths being 24", 36", 48", 60", and 72" * Depth variations: Light-duty models are typically 20" deep, while heavy-duty units are 24" deep * Future growth: Consider selecting a slightly larger unit if you anticipate menu expansion

For a typical restaurant serving 100-150 covers during peak periods with 30% of orders requiring charbroiler cooking, a 36" model is often sufficient. However, steakhouses or burger-focused concepts may need 48" or larger units.

Matching Heat Source to Food Types

Different foods perform better with specific heat sources:

- Steaks and burgers: Radiant or infrared charbroilers provide the high, consistent heat needed for proper searing and juicy interiors

- Chicken: Lava rock or ceramic briquette models help manage flare-ups from higher fat content

- Vegetables: Electric or infrared models offer more precise temperature control for delicate items

- Seafood: Consider models with specialized seafood grates or adjustable grate heights for delicate fish

At our Seattle showroom, we often recommend combination units for restaurants with diverse menus, allowing different cooking techniques on a single piece of equipment.

Energy Efficiency & Ventilation Considerations

Charbroilers rank among the highest energy-consuming appliances in commercial kitchens, making efficiency crucial:

- BTU budgeting: Calculate your energy costs based on local utility rates and anticipated usage hours

- Hot-zone management: Models with individual burner controls allow you to heat only the sections needed during slower periods

- Hood requirements: Ensure your ventilation system can handle the CFM requirements of your chosen charbroiler

- Placement: Position your charbroiler under the center of the hood where capture efficiency is highest

For restaurants in the Pacific Northwest, where energy costs can be higher, we often recommend infrared models that can reduce gas consumption while maintaining cooking performance. These units typically pay for their higher initial cost through energy savings within 1-2 years of operation.

Guide to Commercial Charbroilers for Your Restaurant provides additional details on making the right selection for your specific needs.

Operating, Maintenance & Safety Playbook for Charbroilers

Let's face it – your charbroiler works as hard as you do. After hours of searing steaks and marking burgers to perfection, it deserves some TLC. I've seen how a well-maintained unit can outlast its expected lifespan by years, while a neglected one can become a costly headache.

Routine Cleaning Keeps Charbroilers Performing

Think of cleaning your charbroiler like brushing your teeth – skip it for too long, and problems start to compound.

Your daily cleaning routine should become second nature: brush those grates while they're still warm (not scorching hot – nobody needs burned fingers!), empty the grease traps before they overflow, and give exterior surfaces a good wipe-down. The heat deflectors need regular attention too, as buildup here can dramatically affect cooking performance.

Weekly, you'll want to take things up a notch. Remove and soak those grates in an appropriate cleaning solution – your future self will thank you when food stops sticking. While the grates are soaking, vacuum out any debris hiding beneath them. If you're running a lava rock model, this is when you should rotate those rocks to ensure even wear.

Once a month, block off some time for a more thorough cleaning session. This is your chance to inspect gas connections, check electrical components, and really get into those hard-to-reach spots. If you're using lava rocks or ceramic briquettes, they typically need replacement every 2-3 months in busy kitchens – they'll tell you they're ready when they show significant grease buildup.

One word of caution from someone who's seen it all: never wrap grates in aluminum foil for cleaning! It might seem clever, but it reflects heat back into the unit, potentially causing serious damage to components. And please resist the temptation to incinerate debris under pans – unless you enjoy unexpected grease fires during your dinner rush.

Safety Must-Dos Around High Heat

When you're working with equipment that routinely exceeds 550°F, safety isn't just important – it's non-negotiable.

Your fire suppression system should cover the charbroiler area completely, with regular inspections scheduled and documented. Gas connections need annual check-ups from certified professionals – this isn't the place to cut corners. If you're running electric models, add electrical inspections to your calendar too.

Staff training might seem obvious, but I'm always surprised by how many kitchen teams don't fully understand proper startup and shutdown procedures. A five-minute training session can prevent hours of repair time. And don't forget appropriate heat-resistant gloves and tools – they're a small investment that protects your most valuable assets: your people.

At Charbroilers.com, we include detailed safety guidelines with all our equipment, and we're happy to conduct staff training sessions for our Seattle-area customers. Safety is a partnership, and we take our side of it seriously.

Common Charbroiler Troubleshooting Tips

Even with religious maintenance, charbroilers occasionally have off days. Knowing how to address common issues can save you time, money, and stress.

When facing uneven heating, first check for blocked burners – they're often the culprits. Damaged radiants or warped grates can also cause temperature inconsistencies. If you're experiencing excessive flare-ups (beyond the normal sizzle), it's typically a sign of grease buildup underneath the grates and radiants. A thorough cleaning usually solves this, along with adjusting food placement to avoid direct dripping onto flames.

Ignition failures can bring service to a grinding halt. Start by inspecting and cleaning the pilot light or electronic ignition components, and verify your gas supply is flowing properly. If your grates have warped over time, it's generally more cost-effective to replace them with high-quality cast iron versions designed specifically for commercial use rather than trying to salvage them.

For temperature inconsistencies that persist despite your best efforts, check burner alignment and clean any obstructions. Sometimes the fix is as simple as adjusting the air shutters on your burners for a cleaner flame.

For more in-depth troubleshooting guidance that might save you a service call, our team has put together a comprehensive resource: Getting Fired Up About Commercial Charbroilers. It covers everything from flame color diagnosis to thermostat calibration.

A well-maintained charbroiler isn't just about preventing problems – it's about consistent food quality, energy efficiency, and maximizing the return on your investment. Your equipment takes care of your customers, so take care of your equipment.

Frequently Asked Questions about Commercial Charbroilers

What foods cook best on charbroilers?

If you've invested in a charbroiler, you'll want to make the most of its unique cooking capabilities. The magic of these machines really shines with certain foods.

Steaks and burgers are absolute stars on a charbroiler. That high, intense heat creates a gorgeous sear that locks in juices while developing those complex, caramelized flavors customers crave. There's simply no comparing a properly charbroiled burger to one cooked on a flat-top!

Chicken—whether bone-in or boneless—develops this incredible contrast between crispy, slightly charred exterior and juicy interior that's hard to achieve with other cooking methods. And don't get me started on seafood! While delicate fish fillets and shellfish require a bit more finesse (this is where those specialized seafood grates really earn their keep), the results are well worth it.

Vegetables take on a whole new personality when charbroiled. Bell peppers, zucchini, eggplant, and onions develop sweet, smoky notes that lift them from simple sides to menu highlights. And for sandwich-focused concepts, nothing beats the distinctive grill marks and toasty exterior of a perfectly pressed panini.

The real skill comes in learning your charbroiler's unique hot and cold zones. Most professional units have temperature variations of up to 400°F across the cooking surface—which isn't a flaw but a feature! This allows you to sear items in the hottest areas while simultaneously finishing others in cooler zones.

How often should I replace lava rocks or radiants?

This is one of those questions where the answer truly depends on your specific operation, but I can give you some reliable guidelines based on our experience with thousands of restaurants.

For lava rocks in a busy kitchen, you're looking at replacement every 2-3 months. If your volume is more moderate, you might stretch that to 4-6 months. A good practice is rotating your rocks weekly to distribute grease buildup evenly—this simple step can significantly extend their useful life.

Metal radiants tend to last longer but still need regular inspection. Look for warping or excessive buildup monthly, with typical replacement needed every 12-18 months in high-volume operations. Ceramic briquettes offer even better durability, usually requiring replacement every 6-12 months depending on use.

The champions of longevity are infrared elements, which often last 2-3 years before needing replacement—one reason they're worth considering despite the higher initial investment.

At Charbroilers.com, we understand that keeping track of maintenance schedules can be challenging in a busy kitchen. That's why we offer our customers scheduled maintenance reminders and discounted replacement parts programs—just one more way we try to make your life easier!

What optional accessories boost performance and menu versatility?

The right accessories can transform your charbroiler from a one-trick pony into a versatile cooking powerhouse. Let me share some favorites that our customers have found particularly valuable.

Warming shelves mounted above the cooking surface are practical lifesavers during busy service, keeping finished items at perfect serving temperature while you complete the rest of the order. For operations looking to add distinctive smoky notes without investing in a dedicated smoker, small smoker boxes that hold wood chips can work wonders.

If your menu features items finished with melted cheese, overhead cheese melters eliminate the need to transfer food to a separate salamander. And for solid-fuel models, rotisserie attachments create a show-stopping presentation that draws customer attention in open-kitchen concepts.

Many of our Seattle customers with Mediterranean or Asian menus swear by skewer racks for kebabs and satay. They ensure even cooking and make handling multiple skewers much more efficient.

Don't overlook the impact of different grate options, either. Reversible grates with different bar widths on each side allow you to create varied grill mark patterns depending on the presentation you're after. Height-adjustable grates give you precise control over how close your food sits to the heat source—invaluable when cooking items of varying thickness or density.

The beauty of these accessories is that they significantly expand your menu capabilities without requiring additional kitchen footprint or major equipment investments. In today's competitive restaurant landscape, that kind of versatility can really set your operation apart.

Conclusion

Investing in the right commercial charbroiler is a decision that can dramatically impact your restaurant's food quality, operational efficiency, and bottom line. From the distinctive flavor and appearance of charbroiled foods to the high-volume production capabilities, these versatile pieces of equipment earn their place in commercial kitchens.

At Charbroilers.com, we've been helping Seattle restaurants and food service businesses across the USA select, install, and maintain the perfect charbroilers for their unique needs. Our comprehensive selection includes models for every kitchen size, menu type, and budget, with financing options custom specifically for food service operations.

The right charbroiler doesn't just cook food—it creates experiences that keep customers coming back. Whether you're searing the perfect steak, crafting signature burgers, or adding distinctive grill marks to vegetables for presentation, a quality commercial charbroiler lifts your menu offerings while streamlining your kitchen operations.

Ready to fire up your business with a commercial charbroiler that matches your specific needs? Explore our complete selection online or visit our Seattle showroom to see these powerful cooking tools in action. Our equipment specialists are ready to help you make a selection that will serve your business for years to come.

For more detailed information on selecting the perfect model for your operation, check out our Guide to Commercial Charbroilers for Your Restaurant.